User Information Load-bearing tower Staxo 100 Introduction

5999804302 - 02/2018

Rules applying during all phases of

the assignment

▪ The customer must ensure that this product is

erected and dismantled, reset and generally used for

its intended purpose in accordance with the applica-

ble laws, standards and rules, under the direction

and supervision of suitably skilled persons.

These persons' mental and physical capacity must

not in any way be impaired by alcohol, medicines or

drugs.

▪ Doka products are technical working appliances

which are intended for industrial / commercial use

only, always in accordance with the respective Doka

User Information booklets or other technical docu-

mentation authored by Doka.

▪ The stability and load-bearing capacity of all compo-

nents and units must be ensured during all phases of

the construction work!

▪ Do not step on or apply strain to cantilevers, clo-

sures, etc. until suitable measures to ensure their

stability have been correctly implemented (e.g. by

tie-backs).

▪ Strict attention to and compliance with the functional

instructions, safety instructions and load specifica-

tions are required. Non-compliance can cause acci-

dents and severe injury (risk of fatality) and consid-

erable damage to property.

▪ Sources of fire in the vicinity of the formwork are pro-

hibited. Heating appliances are only allowed if prop-

erly and expertly used, and set up a safe distance

away from the formwork.

▪ The customer must consider all types of weather

conditions on equipment and in connection with the

use or storage of the equipment (e.g. slippery sur-

faces, risk of slippage, effects of wind, etc.) and must

take steps in good time to safeguard the equipment

and the surrounding areas and to protect the work-

ers.

▪ All connections must be checked at regular intervals

to ensure that they are secure and in full working

order.

In particular threaded connections and wedged con-

nections have to be checked and retightened as nec-

essary in accordance with activity on the jobsite and

especially after out-of-the-ordinary occurrences (e.g.

after a storm).

▪ It is strictly forbidden to weld Doka products – in par-

ticular anchoring/tying components, suspension

components, connector components and castings

etc. – or otherwise subject them to heating.

Welding causes serious change in the microstruc-

ture of the materials from which these components

are made. This leads to a dramatic drop in the failure

load, representing a very great risk to safety.

It is permissible to cut tie rods to length with metal

cutting discs (introduction of heat at the end of the

rod only), but it is important to ensure that flying

sparks do not heat and thus damage other tie rods.

The only articles which are allowed to be welded are

those for which the Doka literature expressly points

out that welding is permitted.

Assembly

▪ The equipment/system must be inspected by the

customer before use, to ensure that it is in suitable

condition. Steps must be taken to rule out the use of

any components that are damaged, deformed, or

weakened due to wear, corrosion or rot.

