TEXMAC HAPPY HCS Voyager Setup guide

TEXMAC Inc. HAPPY HCS Voyager Introduction Training page 1

HAPPY HCS Voyager: Level-1 Maintenance & Repair

Intermediate-level repair / maintenance procedures

Table of Contents

Oiling/Cleaning Page 2

Removing Voyager’s Outer Covers Page 3

Control Panel Modes: Maintenance/Reset Page 4

Removing/Reattaching the Moving Head Page 5

Options Menu Settings

Rotary Hook Timing Page 6

Moving Knife Timing Page 7

Moving Knife Positioning/Adjustment Page 8

Setting Presser Foot Depth Page 9

Setting Needle (Bar) Depth Page 10

TEXMAC Inc. HAPPY HCS Voyager Introduction Training page 2

It is important to keep the rotary hook area clear of lint & debris. Approx. every 40

hours of operation,

remove needle plate and blow clear with compressed air, turning the shaft to check all points. Also, ensure

the machine is always stored in a climate-controlled area. Temperature and humidity extremes can affect

the performance and even cause permanent damage.

Daily:

(or every 8 hours of

operation). Oil along the race of the

rotary hook (red arrow)

Weekly:

(or every 40 hours of operation). Oil upper & lower portions of

reciprocator & pressure foot shaft, and all needle bars through take-up lever slots.

Preventive Maintenance/Cleaning

Oiling your Voyager Machine

a

b

c

d

TEXMAC Inc. HAPPY HCS Voyager Introduction Training page 3

Remove the bobbin winder

. Remove both the tensioning knob and switch arm.

Remove these screws

. (Indicated by the red arrows).

Separate

the

locking tabs between

the

covers

. As shown in the 4 locations above.

Disconnect data cable

shown

.

Remove 1 external and 2

internal

screws

. As shown above.

Disconnect data port cable

. (cable for USB/serial/AN jacks).

Remove screws on

control panel

as shown

above, and manual color change knob.

S

crews

for control panel arm

C

olor

change knob

Removing Voyager’s Outer Covers

Remove the right-side cover first. (side without control panel). This can be done without removing the other side.

Some repairs including moving knife timing can be made by removing only this side cover.

Remove the left-side cover. (control panel side). Note: This cover can befreed enough without removing the control panel toallow

some common repairs: CPU board re-set/replace; serial/usb circuit board. Needle change cam repairs, presser foot motor.

TEXMAC Inc. HAPPY HCS Voyager Introduction Training page 4

Starting Voyager in Maintenance Mode

Some operations performed on Voyager require that the machine be started in Maintenance Mode. Follow this short procedure to start

Voyager in Maintenance mode.

1. Power off the machine. (Wait approx. at least 10 seconds after power-down before re-

start)

2. On the control panel, press and hold MENU while restarting. Menu button must be

held continuously while power switch is pressed.

3. Machine will appear to start normally. Standard “HAPPY” screen appears. Press

SET to continue.

4. Go to the Maintenance option. Press MENU and use the arrow keys to go to “Other”.

Then press SET to enter the “Other” sub-menu. Use the arrow key to navigate to

“Maintenance” and press SET.

5. Enter code. Use arrow keys to change code to 2251 and press SET.

The machine is now in maintenance mode. Additional functions are available from

this sub-menu that allow you to re-initialize the machine & perform other adjustments.

Warning: Exiting this “maintenance” sub-menu exits maintenance mode. If so, must re-

enter maintenance mode by re-starting the machine and following steps 1-5 above.

Re-Initializing Voyager

This procedure completely re-sets Voyager’s internal control panel firmware program.

1. Enter Maintenance Mode. Follow the procedure above.

2. Re-set Memory option. While in Maintenance mode, scroll down to Memory. Press SET, then OK. Machine runs quick

self-diagnostic and clears memory.

3. Exit Maintenance Mode and re-enter “Other” menu and go to “Setup”. Press MENU until returned to main menu. Enter

main menu again and scroll down to Other and press SET. In the “Other” menu, navigate to “Setup” and press ENT.

4. Perform “System” reset. In the Setup menu, 2 options will be available: “System” and “Speed”. Choose System and press

ENT. Display may flash.

