TGB CH1 User manual

CH1/CR1 50 ㏄

OWNER-MANUAl

MAINTENANCE HANDBOOK

TAIWAN GOLDEN BEE CO.,LTD.

TGB CONTENTS

CONTENTS

GENERAL INFORMATION/TROUBLE DIAGNOSIS...................................1

MAINTENANCE INFORMATION .................................................................2

LUBRICATION SYSTEM..............................................................................3

FUEL SYSTEM.............................................................................................4

ENGINE REMOVAL......................................................................................5

CYLINDER HEAD/VALVE............................................................................6

CYLINDER/PISTON......................................................................................7

"V" TYPE BELT DRIVING SYSTEM/KICK STARTER ARM .......................8

FINAL DRIVING MECHANISM.....................................................................9

A.C. GENERATOR/STARTING CLUTCH....................................................10

CRANKCASE/CRANKSHAFT .....................................................................11

SPECIAL TOOL............................................................................................12

TGB 1. GENERAL INFORMATION/TROUBLE DIAGNOSIS

1-1

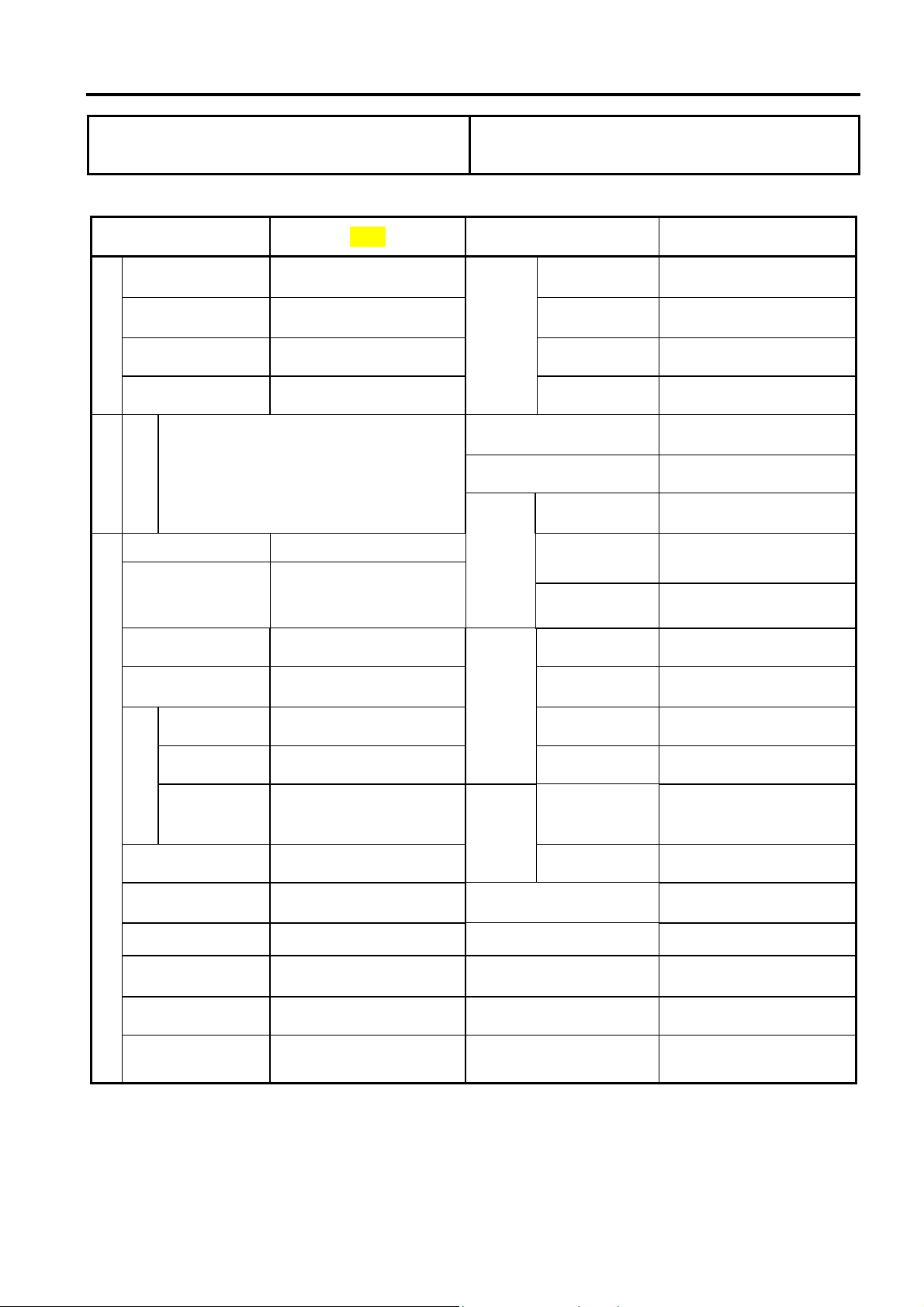

SPECIFICATIONS..............................1-1

TORQUE VALUES (ENGINE) ..........1-2 TROUBLES DIAGNOSIS...................1-4

SPECIFICATIONS

MAKER TGB MODEL CH1/CR1

Overall Length 1780mm Primary

Reduction BELT

Overall Width 695mm Secondary

Reduction GEAR

Overall Height 1075/1170mm Clutch One-way

DIMENSION

Wheel Base 1285mm

Deceleration

equipment

Transmission C.V.T.