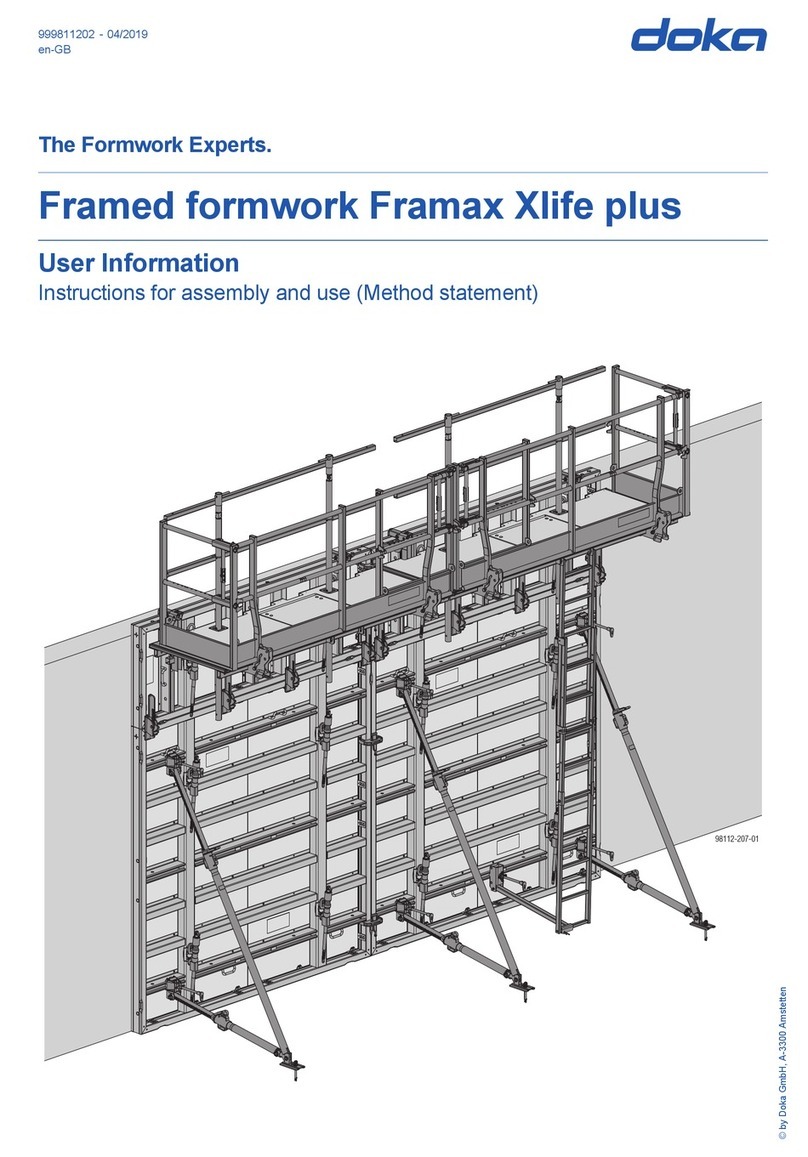

▪ Combining our formwork systems with those of other

manufacturers could be dangerous, risking damage

to both health and property. If you intend to combine

different systems, please contact Doka for advice

first.

▪ The equipment/system must be assembled and

erected in accordance with the applicable laws,

Standards and rules by suitably skilled personnel of

the customer's, having regard to any and all required

safety inspections.

▪ It is not permitted to modify Doka products; any such

modifications constitute a safety risk.

Closing the formwork

▪ Doka products and systems must be set up so that

all loads acting upon them are safely transferred!

Pouring

▪ Do not exceed the permitted fresh-concrete pres-

sures. Over-high pouring rates overload the form-

work, cause greater deflection and risk breakage.

Stripping out the formwork

▪ Do not strip out the formwork until the concrete has

reached sufficient strength and the person in charge

has given the order for the formwork to be stripped

out!

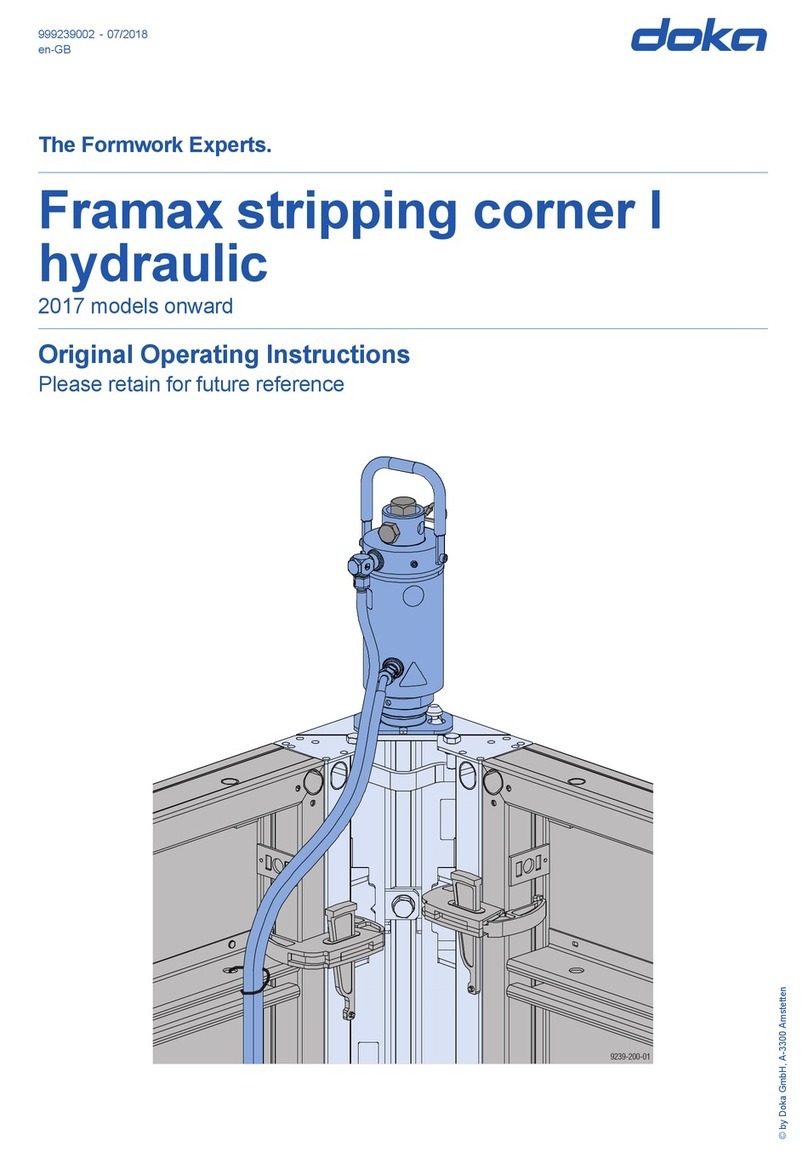

▪ When stripping out the formwork, never use the

crane to break concrete cohesion. Use suitable tools

such as timber wedges, special pry-bars or system

features such as Framax stripping corners.

▪ When stripping out the formwork, do not endanger

the stability of any part of the structure, or of any

scaffolding, platforms or formwork that is still in

place!