5. Perform “Speed” reset. While still in the Setup menu, choose “Speed” and press ENTER. A warning will appear: “Caution!

Main shaft turns”. After a few seconds, main shaft will begin turning from its lowest speed, gradually accelerating to its full

1000 spm before stopping. After machine stops, return to main menu and re-start machine.

TEXMAC Inc. HAPPY HCS Voyager Introduction Training page 5

One on other side

of moving head as

well.

Removing/Re-Attaching the Moving Head

Remove the 2.5 mm hex screws located behind the moving head

As shown in the picture.

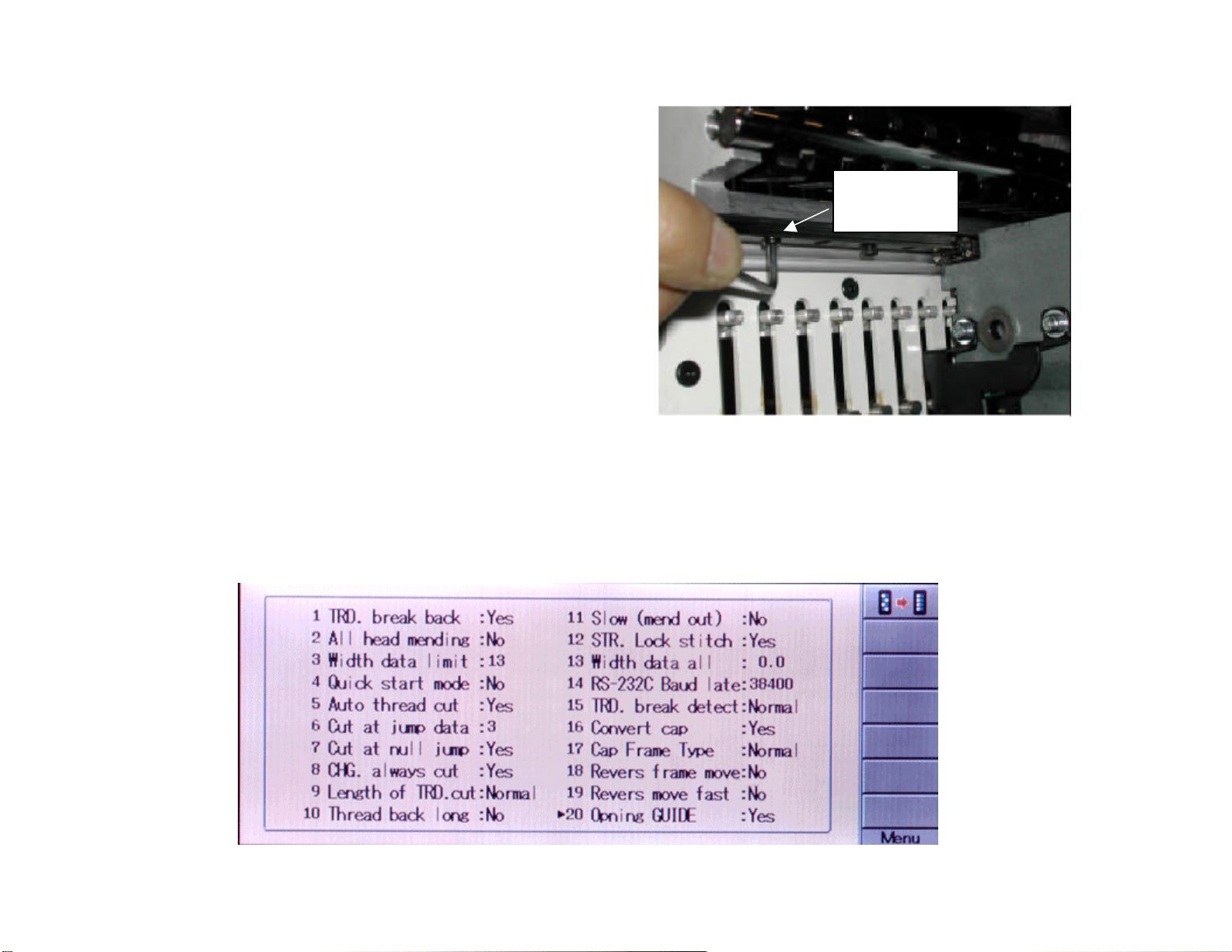

Recommended Options Menu Settings

Standard machine settings are located in the Options menu (select Machine icon to see menu below).You can adjust these

settings to control the behavior of certain tasks that Voyager performs, such as trims,jumps, thread break detection and more.