Exhaust Pipe Position

and Direction Right side, and

Backward

Lubrication System Separated-lubrication

WEIGHT

Curb Weight

92/102kg Solid

Particulate 15 % ↓

Type 4-STROKE ENGINE CO 2.5±0.5 % ↓

Installation and

arrangement Vertical, below center,

incline 80°

Exhaust

Concentration

HC Below 800 PPM

Fuel Used Unleaded (92/95) Head 12V 35/35W

Cycle/Cooling 4-stroke/forced air

cooled Rear 5W

Bore φ39.0 mm Brake 21W

Stroke 41.5 mm

LAMPS

Turn 10W×4

Cylinder

Number/Arran

gement Single Cylinder/

horizontal

Inflation

Pressure

(Ffront/Rear) 1.75㎏f/㎝2 / 2.10㎏f/㎝2

Displacement 49.5 cc

TIRE

Type F:120/70-12 R:120/70-12

Compression

Ratio 11.8±0.1 Lubricate Oil SAE10W-30(0.85L)

Max. HP 2.35KW/ 7500 rpm Gear Oil SAE 85W-140(0.12L)

Max. Torque 2.96N.m /6500 rpm Battery 12V/5AH

Ignition C.D.I. Brake system F:Disc R:Drum

ENGINE

Starting System Electrical & foot type

1. GENERAL INFORMATION/TROUBLE DIAGNOSIS TGB

1-2

TORQUE VALUES (ENGINE)

ITEM Q'TY

THREAD DIA

(mm) TORQUE

VALUE(Kg-m) REMARKS

Cylinder head cover bolts 4 6 0.8~1.2

Cylinder head nuts 4 7 1.0~1.4 Apply oil thread

Cylinder/cylinder head

two-ends bolts 4 7 0.7~1.1 Tighten to crankcase

Cylinder head left bolts 2 6 0.8~1.2

Valve adjustment fixing nuts 2 5 0.7~1.1 Apply oil to thread

Spark plug 1 10 1.0~1.4

Carburetor heat protector

connectin

g

nuts 2 6 0.7~1.1

Engine oil draining plug 1 12 3.5~4.5

Engine oil strainer cap 1 30 1.3~1.7

Gear oil draining plug 1 8 1.0~1.5

Gear oil filling bolt 1 8 1.0~1.5

Oil pump screws 3 3 0.1~0.3

Engine left side cover bolts 9 6 0.8~1.2 Rubber washer

attached

Camshaft chain tensioner

bolt 1 8 0.45~0.6 Hex socket bolt

Camshaft chain adjuster

bolts 2 6 0.8~1.2

Clutch driving plate nut 1 28 5.0~6.0

Clutch outer bracket nut 1 12 3.5~4.5

Driving disk nut 1 10 3.5~4.5

Flywheel nut 1 10 3.5~4.5

Crankcase bolts 9 6 0.8~1.2

Gear box cap bolts 7 8 2.6~3.0

Exhaust pipe bolts 2 6 0.7~1.1

TGB 1. GENERAL INFORMATION/TROUBLE DIAGNOSIS

1-3

The torque values listed in above table are for more important tighten torque values. Please see

standard values for not listed in the table.

Standard Torque Values for Reference

TYPE TIGHTEN TORQUE TYPE TIGHTEN TORQUE

5mm bolt、nut 0.45~0.60kgf-m 3mm screw 0.05~0.08kgf-m

6mm bolt、nut 0.80~1.20kgf-m 4mm screw 0.10~0.15kgf-m

8mm bolt、nut 1.80~2.50kgf-m 5mm screw 0.35~0.50kgf-m

10mm bolt、nut 3.00~4.00kgf-m 6mm screw、SH nut 0.70~1.10kgf-m

12mm bolt、nut 5.00~6.00kgf-m 6mm bolt、nut 1.00~1.40kgf-m

8mm bolt、nut 2.40~3.00kgf-m

10mm bolt、nut 3.50~4.50kgf-m

1. GENERAL INFORMATION/TROUBLE DIAGNOSIS TGB

1-4

TROUBLES DIAGNOSIS

A. Engine hard to start or can not be started

Check and adjustment Fault condition Probable causes

Loosen carburetor drain

bolt to check if there is

gasoline inside the

carburetor

Fuel supplied tom

carburetor sufficient No fuel is supplied to

carburetor

Remove spark plug, install

it into spark plug cap, and

perform a spark test

against engine ground.

perform cylinder

compression pressure test.

Check if sparks Weak sparks, no spark

at all

Low compression

pressure or no pressure

Re-start by following the

starting procedures

No ignition There are some signs of

ignition, nut engine can

not be started

Remove the spark plug

again and check it.

Remove carburetor after 30 minutes

and connect a hose onto fuel rich

circuit. Then blow the hose with air

Dry spark plug Wet spark plug

Blowing in normal Blowing clogged

1. No fuel in fuel tank

2. Check if the pipes, fuel tank to

carburetor and intake vacuum,

are clogged.

3. Float valve clogged

4. Lines in fuel tank evaporation

system clogged

5. Malfunction of fuel pump

6. Loosen or damaged fuel pump

vacuum hose

7. Fuel filter clogged

1. Malfunction of spark plug

2. Spark plug foul

3. Malfunction of CDI set

4. Malfunction of AC generator

5. Ignition coil is in open or short

circuit

6. Ignition coil leads open or short

circuit

7. Malfunction of main switch

1. Piston ring seized

2. Malfunction of cylinder valves

3. Worn cylinder and piston ring

4. Cylinder gasket leak

5. Sand hole in compression parts

1. Malfunction of throttle valve

operation

2. Air sucked into intake manifold

3. Incorrect ignition timing

1. Fuel level in carburetor too high

2. Malfunction of throttle valve

operation

3. Throttle valve opening too wide

1. Malfunction of automatic by-

starter

cylinder compression

pressure normal

TGB 1. GENERAL INFORMATION/TROUBLE DIAGNOSIS

1-5

B. Engine run sluggish (Speed does not pick up, lack of power)

Check and adjustment Fault condition Probable causes

Try gradual acceleration

and check engine speed

Engine speed can be

increased. Engine speed can not be

increased.

