TGB Xmotion 125 User manual

Xmotion 125/250

OWNER-MANUAl

MAINTENANCE HANDBOOK

TAIWAN GOLDEN BEE CO.,LTD.

PDF created with pdfFactory Pro trial version www.pdffactory.com

TABLE OF CONTENT

1. REGULAR INSPECTION

1-1 Delivery Introduction -----------------------------------------------------2

1-2 Inspection Before Running ---------------------------------------------4

1-3 Regular Maintenance Schedule -------------------------------------- 5

1-4 General Inspection -------------------------------------------------------6

1-5 Notes for Inspection ----------------------------------------------------- 7

2. MAINTENANCE INFORMATION

2-1 Specification Sheet -----------------------------------------------------8

2-2 Safety Precautions--------------------------------------------------------10

2-3 Special Tools --------------------------------------------------------------11

2-4 List of Grease & Oil Adopted ----------------------------------------- 24

2-5 Circuit Drawings --------------------------------------------------------- 25

2-6 Troubleshooting ----------------------------------------------------------27

2-7 Tighting Torque of Screws --------------------------------------------27

2-8 Troubleshooting ----------------------------------------------------------30

3. DESCRIPTION OF PARTS AND COMPONENTS

3-1 Engine ---------------------------------------------------------------------39

3-2 Electric System ---------------------------------------------------------- 126

Q Q

Rnrlv 1^1

\J \J UUUjf

I\JI

4. DISASSEMBLY REPAIRMENT

4-1 Notice for Disassembly Repairment ----------------------------- 137

4-2 Removal and lnstallation of Engine -------------------------------138

4-3 Removal and Inspection of Electric Items -----------------------199

4-4 Removal and Inspection of Body Parts ----------------------------206

4-5 Brake System ----------------------------------------------------------- 214

î

PDF created with pdfFactory Pro trial version www.pdffactory.com

CHAPTER I

REGULAR INSPECTION

1-1 Delivery Introduction 1-4 General Inspection

1-2 Inspection Before Running 1-5 Notes for Inspection

1-3 Regular Maintenance Schedule _______________________

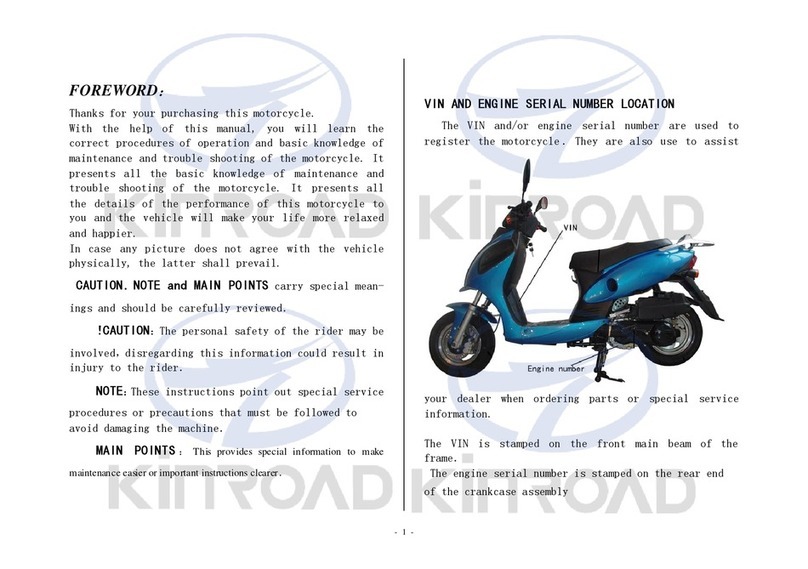

1-1 Delivery Introduction

To inform customers of correct methods to use: To practically and correctly

ride a scooter according to the Instruction of Manual and Maintenance

Handbook. Customers should also try in person according to this manual.

1. Starting:

A. Turn the power switch to "ON."

B. Hold the front or rear brake and press the "START" button.

C. If the scooter is not started, release the "START" button and try again after a few

minutes. Each start should be less than five seconds to avoid battery consumption.

Note: This is an AUTO-CHOKE scooter, thus there is no choke lever.

The fuel is controlled only by throttle grip.

The accelerator has to return to its original place when the scooter is not in use.

D. If the scooter can not be started by the "START" button, try the kick starter.

2. Fuel:

Inform customers to refill the fuel to no more than 80% of the tank capacity only.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2

2

1-1 Delivery Introduction 3

. Lubricant Adopted:

A. WARNING : The engine oil must be refilled when the oil warning lamp lights, otherwise the

engine will be burned-out due to insufficient lubrication. Recommended oil : TGB Genuine

EXTRA 4X OIL.

B. Genuine TGB HYPOID GEAR OIL(or SAE85W-140) will be adopted as gear oil to be

changed on a periodical basis. Gear oil and engine oil are different in their nature.

Attention should be paid to avoid mistake when used.

4. Regular Inspection and Maintenance:

Inform customers of the importance of inspection before running and regular inspection.

A. Inspection Before Running: Riders should perform nspection by themselves before

running.

B. Regular Inspection: Regular inspection should be performed after the first month and

the sixth month and every six months afterwards.

5. Description of Warranty System:

Clearly identify the content of warranty in accordance with the warranty paper.

A. Content and term of warranty.

B. Maintenance items not guaranteed.

C. Items should be followed by customers.

Instruct customers to carry the OWNER'S Manual with them when they come for regular

inspection and maintenance. It is because such inspection should be recorded onto the

Manual.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3

3

1-2 Inspection Before Running

Items to be Inspected Before Running by Customers:

ITEM

CONTENT

GUIDELINE

1. Starter

Is the oil volume

proper?

1 .Check Oil Warning Lamp to see if the oil

volume is proper?

2 .Fuel

Is the fuel volume

sufficient?

1 .Check fuel volume to see if it is enough

to the destination.

3. Lamp &

Direction

Indicator

Is the lamp condition

well? Is there any

dirt?

1 .Check if the lighting condition of head

lamp, tail lamp, licence lamp, brake lamp,

direction indicator and other lamp is well.

2. Lamps should be kept clean and

undamaged.

4. Back Mirror

Is the reflecting

image well?

1. Look at the back mirror from the

seat to check if the rear view is clear.

5. License Plate &

Reflector

No dirt and damage

should appear.

1. License plate should be installed, letters

and numbers should be kept clear and

clean. 2. Dirt and damage should not

appear on the reflector.

6 . Brake

Check the distance of

brake handle lever

and the brake effect.

1 .Operate the handle lever slowly to the

brake begin to effect in order to inspect the

moving distance. 2.Test the brake with low

speed running to see the brake effect of

front and rear brakes.

1.Is the air pressure

proper?

1 .Check if the air pressure of tire is

sufficient with a gauge or by sight.

2.Groove should be

deep enough.

1 .Check if the groove of tires is enough.

3.Unusual wear is not

desired.

1 .Check landing flat of tire to see if

any unusual wear appears.

4.Breaking and damage

are not desired.

1 .Check landing flat and side to see if

any breaking or damage appear.

7. Tire

5.Metal, stone and

other articles are

not desired.

1 .Cneck if any cracking, stone or any

other article sticks into the tire.

4

PDF created with pdfFactory Pro trial version www.pdffactory.com

This manual suits for next models

1

Table of contents

Other TGB Scooter manuals