TEXMAC Inc. HAPPY HCS Voyager Introduction Training page 6

Part 2: Common Maintenance/Adjustment Procedures

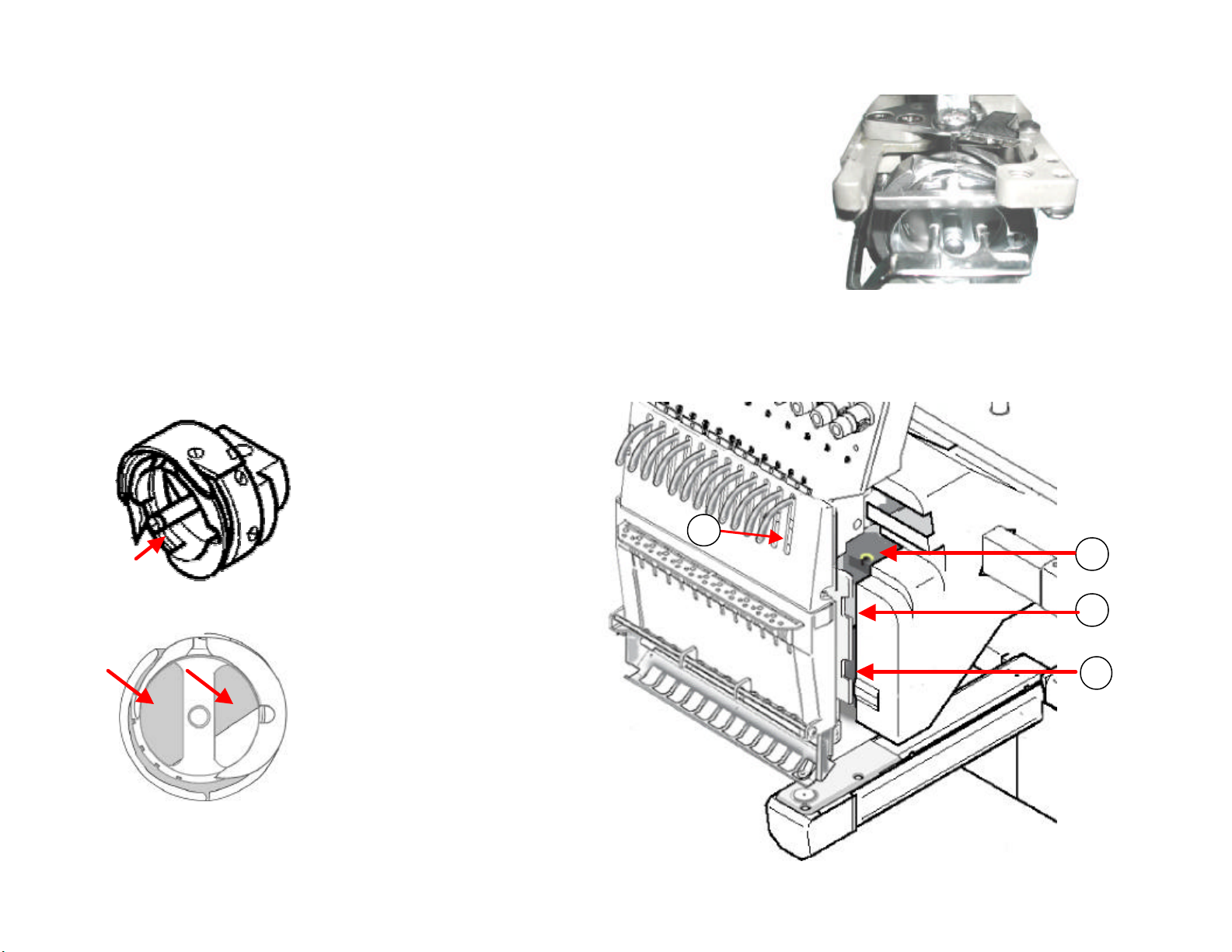

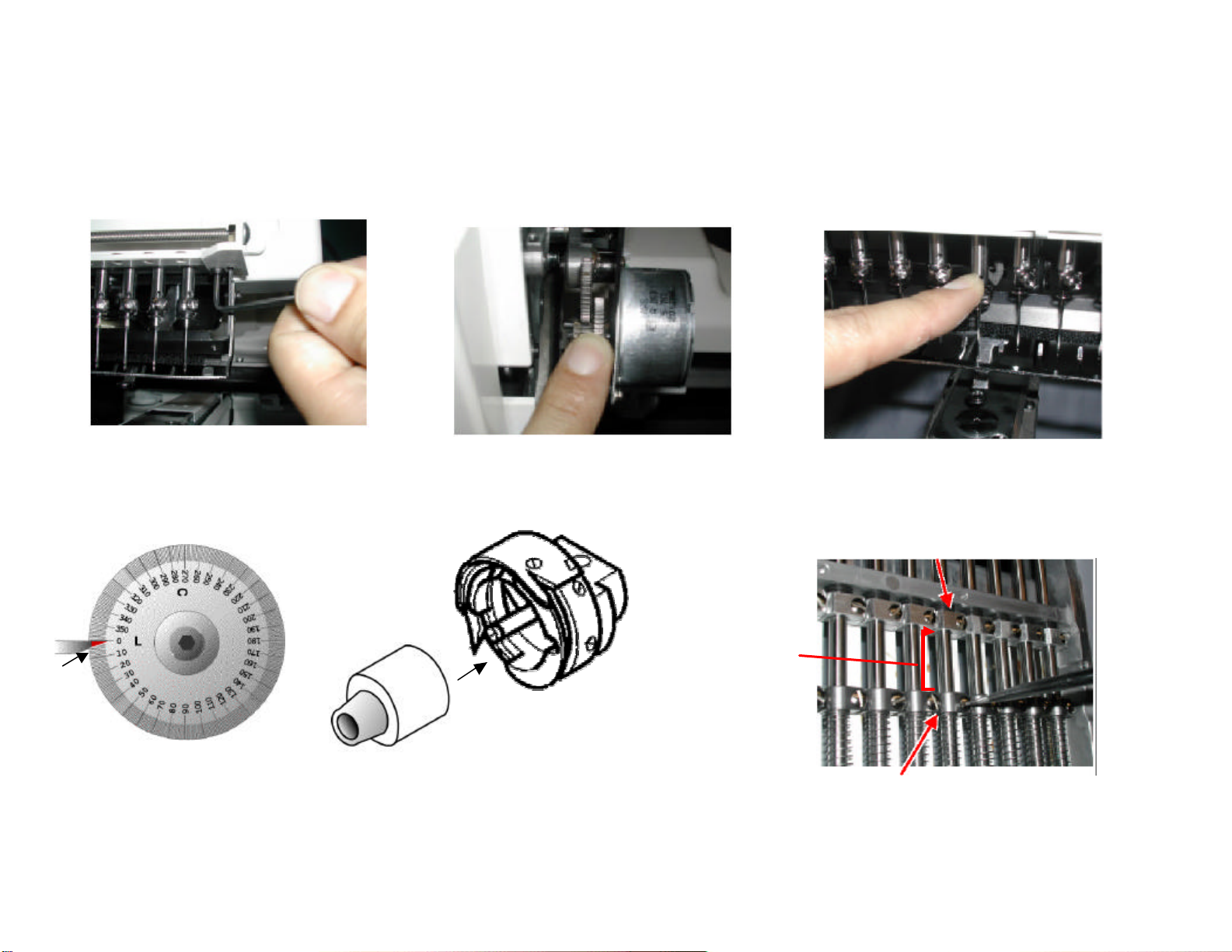

Rotary Hook Timing on HCS Voyager

Preparation: Follow these short steps to prepare for Remove needle plate and loosen

rotary hook from its shaft.

1. Remove needle plate. Will allow access to rotary hook.-

2. Lower presser foot. With machine powered on, press P.FOOT to

lower. (or if powered off, manually turn gear)

3. Lower needle manually until it engages and locks down. Do this

manually.