Check ignition timing

(Using ignition lamp)

Check cylinder compression

pressure (using compression

pressure gauge)

Ignition timing correct Incorrect ignition timing

Compression pressure correct No compression

Check if carburetor jet is

clogged

No clogged Clogged

Remove spark plug

Check if engine over heat

No foul or discoloration Fouled and discoloration

No knock Knock

1. Air cleaner clogged

2. Poor fuel supply

3. Lines in fuel tank evaporation

system clogged

4. Exhaust pipe clogged

5. Fuel level too low in carburetor

6. Fuel nozzle clogged in

carburetor

1. Malfunction of CDI

2. Malfunction of AC alternator

1. Cylinder & piston ring worn out

2. Cylinder gasket leaked

3. Sand hole in compression parts

4. Valve deterioration

5. Seized piston ring

1. Remove foreign

1. Remove dirt

2. Incorrect spark plug heat range

1. Piston and cylinder worn out

2. Lean mixture

3. Poor fuel quality

4. Too much carbon deposited in

combustion chamber

5. Ignition timing too advanced

6. Poor circuit on the cooling

s

y

stem

Normal Engine overheat

Continually drive in

acceleration or high speed

1. Too much carbon deposited in

combustion chamber

2. Lean mixture

3. Poor fuel quality

4. Ignition timing too advanced

1. GENERAL INFORMATION/TROUBLE DIAGNOSIS TGB

1-6

C. Engine runs sluggish (especially in low speed and idling)

D. Engine runs sluggish (High speed)

Check ignition timing

(using ignition lamp)

Good spark Poor

No air sucked Air sucked

Good Poor

Abnormal

Air sucked through

carburetor gasket

Adjust the air screw of

carburetor

Remove spark plug, install

spark plug into spark plug

cap and perform spark test

against engine ground

Normal

Check and adjustment Fault condition Probable causes

Check for fuel supplying

system in automatic fuel cup

Check if carburetor clogged

1. Incorrect ignition timing (malfunction

of CDI or AC alternator)

1. Rich mixture (loosen the screw)

2. Lean mixture (tighten the screw)

1. Poor heat insulation gasket

2. Carburetor lock loose

3. Poor intake gasket

4. Poor carburetor O-ring

5. Vacuum hose crack

1. Spark plug fouled

2. Malfunction of CDI

3. Malfunction of AC generator

4. Malfunction of ignition coil

5. Open or short circuit in spark plug

leads

6. Malfunction of main switch

1. Insufficient fuel in fuel tank

2. Fuel filter clogged

3. Restricted fuel tank vent

Good Poor

Check and adjustment Fault condition Probable causes

Check ignition timing

1. Malfunction of CDI

2. Malfunction of AC alternator

Normal Abnormal

No clogged Clogged 1. Cleaning

TGB 1. GENERAL INFORMATION/TROUBLE DIAGNOSIS

1-7

E. CLUTCH, DRIVING AND DRIVING PULLEY

1. Clutch ling spring broken

2. Clutch outer stick with clutch balance weights

3. Connection parts in clutch and shaft worn out

or burned

Engine can be started but

motorcycle can not be moved.

FAULT CONDITIONS PROBABLE CAUSES

1. Driving belt worn out or deformation

2. Driving disk damaged

3. Driving pulley spring broken

4. Clutch ling broken

5. Driving slide-shaft gear groove broken

6. Transmission gear damaged

Engine running and misfire as

motorcycle initial forward moving

or jumping suddenly (rear wheel

rotating as engine in running)

Poor initial driving ( Poor

climbin

g

p

erformance

)

1. Driving belt worn out or deformation

2. Balance weight roller worn out

3. Driving sliding gear shaft worn out

4. Driving disk spring deformation

5. Driving sliding gear shaft worn out

6. Greased in driving belt and sliding gear.

TGB 2. MAINTENANCE INFORMATION

2-1

PRECAUTIONS IN OPERATION .......2-1

PERIODICAL MAINTENANCE SCHEDULE........2-2

LUBRICATION SYSTEM....................2-3

VALVE CLEARANCE ADJUSTMENT 2-4

CARBURETOR IDLING SPEED ADJUSTMENT 2-5

IGNITION SYSTEM/SPARK PLUG .. 2-6

CYLINDER COMPRESSION PRESSURE .2-7

DRIVING SYSTEM............................. 2-7

PRECAUTIONS IN OPERATION

Specification

capacity 850 c.c.

Engine Oil change 750 c.c.

capacity 120 c.c.

Transmission Gear oil change 110 c.c.

Clearance of throttle valve 2~6 mm

Spark plug TORCH A7RC Gap: 0.6~0.7 mm

“F” Mark in idling speed Before TDC 13º / 2200 rpm

Full timing advanced Before TDC 26º / 8000 rpm

Idling speed 2200±100 rpm

Cylinder compression pressure 12±2 kg/cm²

Valve clearance: IN/EX 0.06±0.02 mm

2. MAINTENANCE INFORMATION TGB

2-2

PERIODICAL MAINTENANCE SCHEDULE

Maintenance

Code Item Initial 500KM 6 Month

Every3000KM

12 month

Every6000KM

18 month

Every9000KM

24 month

Every12000KM

01 ☆Engine oil R R

ENGINE OIL SHALL BE CHANGED PER 1000KM

02 ☆Filter, Engine oil C C C C C

03 ☆Air Cleaner C R C R

04 ☆Second-Air Control Assy C R C R

05 ☆Spark plug C R C R

06 ☆Carburetor I I,A I,A I,A I,A

07 ☆Idle speed A A A A A

08 ☆Throttle Cable I I I I I

09 ☆Brake System I,A I,A I,A I,A I,A

10 ☆Wheel I I I I

11 ☆Nut,Bolt,Fastener I I I I I

12 ☆Battery I I I I

13 ☆C.V.T Belt I R I R

14 ☆Oil,Reducing Gear Box R R R

15 ☆Fuel Filter I R I R

16 ☆Speedometer Gear Box L L L

17 ☆Front Fork I I I

18 ☆Absorber Shock,Rear I,A I,A I,A

Code: I ~ InspecT or replace if necessary A ~ adjustment R ~ Replacement C ~ Cleaning (replaced if necessary)

L ~ Lubrication

Have your motorcycle checked, adjusted, and recorded maintenance data periodically by your TGB Authorized Dealer to

maintain the motorcycle at the optimum condition

The above maintenance schedule is established by taking the monthly 1000 kilometers as a reference which ever comes

first.

Remarks:

1. Clean or replace the air cleaner element more often when the motorcycle is operated on dusty roads or in the

Heavily- polluted environment.

2. Maintenance should be performed more often if the motorcycle is frequently operated in high speed and after the

motorcycle has accumulated a higher mileage.

3. Preventive maintenance

a. Ignition system - Perform maintenance and check when continuous abnormal ignition, misfire, after-burn,

overheating occur.

b. Carbon deposit removal - Remove carbon deposits in cylinder head, piston heads, exhaust system when power is

obvious lower than ever.

c. Replace worn out pistons, cylinder head.

