Texlabel SP4 User manual

User Guide

V. 20.0319

SP4

2

Summary

OVERVIEW ......................................................................................................................................................... 3

PRINTER INSTALLATION..................................................................................................................................... 5

DRIVER INSTALLATION FOR WINDOWS USERS ................................................................................................. 5

LOADING RIBBONS AND FOILS .......................................................................................................................... 6

USING THE SOFTWARE - GoLabel (only Windows)............................................................................................ 9

MAINTENANCE ................................................................................................................................................ 13

PARAMETERS FOR WHITE AND COLORED STICKERS....................................................................................... 14

PARAMETERS FOR TRANSPARENT STICKERS................................................................................................... 16

PARAMETERS FOR CARE LABELS ..................................................................................................................... 18

PRINCIPAL REQUIREMENTS FOR INTERNATIONAL CARE LABELS.................................................................... 23

3

OVERVIEW

Please keep the original packaging in case the printer must be returned.

Box Content:

SP4 Label Printer

DVD Including software and printer driver for Windows.

Empty cylinder core for rewinding the foil

Foil spindle –Set of 2

USB Cable.

AC Adapter

Power adapter

Printer View:

1. LED status indicator

2. Power /pause button

3. Tab for opening the upper printer cover

4. Ribbon exit

1. ON/OFF Power Switch

2. AC Power port

3. USB 2.0 port

4. USB port

5. Serial port

6. Ethernet port

4

1. Upper cover

2. Foil supply support

3. Foil supply wheel

4. Foil rewinder wheel

5. Foil rewinder support

6. Printhead unlock button

7. Fastening tabs

8. Ribbon supply support

9. Platen

10. Marker sensor

11. Spatial sensor

12. Cover for ribbon supply wheel

13. Ribbon guide regulator

14. Printhead

5

PRINTER INSTALLATION

1. Place printer onto flat and regular surface

2. Make sure ON/OFF switch is set to OFF

3. Connect printer to the computer with USB cable or Ethernet cable

4. Connect AC cable to the AC Power port on the back of the printer, and then connect the Power

Adapter to a grounded socket

5. Turn printer ON from the ON/OFF switch

6. Turn ON printer display from the Power button

DRIVER INSTALLATION FOR WINDOWS USERS

Option 1.

Connect to the following link for instructions on how to download the Windows driver for

the printer

www.texlabel.eu/wp/download-it

Option 2.

Turn on printer and wait for the writing “Ready” to appear on the display

Run DVD as an administrator and follow the printer setup wizard

Installing Software

Note! When the printer is connected with the USB cable, the driver installation will be automatically done.

1. Insert the DVD in the computer.

2. Choose "Software" on the Welcome screen.

3. Press the icon "install software" to start the installation.

6

LOADING RIBBONS AND FOILS

LOADING THE FOIL

Pull the cover release catches on both sides of the printer.

Insert the foil spindle into new foil.

Insert the foil spindle into empty cylinder core.

Insert the foil spindle with the new foil into the indicated space (1) as shown in the image below.

7

Insert the foil spindle with the empty cylinder core into the foil rewind wheel, as shown in the image below.

Attach foil extremity to the empty cylinder core with the adhesive strip at the end of the foil.

Wind the foil around the empty foil core for a few centimeters until you see the ink beginning strip.

WARNING: The foil has a matt side and a glossy side, make sure that the matt side is

the one in contact with the ribbon.

LOADING RIBBON

Load the ribbon onto the ribbon supply support. Use the ruler on the support to center the

position of the ribbon, in a way that it aligns with the ink foil to print.

8

Pass the ribbon through the ribbon guides, using the guide regulator wheel on the side. Regulate the width

based on the width of the ribbon.

Close the printhead and close the upper printer cover.

The printer is now ready to print! This procedure is the same for printing on label stickers. However, if the

label stickers come in a pack and not a roll, position the pack behind the printer and insert the stickers

through the back of the printer. Pass the stickers through the ribbon guides, under the sensor (adjust width

to fit stickers) and through the printhead just like instructions above for ribbons.

9

USING THE SOFTWARE - GoLabel (only Windows)

Click the "New" button

Click "Media Type" and set the type of label.

Click "Media Size" and set the size of label, click "Ok".

10

To insert Shape, Bar code, Text and Graphics use the left Side menu bar

Click "Printer Setup" to select the printer, number of copies and launch command print.

11

TO INSERT THE WASH SYMBOLS ON THE LABEL,

FOR EXAMPLE: FL R W bh d Y r n

YOU MUST INSERT A TEXT BOX SELECTING THE TYPE OF FONT, E.G.:

THIS REFERS TO THE "CHARACTER MAP TEXLABEL –ISO" FOR THE FOLLOWING

TABLE (EVERY SYMBOL CORRESPONDES TO A CHARACTER).

TEXLABEL - ISO

TEXLABEL fonts can also be purchased at a later time by contacting TEXLABEL.