4. Loosen retaining finger.

5. Loosen rotary hook on shaft. There are 3 screws (shown right)

Adjust rotary hook.

1. Turn timing wheel to 25degrees. You’ll find the timing

wheel at the rear of the machine.

2. Adjust rotary hook position as shown. Rotary hook must

be aligned in the following 2 ways:

a. Alignment with needle: Tip of

rotary hook must be passing

just behind needle.

b. Depth alignment: Hook must be positioned

as shown

Timing for HCS

Voyager is at 25

degrees.

Back of needle

should be 1

business cards’

width in front of the

point of the hook

Location of 3 set

screws. Loosen this

one first along the flat

portion of

the rear of the

hook assembly.

Loosen retaining

finger.

(2 red arrows)

TEXMAC Inc. HAPPY HCS Voyager Introduction Training page 7

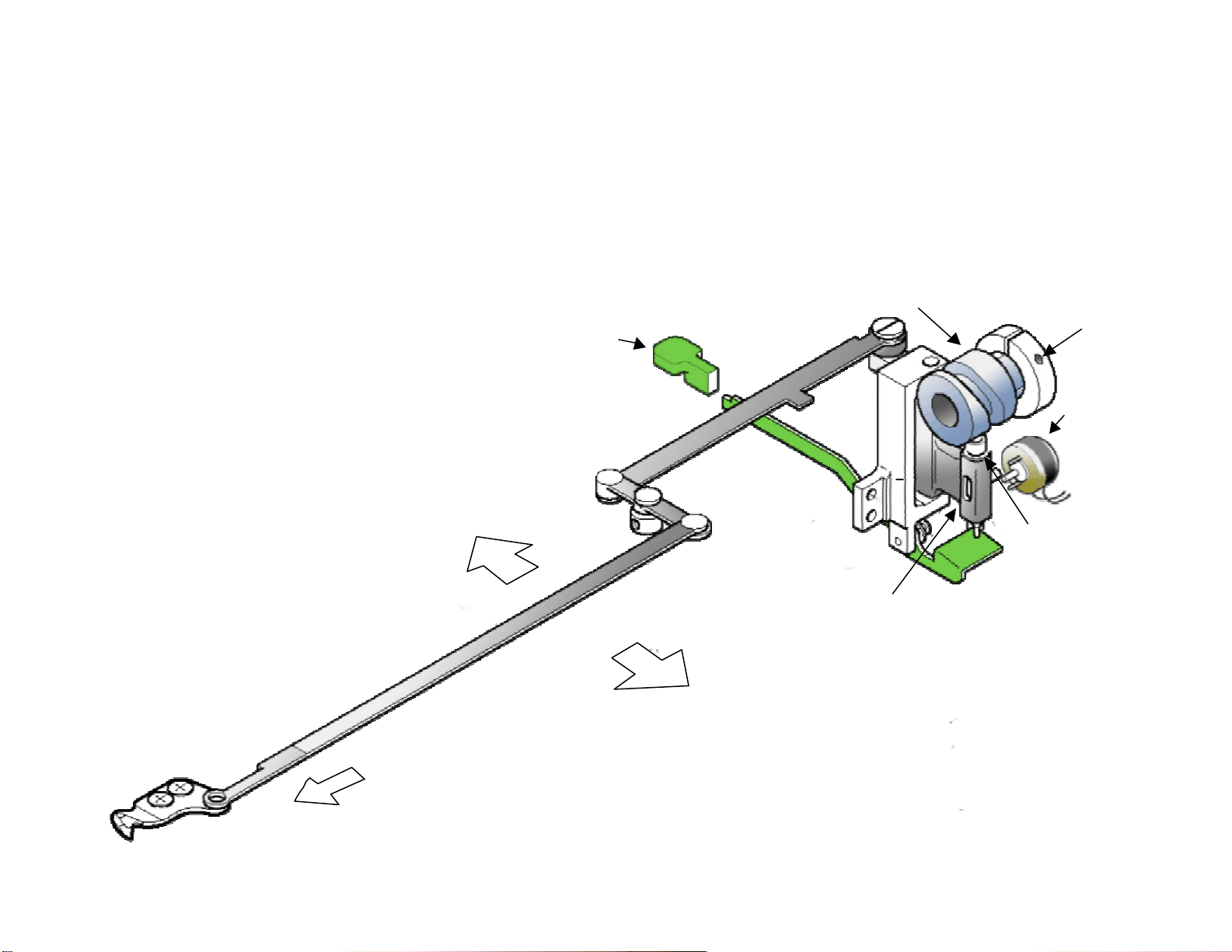

Moving Knife Timing

From time to time, the moving knife can be knocked out of position or time due to jams, buildups (bird nests) or other events.

