The Frank G. Hough HA PAYLOADER Installation and user guide

TABLE OF CONTENTS

o

MAINTENANCE SECTION • •

Brakes - Adjustment

Brakes - Bleeding •

Bucket - Adjustment

Clutch - Adjustment

Drive Shaft . • . •

Engine. • • • . • • • •

Fan Belt - Adjustment ••••

Final Drive Removal •

Fuel System • • • • • • •

Hydraulic System Care of.

Hydraulic System - Draining

Hydraulic System - Bleeding

Pump Adjustment . • • • •

Ram - Packing Adjustment.

Steering Gear Adjustment •••••

Tires - Changing •••

Tires - Pressures • •

Toe-in Adjustment • •

Transmission Removal.

Valve Adjustment .•••••

NUMERICAL INDEX • • • • • • ", •

OPERATING THE PAYLOADER • • • •

Cold Weather Operation. •

Dash Instruments •••

Directional Lever •

Dumping the Bucket.

Foot Pedals • • • •

Latching the Bucket •

Loading the Bucket ••

Operating the Hoist •

Range Lever • •.• • •

Routine Service • •

Starting the Engine •

Transporting Loads.

PARTS SECTION • • . •

Accelerator Group • •

Body Group ••••.

Boom Group •• , ••

Brake Assly Group ••

Brake Control Group •

.Bucket Group. .,, .

Bucket Snubber, , .

Carrier Group • • • • •

Clutch Assly Group ••

Clutch Control Group.

Drive Shaft Group ••

Engine Group ••••.•

Frame Group • • • • •

Front Axle

&

Reduction Drive.

Hoses

&

Connections Assly •

Pump Assly Group •.••••

Ram Assly Group ••••••

Rear Axle

&

Steering Ass'Y.

Shifter Levers Group. • • .

Steering Gear Group • • • •• •

Transmission

&

Final Drive Assly.

Transmission Group ••.•

Valve Group • • • • • • • ••

Valve Control Group • • • • • •

Wiring

&

Connection.Assly •••

PREPARATION OF PAYLOADER FOR OPERATION.

SPECIFICATION AND SERVICE DATA. • • • •

.

..

PAGE

70

3

71

- 72

13

23 - 24

23

17

20

21

18

18

19

18

13

13

13

16

14

21

22

23

22

19

15

74 - 75

EXTRA EQUIPMENT • • •

LIST OF ILLUSTRATIONS

LUBRICATION POINTS ••

•• 11

8

- 12

8

8

10

8

10

9

9

8

11

9

10

-,

25

•.32 - 33

29

65

37

36

69

70

67

42

43

38

31

27

. • .• 45

• 55 - 57

58

59

47

39

49

35

• • •• 41

• • 60 - 61

• 62 - 63

51.- 53

.,

,

.

.

6

4

1

u

•

J

2

LIST OF ILLUSTRATIONS

Accelerator Group

Body Group ••••

Boom Group. . . • •

Brake Control • •

Brake Drum Group.

Brake Pedal Adjustment.

Brake Shoe Adjustment

Bucket Group •••••

Carrier Group • • • . .

Clutch Group. • • • • .

Clutch Control Group .•

Clutch Pedal Adjustment

Clutch Section. •

Control Levers ••

Dash Instruments ••

Drive Shaft • • • ,

Engine Group. . . •

Final Drive Removal

Frame Group • . • •

Front Axle Reduction Drive.

Hydraulic Diagram •

Lubrication Chart •

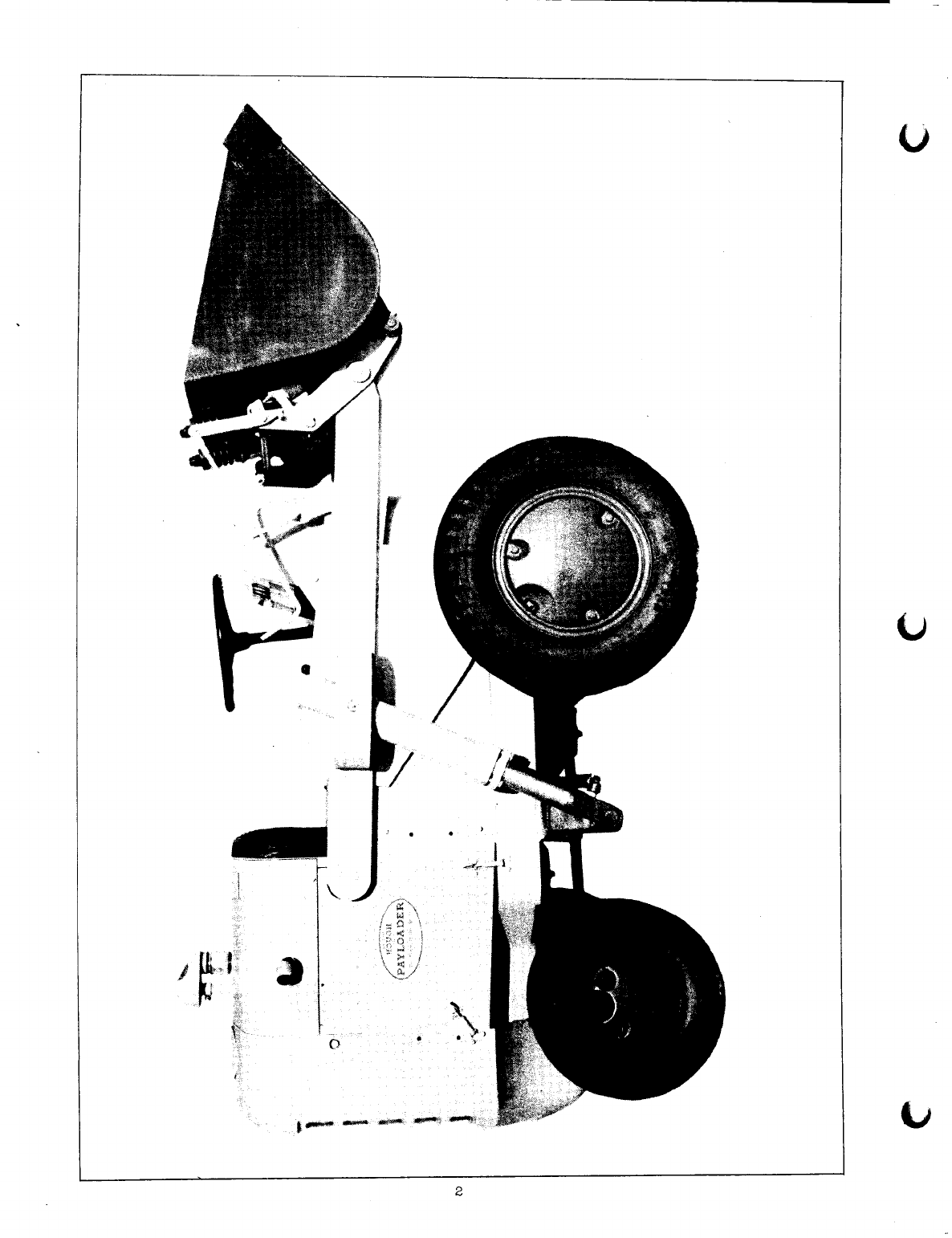

Payloader Side View

Pump Assembly •

Pump Group •••..

