2) Make sure you alternate starting with a Small Hog Leg®

Extension (2-3/8” OD) or a Large Hog Leg® Extension

(2-7/8” OD) at every other brace. This will keep the amount of

Extensions used equal, maximizing the amount of braces you

will get from each Hog Leg® Wall Brace Kit.

3) Continue adding Hog Leg® Extensions as shown in Detail B

until the desired length is obtained. To locate where to pour

the deadman for the base of the Hog Leg®, take the height

of the brace installation and multiply by 0.75. Example:

Brace Height of 16 feet x 0.75 = Brace Run of 12 feet from

the wall.

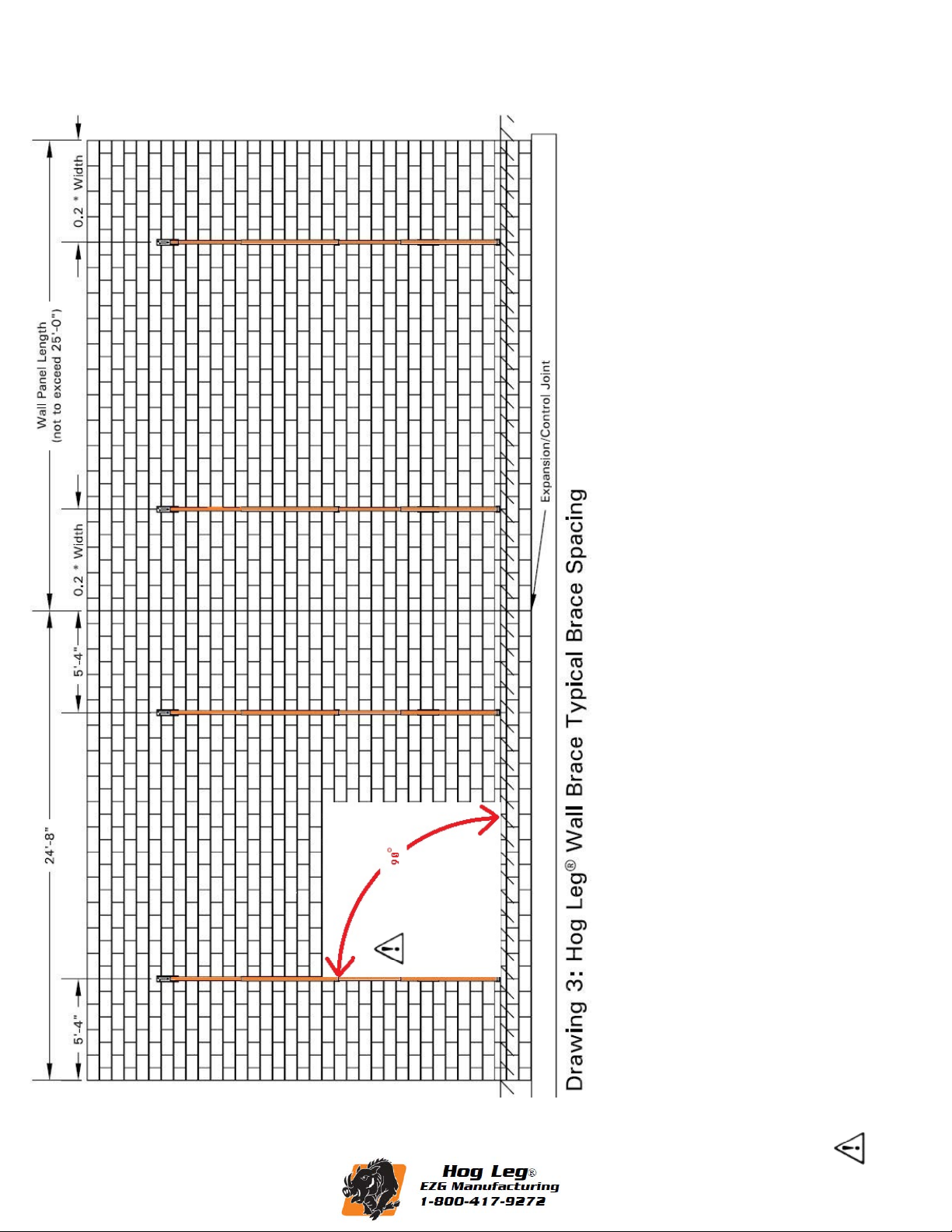

CAUTION: Keep installation as close to the design

guidelines shown in this manual as possible. If the brace

is installed at a steeper angle or beyond 90° perpendicular

to the wall, the holding power of the brace will be

reduced.

4) Secure the Floor Bracket with anchors that meet all

applicable standards and regulations as shown in Detail C.

Kicker Installation: For extreme wind speeds (greater th 40

MPH) or requirements that exceed Standard Practice for

Bracing Masonry Walls Under Construction a kicker is

required , on brace lengths 22’-11” or longer. For Brace

Lengths longer than 26’-3” a Kicker is required for all

circumstances. For extreme wind speeds (greater than 40

MPH) or requirements that exceed Standard Practice for

Bracing Masonry Walls Under Construction a Kicker and

Guide Wires are required, on brace lengths 26’-3”. For Brace

Lengths longer than 30’-5” a Kicker and Guide Wires are

required for all circumstances. The Kicker should be installed

at the midpoint of the Hog Leg® Wall Brace. The Kicker

then extends downward at a 90° angle from the Hog Leg®

Wall Brace and mounts to the wall. To determine wall height

to install kicker, refer to page 10 of this manual. For Guide

Wire installation, refer to page 11 of this manual.

1) Install the Kicker Adjustment Pipe to the Hog Leg® by

inserting the Hitch Pin through the Hog Leg® Extension

and insert Safety Clip as shown in Detail D.

2) Add Hog Leg® Extensions as required to reach the

Wall Bracket.

Removal of Hog Leg® Bracing

To comply with Standard Practice for Bracing Masonry

Walls Under Construction, the Hog Leg® Bracing System

must not be removed until the wall is permanently supported.

You may refer to this standard in Chapter 3 Section 3.5 of

the Standard Practice for Bracing Masonry Walls Under

Construction manual.

WARNING!

!

Warning: Minimum of 10” of overlap required

on Hog Leg® Extension connection.

Falling Walls, Braces, or

Components can cause

severe injury or death

Moving or relieving this brace may

cause serious injury or death. Consult

the Structural Engineer before

attempting to remove or relieve this

brace or any component. Do not

remove brace until all structural

connections are in place. Refer to

Standard Practice for Bracing

Masonry Walls Under Construction.

DANGER!

!

©Copyright 2014

www.ezgmfg.com