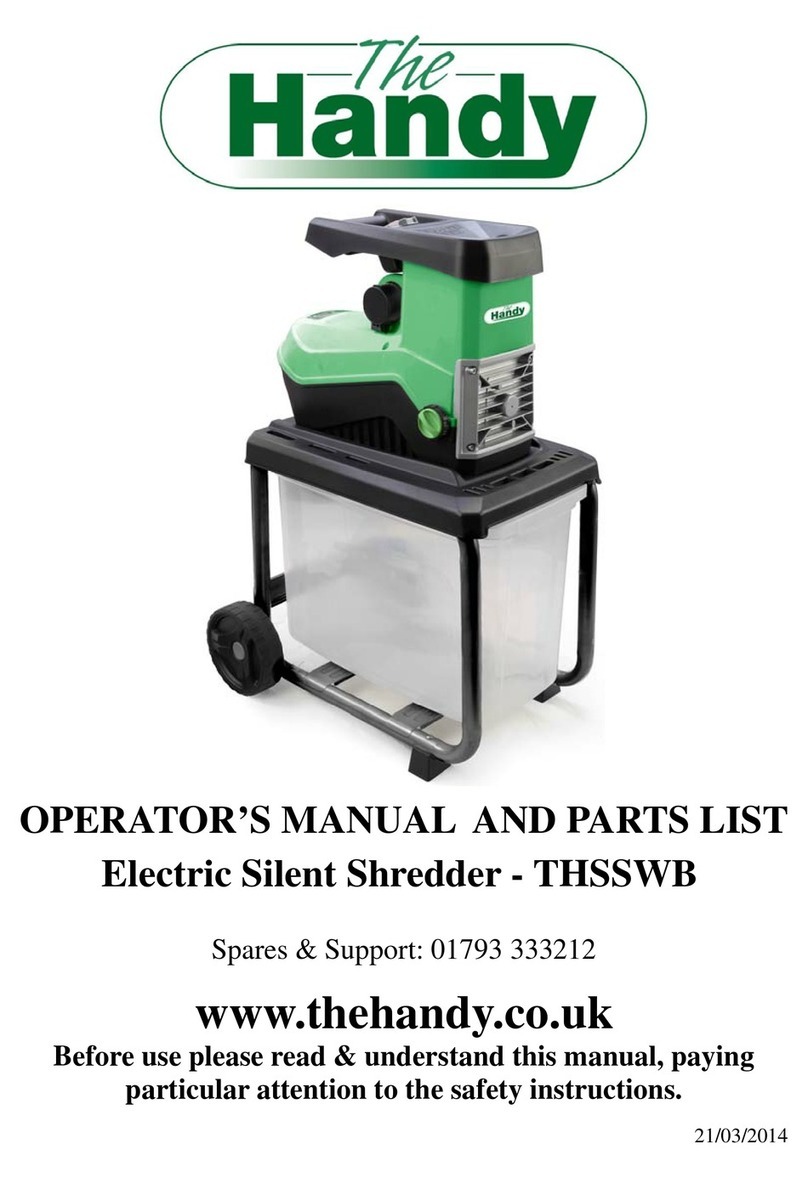

The Handy THISWB User manual

THISWB - 193895001

07/03/2016

INSTRUCTION

MANUAL

2500 WATT ELECTRIC IMPACT SHREDDER

WITH COLLECTOR & HOPPER

SPARES & SUPPORT: 01793 333212

Please read & understand this manual, payingparticular attention to the safety instructions, before

use.

The manufacturer reserves the right to change the product specification and livery according to

continued product improvements.

CONTENTS

SPECIFICATIONS

IMPORTANT INFORMATION

GENERAL SAFETY INSTRUCTIONS

THE MACHINE

ASSEMBLY

OPERATION

CLEANING

MAINTENANCE

STORAGE & TRANSPORT

TROUBLE SHOOTING

NOTES

PARTS DIAGRAM & LIST

WARRANTY

EC DECLARATION OF CONFORMITY

Assembly Is Required

This product requires assembly before use. See the “Assembly” section for instructions.

Please check that all parts required for the assembly of this spreader are included. If for any

reason you believe a part for the assembly is missing or damaged, please contact us.

If you require any assistance with regards to the contents or operation of

your machine, please contact us:

TEL: 01793 333212

(MON –FRI 8.00AM TO 5.30PM EXCL. BANK HOLIDAYS)

SPECIFICATIONS

The manufacturer reserves the right to change the product specification and livery according to

continued product improvements.

Model Number

THISWB

Product Number

193895001

Voltage

230-240V~, 50Hz

Rated Power (Watt)

2500

Idle Speed (rpm)

4500

Maximum Branch Diameter (mm)

45

Collector Capacity (Litre)

40

Cable (m)

3

Degree of Protection

IP24

Protection Class

II

Overall Size (mm)

(L) 460

(W) 360 front - 455 rear with wheels

(H) 1050 –1230 with Hopper

Weight (kg)

G.W 14.5 - N.W 13.8

* The diameter of the branch is not the only factor that determines how easy it will be to shred. A

small branch can be difficult to shred when it has knots or is a particularly hard wood.