Ram Section • • • •

Ram Group ••.•••

Rear Axle

&

Steering Group.

Shifter Levers Group ••••

Steering Gear Group . . • •

Steering Gear Adjustment •.

Transmission

&

Final Drive Group ••

Transmission Group.

Valve Group • • . .

Valve Control Group

Valve Section . •

Wiring Diagram. '••

PAGE

32 - 33

28

64

36

37

24

23

68

66

42

43

21

20

7

7

38

30

19

26

44

54 - 56

73

2

16 - 17

58

14

59

46

39

48

• 21 - 22

34

40

60 - 61

• 62 - 63

•• 15 - 16

• 50 - 52

3

CONDENSED SPECIFICATIONS ~& SERVI CE DATA

ENGINE

No. Cylinders

Bore .

Stroke .

Displacement .

Speed (Governed).

Horse Power .

4

3-1/4"

4"

133 cu. in.

1800 R.P.M.

29

Complete with electrical starting equipment, oil bath air cleaner

with centrifugal type pre-cleaner and engine oil filter.

TRANSMISSION

HOUGH two speeds forward and two speeds reverse, completely

equipped with anti-friction ball bearings.

Low

High

FORWARD

2.5 to 1

1 to 1

REVERSE

1.53 to 1 (Reduction)

1.64 to 1 (step up)

GEAR RATIOS:

FINAL DRIVE:

HOUGH heavy duty double reduction spiral bevel and spur gear de-

sign. First reduction spiral bevel with differential ahead of final

drive. Full floating axle shafts. Completely equipped with ball and

roller bearings.

GEAR RATIO:

22

to

1

PAYLOADER SPEEDS, MILES PER HOUR (ENGINE AT 1800 R.P.M.)

TRAVELING SPEEDS: FORWARD REVERSE

Low

High

2.5

10.0 3.5

11.0

CAPACITIES:

Cooling System . .

Fuel Tank. . . . .

Transmission Case.

Final Drive Case

Crankcase ....

Hoist Reservo:!-r.

3-1/2 gal.

6-1/2 gal.

6-1/2 Ibs.

15-1/2 Ibs.

5

qts.

6

gal. approx.

BUCKET:

Width .

Capacity, Volume .

Capacity, Weight .

Dumping Clearance.

Dumping Angle ...

42"

10-1/2 cu. ft.

1000 Ibs.

56"

30

0

CLUTCH:

11" Spring Loaded, Single Plate Dry Disc.

BRAKES:

INTERNAL EXPANDING HYDRAULIC BRAKES ON BOTH FRONT DRIVE WHEELS.

13" Dia. x 2" Wide Brake Band

4

STEERING:

o

Heavy Duty Truck Recirculating Ball Type Steering Mechanism.

PNEUMATIC TIRES:

Front (Drive Wheels)

Rear (Steering Wheels)

7:00-16

6:00-9

6

Ply

6

Ply

HOIST TRAVEL SPEE~S:

Raise:

Lower: 5 sec.

3

sec.

PAYLOADER DIMENSIONS:

Overall Height

Overall Width

Overall Length

Turning Radius

Wheelbase

Floor Clearance

61"

50-1/4"

9' 6"

6' 6"

48-1/2"

5"

WEIGHT:

PAYLOADER EMPTY PAYLOADER WITH 1000 LBS. IN BUCKET

Front

Rear

Total

2450

1700

4150

Front

Rear

Total

4310

790

5150

SPECI AL ATTACHMENTS: See page 70.

Variations in bucket sizes can be supplied to meet special conditions.

IT IS THE POLICY OF THE FRANK G. HOUGH CO. TO IMPROVE ITS

PRODUCTS WHENEVER IT IS POSSIBLE AND PRACTICAL TO DO SO.

WE RESERVE THE RIGHT TO MAKE CHANGES OR ADD IMPROVEMENTS

AT ANY TIME WITHOUT INCURRING ANY OBLIGATION TO MAKE SUCH

CHANGES ON MODEL "HA" PAYLOADERS PREVIOUSLY SOLD.

WARRANTY

This Model HA Payloader is warranted free from defects of material or workmanship for a

pe~iod of six months from date of sale; it is further warranted to be mechanically practical

for the purposes advertised by THE FRANK G. HOUGH CO.

Parts claimed to be defective are to be reported to us promptly and returned to us with

transportation charges prepaid. If we find the parts defective upon our examination, credit

will be issued or the parts replaced.

5

This warranty will not apply to machines that have been misused, loaded beyond factory

rated capacities, neglected or damaged through accident.

Any expense incurred without authorized consent for repairs or replacement will not be

allowed. The use of any but THE FRANK G. HOUGH CO. parts nullifies the warranty.

"

PREPARATION OF THE PAYLOADER FOR OPERATION

o

Before operating this Payloader, even to unload, check the entire unit to make sure

nothing has become loose or damaged in transit or storage. Battery cables have been dis-

connected at the factory and the cooling system drained before shipment.

DO NOT ATTEMPT TO START THE ENGINE BEFORE THE FOLLOWING POINTS HAVE BEEN CHECKED

OR DAMAGE MAY RESULT.

1.

Check the oil level in the hydraulic system reservoir to make sure it is up to the

"full" mark on the bayonet gage. The hydraulic system pump is coupled directly to

the engine crankshaft and MUST NOT be operated without oil in the hydraulic system.

(See Page 54 or 53)•

2. Check the oil level in the engine crankcase by removing the oil dip stick from the right

hand side of the engine. (See Chart Page 73).

3. Check the oil level in the transmission to be sure it is to the height of the oil level

plug on the left side.

4. Check the oil level in the final drive. Oil level plugs of the final drive are located

on the rear side of both housing extensions.

5. Check oil in the engine air cleaner cup to be sure it contains the correct amount and

grade of oil.

6. Check the master brake cylinder to make sure it is filled with brake fluid. If not fill

with "Lockheed" hydraulic brake fluid. (See Page 36).

7.

Be sure all hoses and connections are tight to prevent hydraulic oil from leaking out

and to keep mud or water from entering the system. Water entering the system will cause

pump co~osion at high velocities. (See Page 54 or 56).

o

8. Check the tire pressures. Be sure they are up to pressures recommended. Keep the valve

caps in place and tightened securely to prevent mud, dust and moisture from damaging the

valve core. (See Page 23).

9. Fill the cooling system with clean soft water, free from alkaline; never, at any time,

run the engine without the full quantity of water in the cooling system. The radiator

is fitted with a pressure type cap which must be removed to permit draining.

Capacity of the cooling system is

3i

gallons.

