The Handy THSSWB User manual

OPERATOR’S MANUAL AND PARTS LIST

Electric Silent Shredder - THSSWB

Spares & Support: 01793 333212

www.thehandy.co.uk

Before use please read & understand this manual, paying

particular attention to the safety instructions.

21/03/2014

1

12

2

1

3

13

5

6

4

9

5

11

10

7

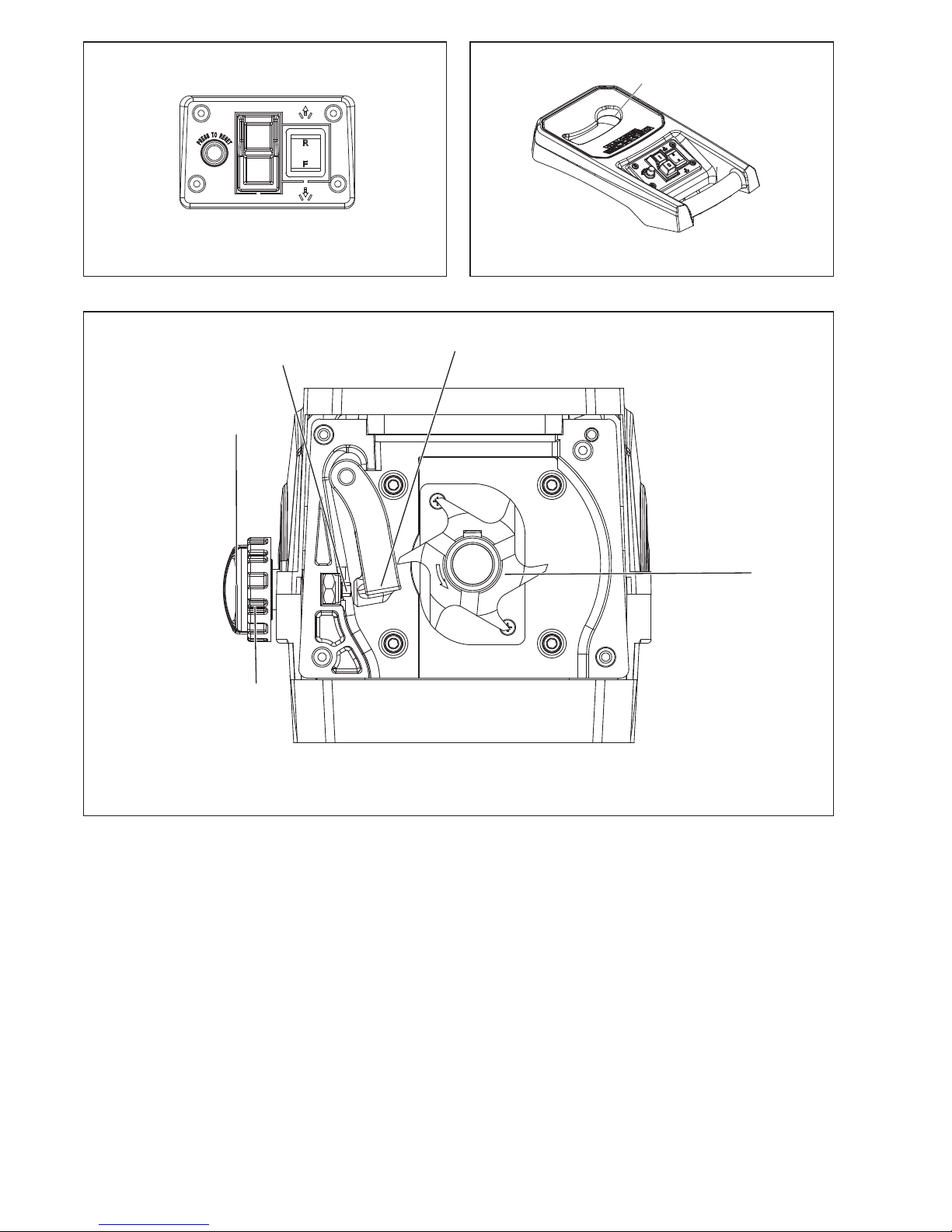

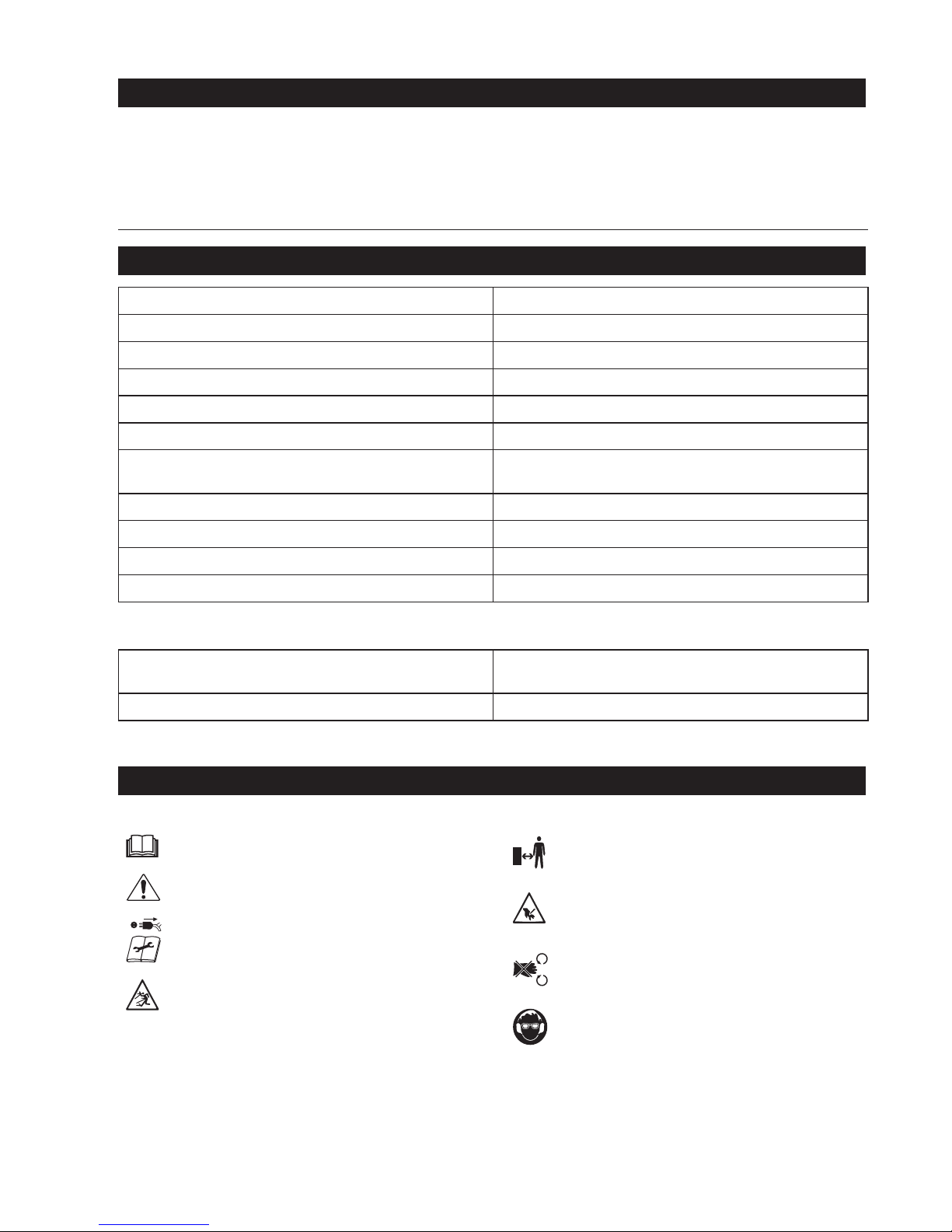

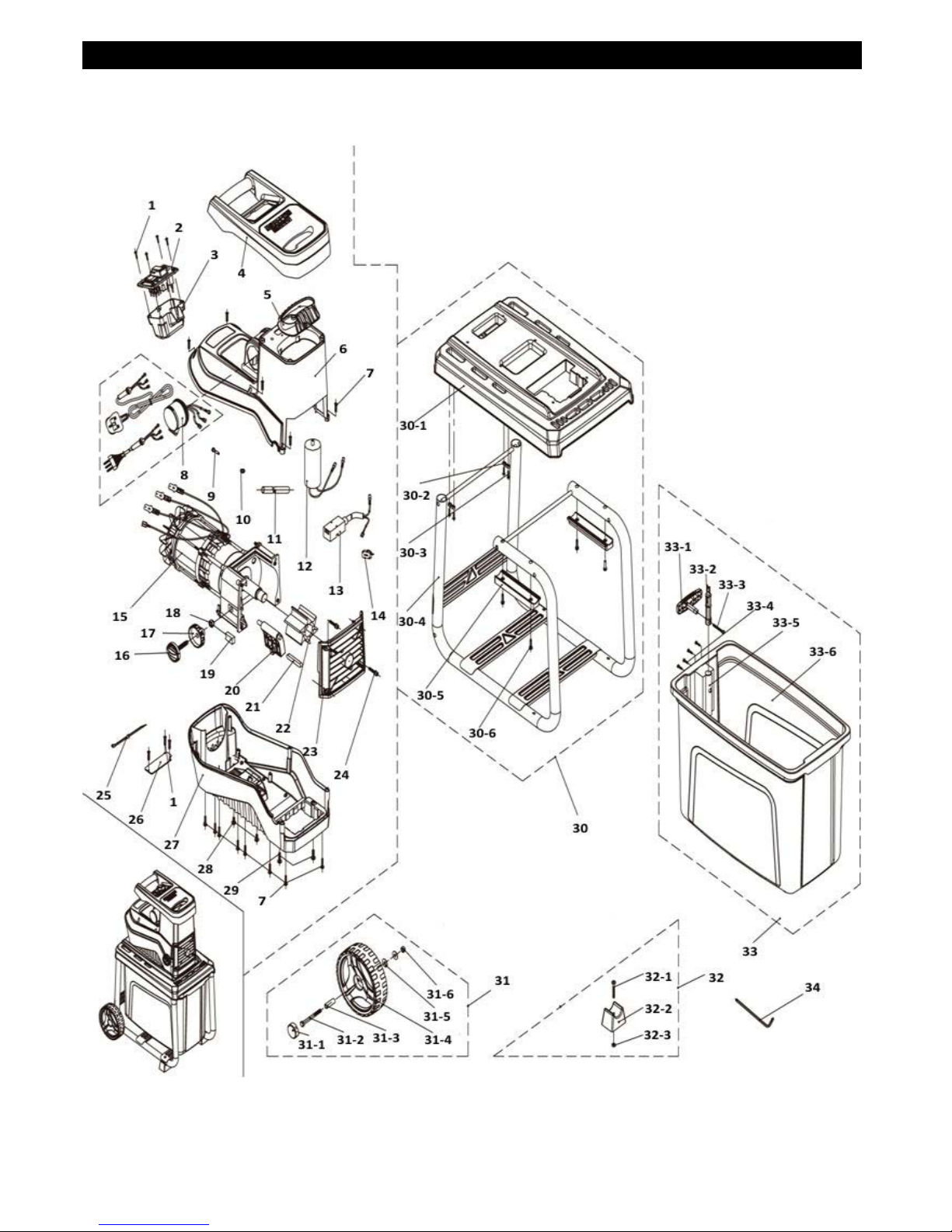

1 - Filling Hopper

2 - Power Switch

3 - Handle

4 - Power Supply Plug

5 - Lock Lever

6 - Control Panel

7 - Upper Enclosure

8 - Collection Box

9 - Base Frame

10 - Adjusting Knob

11 - Fixing Knob

12 - Blade Cover

13 - Feed Hopper

8

2

2

4 3

5 6

3

7 8

16

14

11

10

15

9

13

4

40 mm

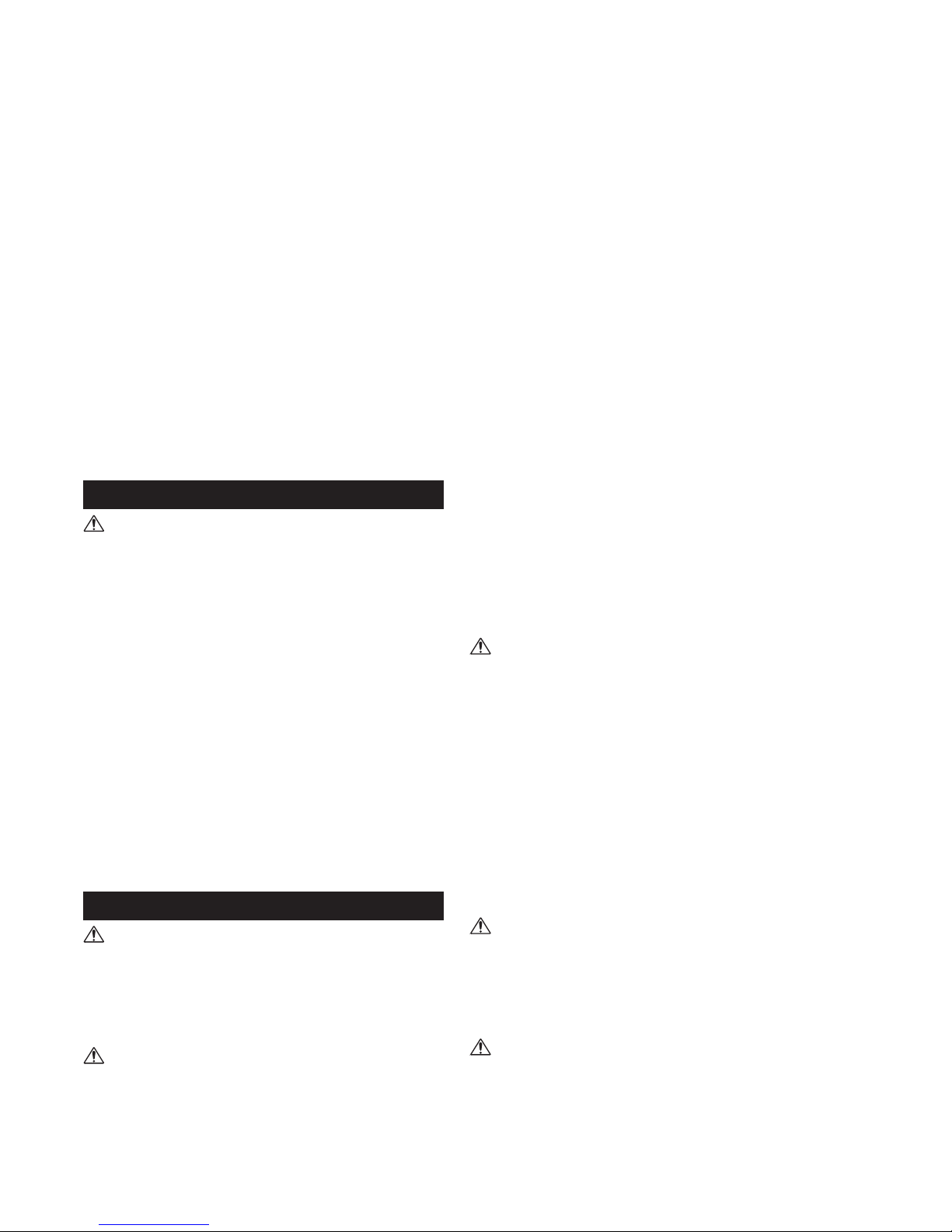

DESIGNATION OF PARTS

1 Filling hopper

2 Power switch

3 Handle

4 Power supply plug

5 Lock lever

6 Control Panel

7 Upper enclosure

8 Collection Box

9 Base frame

10 Adjusting knob

11 Fixing knob

12 Blade cover

13 Feeding hopper

14 Screw

15 Counter blade

16 Cutting roller

TECHNICAL DATA

Model

Name Electric Shredder

Motor AC-Motor 230V~50Hz

Motor rating P1 S6-40% 2,500W

Motor rating P1 S1 2,000W

Rotational speed cutting roller 40 min–1

Power switch overload protection; cutting and reverse function, zero-