IMPORTANT INFORMATION

INTENDED USE

The device is intended for chopping up fibrous or woody organic material from household and

garden. It may not be filled with stones, glass, metal, bones, plastics or material scraps.

This product is not intended for commercial use. Generally acknowledged accident prevention

regulations and enclosed safety instructions must be observed.

Only perform work described in these instructions for use. Any other use is incorrect. The

manufacturer will not assume responsibility for damage resulting from such use.

ELECTRICAL REQUIREMENTS

Connect the main leads to a standard 230V+10% (50Hz+1Hz) electrical supply which has protection

devices for under-voltage, over-voltage, over-current as well as a residual current device (RCD) with

maximum residual current rated at 0.03A.

EXTENSIONS LEADS

Improper use of extension leads may cause inefficient operation of the log splitter which can result

in overheating. Be sure the extension lead is no longer than 10m and its cross-section is no less than

2.5mm² to allow sufficient current flow to the motor. Avoid use of loose or inadequately insulated

connections. Connections must be made with a protected material suitable for outdoor use.

WORKING CONDITIONS

This log splitter is a domestic use model. It is designed for operating under ambient temperatures

between +5°C and 40°C and for installation at altitudes no more than 1000m above M.S.L. The

surrounding humidity should be less than 50% at 40°C. It can be stored or transported under

ambient temperatures between -25°C and 55°C.

INSPECT YOUR BRANCH

Make sure there are no nails or foreign objects in branches to be shred.

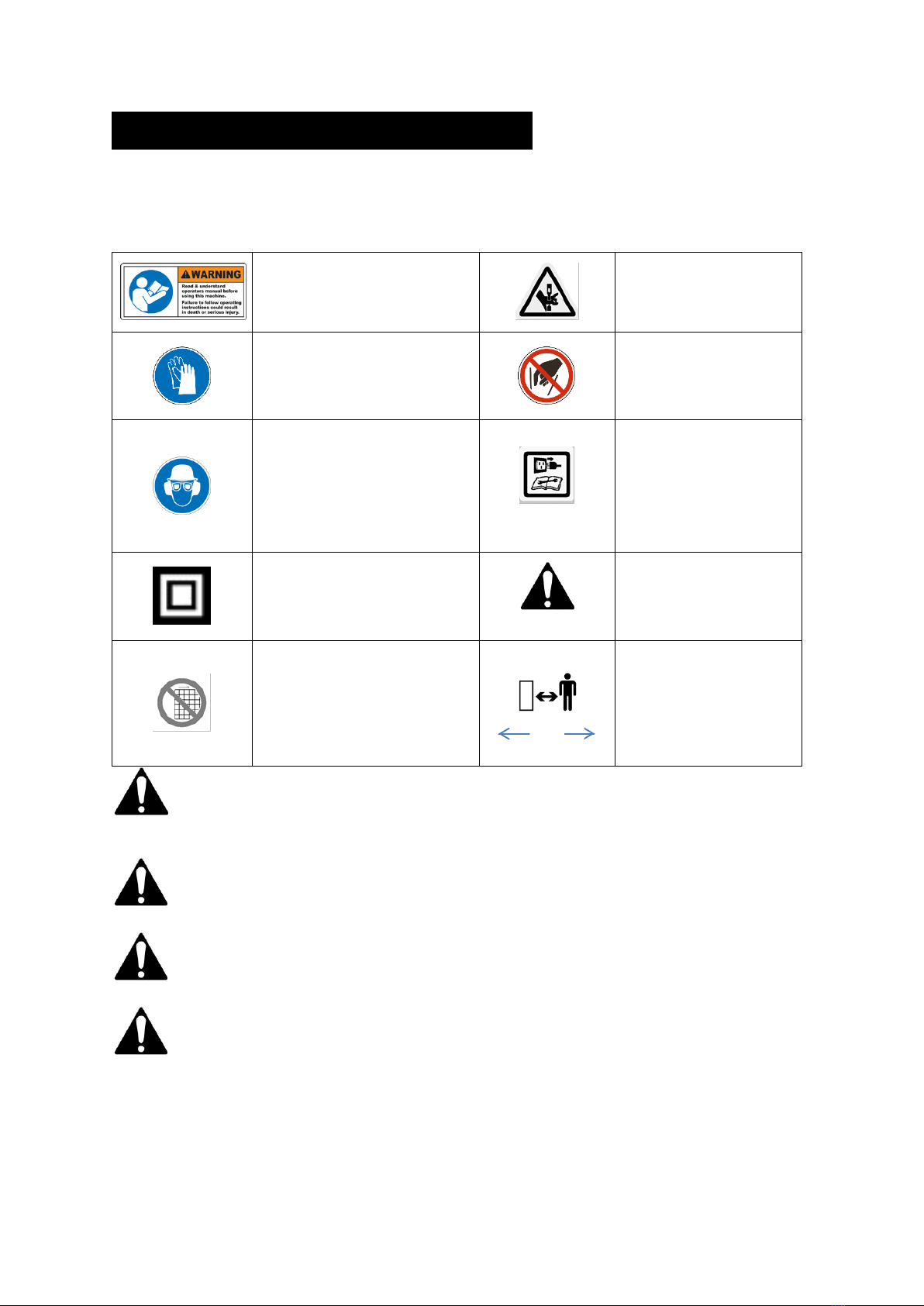

GENERAL SAFETY INSTRUCTIONS

It is important that you read and understand the owner’s manual and labels affixed to the