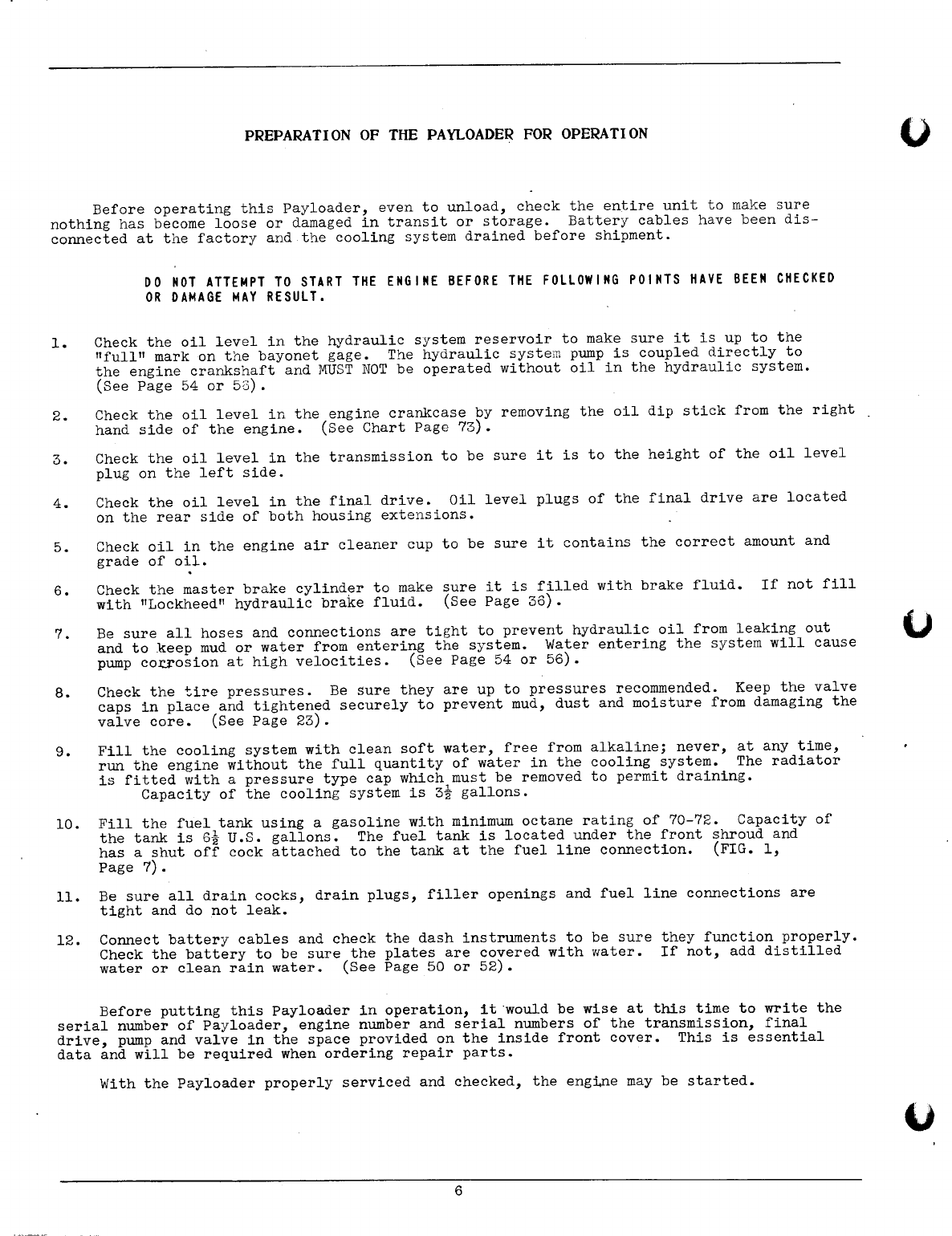

10. Fill the fuel tank using a gasoline with minimum octane rating of 70-72. CapaCity of

the tank is

6i

U.S. gallons. The fuel tank is located under the front shroud and

has a shut off cock attached to the tank at the fuel line connection. (FIG. 1,

Page 7).

11. Be sure all drain cocks, drain plugs, filler openings and fuel line connections are

tight and do not leak.

12. Connect battery cables and check the dash instruments to be sure they function properly.

Check the battery to be sure the plates are covered with water. If not, add distilled

water or clean rain water. (See Page 50 or 52).

Before putting this Payloader in operation, it ·would be wise at this time to write the

serial number of Payloader, engine number and serial numbers of the transmission, final

drive, pump and valve in the space provided on the inside front cover. This is essential

data and will be required when ordering repair parts.

With the Payloader properly serviced and checked, the engine may be started.

6

"

TANK FILLER

~~+----,\-Ol L GAGE

~I-\---+--.

AM METER

TEMPERATURE

GAGE

Fig. 1

DASH INSTRUAIENTS

&

CONTROLS

STARTER

BUTTON

'I..AJJj_£

CONTROL

LEVER

CHOKE

Fig. 2

VALVE LEVER

&

STARTER BUTTON

7

OPERATING THE PAYLOADER

DRIVING THE PAYLOADER (See Fig. I and 2, page 7).

This Payloader is equipped with a two speed forward and a two speed reverse trans-

mission.

The speeds and direction desired is selected by shifting a RANGE LEVER and a DIRECTIONAL

LEVER, located on each side of the steering column.

RANGE LEVER

The

RANGE

lever is located on the right hand side of the steering column. This lever is

in

NEUTRAL

when it is in a vertical position. When pulled backward from neutral the trans-

mission has been shifted to

LOW

range. When pushed forward from neutral the transmission has

been shifted to

HIGH

range.

The low speed range is used for working conditions where more power is needed.

The high speed range is used primarily for transporting loads to various ~ocations.

DIRECTIONAL LEVER

The

DIRECTIONAL

lever is located on the left hand side of the steering column. This

lever is in

NEUTRAL

when it is in a vertical position. When pulled backward from neutral the

transmission is in

REVERSE

gear. When pushed forward from neutral the transmission has been

shifted to

FORWARD

gear.

FOOT PEDALS

The

CLUTcH

pedal is located on the LEFT side of the directional lever. When pushed down

the transmission is disengaged from the engine. Always keep the clutch pedal depressed when

shifting either the range lever or the directional lever. DO NOT engage the clutch suddenly,

'I

thus allowing the Payloader to jerk with the load. Release the pressure on this pedal slowly '-'

allowing the clutch to engage gradually.

CAUTION: DO NOT ATTEMPT TO SHIFT GEARS WHILE THE PAYLOADER IS IN MOTION.

DO NOT DRIVE THE PAYLOADER WITH THE FOOT RESTING ON THE CLUTCH PEDAL. THIS WILL

CAUSE UNDUE WEAR ON THE CLUTCH FACINGS AND THROWOUT BEARING.

The

BRAKE PEDAL

Payloader to a STOP.

clutch engaged until

pressing the brake.

lye This allows the

ings.

is located on the right side of the range lever and is used to bring the

Depress the brake firmly when braking. It is good practice to keep the

the Payloader has been slowed down and nearly brought to a halt by de-

Then disengage the clutch and stop the motion of the Payloader complete-

engine compression to assist the brake and saves wear on the brake lin-

The

ACCELERATOR

pedal is located to the right of the brake pedal. Applying pressure on

this pedal increases the flow of fuel to the cylinders by opening the carburetor intake.