12

Separately purchased TEXLABEL fonts:

TEXLABEL - ISO

TEXLABEL –KR

TEXLABEL –ASTM

13

MAINTENANCE

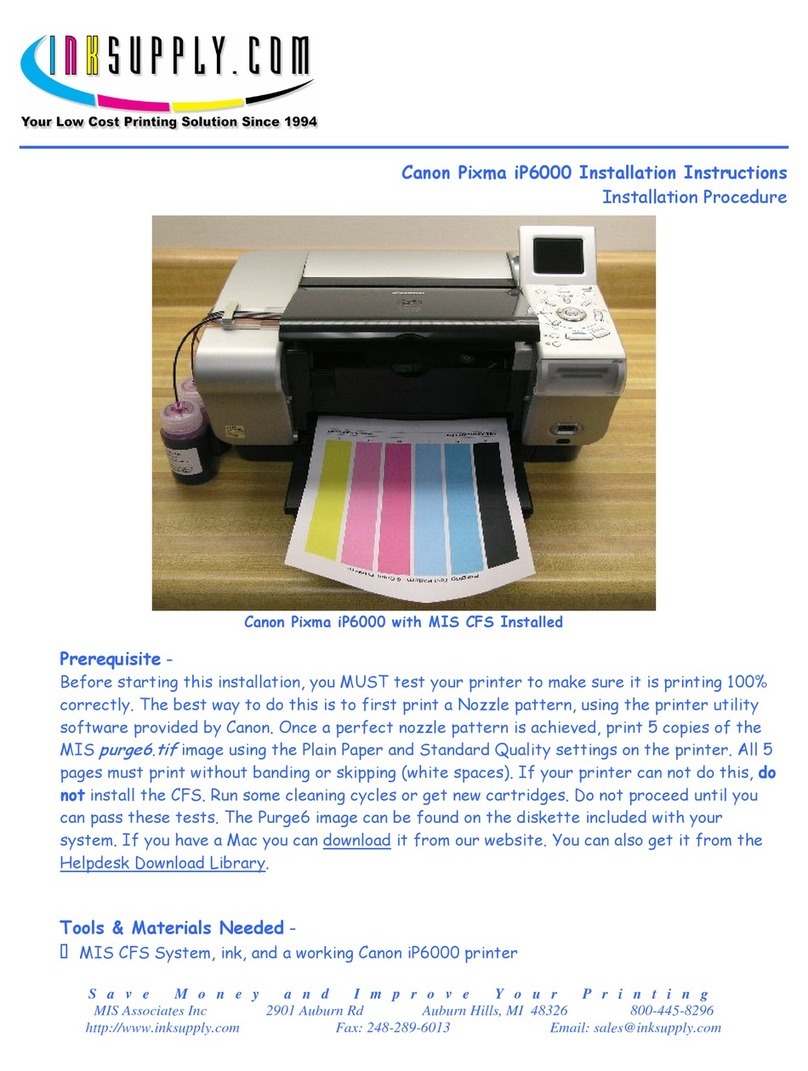

In order to always ensure optimum printing and maximum durability of the mechanical components and

print head, it is essential to clean the printer and print head at each ribbon change.

• PRINTHEAD

Wait about 1 minute after the last print, in order to let the printhead cool down. Using a dampened alcohol

cloth, wipe the printhead, rub the area shown in the image, until it completely removes the print residues.

•PLATEN

Ruotare il rullo (indicato in figura) e pulirlo con un panno che non rilasci impurità, inumidito con alcool, fino

alla completa rimozione dello sporco accumulato.

14

PARAMETERS FOR WHITE AND COLORED STICKERS

After clicking on "Document Properties", a window opens where you need to set the size of the adhesive

labels in the "Page Setup" tab in the area called "Stock". If the labels format has already been created, it

will be enough to select them from the drop-down menu. Otherwise, you need to click on the button

“New” and enter the size of the format you want to create.

Set the print orientation by selecting Portrait.

By selecting the "Graphics" tab you can set the dithering. For sticker labels select "None".

15

In the figure the "Stock" tab is selected. Here for adhesive labels you have to set it as a "thermal transfer"

print method and as media type "Labels With Gaps", the "Gap Height" must remain set to 3.0 mm.

Select the "Options" tab and set the print speed, which is recommended for adhesive labels at 76.20

mm/sec. The intensity of the black level set to 6.

We do not recommend using the default "Use Printer Current Setting" parameters, but always indicate

METHOD: THERMAL TRANSFER (CONTINUOUS TYPE / LABEL WITH SPACE / LABEL WITH SIGNALS, ACTION

AFTER PRINTING NONE / CUT / TEAR OFF).

After printing, if the label does not align exactly at the tear point, you can adjust the parameter

by adding or removing (”-“minus sign) 1mm or more millimeters.

16

PARAMETERS FOR TRANSPARENT STICKERS

For transparent stickers, the parameters set in "Page Setup" and "Graphics" are the same as white or

colored stickers.

In the "Stock" tab settings, set the parameters to the settings as shown below.

WARINING: We do not recommend using the default "Use Printer Current Setting" parameters, but always

indicate METHOD: THERMAL TRANSFER (CONTINUOUS TYPE / LABEL WITH SPACE / LABEL WITH SIGNALS,

ACTION AFTER PRINTING NONE / CUT / TEAR OFF).

17

In the "Options" tab settings, set the parameters to the settings as shown below.

After printing, if the label does not align exactly at the tear point, you can adjust the parameter

by adding or removing (”-“minus sign) 1mm or more millimeters.

18

PARAMETERS FOR CARE LABELS

19

We recommend that you leave the first 12-15 millimeters of the top of the label blank (not printed), which

is the space needed to sew the label into the garment.

We also recommend setting the “Orientation” parameter to “Portrait 180°”so that the label is pulled out of

the printer with the unprinted part.

For care labels it is advisable to set Dithering to "Error Diffusion".

20

In the "Stock" tab, set "Thermal transfer" as the printing method and "Type" set to "Continuous", and select

"None" for the "Post-Print Action" drop down menu.

If the cutter is installed on the printer, set the parameters in the "stock" tab as follows:

Table of contents

Other Texlabel Printer manuals