TGB 2. MAINTENANCE INFORMATION

2-3

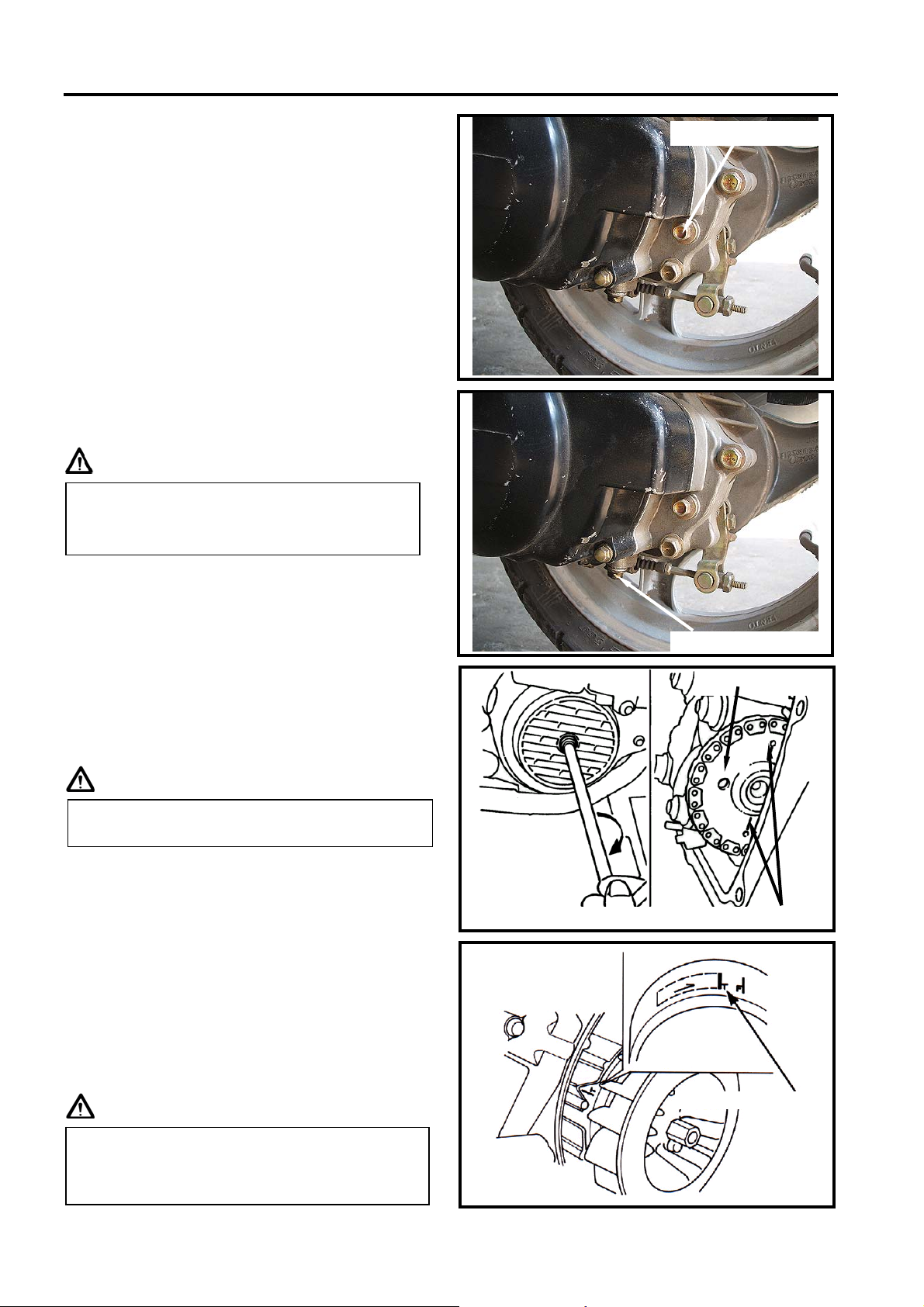

LUBRICATION SYSTEM

Engine Oil Capacity

Caution

Remove dipstick to check the oil level. If oil

level is below the lower limit mark, add oil to

the specified upper limit mark.

Oil change

Shut off the engine and remove dipstick.

Remove the oil drain plug on the bottom-left

of crankcase to drain oil.

After draining out oil, clean oil plug and its

gasket and reinstall. Replace the gasket if it

is damaged.

Torque value: 3.5~4.5 kgf-m

Caution

Add oil to the specified capacity.

Oil Viscosity: SAE 10W-30, recommended

using King-Mate serial oil.

Engine oil capacity:

Disassembly: 850cc

Change: 750cc

When checking for oil leak, run the engine at

idle speed for a few minutes, then check oil

capacity with dipstick.

Cleaning the oil strainer

Drain oil from engine, remove the strainer

cover, spring and strainer.

If there is an accumulation on the screen,

wash it off with suitable solvent

(recommended using compressed air).

Check O-ring for damage, replace if

necessary.

Reinstall strainer, spring, O-ring and strainer

cover.

Torque value: 1.3~1.7 kgf-m

yThe vehicle must be parked on a level

ground when checking oil capacity.

yRun the engine for 2-3 minutes then

stop, wait about 2-3 more minutes

allowing engine oil to settle before

checkin

g

the oil level.

Warm up the engine. This will make the

oil flow out easily.

Oil drain plug

strainer cove

r

oil straine

r

spring

Dipstick

2. MAINTENANCE INFORMATION TGB

2-4

Gear Oil

Inspection

Check gear oil if leaking.

Park the motorcycle with main stand on flat

level place.

Turn off engine and remove the gear oil

draining plug.

Place a measurement cup under the draining

hole.

Remove the oil drain plug and drain gear oil

into a measurement cup.

Check gear oil if enough.

Replacement

At first, remove the gear oil refilling bolt, and

then remove the draining plug.

Install the draining plug after drained oil out.

Torque value: 0.8~1.2 kgf-m

Caution

Fill out gear oil to specified quantity from the

engine oil filling hole.

Install the oil filling bolt.

Torque value: 0.8~1.2 kgf-m

Transmission oil capacity: 120 c.c.(110

c.c. for change)

Recommended: King-Mate HYPOID GEAR

OIL ( #140 ).