voltage initiator

Weight 25 kg

Max. branch diameter (only for freshly cut wood) Max.

Safety class I

Protection class IP X4

NOISE DATA

measured sound power level 89.33dB(A)

K=2.39dB(A)

guaranteed LwA 95.0dB(A)

The sound intensity level for the operator may exceed 80 dB (A). Wear ear protection.

SYMBOLS

The following symbols are used for the machine. Be sure that you understand their meaning before use.

Read instruction manual.•

Take particular care and attention.•

Switch off the motor and unplug it

before servicing, cleaning, maintenance or

repairing.

•

Objects may be thrown out at high speed.•

Keep bystanders and pets away from

the workarea.

•

Danger — Rotating blades. Keep hands

and feet out of openings while the

machine is running.

•

Danger — Rotating blades. Keep hands

and feet out of openings while the

machine is running.

•

Wear eye and ear protection.•

THSSWB

5

Wear protective gloves.•

Do not expose to rain or moisture.•

Turn the knob clockwise for narrower

clearance / turn the knob

counter-clockwise for wider clearance.

•

Open the blade cover to adjust the blade or

clean the wood.

•

Wait until all the machine parts stop

completely.

•

Do not use the machine as a step.•

Only for EU countries

Do not dispose of electric equipment or

battery packstogether with household

waste material! In observance of European

Directive 2002/96/EC on waste electric

and electronic equipment, 2006/66/EC

on batteries and accumulators and waste

batteries and accumulators and their

implementation in accordance with national

laws, electric equipment and battery pack

that have reached the end of their life must

be collected separately and returned to

an environmentally compatible recycling

facility.

•

SAFETY WARNINGS

READ CAREFULLY BEFORE USE

KEEP INSTRUCTION MANUAL FOR FUTURE

REFERENCE

Do not start to operate the machine until you have

read these operating instructions. Observe all the

instructions given, and install the machine as described.

Intended use of the machine

The garden shredder is intended for shredding the

following items:

All types of branches up to a maximum diameter

of 40mm (depending on the type and

and condition of the wood.)

Garden refuse such as plants should be dried

before shredding and fed alternately with

branches to avoid blocking the shredder.

The garden shredder is intended for private use only,

and not for commercial use. Do not use it in public

places either.

•

–

–

•

For public low-voltage distribution systems of

between 220 V and 250 V.