This increases the engine speed thus accelerating the motion of the Payloader. Apply a

slight increasing pressure on the accelerator pedal while slowly releasing pressure on the

clutch pedal. This allows the Payloader to start evenly, without jerking. The raising and

lowering speed of the booms and bucket is also governed by the accelerator.

DASH INSTRUMENTS

IGNITI~N

SWITCH.

controls the current to the dash instruments. It is also used in start-

ing and stopping the engine.

AMMETER

indicates whether the battery is being charged or discharged. The needle should

be in the "charge" range during operation. If in "discharge" range continuously, the cause

should be investigated to avoid completely discharging the battery.

TEMPERATURE GAGE

indicates the temperature of the liquid in the cooling system. The

gage should register in the Vicinity ~f 160

0

F. for normal operation. Temperature may

indicate as high as 200

0

F. when operating in confined quarters.

GIL PRESSURE GAGE

indicates the pounds pressure of the oil circulating through the en-

gine. If this gage fails to register, .stop the engine immediately and determine the cause.

S

CHOKE ROD

is used to enrich the fuel mixture. Pull the rod out to choke.

STARTER BUTTON

completes the electrical circuit between the battery and the starting

motor. Release the pressure on this button as soon as the engine starts. Do not run the

starting motor more than

t

minute at one time.

OPERATING THE HOIST

Since the engine also operates the hydraulic pump, the hoists may be used as soon as the

engine is started.

The travel of the booms and bucket is controlled by a hydraulic valve which regulates

the flow of oil to the rams. This valve has "RAISE", "HOLD", and "LOWER" positions and is

operated by a valve control lever located on the left side of the seat support plate.

The bucket is "RAISED" by moving the valve control lever backward, toward the operator's

seat. The booms and bucket will raise in proportion to the engine speed.

The "HOLD" is the neutral or centralized position of the valve control lever. The booms

and bucket may be stopped and held in any point of travel by placing the valve control lever

in the "HOLD" position.

The bucket is "LOWERED" by moving the valve control lever forward or away from the

operator's seat.

LOADING THE BUCKET

When loading the bucket the normal operation is to drive the Payloader forward with the

bucket down. (Low gear is the best average loading speed). As the bucket fills, it should

be raised gradually. This movement, combined with the forward motion of the Paylpader will

cause an action similiar to a "dipper" stick shovel.

o

The loading operation should be done on a level or slightly uphill grade if possible.

The inherent tendency is to "dig in" when working down slope. Also, backing up-hill

with a load is difficult due to increased weight on the drive wheels.

STARTING THE ENGINE

CAUTION: NEVER ATTEMPT TO START THE ENGINE WITHOUT OIL IN THE HYDRAULIC SYSTEM.

Before starting the engine, place the RANGE lever and the DIRECTIONAL lever in the

neutral positions; and the bucket CONTROL lever in the hold position. (See fig. 1

&

fig. 2

page 7).

Be sure the gasoline shut off cock is open. (See fig. 1 page 7).

Pullout the ignition switch on the left hand side of the dash and check the ammeter to

see that it registers. (Fig. 1 page 7).

Press the starter button located on the right side of the seat plate. The choke rod is

located on the left side. (Fig. 2 page 7). If necessary pull the choke rod out slightly

to start.

Immediately on starting the engine, check the oil pressure gage to be sure it is

registering. If not, stop the engine immediately by pushing in the ignition switch, and

inspect the oil system to learn the cause of oil pressure failure.

The oil pressure gage will register between 15

&

20 Ibs. at normal operating speeds.

STOPPING THE ENGINE

To stop the engine, merely push on the ignition switch button. Be sure all levers are

in neutral position before leaving the seat.

It is advisable to close the fuel line shut-off cock if the Pay~oader is to remain idle

for any length of time.

9

----- -- --_

TRANSPORTING LOADS

For transportation of loads under average conditions it is recommended that the cutting

edge of the bucket be held about four (4) feet off the ground. Do not transport loads with

the'bucket fully raised ..

If traveling on a side slope, it is advisable to transport loads with the bucket near

the gro~d as this will give better stability.

DUMPING THE BUCKET

To "dump the bucket", pull back sharply on the bucket trip lever, located on the right

hand boom. This action "Trips" or untatches the bucket hooks and allows the bucket to pivot

forward on the hinge pins, 'dumping the load.

LATCHING THE BUCKET

To "relatch" the bucket, lower the booms and bucket while the Pay-loaderis moving in a

reverse direction. As the cutting edge touches the floor or ground, the bucket will pivot on

the hinge pins and automatically relatch.

AVO I D

Ace IDE N T S

Most aCCidents, whether they occur in industry, on

the farm, at home, or on the highway, are caused by

the failure of some individual to follow simple and

fundamental safety rules or precautions. For this

reason most accidents can be prevented by recognizing

the real cause and doing something about it before the

accident occurs.

Regardless of the care used in the design and con-

struction of any type of equipment, there are many con-

ditions that can not be completely safe guarded against

without interfering with reasonable accessibility and

efficient operation.

A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST AN

ACCIDENT.

THE COMPLETE OBSERVANCE OF ONE SIMPLE RULE WOULD PREVENT

MANY THOUSAND SERIOUS INJURIES EACH YEAR. THAT RULE IS:

"'ever attempt to clean. otl

or

adjust

a

machtne whtle tt

ts

tn motion!"

"National Safety Council"

10

ROUTINE SERVICE AND INSPECTION

The operating life of the Payloader may be considerably extended and fewer shut downs

will be experienced if the unit is properly serviced at regular intervals. Often major

repairs or shut downs can be avoided if the Payloader is inspected regularly and trouble

corrected while it is of a mirtornature.

The following outline gives points which should be lubricated and checked at each

inspection period.

For all lubrication points refer to Lubrication Chart and Lubrication Instruction on

pages 73-72-71.

TEN

(10)

HOUR SERVICE

Lubricate

Steering Axle Bell Crank

Tie Rod Ends

King Pins

Spindles

Drag Link

Radius 'Rod Pivots

Clutch Release Bearing

Valve Control Lever

Brake Pedal

Clutch Pedal

Gear Shift Levers

Boom Pivots

Guide Pivots

Ram Pivots

Latch Shaft

Latch Hooks

Check

Battery

Connections

Hydraulic Hoses

Clutch Pedal Play

Crank Case Oil Level

Cooling System Content

Air Cleaner

SIXTY (60) HOUR SERVICE

Brake

&

Clutch Pedal Play

Grease Hydraulic Pump

Check Hydraulic Oil

Flush Cooling System

Check Water Pump

Check Oil Level in Master Brake

Cylinder

Gasoline Line Filter

Tighten Nuts

&

Capscrews

Clean

&

Refill Engine Air Filter Cup

Fill Distributor Grease Cup

Clean Transmission Breather

Clean Crank Case Breather

Change Crank Case Oil

Lubricate Universal Joints

Check and Clean Hydraulic

Suction Line Strainer Drain

&

Refill Hydraulic System

Check

&

Grease Steering Gear

TWO HUNDRED

(200)

HOUR SERVICE

FOUR HUNDRED

(~OO)

HOUR SERVICE

Repack Wheels

Flush Hydraulic System

Change Transmission Oil

Change Final Drive Oil

Check Distributor

Check Wiring Connections

When operating in wet or muddy conditions be sure all connections are tight. Do not

allow moisture to enter the hydraulic system.