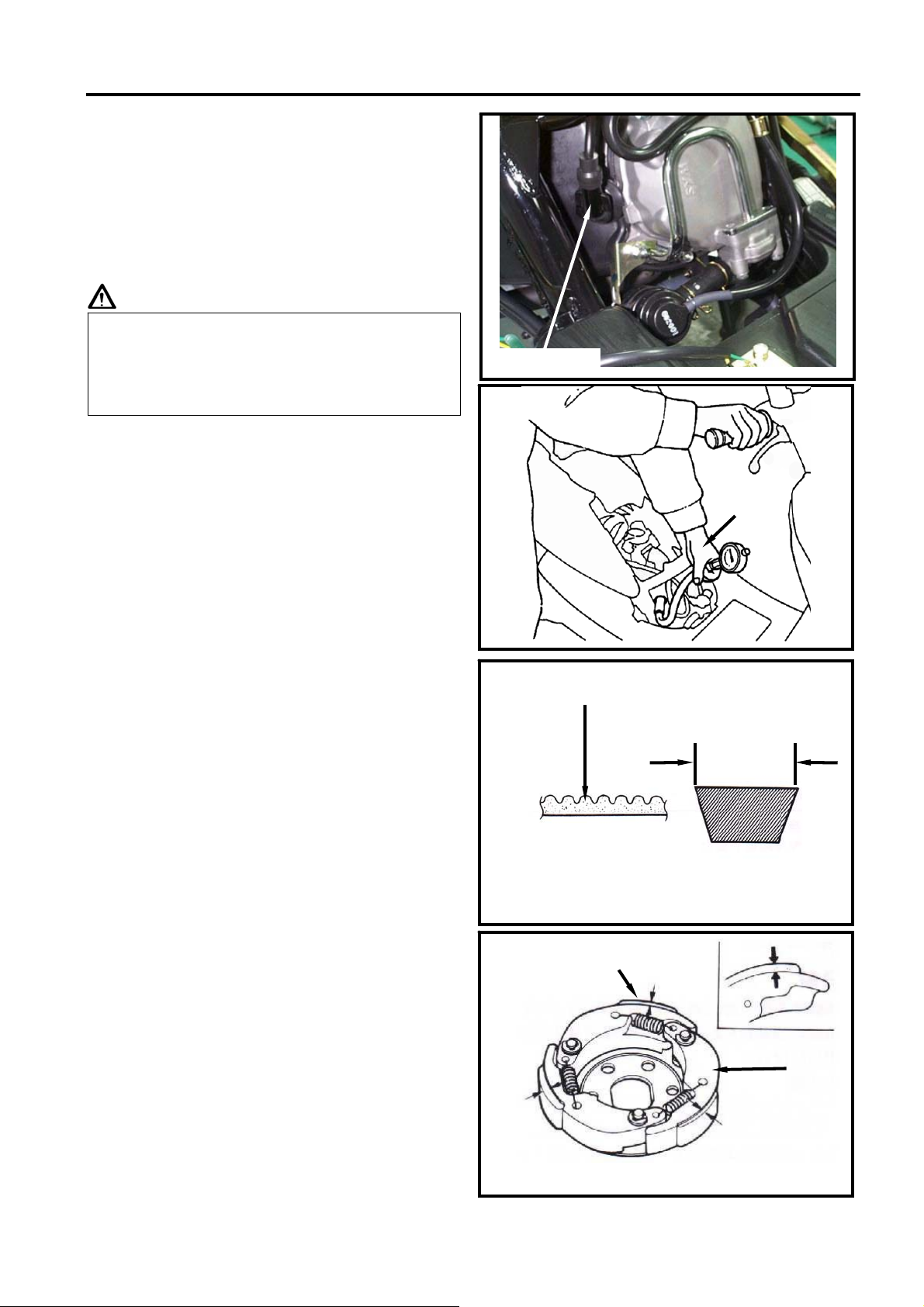

VALVE CLEARANCE ADJUSTMENT

Caution

Remove luggage box and front center cover.

Remove the left body cover & left side cover.

Remove cylinder head cap.

Remove the ignition timing check hole on the

cooling fan cover.

With “T” type wrench, turn crankshaft in

clockwise motion so that mark (“T”) on the

generator flywheel aligns with the mark on

the crankshaft, and camshaft is at TDC

position also as same as level of cylinder

head top-end. A single hole on camshaft

sprocket is forward to up. (Piston is at TDC

position in the compression stroke.)

Caution

Inspect if washer is in good condition.

Replace it with new one if it was

deformed or damaged.

Checks and adjustment must be performed

when engine is cold (below 35℃).

The crankshaft can not be rotated in

counter-clockwise to prevent from damage

so that valve clearance can not be

measured.

Ignition timing mark

TDC mark

Inspection hole

Gear oil refilling bolt

Gear oil draining plug

TGB 2. MAINTENANCE INFORMATION

2-5

Check & adjust valve clearance with feeler

gauge.

Valve clearance (IN/EX): 0.06±0.02 mm

Loosen fixing nut and turn the adjustment

nut for adjustment.

Caution

CARBURETOR IDLE SPEED

ADJUSTMENT

Caution

Park the motorcycle with main stand and

warn up engine.

Open the carburetor cover from the luggage

box.

Turn the throttle valve stopper screw to

specified idle speed.

Specified idle speed: 2200±100 rpm

Emission adjustment in Idle speed

Warm up the engine for around 10 minutes

and then conduct this adjustment.

1. Connect the tachometer onto engine.

2. Adjust the idle speed adjustment screw and

let engine runs in 2200±100 rpm.

3. Insert the exhaust sampling muffler of

exhaust analyzer into the front section of

exhaust pipe. Adjust the air adjustment

screw so that emission value in idle speed

is within standard.

4. Slightly accelerate the throttle valve and

release it immediately. Repeat this for

2~3 times.

5. Read engine RPM and value on the

exhaust analyzer. Repeat step 2 to step 4

procedures until measured value within

standard.

Emission standard: CO: below2.5±0.5 %

HC: below 800 ppm

It has to make sure that valve-rocker arm

is be adjusted to standard level when

adjusting it, and re-check the valve

clearance after tightened the fixing nut.

yInspection & adjustment for idle speed

have to be performed after all other

parts in engine that needed adjustment

have been adjusted.

yIdle speed check and adjustment have

to be done after engine is being warm

up (around 10 minutes).