machine. Learn its application and limitations as well as the specific potential hazards. Retain

these instructions for future reference. The operator is responsible for following the warnings &

instructions in this manual and on the product.

Read & understand operator’s manual

before using the machine. Failure to

follow instructions could result in death

or serious injury.

Risk of Slicing.

Keep hands out of the way of all

moving parts.

Wear gloves to protect your hands

DO NOT REACH INTO THE

HOPPER

Whenever the machine is in use, safety

glasses must be worn to safeguard

against flying objects.

Hearing protection must also be used to

protect the operators hearing.

If the operator is working in an area

where there is a risk of falling objects, a

safety helmet must also be worn.

Unplug when not in use, before

making adjustments, changing

parts, cleaning, or working on the

log splitter. Consult the technical

manual before servicing.

Double Insulated Protection

DANGER

Foreign bodies may be thrown

from the machine

Check your machine before turning it on.

Keep guards in place and in working

order. Frequently check to see that tools

are removed from the machine area

before turning it on. Replace damaged,

missing or failed parts before using it.

10m

Keep all bystanders & animals at

least 10 metres away from the

machine during operation.

If approached, stop the machine

immediately.

Safety alert symbol. Used to alert you to potential personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury.

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in serious injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in serious injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION

Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

STAY ALERT

Do not operate the machine while under the influence of drugs, alcohol, or any medication that

could affect your ability to use it properly. Do not use this machine when you are tired or distracted

from the job at hand. Be aware of what you are doing at all times. Use common sense.

AVOID DANGEROUS CONDITIONS

Make sure there is adequate surrounding workspace. Cluttered areas invite injuries.

Keep your work area clean with sufficient light. Keep the area around the machine clear of

obstructions, grease, oil, rubbish and other debris which could cause persons to fall onto moving

parts.

INSPECT YOUR MACHINE

Check all bolts, nuts, and screws for tightness before each use, especially those securing guards and

drive mechanisms. Vibration during use, may cause these to loosen.

Form a habit of checking to see that all other tools/equipment are removed from the working area

before turning it on.

Replace damaged, missing or failed parts before using it. Warning labels carry important

information. Replace any missing or damaged warning labels.

DRESS PROPERLY

Do not wear loose clothing, gloves, scarfs, neckties or jewelry (rings, wrist watches), which can be

caught in moving parts. Protective electrically non-conductive gloves and non-skid heavy duty

footwear are highly recommended when working. Wear a face or dust mask if the operation is dusty.

Always wear safety glasses/goggles and/or face shields. Everyday eyeglasses have only impact

resistant lenses; they are not safety glasses/goggles. Wear protective hair covering to contain long

hair, preventing it from getting caught in machinery.

AVOID ELECTRICAL SHOCK

Check that the electrical circuit is adequately protected and that it corresponds with the power,

voltage and frequency of the motor. Check that there is a ground connection, and a regulation

differential switch, further up the circuit. Ground the machine. Prevent body contact with grounded

surfaces: pipes, radiators, ranges, and refrigerator enclosures.

Never open the pushbutton box on the motor. Should this be necessary, contact a qualified

electrician. Make sure your fingers do not touch the plug’s metal prongs when plugging or

unplugging the machine.

KEEP BYSTANDERS AND CHILDREN AWAY

Keep unauthorised persons a minimum distance of 10 metres away from the machine. If

approached, stop the machine immediately. Do not allow children to handle, climb on or in the

machine.

DO NOT OVERREACH

Keep proper footing and balance at all times when using the machine. Never stand on the

machine. Serious injury could occur if the machine is tipped or if the moving parts are

unintentionally contacted. Do not store anything above or near the machine, where anyone might

stand on the machine to reach them.

AVOID INJURY FROM UNEXPECTED ACCIDENT

Keep hands & feet out of the way of all moving parts. Do not place any part of your body or any

tool e.g. in the machine during operation.

DO NOT FORCE TOOL

Always work within the rated capacity. Do not use the machine for a purpose for which it was not

intended.

NEVER LEAVE MACHINE RUNNING UNATTENDED

Do not leave the machine unattended until it has come to a complete stop.

MAINTAIN YOUR MACHINE WITH CARE

Clean the machine immediately after use. Keep the machine clean to ensure it operates to its full &

safest performance. When maintaining this machine, only the manufacturer’s original replacement

parts should be used. The use of non-original manufacturer parts may invalidate your warranty.