Switching operations of electric apparatus can cause

voltage uctuations. The operation of this device under

unfavourable mains conditions can have adversly effect

the operation of other equipment. With a mains impedance

equal or less than 0.45 Ohms it can be presumed that

there will be no negative effects. The mains sockets used

for this device must be protected with a fuse or protective

circuit breaker having slow tripping characteristics.

General Instructions

Read this instruction manual to become familiar with

how to handle the machine. Users insufciently

informed are more likely to be involved in accidents

due to improper handling.

Do not lend the machine to people who have not read

the instruction manual.

When lending the machine, always attach this

instruction manual.

The electric shredder is not intended for use by persons

with reduced physical, sensory or mental capabilities,

or a lack of experience and knowledge. Young

children should be supervised to ensure that they do

not play with the machine. Do not allow children to

operate this equipment.

Operate only if you are in good physical condition.

Perform all work calmly and carefully. The user is

responsible for the safety of bystanders and any

damage caused by the machine in the operating area.

Never use this machine after consumption of alcohol or

drugs, or if feeling tired or ill.

Use the machine in accordance with these instructions,

considering the working conditions and the application.

It can be dangerous to use the machine for applications

which it is not intended for.

Never alter the machine, including safety devices such

as the interlock device. This will endanger your safety.

National or local regulation may restrict the handling of

the machine.

Stay alert. Watch what you are doing. Use common

sense. Do not operate machine when you are tired.

Personal protective equipment

Dress Properly. Work clothes should be functional and

appropriate, i.e. it should be tight-tting but not

cause hindrance. Do not wear either jewelry or clothing

which could become entangled in the machine.

Cover long hair, tying it back may not be sufficient.

Always wear ear protection to avoid hearing loss.

Wear protective glasses or goggles to protect your eyes

from debris thrown from the lling hopper.

Wear protective gloves to prevent injury to ngers.

Wear a face mask when shredding dry branches,

hedges with leaves or anything that will create dust.

When using the machine, always wear sturdy shoes

with a non-slip sole. This will reduce the chance of

injuries and ensure a good footing.

Work area safety

Keep children and bystanders clear while operating the

machine.

Operate the machine in open space on a rm, level

surface. Do not operate the machine close to a wall or

other objects.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

6

Do not operate the machine in explosive

atmospheres, such as in the presence of ammable

liquids, gases or dust. The machine creates sparks

which may ignite flammable materials.

Do not operate the machine on a gravel or uneven

surface where ejected material may result in injury.

Keep the work area clean and well lit. Cluttered or

dark work areas invite accidents.

Do not expose the machine to rain or wet conditions.

Water entering the machine may increase the risk of

electric shock.

Starting up the machine

Before connecting the plug to the machine:

Check all the screws, nuts and other fasteners

are properly secured.

Check guards, deectors and screens are in

place and good working condition.

Make sure the lling hopper is empty.

Make sure the inlet and discharge opening

guards are properly in place.

Check all the parts of the machine carefully to

determine if it operates properly and performs

its intended function. Especially, never use the

machine if the switch does not work normally.

If the supply cord is damaged, ask one of our

authorised service dealers, always using genuine

replacement parts, to replace it.

Electrical safety

WARNING:

This is a Class I appliance. Connect with a supply

socket with an earth terminal. Improper earth may

cause electric shock and death. Use only three-wire

extension cords which have three-prong grounding-

type plugs and three-pole receptacles which accept the

tool’s plug.

Avoid contact with earthed or grounded surfaces

(e.g. pipes or radiators) during operation.

Use only IEC60245 (H07RN-F) extension cable for

outdoor use with splash-proofed connector. Its cross-

section must be at least 1.5 mm2for cable lengths up to

25 m, and 2.5 mm2for cable lengths over 25 m.

Voltage drop may occur when using a long thin cable,

this will reduce the power of the machine.

When using the extension cable, make sure that it does

not interfere with the operation of the machine and is

not squeezed or bent, and the plug does not get wet.

When using a cable reel, wind the cable completely off

the reel.

Do not misuse the cord. Never use it for carrying,

pulling or unplugging the machine. Keep it away

from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

Check the extension cable regularly for damage to the

insulation. Replace it if damaged.

If the connecting cable is damaged, withdraw the mains

plug immediately. A damaged cable may cause contact

with live parts and electric shock.

Never use damaged cables.

Only plug the machine into sockets in tested electrical

circuits. Check that the system voltage matches that on

the rating plate.

•

•

•

•

•

–

–

–Make sure you are wearing appropriate clothes.

–

–

–

•

•

•

•

•

•

•

•

•

•

•

•

Never deactivate or bypass the protective devices.

When using the machine outdoors, always use a

residual current-operated circuit-breaker (RCD) with an

operating current of 30 mA or less.

Operation

Keep your face and body away from the inlet opening.

Never put your hands or other partsyour body or

clothing inside the inlet and discharge opening, or near

moving parts. This may result in serious injury.

Do not overreach. Keep proper footing and balance at

all times. This enables better control of the machine in

unexpected situations. Don't stand at a higher level than

the base of the machine when feeding material into it.

Always keep clear of the discharge opening during

operation.

Observe regional regulations for noise protection.

Do not shred rocks, metal, bottles or other foreign

matter. Make sure that these foreign objects are not

in the branches that you shred.

Immediately switch off the motor and unplug it if the

blade strikesa foreign object or the machine starts

vibrating or making noise unusually. Check the

shredder for damage, and tighten any loose parts. Ask

an authorised service dealer to repair the machine.

Do not let the processed material accumulate in

the discharge opening. Otherwise it may result in

material being thrown through the inlet opening.

Switch off the motor and unplug it:

Whenever leaving the machine unattended

Before clearing a blockage or any fault

Before checking, cleaning or working on the

machine

Before making any adjustments, changing

accessories or storing

Whenever the machine starts vibrating or making

noise unusually

Clearing the inlet or discharge opening

Attaching or removing the collection box

Transporting.

Do not tilt the machine during operation.

Keep well clear when you shred long material. It may

spring back and this may result in personal injury.

Do not operate without the lling hopper.

Do not force the machine. It will do the job better

and safer at the rate for which it was designed.

Frequent overload may cause motor damage or re.

Use the right appliance. Do not use appliances for

purposes that it is not intended for. Never shred

metal, glass, stone, ceramics, plastics, thicker

branches, hard wood or thick wood plates, etc.