Throttle valve stopper screw

I

g

nition coil cable

Air adjustment screw

Feeler gauge

Fixing nut

2. MAINTENANCE INFORMATION TGB

2-6

IGNITION SYSTEM

Ignition timing

Caution

Remove right side cover.

Remove ignition timing hole cap located on

the cooling fan cap, or remove the cooling

fan cap.

Check ignition timing with ignition light.

Start engine and set engine idle speed in

1700 rpm, and if the mark aligns with the “F”,

then it means that ignition timing is correct.

Increase engine speed to 8000 rpm to check

ignition timing advance. If the detent aligns

with advance mark “װ”, then it means ignition

timing advance is in functional. If not,

check CDI set, pulse flywheel, and pulse

generator. Replace these components if

malfunction of these parts are found.

SPARK PLUG

Appointed spark plug: TORCH A7RC

Remove luggage box.

Remove body side cover.

Remove spark plug cap.

Clean dirt around the spark plug hole.

Remove spark plug.

Measure spark plug gap.

Spark plug gap: 0.6~0.7 mm

Carefully bend ground electrode of the plug

to adjust the gap if necessary.

Screw the park plug into the plug hole with

hands, then tighten the plug with a wrench to

prevent from damaging the spark plug's

thread.

Torque value: 1.0~1.2 kgf-m

Connect spark plug cap.

C.D.I ignition system is set by

manufacturer so it can not be adjusted.

Ignition timing check procedure is for

checking whether C.D.I. function is in

normal or not.

I

g

nition li

g

ht

F mark

0.6~0.7mm

Side electrode Center electrode

Spark plug

TGB 2. MAINTENANCE INFORMATION

2-7

CYLINDER COPMRESSION PRESSURE

Warn up engine and then turnoff the engine.

Open the seat. Remove the luggage box.

Remove spark plug cap and spark plug.

Install compression gauge.

Full open the throttle valve, and rotate the

engine by means of stepping the

kick-starting lever.

Caution

Compression pressure: 12±2 Kg/cm²

Check following items if the pressure is too

low:

zIncorrect valve clearance

zValve leaking

zCylinder head leaking, piston, piston ring

and cylinder worn out

If the pressure is too high, it means carbon

deposits in combustion chamber or piston

head.

DRIVING SYSTEM

DRIVING BELT

Remove left side cover.

Remove mounting bolt located under air

cleaner.

Remove 9 bolts of the engine left crankcase.

Remove the left crankcase cover.

Check if the belt is crack or worn out.

Replace the belt if necessary or in accord

with the periodical maintenance schedule to

replace it.

Width limit: above 17.5 mm

Clutch pad

Start the motorcycle and gradually increase

throttle valve openness to check clutch pad

operation.

If the motorcycle moves with shaking, then

check its clutch pad for wearing. Replace it

if necessary.

Rotate the engine until the reading in the

gauge no more increasing.

Usually, the highest pressure reading will

be obtained in 4~7 seconds.