Never, under any circumstances, pour cold water into a hot engine. To do so may result

in cracking the cylinder head or the cylinder block.

COLD WEATHER OPERATIONS

"

When operating the pay'loaderin temperatures of 32 F. (0 C.) or lower, there is,danger

of the water freezing in the cooling system. To prevent this, use one of the anti-freeze

solutions shown on chart page 12.

11

ANTI-FREEZE SOLUTIONS

Distilled Glycerine Ethylene Glycol

Percent

by Freezing Point Specific Freezing Point Specific

Volume OoC 32

0

FGravity OoC 32

0

FGravity

0% 032 1.000 032 1.000

10% -2 29 1.029 -3 26 1.016

20% -6 21 1.057 -9 16 1.031

30% -11 12 1.085 -16 31.045

40% -18 01.112 -24 -11 1.058

50% -26 -15 1.140 -35 -31 1.D70

IMPORTANT:

Do not use alcohol as an anti-freeze as it will boil away at average temperatures.

Do not use a calcium chloride solution or any alkaline solution as they are in-

jurious to metal.

Before filling radiator in freezing weather, cover entire radiator, start engine

and put in the water immediately. This prevents the water from freezing during

the warm up period.

12

MAINTENANCE SECTION

HYDRAULIC HOIST SYSTEM

(See Page 56 or Page 54)

The hydraulic system consists of an oil reservoir, a Vickers vane type pump, a control

valve, two rams and the connecting hoses.

The pump draws oil from the reservoir thru the suction line, and forces it thru the

high pressure line into the control valve, which is manually regulated by the operator.

In "raise" position the oil is directed into the rams; in "hold" position the oil passes

thru the valve to the reservoir; in "lower" position the valve permits the rams to telescope,

so that oil from the rams flows back to the reservoir along with the oil coming from the

pump.

The pump is protected, by a pressure relief, agai~st severe overloads.

CARE OF HYDRAULIC SYSTEM

1. Check the oil level in the reservoir every ten (10) hours of operation. The level

should be to the "full" mark on the bayonet gauge or approximately 3 inches from the

top of the reservoir. The bucket should be resting on the ground when the oil level

is checked.

2. Check all hoses and connections for leaks every ten (10) hours of operation.

3. Change hydraulic oil after every two hundred (200) hours of operation.

4. A "high" reservoir oil level will result in fouled spark plugs and oil in the air pre-

cleaner bowl.

To change oil procede as follows.

~ DRAINING THE SYSTEM

ALWAYS DRAIN THE SYSTEM AFTER LOADER OPERATION, WHILE THE OIL IS STILL WARM.

1. Remove cleanout cover and filler plug from top of Reservoir.

2. Place a container large enough to hold 7 or 8 gallons directly under the drain plug

on the bottom of the reservoir and remove the drain plug.

3. Break the hose connection at the "tee" in the line between the rams to drain the high

pressure line.

4. Break the suction line hose connection at the reservoir to drain the low pressure line.

5. When the oil has drained reach into the reservoir and remove the suction line strainer

and wash in clean gasoline ~eing sure to remove all particles of dirt. A dirty strainer

will retard the oil flow and cause the pump to "howl".

6. Clean out all dirt and sludge which has collected on the bottom of the reservoir.

7. The drain plug is a magnetic type and must be cleaned thoroughly before replaclllg.

8. Flush the system every four hundred (400) hours of operation. To flush the system re-

fill the reservoir with 3 gals. of kerosene mixed with 2 gals. of lubricating oil. Run

the pump for approximately five minutes raising and lowering the bucket at an acceler-

ated speed during this period. Then shut off the engine and drain as before being sure

to disconnect the hoses.

13

9. Clean off all parts of the system, paying special attention to all connection points.

Connect all hoses, replace drain plug and hand hole cover. Refill with best grade of

SAE 10 oil.

Capacity of the hydraulic system is 6 gals approx. to the "full" mark on the

bayonet gauge, approximately 3" from the top of the reservoir.

10. After any work has been done on the hydraulic system or after changing oil, the system

must be "bled" or purged of air. This must be done before the loader is again put into

operation.

"BLEEDING" THE SYSTIM

Air in the hydraulic system will cause difficulty in controling the action of the

bucket. The booms and bucket will raise and lower with a series of jerks and the rams may

chatter. To enable the bucket to act smoothly procede as follows.

1.

Raise the booms and bucket to full height and hold them in this position.

2. Loosen the screw or plug in the upper end of the ram until air begins to escape. Moving

the valve control lever alternately between raise and hold positions will cause the air

to escape faster. Note that as the air is removed the bucket tends to lower itself thus

forcing out air by the weight of the bucket. This must be done on each ram.

3. As soon as air bubbles cease, tighten the bleeder plug securely. Raising the bucket

with the bleeder plug opened may cause more air to be drawn into the system.