PROTECT THE ENVIRONMENT

Take left over materials to an authorised collection point or follow the stipulations in the country

where the machine is used. Do not discharge into drains, soil or water.

STORE IDLE EQUIPMENT

When not in use, the machine should be stored in a dry location. Keep the machine away from

children and others not qualified to use it.

This symbol on the product or on its packaging indicates that this product may not be treated as

household waste. Instead it shall be handed over to the applicable collection point for the recycling

of electrical and electronic equipment.

For more detailed information about recycling of this product, please contact your local council

office, your household waste disposal service or shop where you purchased the product.

THE MACHINE

SUPPLIED AS STANDARD

Instruction Manual, Shredder, Collector, Paddle Prod, Frame, Axle, Wheels, Wheel Trims, Fixing Kit

1. The Hopper

2. Reset Button

3. Transport Handle

4. Locking Screw

5. On-Off Switch

6. Mains Three Pin Plug

7. Collector Locking Lever

8. Collector

1

5

4

3

2

6

8

7

ASSEMBLY

–

Screw down the frame (9) to the device as illustrated with the screws (10).

–

Push the axle (11) into the frame.

–

Push the washer and socket (12) onto the axle.

–

Push the wheel onto the axle.

–

Tighten the wheel with the washer and nut (13).

–

Place the wheel cap on the wheel.

–

Repeat the procedure for the other wheel.

–

Push the collection tray (8) into the frame.

–

Change locking lever (7) to top position.

8

7

OPERATION

DANGER

The product must only be put into operation if no defects are found. It is crucial that any

defective parts are replaced before the product is used again.

Check the safety equipment and the safe condition of the product:

–

Check whether the hopper is empty.

–

Check all parts to make sure that they fit tightly.

–

Check whether there are any visible defects: broken parts, cracks, etc.

COLLECTOR LOCK LEVER

The machine is supplied with a safety function, which prevents it being operated if the collector lock

lever is in the unlock position. The machine will automatically stop, if the collection box is unlocked

during operation.

Upper position → The collection box is locked.

Lower position → The collection box is unlocked.

SWITCHING THE MACHINE ON & OFF

Before starting the product, make sure that there is no material in the hopper.

Before feeding material in, wait until the chipper has reached its working speed.

Switch on = Press Green [I] Button

Switch off = Press Red [0] Button

OVERLOAD PROTECTION

Note: If a blocked blade causes an overload, the circuit is automatically interrupted to protect the

motor.

–

Unplug the machine from the electrical source.

–

Remove blocked chippings. Note: Allow the motor to cool down for at least five minutes!

–

Press Reset Button (2).

–

Re-connect the power supply.

–

Start theproduct.

2

3

EMPTY THE COLLECTOR

WARNING

Press the Off Button [O] and separate the device from the main power supply before removing or

inserting the collector.

Note: The Locking Lever has the function of a safety switch and must be in its top position while

operating the product.

If the Locking Lever is correctly located, but the machine is not operating, this & the switch must be

cleaned, if required.

–

Move Locking Lever (7) to bottom position.

–

Pull the collection container (8) completely out of the

frame.

–

Empty the container (8).

–

Slide the collection container (8) onto the frame as far as

it will go.

–

Move Locking Lever (7) to top position, when

NOTES ABOUT CHIPPING

–

Organic garden waste can be chipped as biological fertiliser for the garden. Feed material which

breaks down naturally such as leaves, small branches, and grass in appropriate quantities into

the hopper (1) so that it does not get blocked.

–

Alternate chipping branches and garden waste, that has been stored for a few days & is

therefore withered and damp. This prevents blocking of the motor cylinder.

–

Do not put soft waste such as kitchen waste into the chipper; compost it instead.

–

Large branches with leaves must first be chipped completely before any other material is fed in.

–

If you cut heavy material or branches without interruption, this may block the chipper. Pull out

the material by hand a little, to counteract this problem (DO NOT REACH INTO THE HOPPER).

–

Stones, nails or similar objects can cause major damage to the chipper. (CHECK CAREFULLY)

–

If the chipper begins to vibrate strongly, the blades are damaged or worn out. Replace the

blades if necessary (see later pages in this manual for details).

ATTACH THE HOPPER

The detachable hopper can be fitted and removed from the top of the shredder to help the user

feed material into the shredder.

–

Place the hopper on top of the shredder.

–

Loosen the green side clasps on the hopper.

–

Ensure the metal link is positioned under

the hook of the shredder.

–

Pull the green side clasps of the hopper

upwards to lock into place.

–

To remove, follow the above steps in

reverse.

7

8

CLEANING

DANGER

Before all cleaning and maintenance work, switch the device off and disconnect the mains plug

from the electrical source. Wait until all moving parts have come to a complete stop and the

device is cooled off.

CLEANING THE DEVICE

–

Careful handling and regular cleaning ensure that the device will remain functional & powerful

for a long time.

–

Brush off coarse dirt.