Result is failure to cut thread properly or cleanly. Follow the procedures on this page to time or position the moving knife.

Diagram of thread cut system. Refer to diagram below for the instructions on this page and the following.

CONTROL

PANEL SIDE

FRONT OF

MACHINE

Trim Cam.

Mounted on back of

main shaft. Imparts back-and-

forth

motion on lever system with

turning groove.

Trim Solenoid.

When trim

command is issued,

solenoid engages

spring-mounted

engagement roller

Engagement

roller. Is raised

manually or by

solenoid into groove

of trim cam

Drive arm.

Swivels

in place during the

trim cycle to move

the drive link

assembly

Timing Procedure

1. Preparation: Remove outer cover and

(optional) remove power supply.

2. Loosen collar. This de-couples the trim

cam from the main shaft.

3. Set timing wheel to 115 degrees.

This

is the timing point at which the roller

should engage the trim system.

4. Depress manual engagement lever

while performing step 6.

5. Press cam backwards firmly against

collar while performing step 6.

6. Manually turn trim cam until strong

resistance is encountered –at this point

moving knife is just beginning to open.

7. Re-tighten collar around trim cam.

Collar.

Locks trim

cam onto main shaft.

Loosen from set

screw.

Manual engagement lever.

(shown in green) allows you to

cycle the trimmer manually to re-

set the trim system.

Set screw

for trim

cam

Moving knife

(shown in open

position)