Gear teeth

Width

Cylinder

pressure gauge

Clutch

Clutch pad

Spark plug

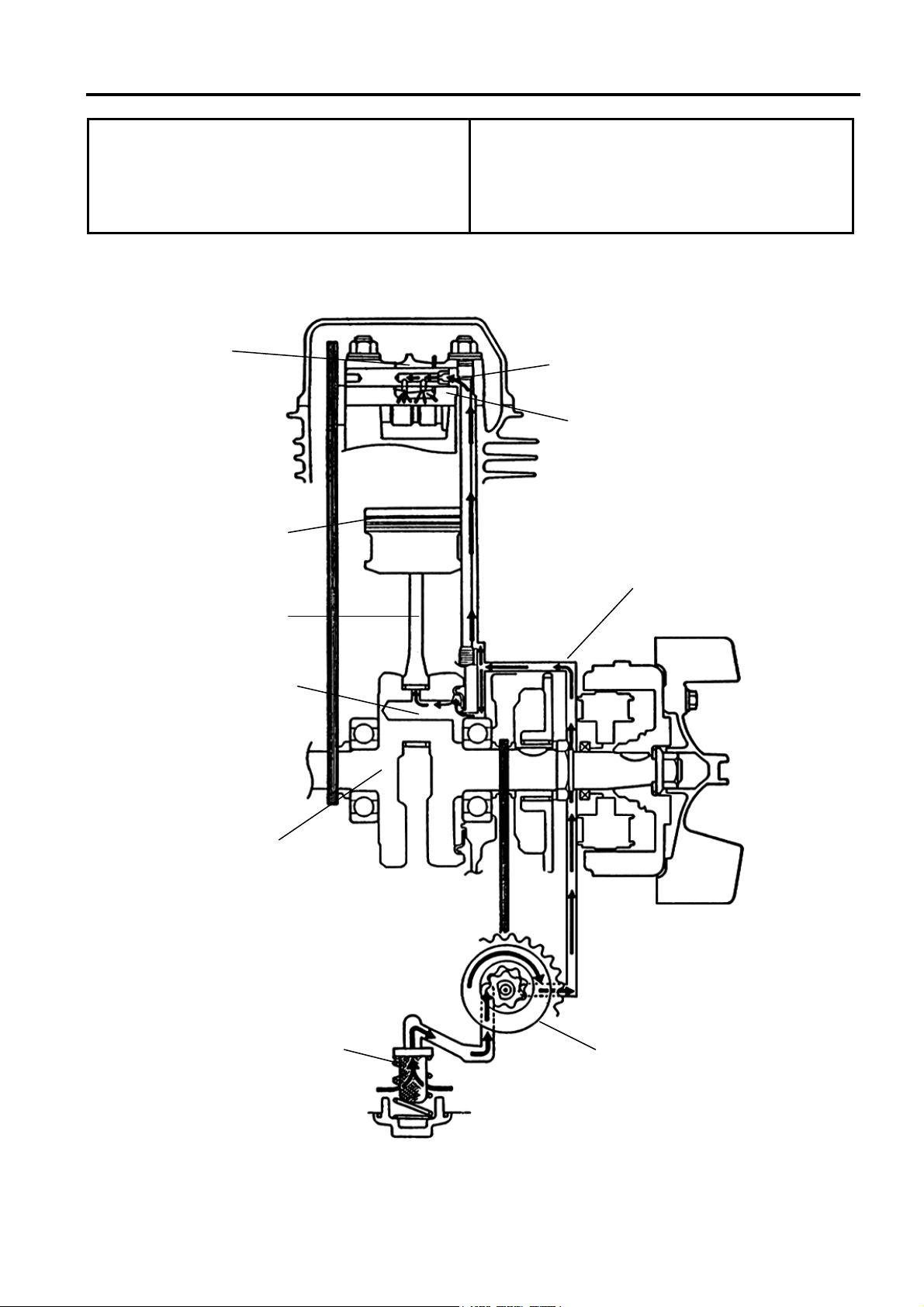

TGB 3.LUBRICATIONSYSTEM

3-1

MECHANISM DIAGRAM....................3-1

OPERATIONAL PRECAUTIONS .......3-2

TROUBLE DIAGNOSIS......................3-2

ENGINE OIL.......................................3-3

CLEANING ENGINE OIL STRAINER...3-3

OIL PUMP............................................3-4

GEAR OIL ............................................3-7

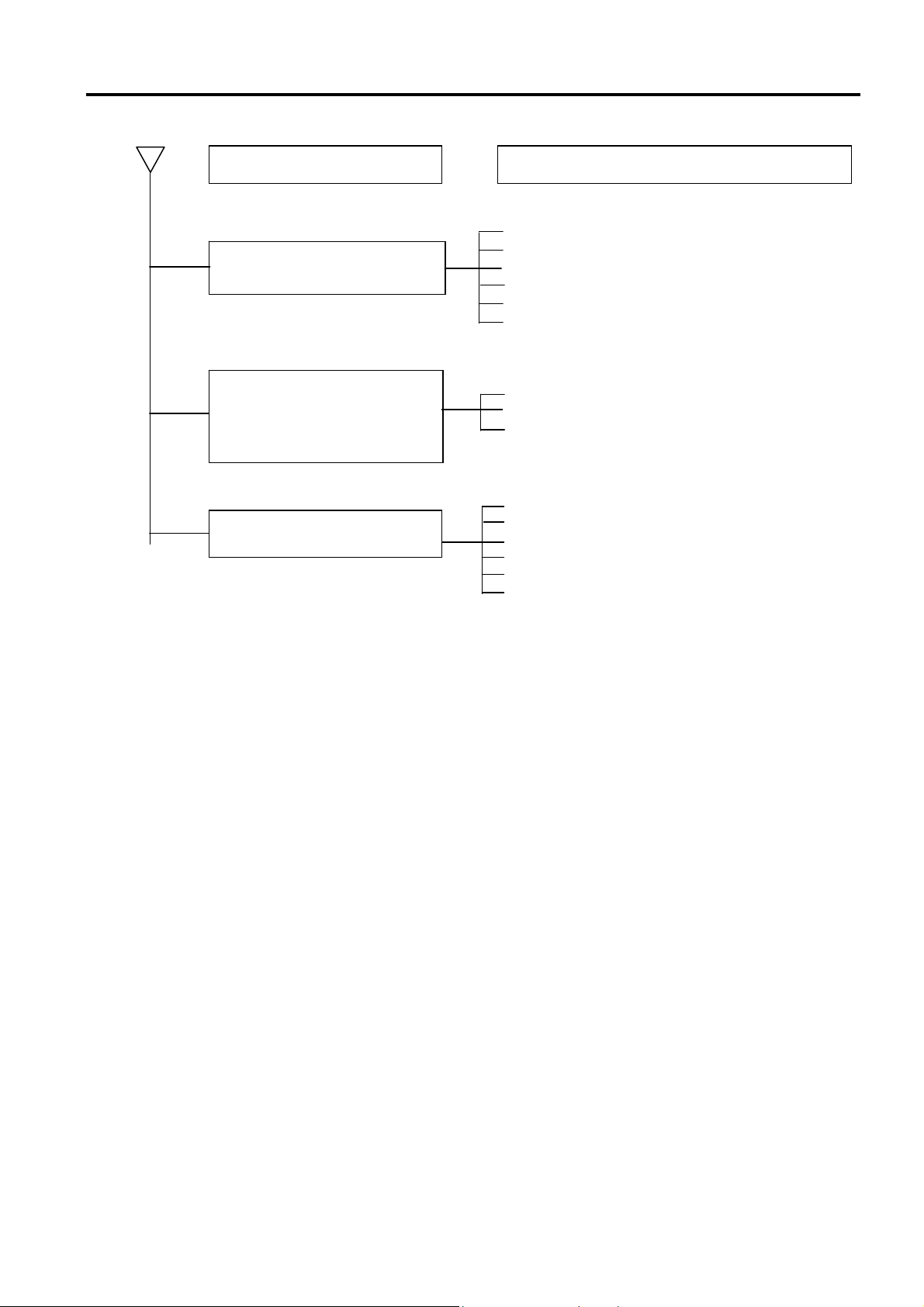

MECHANISM DIAGRAM

Valve rocker

arm

Camshaft

Scoop lubrication

Forcedly lubrication

Forcedly

lubrication

Inner passage

Connecting rod

Oil pump

Oil strainer

Crankshaft

3.LUBRICATIONSYSTEM TGB

3-2

OPERATIONAL PRECAUTIONS

General Information

zThis chapter contains maintenance operations for the engine oil pump, engine oil and

gear oil.

Specifications

Engine oil quantity Disassembly 850 c.c.

Replacement 750 c.c.

Oil viscosity SAE 10W-30 or equivalent

(Recommended King-Mate

serial oils)

Gear Oil Disassembly 120 c.c.

Replacement 110 c.c.