–

Wipe down the device with a slightly damp cloth.

–

Never spray the device with water orsubject it to water.

–

To clean, never use cleansers or solvents. This can cause irreparable damage to the device. The

plastic parts can be eaten away by the chemicals.

MAINTENANCE

CHANGING BLADES

SAFETY GLOVES MUST BE WORN AT ALL TIMES.

–

Loosen the closure screw (4) and fold out

the hopper.

–

Insert a suitable object (Allen Key or

Screwdriver) as shown and hold it in the

hole (14).

–

Loosen the screws (15) with an Allen

Key.

–

Turn or replace the blade (16).

–

Install in the reverse order.

Note: Blades can also be sharpened.

However, this should be done by a

professional, both blades must maintain the

same weight in order to maintain a balanced

operation. An imbalance of the blades can

cause damage and injuries.

4

16

14

15

STORAGE & TRANSPORT

STORAGE

WARNING

Make sure that unauthorised persons do not have access to the device!

–

Allow the device to cool completely, before storing.

–

Store the machine in a dry place.

–

Store away from direct sunlight.

–

Do not store anything above or near the machine, where anyone might stand on the machine to

reach them.

–

Keep the machine away from children and others not qualified to use it.

TRANSPORT

–

Secure the device against slipping.

–

When shipping, use the original packaging if possible.

TROUBLE SHOOTING

DANGER

Improper repairs can cause your device to stop functioning safely. You therefore endanger

yourself, bystanders and your environment. You also risk invalidating your manufacturer’s

warranty.

PROBLEM

PROBABLE CAUSE

REMEDY SUGGESTED

Motor not running.

No Mains Voltage?

Check cable, plug, socket and fuse.

Cable Faulty?

Contact your local Approved Service

Dealer or Electrical Specialist if out of

Warranty.

Motor Protection Activated?

Remove all chipped debris & press

reset button

Safety Trigger not triggered?

Check the hopper motor housing

connection

Locking Lever is bottom

position?

Ensure Locking Lever on collector is

positioned in upper most position.

Material is not being

pulled into machine.

Material blockage?

Remove all chipped debris from blades.

(SAFETY GLOVES MUST BE WORN)

Are the blades

jammed/blocked?

Remove all chipped debris & press

reset button

Are the blades worn?

Replace the blades where necessary,

see blade removal instructions.