Maintenance instructions

Have your machine serviced by our authorised service

dealer, only use genuine replacement parts. Incorrect

repair and poor maintenance can shorten the life of the

machine and increase the risk of accidents.

Before servicing, inspection, adjustment, storage, or to

change an accessory, take following steps:

Shut off the power

Disconnect the machine from the power supply

Make sure that all moving parts have come to a

complete stop

Allow the machine to cool.

•

•

•

•

•

•

•

•

•

•

•

–

–

–

–

–

–

–

–

•

•

•

•

•

•

•

–

–

–

–

7

Check the machine for damage.

Make sure safety devices work properly for

their intended function

Check that all the moving parts work smoothly

and adequately

Ensure parts are not damaged and are properly

installed

Any damaged parts should be replacedor

repaired by one of our service dealers.

Pay close attention when servicing the cutter. The

cutter may move manually even if theinterlock feature

is enabled.

Do not clean the device with water. It may cause

electrical shock.

Wear protective gloves during maintenance or

assembly work to reduce the chance of injury.

Do not carry out maintenance or repair work other than

that described in this instruction manual. Any other

work must be carried out by one of our authorised

service dealers.

Only use original replacement parts and accessories

intended for your machine. Use of non-genuine parts

may result in personal injury or damage to the machine.

Store the machine in a dry room. Keep it out of reach of

children. Never store the machine outdoors.

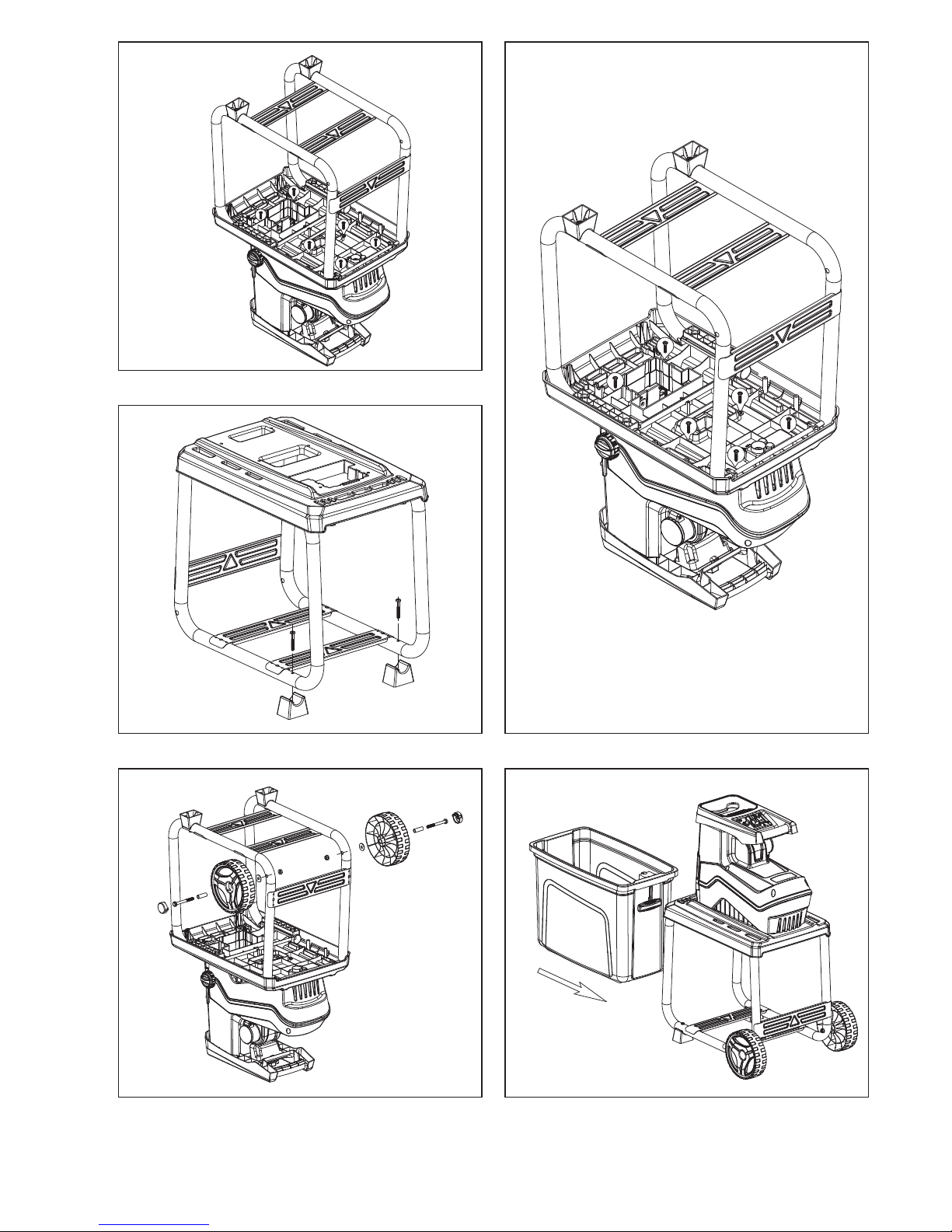

ASSEMBLY

CAUTION:

Always be sure that the machine is switched off and

unplugged before carrying out any work on the tool.

1. Place the upper enclosure upside down on aat

surface. Then put the base frame onit. Make sure

the base frame is the right way around.(Fig. 2)

2. Fasten each part by tightening the screws. Make sure

all parts are perfectly stable. (Fig. 3)

3. Attach the feet using screws. Make sure they are

fastened tightly. (Fig. 4)

4. Attach the wheels by following these steps: (Fig. 5)

Put the wheel bolt through the spindle sleeve.

Place the wheel on the wheel bolt.

Place a washer on the wheel bolt before

inserting the bolt through the base leg. Secure

it with a nut. Make sure the nut is tight.

Repeat on the other side.

5. Insert the collection box. And then raise the lock

lever. (Fig. 6)

FUNCTIONAL DESCRIPTION

WARNING:

Before plugging the machine in, always make sure that

the machine is switched off. Plugging the machine in

with the switch on may cause an unexpected start

resulting in serious personal injury.

Power Switch (Fig. 7)

CAUTION:

Do not use the machine if the switch does not turn it on

and off. Defective switches must be replaced by one

of our authorised service dealers.