Oil viscosity of gear oil SAE 85W-140

(Recommended King-Mate

gear oil series SYM

HYPOID GEAR OIL)

unit : mm

Items Standard Limit

Inner rotor clearance - 0.12

Clearance between outer

rotor and body - 0.12

Oil pump Clearance between rotor

side and body 0.05~0.10 0.20

Torque value

Engine oil drain plug 3.5~4.5kgf-m

Engine oil screen cover 1.3~1.7kgf-m

Gear oil drain bolt 0.8~1.2kgf-m

Gear oil filling bolt 1.0~1.4kgf-m

Oil pump connection screw 0.1~0.3kgf-m

TROUBLE DIAGNOSIS

Low engine oil level

Oil leaking

Valve guide or seat worn out

Piston ring worn out

Low Oil Pressure

Low engine oil level

Clogged in oil strainer, circuits or pipes

Oil pump damage

Dirty oil

No oil change in periodical

Cylinder head gasket damage

Piston ring worn out

Oil viscosity

TGB 3.LUBRICATIONSYSTEM

3-3

ENGINE OIL

Turn off engine, and park the motorcycle in

flat ground with main stand.

Check oil level with oil dipstick after 3-5

minutes.

Do not rotate the dipstick into engine as

checking.

If oil level is nearly low level, fill out

recommended oil to upper level.

Oil Replacement

Caution

Place an oil pan under the motorcycle, and

remove oil strainer cap.

Make sure if the aluminum washer of the

draining bolt is damaged. If so, replace it

with new one.

Install the drain bolt and tighten it.

Torque value: 3.5~4.5 kgf-m

CLEANING ENGINE OIL STRAINER

Remove the oil strainer cap.

Remove oil strainer and spring.

Clean oil strainer (recommended using

compressed air to clean dirty foreign).

Check if the strainer and O-ring of the oil

strainer are broken. Replace with new one if

found.

Install the oil strainer and spring.

Install the oil strainer cap and tighten it.

Torque value: 1.3~1.7 kgf-m

Fill out oil to the oil filler (Oil viscosity SAE

10W-30) (Recommended King-Mate serial

oils).

Engine oil quantity: Replacement 850 c.c.

Drain oil as engine warmed up so that

make sure oil can be drained smoothly and

completely.

Oil

stra

i

ner cap

Dipstick

Oil drain plug

oil straine

r

spring

3.LUBRICATIONSYSTEM TGB

3-4

OIL PUMP

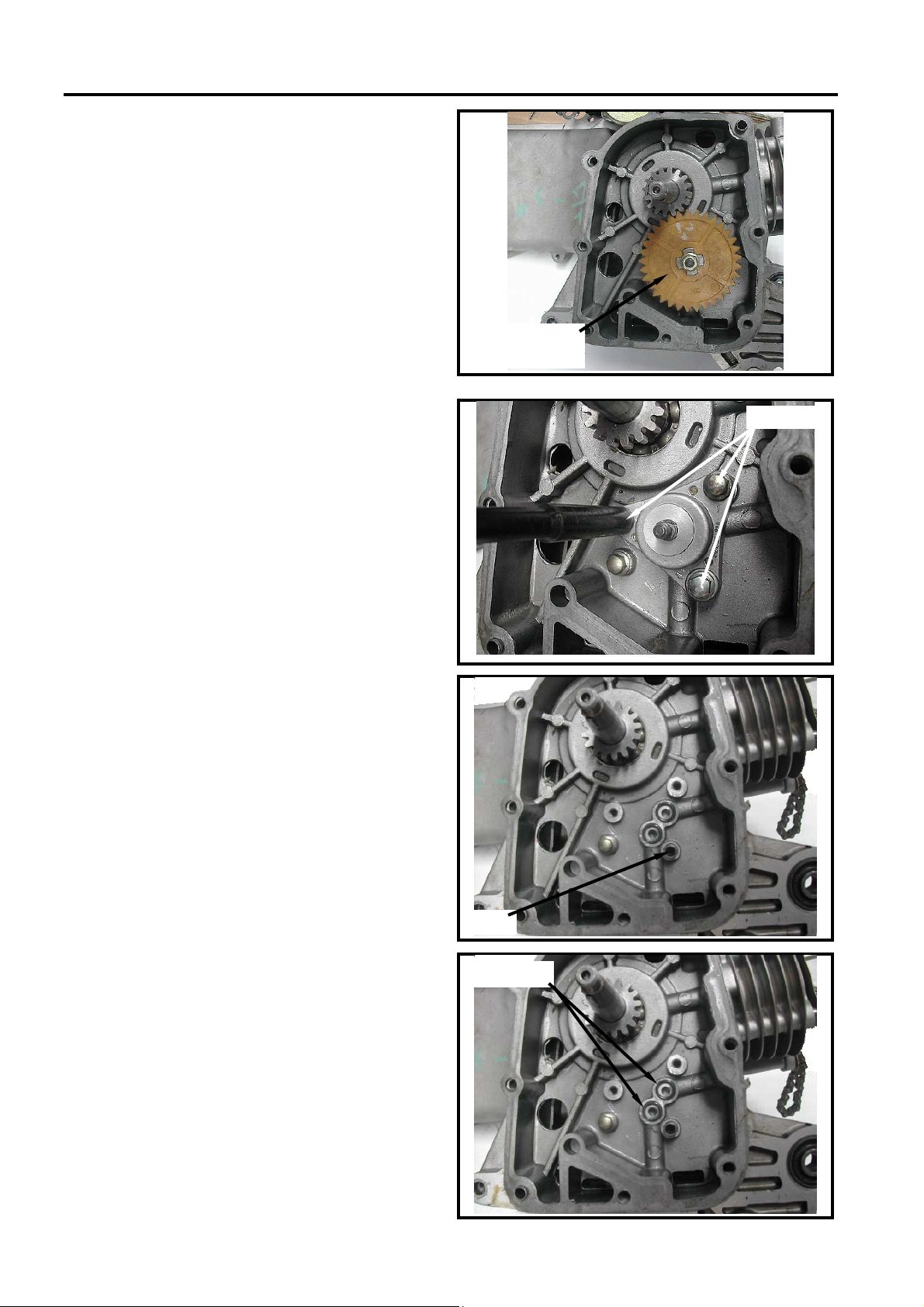

Oil Pump Removal

Remove the alternator (refer to chapter10).

Remove the engine right crankcase cover.

Make sure that the pump axle can be rotated

freely.

Remove the oil pump driving gear nut.

Remove oil pump body bolts (3 bolts).

Remove the oil pump pin.

Remove the oil pump.

Remove the 2 O-rings.

pump driving

gear nut

3bolts

pin

2 O-rings

This manual suits for next models

1

Table of contents

Other TGB Scooter manuals