NOTES

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

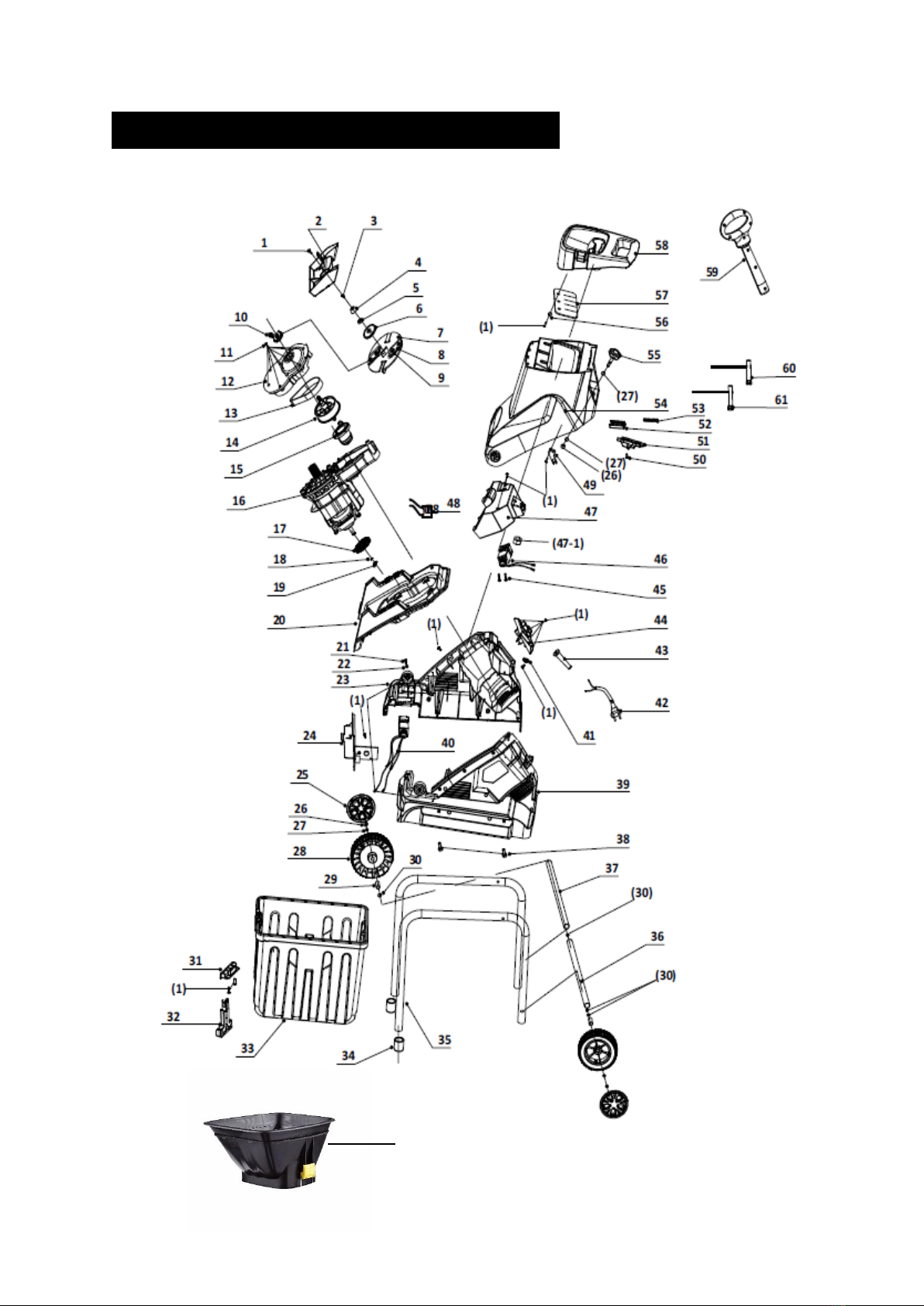

PARTS DIAGRAM –THISWB (193895001)

62

NOTE: Parts Lists are supplied for information

purposes only, not all parts are stocked

individually & we recommend you contact our

Spares Team on 01793 333212 for expert advice.

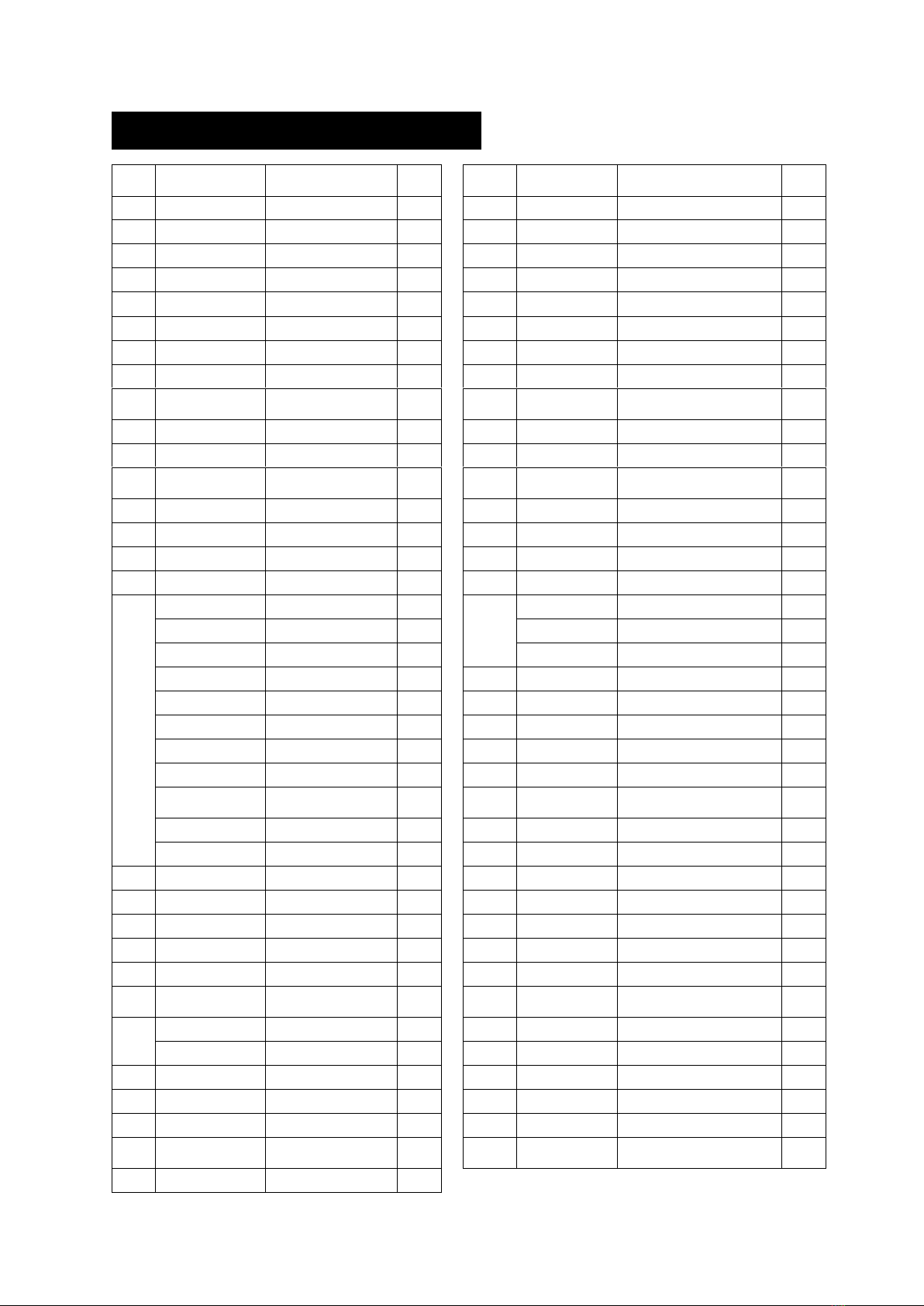

PARTS LIST –THISWB (193895001)

ITEM

HANDY PART NO.