TEXMAC Inc. HAPPY HCS Voyager Introduction Training page 8

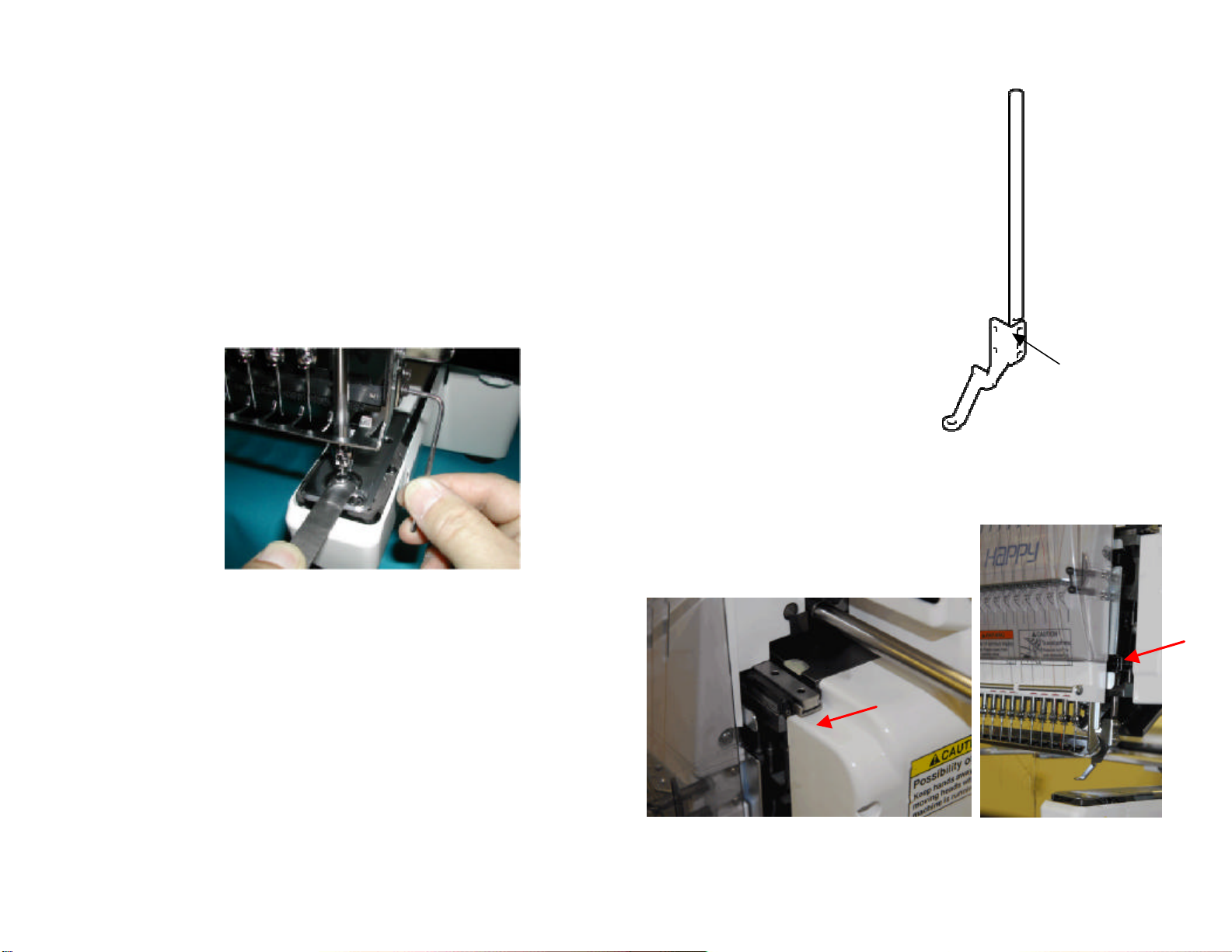

Moving Knife Positioning/Adjustment

Sometimes the moving knife can be knocked out of position. Follow this short procedure the re-position the moving

knife properly.

Procedure

1. Remove the right-side outer cover (non-control panel side). You won’t need to remove the other cover to do

this.

2. Loosen set screw. (see figure 2.6a below). Use 2 mm hex wrench.

3. Adjust eccentric bolt. This is the timing point at which the roller should engage the trim system. Adjust until

moving knife is positioned as shown in figure 2.6 c.

4. Re-tighten set screw.

Figure 2.6a.

Loosen this set screw with a 2mm

hex wrench.

Figure 2.6b.

Turn eccentric bolt until moving

knife is positioned as shown in Figure 2.6c.

Figure 2.6c.

Proper position of moving knife in

closed position

fixed knife (black)

–

above

moving knife

moving knife

Tip should be

just barely visible

TEXMAC Inc. HAPPY HCS Voyager Introduction Training page 9

Pressure Foot Adjustment

Procedure for checking pressure foot clearance

1. Select Needle 1 from control panel.

2. Lower presser foot by pressing P.FOOT

3. Drop needle manually until it locks down in place.

4. Set timing wheel to 0 degrees.

5. Loosen set screws as shown in diagram below.

6. Adjust pressure foot height –recommended height approx. 1.5 mm above surface of needle plate

(less than a dime’s thickness).

7. Re-tighten pressure foot on shaft.

Adjusting Presser Foot Clearance

Follow these steps to adjust presser foot clearance if above measurement is incorrect

1. Select needle 1 and dropthe presser foot with the P.FOOT

button.

2. Remove the retaining clip on the end of the bar as shown on

the right.

3. Move the head manually to“needle zero”position to expose

the set screw for the presser foot as shown.

4. Make adjustments as necessary and re-tighten.

2 set screws

–

allow

some play in the

vertical direction

allowing for

adjustment.

S

et

screw for presser foot

is now accessible.

Remove this retaining clip.

TEXMAC Inc. HAPPY HCS Voyager Introduction Training page 10

Setting Needle Depth

This procedure can be done with the machine powered on or off.

1. Remove the lower front panel.

2. Lower the pressure foot with the P.FOOT

button or manually as shown below.

3. Press and lock down needle as shown

below.

4. Set timing wheel to L + 5. 5. Insert needle depth gauge

6. Loosen upper needle bar boss (no

t

lower) and adjust so that tip of needle

just brushes gauge inside rotary hook.

Ensure that

clearance between

these bosses is

exactly 25mm.

Table of contents