To turn on the machine, push the green button.

To turn off the machine, push the red button.

•

–

–

–

–

•

•

•

•

•

•

•

–

–

–

–

LED light

The LED light indicates the status of the machine as

follows:

RED color: When the machine is connected to the

power supply and the machine is switched off.

GREEN color: When machine is switched on.

Flickering GREEN color constantly: When the

machine is blocked during operation.

Flickering RED color: When the machine cannot

recover automatically. Clear the problem manually

when this happens.

Unintentional restart proof

The machine switches off automatically when a power

failure occurs. To restart, push the green button again.

Overload protection

The motor is equipped with overload protection. When

overloaded, the machine will run the following procedure:

The blade will run in reverse for 2or 3seconds

to try to push the shredded material back out.

The blade runs forward again.

If the material is still clogged after three

attempts to unblock itself, the machine will stop

and the LED light will icker red.

When the LED flickers red follow the steps below:

Turn off the machine.

Wait until the blades stop completely.

Remove the clogged material.

Turn the shredder on again after about 5 minutes,

and feed material that is easier to shred.

If you cannot turn on the machine after this

waiting time, refer to “Trouble Shooting”.

Forward / Reverse switch

CAUTION:

Switch off the shredder before changing the forward /

reverse switch.

Position e

The blades rotate in the forward direction.

Position d

The blades rotate in the reverse direction to release

jammed material.

When you change the direction into d(reverse), hold

the green power switch to rotate the blades. The

shredder automatically stops when you release the

power switch.

NOTE:

Several repetitions of reverse and forward operations

may be required to shred a large object.

CAUTION:

Always use a hook or a stick to remove jammed objects

to prevent accidents.

Always wait until the shredder stops completely before

restarting.

Collection Box

CAUTION:

Switch off and unplug the machine before attaching or

removing the Collection Box.

Check the functionality of the interlock feature every

two hours for safe operation.

Never attempt to override the interlock feature.

–

–

–

–

–

–

–

–

•

•

•

•

•

•

8

Lock lever:

Upper position →The collection box is locked.

Lower position →The collection box is unlocked.

The device does not switch on

because of a safety function.

The machine cannot be switched on if the lock lever is in

the unlock position. The machine automatically stops if

the collection box is unlocked during operation.

Blade cover

CAUTION:

Make sure that the machine is switched off and un-

plugged before opening the blade cover.

Wear protective groves before opening the blade

cover.

The cutter does not stop immediately after switch off.

Wait until all the parts stop.

Ifthe material clogs badly in the upper enclosure,

remove it by opening the blade cover.

OPERATION

Set up the machine:

On a flat, level surface. Do not place the machine on

graveled ground.

Work at a safe distance (at least 2 m) away from

walls or other objects.

Before starting, make sure that:

The connection cables are not damaged. If there are

cuts or tears, stop operation and replace it immediately.

There is no damage on the machine, and all screws

are tight.

The machine is assembled completely and correctly.

Check the mains connection:

Make sure that the mains voltage matches the rated

voltage on the nameplate and the machine is properly

grounded.

Use only extension cords with sufficient core

cross-section.

The shredder can process the following types of

material:

All types of branches up to the machine's maximum

diameter capacity of 40mm, depending on type and

condition of the wood.

Dry garden refuse such as plants, which should be

dried before shredding and fed alternately with

branches to avoid blocking the shredder.

The shredder can NOT process the following types

of material:

Glass, metal, plastic, stone, ceramics, thicker

branches, hard wood, thick wood plates, cloth, plastic

bags, roots with soil.

Refuse which is in an almost liquid state, e.g. kitchen

waste.

Operation: (Fig. 8)

Feed the material into the filling hopper from the right

side.

In case of branches, twigs and wood, shred them just

after they are cut. They may get very hard as they

become dry.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Remove any side shoots from branches if they are not

easy to feed.

Turn off the motor and disconnect the machine from the

power supply before cleaning the ejection opening.

Do not let the shredded material accumulate in the

ejection opening. Otherwise the shredded material

may block the ejection opening. Empty the collection

box regularly.

Do not shred material which is more than the maximum

branch diameter of 40mm. The maximum branch

diameter may vary depending on the freshness and

condition of the wood.

Shredding wet garden waste may clog the shredder.

To reduce the chance of the machine clogging

alternate waste with wood.

Soft material or wet branches may be torn instead of

being cut. A worn counter blade may also cause this

problem.

Adjusting the blade clearance (Fig. 9)

For an effective operation, adjust the clearance between

the counter blade and cutting roller.

Setting the clearance:

Switch on the device.

Turn the fixing knob counterclockwise to release the

adjusting knob.

Turn the adjusting knob clockwise slowly to place the

counter blade closer to the cutting roller. Turn it until fine

aluminum chips are falling from the ejection opening.

Turn the fixing knob clockwise to lock the adjusting

knob.

MAINTENANCE

CAUTION:

Always be sure that the machine is switched off and

unplugged before inspectingor performing maintenance.

Wear protective gloves before performing inspection or

maintenance.

The cutter does not stop immediately after switch off.

Wait until all the parts stop before performing any

maintenance work.

Make sure that all the tools are removed after

maintenance work.

Never use petrol, benzine, thinner, alcohol or similar.

Discoloration, deformation or cracks may result.

To clean the machine, use only moist cloth and soft

brush.

Do not hose or clean the machine with high pressured

water.

After each operation, perform the following maintenance:

Check whether all the locking screws are tight (tighten

if necessary).

Lubricate metal parts to protect them against

corrosion.

Keep the vents clean and free from dust.

The cutting roller and counter blade will wear out over

time. Ask your nearest authorised service dealer for

replacement when it is necessary.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Before operation, adjust the Adjusting Knob to release

any foreign objects which may interfere with the Cutting

Roller and Counter Blade.

Switch on the tool, then adjust the Adjusting Knob, you

should hear the Cutting Roller touching the Counter Blade.

The shredder should produce small metal filings. Tighten

the Fixing Knob, make sure the Counter Blade is tight.

REVERSE SWITCH

The shredder is fitted with a reverse switch to enable

the removal of jammed material. If material becomes

jammed stop the machine by pressing the OFF button.