DESCRIPTION

QTY

ITEM

HANDY PART

NO.

DESCRIPTION

QTY

1

TH104030161

S.T Screw 4.2 X 15B

47

29

TH103010098

Wheel Sleeve Φ14Xφ10X32

2

2

TH4010022

Blade Defend Plate

1

30

TH104010136

Flat Washer Ф10Xф20X1.5

4

3

TH104030408

Bolt M5X12

1

31

TH3010800086

Collector Key Entrance

1

4

TH103990484

Nut Cover

1

32

TH3010800087A

Collector Switch

1

5

TH104020048

Check Nut M12

1

33

TH301080367

Collector

1

6

TH103990450

Blade Block

1

34

TH301080369

Rubber Feet

2

7

TH103990449-1

Blade Plate Φ178.5X5

1

35

TH4050141

Supporting Leg Assembly

2

8

TH103040077B

Blade

2

36

TH4050143

Axle Sleeve Ф14*Ф12*308

1

9

TH104030246

Hex.Socket Bolt

M10X12

4

37

TH103050227

Axle 451*Ф10*M8

1

10

TH103990448

Drive Block

1

38

TH104030407

Hex.Socket Bolt M6X45

4

11

TH104030149

S.T Screw 4.8X19B

8

39

TH301080363

Left Housing

1

12

TH3010800069

Gearbox Top Cover

c/w Bearing Assembly

1

40

TH4080038

Pre Forced Switch

1

13

TH105990120

Belt 10PJ375

1

41

TH301990135

Cord Clamp

1

14

TH3010800072

Pulley

1

42

TH102070670

Three Pin Plug & Cable

1

15

TH3010800071

Pulley Tensioner

1

43

TH3010800063

Cable Sheath

1

16

TH4070184

Motor Assembly

1

44

TH4080041

Switch Assembly

1

TH2020121

S.T Screw 5X85B

2

TH102990141

Over-Load Protector

1

TH301080368

Motor Bracket

1

TH301080366

Switch Panel

1

TH102010386A

Motor Stator

1

TH102020203

Solenoid Switch

1

TH104030010

Male Tab F6.3*0.5

2

45

TH104030247

S.T Screw 4.2X35

2

TH103050142

Little Belt Wheel

1

46

TH4080039

Back Forced Switch

1

TH103050144

Bearing

1

47

TH301080361

Blade Panel Upper Cover

1

TH102010386B-1

Motor Rotor

1

47-1

TH104020072

Nut M8*14*11.7

1

TH103050100

Bearing

1

48

TH102030030

Capacitor

1

TH102060061

Brush Assembly

17*13*7

2

49

TH103990724

Key

1

TH103020119

Brush Bracket

2

50

TH104030126

S.T Screw 3*8 A

4

TH301080373-1

Motor Back

1

51

TH301080377

Top Block

1

17

TH301080375

Fan Ф95

1

52

TH301080376

Cover Plate

1

18

TH104050007

C-Ring Ф9

1

53

TH103060273

Spring Φ0.5*Φ4.8*40

1

19

TH3010800060

Fan Cover

1

54

TH301080360

Upper Housing

1

20

TH301080362

Blade Panel Base

1

55

TH301080123I-1

Knob

1

21

TH104030159

S.T Screw 4.2X10B

2

TH103990725-1

Knob Insert

1

22

TH104010135

Flat Washer

Ф4Xф11X1.5

2

56

TH104010024

Flat Washer Φ5*Φ14*1.5

3

23

TH301080364

Right Housing

1

57

TH301080356

Inlet Back Plate

1

TH103990748

Housing Insert M6*9.2

4

58

TH301080374

Inlet Panel Plate

1

24

TH301080365

Cable Cover

1

59

TH3010800030

Plunger

1

25

TH301080126G

Wheel Trim

2

60

TH4050083-1

Allen Key

1

26

TH104020020

Check Nut M8

3

61

TH103090050

Allen Key

1

27

TH104010047

Flat Washer

Ф8Xф20X1.5

4

62

TH3880065

Hopper

1

28

TH301080119

Wheel

2

GJ HANDY & CO LTD USER WARRANTY POLICY

1. Users Statement of Warranty

Each new machine is warranted against defective material or assembly of material under normal

usage. The warranty applies to the original purchaser and covers faulty parts and the labour involved

in replacing and repairing those parts, which are of original manufacture.

2. Period of Warranty

All Webb, Handy Pro (Brushcutter & Long Handle Hedgecutter only) products

2 years from the original date of sale to the first domestic user.

90 days from the original date of sale to the professional/commercial user.