4. Clean the rams of escaped oil.

HYDRAULiC RAMS

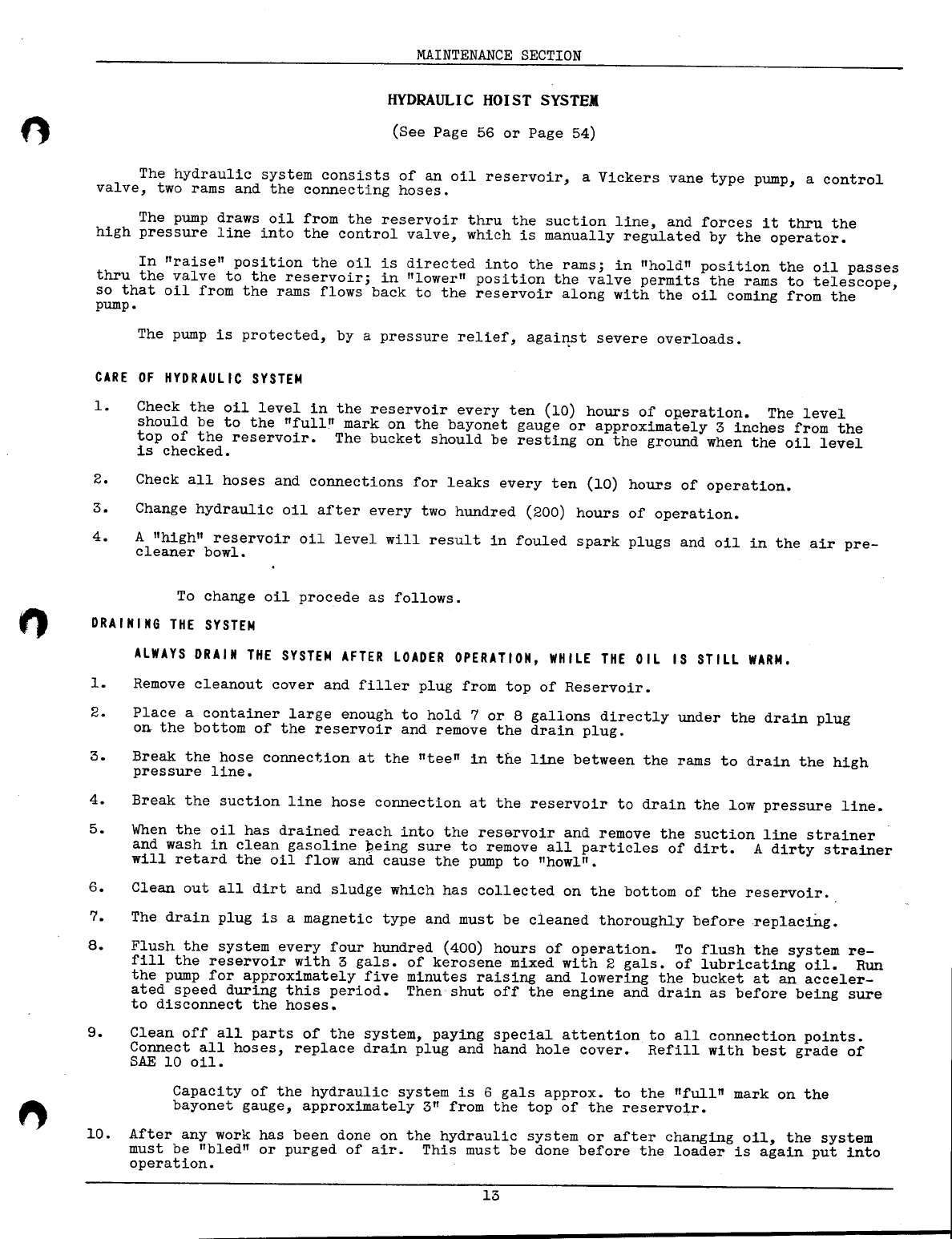

For Ram Assembly on Payloaders of serial number 8003 to 8047 see fig. 3.

For Ram Assembly on Payloaders of serial number 8048 and up see fig. 4.

The hydraulic rams are so constructed that no adjustments are necessary other than to

tighten the packing if oil tends to escape. If the packing becomes overly tight, it may

seize the rams and prevent the bucket from being lowered. If this occurs loosen the packing

gland slightly.

If unable to tighten the packing securely because it has become worn the packing must be

replaced. To replace packing procede as outlined.

1. Drain the hydraulic system.

2. Disconnect hose at ram connection and remove elbow

&

nipple from the ram plunger.

3. Remove ram from the Payloader and place in a vertical position with the stuffing box up.

4. Remove packing cap and take out old packing and wiper ring. Pay special attention to

the order in which old packing was arranged.

5. Be sure to clean out packing recess thoroughly.

6. The packing cap on Payloaders of serial number 8003 thru 8047 contains a seal which must

be replaced with a new seal before reassembling.

Fig. 3

RAJ(

ASS'Y ON

PAYLOADERS

of Sedal Nos.

8003

to

8047

Fig. 4

RAJ(

ASS'Y ON

PAYLOADERS

of Serial Nos.

8048

&:

up

14

o

7. The leather rings and the seal of the replacement packing should be soaked in oil before

inserting in the ram. Do not soak the Neoprene rings.

8.

Insert the new packing rings in the same order and position in which the old packing had

been removed. Make sure each lip is worked down smoothly, an ice pick or similar tool

may be used for this purpose. Do not use cut or distorted rings.

9. With'the new packing inserted properly, there should be 1/16" to 3/32" compression when

the packing cap is tightened.

10. Pull the packing cap down tightly. There is no other adjustment necessary other than

retightening the packing cap after the packing rings become worn.

CONTROLVALVE

The function of the control valve is to control the .direction of oil flow to raise and

lower the bucket and to enable the operator to stop and hold the bucket at any point of

travel.

This paragraph pertains to valves used on Payloader of Serial numbers 8003 thru 8047.

It is imperative that the operator and mechanic know the position of the poppets if the

system fails to operate due to the valve.

With the valve control lever in "RAISE" position the poppets in both valve chambers must

seat solidly. See fig. 5.

In observing fig. 5 note the high pressure poppet is open due to pressure from the pump

and is free of the cam shaft.

Fig. 5

POPPETS IN "RAISE" POSITION Fig. 6

POPPETS IN "HOLD" POSITION

~I

Fig. 7

POPPETS IN "LOWER" POSITION

If the poppets do not seat solidly, remove them from the.valve body and grind just

enough stOC$ from the lower ends of the poppets so they will not rest on the cam shaft with

the valve in "Raise" position. The poppets, both inner and outer, must then be "Lapped" in

with regular automotive valve grinding compound, in order to provide a good seat.

NOTE: IF THE ABOVE PROCEDURE IS NECESSARY, WASH AND CLEAN VALVE THOROUGHLY BEFORE OPERATING

HYDRAULIC SYSTEM.

With the Valve Control Lever in "Hold" position the high pressure poppet should be

closed and the low.pressure poppet should be open. (See fig. 6).

With the Valve Control Lever in "Lower" position, both the high and low pressure poppets

should be open. (See fig. 7).

15

HYDRAULIC CONTROL VALVE

(Payloader Serial Nos. 8048

&

up)

The type valve used on these machines

is a "Hydreco spool valve". (See fig. 8).

There are no adjustments to be made

on this valve. It is advisable to remove

valve from Payloader, disassemble, wash

and clean thoroughly every 400 hours of

operation. Use parts drawing on page 61

to identify and locate the various parts

of this unit.

Fig. 8

VALVE ASS'Y PAYLOADERS

of Serial Numbers

8048

&

up

HYDRAULI C PUMP

This pump is a "Vickers" Rotary vane type, assembled for left hand operation, and has no

volume adjustment.

An

arrow stamped on the body indicates direction of rotation. The pump

must be lubricated every sixty (60) hours of operation with a high temperature sodium soap

type grease. There is a grease fitting provided for this on the upper side of the pump

body. (See page 58).

Shaft packing of the pump is not subject to pressure and normally does not require

replacement.

Vanes, being subject to centrifugal force and fluid pressure, automatically compensate

for.any normal year.