When the machine has come to a complete stop

change the direction of rotation by pressing the reverse

arrow on the reverse switch and pressing the ON button

(note that the machine will not stay ON while in reverse

-- the button has to be held down). When the blockage

has cleared,stop the machine and return the reverse

switch to its original position. Do not continue to run the

machine in reverse mode as this could cause injury to

the operator or damage to the machine.

9

TROUBLE SHOOTING

WARNING: Before performing maintenance, switch off the machine, pull out the mains plug, and wait until the

machine stops completely.

Problem Possible cause Remedy

Motor does not start No power supply Check the mains supply.

Mains cable defective Ask one of our authorised service dealersto inspect it.

Overload protection is activated Wait until the machine cools down and press the green

button.

Collection box safety cut-out device

(collection box is unlocked) Check and lock the collection box.

Motor sounds but does not

start

Cutting roller is blocked

Turn off the device.

Switch the forward/reverse switch into the reverse direction.

Switch on the machine until the jam has been cleared.

Switch the machine off again.

Change the direction to forward rotation.

Capacitor fault Bring the machine to one of our service dealers for repair.

The shredding material isnot

drawn into the shredder Reverse rotation. Turn off the machine and change the direction of rotation

using the selector switch.

Shredding material caught in lling

hopper

Switch off the machine. Switch the forward/reverse switch

to the reverse direction. Switch on the machine to release

the material, remove any foreign matter.

Switch the machine off again.

Change the direction to forward rotation.

Shredding material too soft or wet Push down with a branch

Cutting roller worn

Adjust the xed counter blade as described under

"Adjusting the blade clearance”.

If the cutting roller is severely worn, replace it.

Shredding material is not cut

cleanly

Fixed counter blade is not adequately

adjusted Adjust the counter blade.

Device starts but is blocked

by even a slight load, and

is switched off bythe

protective motor switch.

Extension cable is too long or

cross-section is too thin.

Socket is too far from mains supply or

cross-section of mains cable is too thin.