90 days from the original date of sale when used for hire.

Engines as per the manufacturer’s warranty statement which will be supplied with the machine.

90 days from the original date of purchase for Replacement Spare Parts (unless normal wear & tear

component, which are covered for 30 days).

All machines’ must be serviced within the first 12 months from the original date of purchase to

comply with the warranty, failure to do so will invalidate the 2nd year of the warranty.

A reduced warranty period of 90 days applies to those items which are subject to normal wear and

tear (e.g. wheels, tyres, cutter bars, cylinders, bottom blades, belts, cables, grass bags, spark plugs).

All Handy, Handy Pro (All others), Mowerland and Q-Garden domestic products

1 year from the original date of sale to the first domestic user.

90 days from the original date of sale to the professional/commercial user.

90 days from the original date of sale when used for hire.

Engines as per the manufacturer’s warranty statement which will be supplied with the machine.

90 days from the original date of purchase for Replacement Spare Parts (unless normal wear & tear

component, which are covered for 30 days).

A reduced warranty period of 90 days applies to those items which are subject to normal wear and

tear (e.g. wheels, tyres, cutter bars, cylinders, bottom blades, belts, cables, collection bags, spark

plugs).

All warranty repairs must be undertaken by an authorised service dealer.

These dealers have been accredited by GJ Handy & Co Ltd and agree to only use genuine parts and

follow our repair procedures.

Version 2 06-15

GJ HANDY & CO LTD USER WARRANTY POLICY

3. Not covered by this warranty

The warranty policy does not cover any depreciation or damages caused by ordinary wear, rusting or

corrosion, lack of correct maintenance or operation, misuse, abuse, lack of transportation or

accident.

The warranty policy does not cover any costs necessary for the standard periodic maintenance

services instructed by the operators manual, or service parts replacement which would include oil,

filters, tyres, belts, brake linings, fuses, blades, seals and other service parts unless it can be proven

that the item has evidence of faulty manufacture.

The warranty policy will not cover failure or damage caused as a result of parts or accessories being

modified without the written approval of GJ Handy & Co Ltd.

The warranty policy will not cover the unit if non-genuine parts have been fitted and as a result

damage has occurred to the unit.

The warranty policy is non-transferable and is only applicable to the original purchaser.

4. Disclaimer

This warranty is only a remedy for defect of products. GJ Handy & Co Ltd will never warranty in

terms of the merchantability or the fitness for a particular purpose.

No person is authorised to make any warranties, representations or promises, expressed or implied,

on behalf of GJ Handy & Co Ltd, or to modify the terms conditions or limitation of this warranty

policy in any way.

Neither GJ Handy & Co Ltd nor any company affiliated with GJ Handy & Co Ltd shall be liable in any

event or manner whatsoever for incidental or consequential damages or injuries, including, but not

limited to, loss of crops, loss of profit, out of pocket expenses or profits, rental of substitute

equipment or other commercial losses.

5. General

Most warrantable failures show up within the first few weeks of use. These failures are usually

straightforward and warranty assessment is relatively easy.

Failures relating to cutter decks and belts need careful investigation, as the cause may not always be

straightforward. Look for damage to blades and pulleys especially when the cutter belt or blade boss

have snapped or cracked as this could be due to impact damage.

Customers should always refer to the operator/instruction manual when any disputed problem

arises, you will find most areas covered within the manual.

Version 2 06-15

EC DECLARATION OF CONFORMITY

We Handy Distribution Ltd - SN3 5HY (Importer) declare that the product:

Designation:

2500 Watt Electric Impact Shredder with Collector

Model(s):

THISWB

Type/Serial No:

As per rating label on machine

Complies with the following directives:

2006/42/EC –Machinery Directive

2014/30/EU - Electromagnetic Compatibility

The conformity assessment procedure followed was in accordance with

EN60335-1/A11:2014, EN13683/A2:2011, EN62233:2008

EN55014-1:2006/A2:2011, EN55014-2:1997/A2:2008, EN61000-3-2:2014, EN6100-3-11:2000

Notified Body:

TÜV SÜD Product Service GmbH

Address(es):

Zertifizierstelle, Ridlerstraße 65, 80339 München, GERMANY

Guaranteed Sound Power Level:

106 dB(A)

Authorised signatory & technical file holder

Date:

08/03/2016

Signature:

Name:

Mr Simon Belcher

Position:

Managing Director

Company:

Handy Distribution Ltd

Address:

Murdock Rd, Dorcan, Swindon, Wiltshire, SN3 5HY.

This manual suits for next models

1

Table of contents

Other The Handy Paper Shredder manuals

The Handy

The Handy THSSWB User manual

The Handy

The Handy THSS User manual

The Handy

The Handy THIS User manual

The Handy

The Handy THSSWB User manual

The Handy

The Handy THIS Installation and maintenance instructions

The Handy

The Handy THIS User manual

The Handy

The Handy THPDS65 User manual

The Handy

The Handy THHSWB Installation and maintenance instructions