DISMANTLING AND. REASSEMBLING PUMP

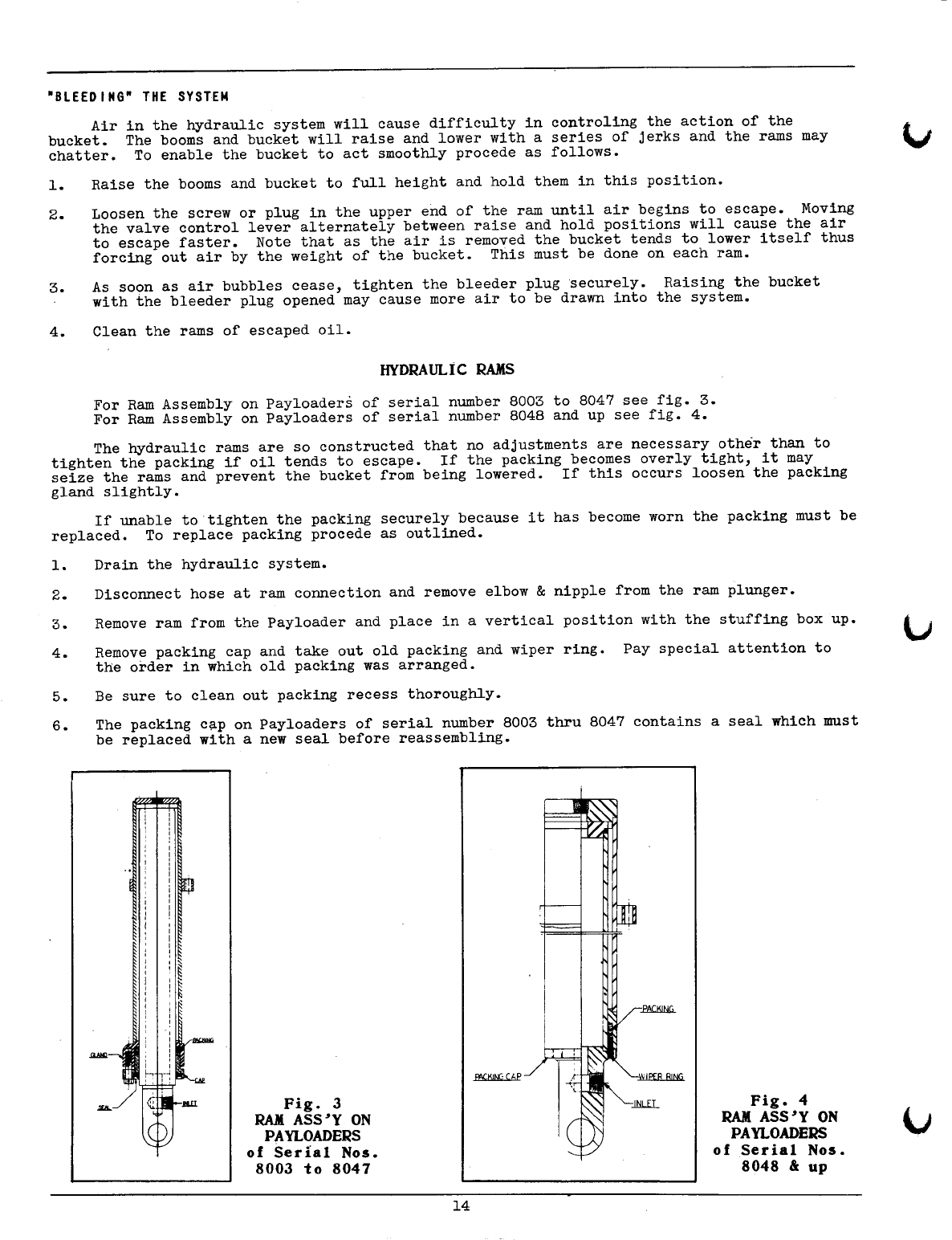

Inspection of the pumping

cartridge parts in the vane type

single pump can be made as

follows:

The pumping cartridge consist of

a rotor "E", vanes "F" valve plate

bushings "D" and "H", and cam ring

"G". All moving parts, except shaft

and shaft bearings, operate within

this cartridge assembly. No moving

parts therefore are in contact with

the body "T".

Remove the.head screws "A" and

the head "B". The head end valve

plate bushing "D" can then be pulled

out, leaving exposed the rotor "E",

vanes "F" and the cam ring "G".

,..--------T-BO DY

• fiTTING

>:":"\"r-~----v-SCREW

H-BUSHING

~~~~H!~iE~iiiiiiiif~-KEY

Q-BEARING

A-SCREW

C -PACKING

B- HEAD- __

..J

- PIN

Fig. 9

PUMP ASSEMBLY - SIDE VIEW

Be parti~ularly careful to note the position of the rotor and vanes, also the position

of the ring pin "P". These parts may all be reassembled incorrectly if not carefully

checked, because of the fact that provision is made in the design for either right-hand or

left-hand assembly. The position of cam ring "G" should also be noted carefully.

These parts can all be removed for inspection, and the shaft-end valve plate bushing

"H" will then be exposed. It too can be removed by a hook-shaped tool. Parts that show

damage or excess wear should be replaced. The vanes can be turned end-for-end so that the

inside edge is now against·the cam ring-----thus renewing the vanes for future service.

Worn edges must be stoned so vanes move freely in rotor slots and beveled edges must trail

direction of rotation.

Reassemble in reverse order with parts replaced in original pOSitions, using parts

drawing as a supplementary guide. Renew head ring packing

"c"

if it has become compressed

or damaged, otherwise air will be drawn in when the pump is running or oil will leak out

when not running. Assemble the pump head so that ring hole registers with protruding part

of ring pin "P".

16

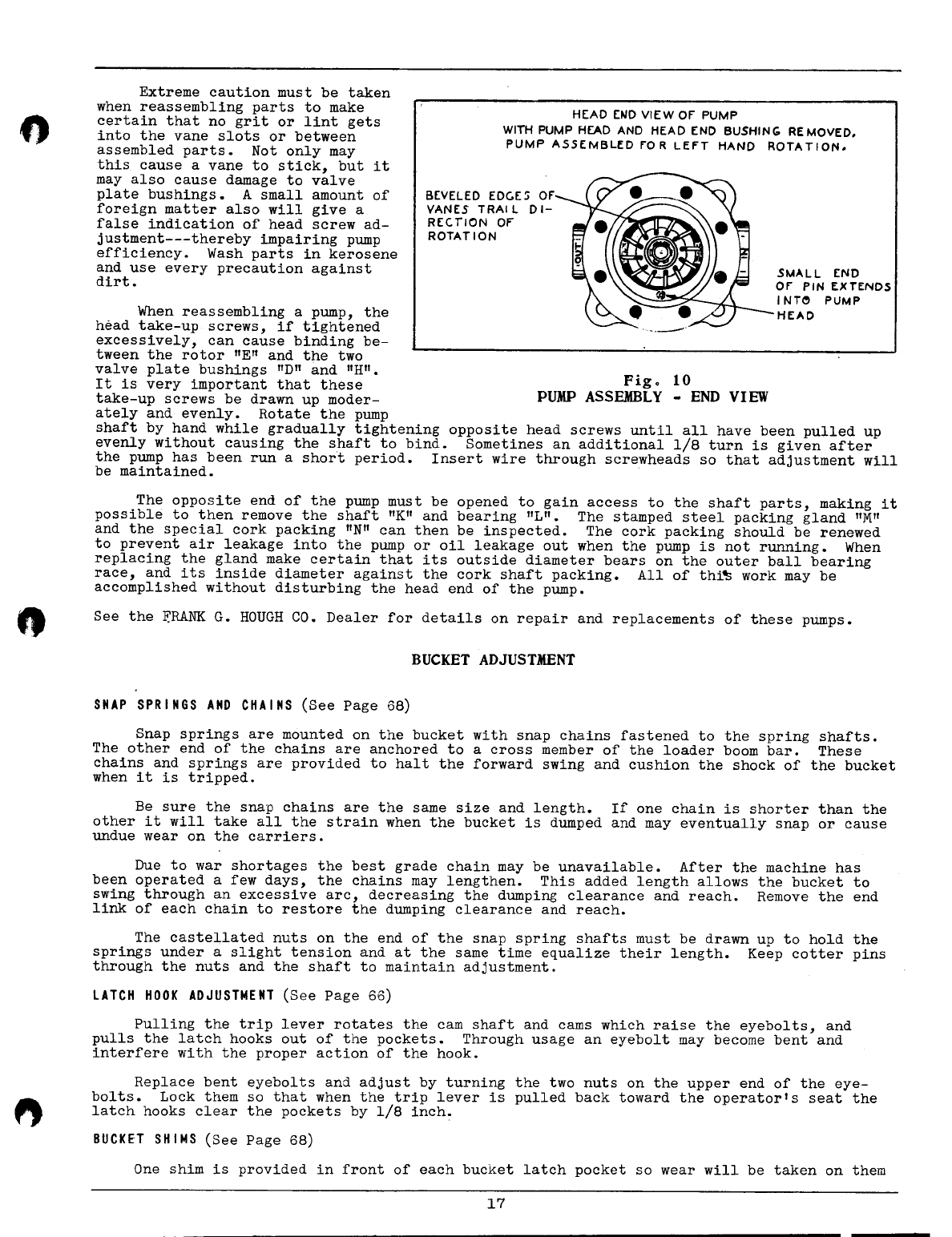

When reassembling a pump, the

head take-up screws, if tightened

excessively, can cause binding be-

tween the rotor "E" and the two

valve plate bushings "D" and "H".

It is very important that these

take-up screws be drawn up moder-

ately and evenly. Rotate the pump

shaft by hand while gradually tightening opposite head screws until all have been pulled up

evenly without causing the shaft to bind. Sometines an additional 1/8 turn is given after

the pump has been run a short period. Insert wire through screwheads so that adjustment will

be maintained.

Extreme caution must be taken

when reassembling parts to make

certain that no grit or lint gets

into the vane slots or between

assembled parts. Not only may

this cause a vane to stick, but it

may also cause damage to valve

plate bushings. A small amount of

foreign matter also will give a

false indication of head screw ad-

justment---thereby impairing pump

efficiency. Wash parts in kerosene

and use every precaution against

dirt.

HEAD E~D VIEW OF PUMP

WITH PUMP Hf:AD AND HEAD END BUSHING REMOVED.

PUMP ASSEMBLED FOR LEFT HAND ROTATION.

BEVELED EDC.E~ OF

YANES TRAI L DI-

RECTION OF

ROTATION

SMALL END

OF PIN EXTENDS

INT~

PUMP

HEAD

Fig

0

10

PUMP ASSEMBLY - END VIEW

The opposite end of the pump must be opened to gain access to the shaft parts, making it

possible to then remove the shaft "K" and bearing "L". The stamped steel packing gland "M"

and the special cork packing "N" can then be inspected. The cork packing should be renewed

to prevent air leakage into the pump or oil leakage out when the pump is not running. When

replacing the gland make certain that its outside diameter bears on the outer ball bearing

race, and its inside diameter against the cork shaft packing. All of thi~ work may be

accomplished without disturbing the head end of the pump.

See the

ERANK

G. HOUGH CO. Dealer for details on repair and replacements of these pumps.

SNAP SPRINGS AND CHAINS

(See Page 68)

BUCKET ADJUSTMENT

Snap springs are mounted on the bucket with snap chains fastened to the spring shafts.

The other end of the chains are anchored to a cross member of the loader boom bar. These

chains and springs are provided to halt the forward swing and cushion the shock of the bucket

when it is tripped.

Be sure the snap chains are the same size and length. If one chain is shorter than the

other it will take all the strain when the bucket is dumped and may eventually snap or cause

undue wear on the carriers.

Due to war shortages the best grade chain may be unavailable. After the machine has

been operated a few days, the chains may lengthen. This added length allows the bucket to

swing through an excessive arc, decreaSing the dumping clearance and reach. Remove the end

link of each chain to restore the dumping clearance and reach.

The castellated nuts on the end of the snap spring shafts must be drawn up to hold the

springs under a slight tension and at the same time equalize their length. Keep cotter pins

through the nuts and the shaft to maintain adjustment.

LATCH HOOK ADJUSTMENT

(See Page 66)

Pulling the trip lever rotates the cam shaft and cams which raise the eyebolts, and

pulls the latch hooks out of the pockets. Through usage an eyebolt may become bent and

interfere with the proper action of the hook.

Replace bent eyebolts and adjust by turning the two nuts on the upper end of the eye-

bolts. Lock them so that when the trip lever is pulled back toward the operator's seat the

latch hooks clear the pockets by 1/8 inch.

BUCKET SHIMS

(See Page 68)

One shim is provided in front of each bucket latch pocket so wear will be taken on them

17

and not on the pockets. When the upper edges of the shims become worn they should be in-

verted or turned end for end, thus keeping a square edge in contact with the latch hook. If

this is not done the bucket will not latch properly.

ENCiINE

See CONDENSED Specifications

&

Service Data page 4.

Payloaders, serial no's 8003 thru 8047 have a Waukesha FC157C engine equipped with

Magneto ignition system. See page 27.

Payloaders, serial no's 8048

&

up have a Waukesha FC157D engine equipped with

Distributo~ ignition system. See page 30.

A Waukesha FC engine Parts and Instruction manual is inserted in the envelope located on

the·inside rear cover of this manual.

FUEL SYSTEM:

The fuel system of this Payloader is a gravity feed type with the fuel strainer located

on the left side of the engine.

A fuel pump may be 'used on the Payloader which must be a special A-C Spark Plug fuel

pump #1538791 and can only be serviced by the FRANK G. HOUGH CO. Dealers or any United Motors

service station.

FAN BELT

REMOVING

&

REPLACING

1. Shut off engine and lower bucket to the floor.

2. Remove hood sides from Payloader.

3. Remove hose clip which attaches to governor on the left hand side of the engine.

4. Remove inspection cover from rear grille casting.

5. Remove the 6 capscrews holding pump drive flange to engine fan belt pulley.

o.

Remove four bolts which hold pump to pump mounting bracket.

7. Pull the pump out toward rear of machine as far as it will go.

8. Loosen the generator bracket adjusting nut and push generator in toward the engine and

tighten nut.

9. Remove fan belt from generator pulley and lower fan belt pulley; then slip belt over the

fan to remove from the machine.

NOTE: THE ABOVE OPERATION MAY BE DONE WITHOUT REMOVING THE RADIATOR GRILLE CASTING.

ADJUSTING FAN BELT

Install the new fan belt by reversing the procedure above. With the fan belt on all

three pulleys reset the generator so that the belt can be pushed inward approximately 3/4" to

1". This is the proper tension of the belt when the generator bolts have been tightened.

18

Table of contents