Check the extension cable is at least 1.5 mm2, maximum

25 m long. If using longer cable, minimum cross-section

is 2.5 mm2

10

PARTS DIAGRAM

11

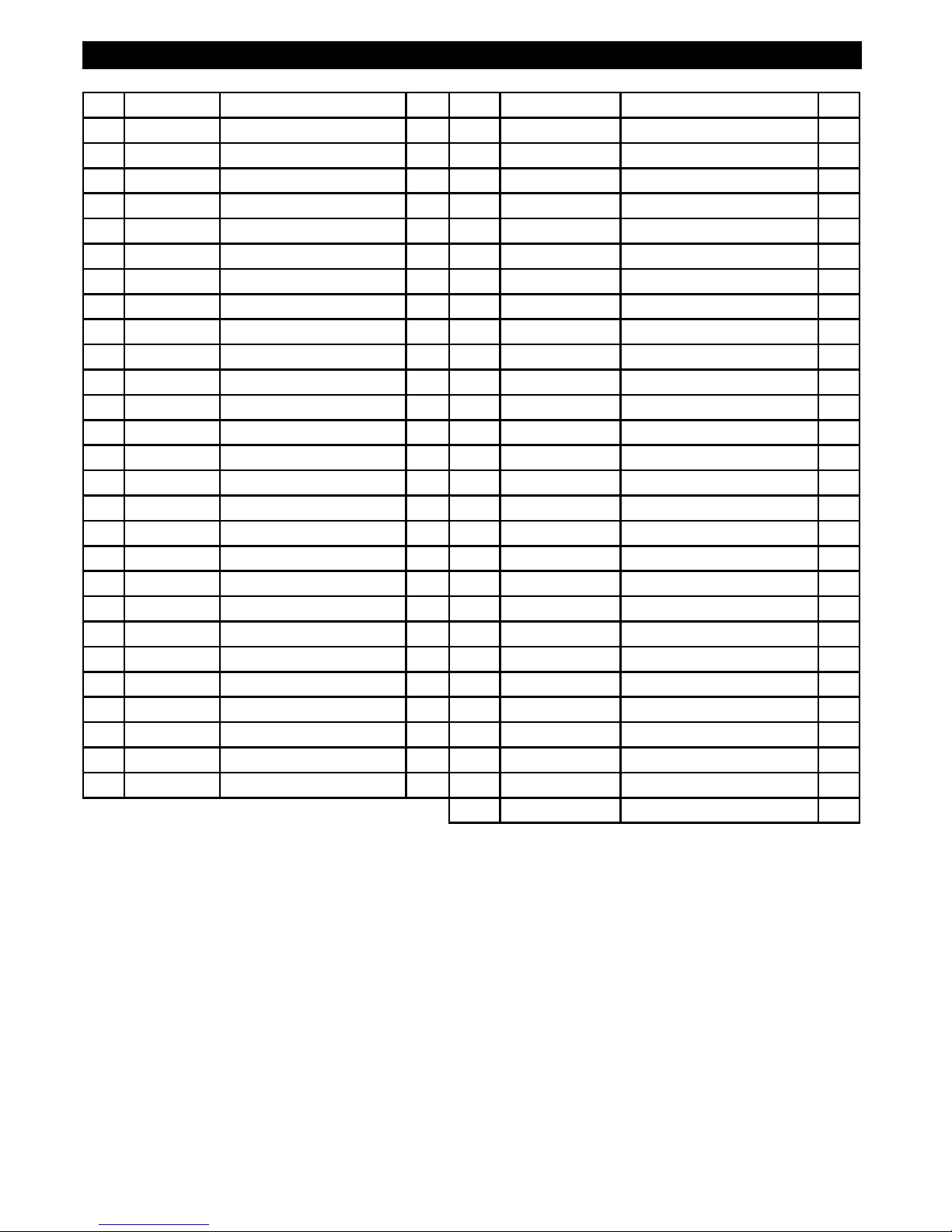

No Part No Description QTY No Part No Description QTY

1 TH203-1 Screw 7 28 TH203-28 Screw 2

2 TH203-2 Switch Assembly 1 29 TH203-29 Screw 2

3 TH203-3 Switch Housing 1 30 TH203-30 Base Assembly 1

4 TH203-4 Hopper Top 1 30-1 TH203-30-1 Base Plate 1

5 TH203-5 Feeder 1 30-2 TH203-30-2 Cable Clamp 2

6 TH203-6 Upper Housing 1 30-3 TH203-30-3 Self Tapping Screw 4

7 TH203-7 Self Tapping Screw 18 30-4 TH203-30-4 Support Base 1

8 TH203-8 Power Cable 1 30-5 TH203-30-5 Clamp 2

9 TH203-9 Screw 1 30-6 TH203-30-6 Self Tapping Screw 4

10 TH203-10 Lock Washer 1 31 TH203-31 Wheel Assembly 2

11 TH203-11 Heat Shrinkable tube 1 31-1 TH203-31-1 Wheel Cap 1

12 TH203-12 Capacitor 1 31-2 TH203-31-2 Wheel Bolt 1

13 TH203-13 Switch 1 31-3 TH203-31-3 Spindle Cover 1

14 TH203-14 Microswitch 1 31-4 TH203-31-4 Wheel 4

15 TH203-15 Motor 1 31-5 TH203-31-5 Washer 2

16 TH203-16 Adjustor Knob 1 31-6 TH203-31-6 Nut 1

17 TH203-17 Lock Knob 1 32 TH203-32 Bracket Assembly 2

18 TH203-18 Nut holder 1 32-1 TH203-32-1 Screw 1

19 TH203-19 Nut Housing 1 32-2 TH203-32-2 Bracket Assembly 1

20 TH203-20 Inlet Baffle 1 32-3 TH203-32-3 Nut 1

21 TH203-21 Type A Flat Key 1 33 TH203-33 Collector Box 1

22 TH203-22 Blade 1 33-1 TH-203-33-1 Push Button 1

23 TH203-23 End Cover 1 33-2 TH-203-33-2 Button Rod 1

24 TH203-24 Screw 2 33-3 TH-203-33-3 Self Tapping Screw 1

25 TH203-25 Nylon Cable Tie 6 33-4 TH-203-33-4 Screw 4

26 TH203-26 Switch Board 1 33-5 TH-203-33-5 Rod Housing 1

27 TH203-27 Lower Housing 1 33-6 TH-203-33-6 Collector Box 1

34 TH203-34 Allen Key 1

PARTS LIST

12

EC Declaration of Conformity

We, Importer

Handy Distribution

SN3 4NS

Declare that the product

Designation: ELECTRIC SILENT SHREDDER

Model: THHSWB

Complies with the following directives:

2006/42/EC / Annex 1 - Machinery Directive

2006/95/EC / Annex 1 – Low Voltage Directive

2000/14/EC amended by 2005/88/EC / Annex 3 - Noise Emission in the Environment by

Equipment for Use Outdoors Directive.

The conformity assessment procedure followed was in accordance with

Directive 2006/42/EC

Name of the Notified Body: TÜV Rheinland LGA Products GmbH

Address: Tillystraße 2 - 90431 Nürnberg

- Measured Sound Pressure Level: 84.4 dB (A)

- Guaranteed Sound Power Level: 95 dB (A)

Standards and technical specifications referred to:

2006/42/EC / Annex 1 - DIN 11004-1:1988, EN136:2003+A2, EN 292-1:1991, EN 953,

EN 954-1:1996, EN13683:2003+A2:2011, EN ISO 3744:1995, EN 41003, EN 50366,

EN 60068-2-75, EN 60335-1:2002+A11+A1+A12+A2+A13+A14+A15 Annex H,

EN 60335-1:2012, EN 61032, EN 62233-2008, ISO 3767-1:1998, ISO 3767-3:1995,

ISO 3767-4:1993, ISO 9772, ISO 11094:1991, EN 11688-1, EN ISO 11691-1995,

EN ISO 11820:1996, EN ISO 12100-2:2003, EN 13849-1, EN ISO 13857: 2008, IEC 60065,

IEC 60068-2-31, IEC 60068-2-78, IEC/TR 60083, IEC 60112, IEC 60127, IEC 60245,

IEC 60252-1, IEC 60227, IEC 60238, IEC 60320-1, IEC 60309, IEC 60320-1, IEC 60320-2-2,

IEC 60320-2-3, IEC 60335-1:2012, IEC 60335-1:2010 (Fifth Edition), IEC 60384-14,

IEC 60417-5005, IEC 60417-5006, IEC 60417-5019, IEC 60417-5036, IEC 60417-5172,

IEC 60417-5180, IEC 60529, IEC 60664-1, IEC 60664-3, IEC 60664-4, IEC 60691,

IEC 60695-2-11, IEC 60695-2-12, IEC 60695-2-13, IEC 60695-10-2, IEC 60695-11-5,

IEC 60695-11-10, IEC 60730-1, EN 60730-2-8, EN 60730-2-10, IEC 60906-1, IEC 60990,

IEC 60999-1, IEC 61000-4-2:2008, IEC 61000-4-3:2006+A1+A2, IEC 61000-4-4:2012,

IEC 61000-4-5:2005, IEC 61000-4-6:2008, IEC 61000-4-11:2004, IEC 61000-4-13:2002+A1,

IEC 61000-4-34, IEC 61032:1998, IEC 61058-1:2000+A1+A2, IEC 61058-1:2002+A2,

IEC 61558-1, IEC 61558-2-6, IEC 61770, IEC 62151, IEC 62233:2008, ZEK 01.4-08/11.11

Authorised signatory and technical file holder

Date: 19/03/2014

Signature:

Name / title: Mr. Simon Belcher / Managing Director

Hobley Drive, Stratton St Margaret, Swindon, Wiltshire, SN3 4NS.

13

GUARANTEE

This product is guaranteed against manufacturing

defects for a period of 12 months. This does not cover

the product where the fault is due to misuse, abuse,

use in contravention of the instructions, or where the

product has been the subject of unauthorised

modifications or alterations. This warranty only covers

domestic use and will be void if the tool is used for a

commercial application.

In the event of a problem with the product within the

guarantee period, please contact Customer Service on

01793 333212 or email:

If the issue cannot be resolved over the telephone or by

email, you may be referred to your local approved

service dealer.

Please keep your sales receipt as proof of purchase

Your statutory rights remain unaffected.

Guarantor: Handy Distribution SN3 4NS

Whilst every effort is made to accurately represent the

product, small variations in colour, design and

specification may occur. We reserve the right to alter

the product without giving notice. All images are

illustrative only and may differ from the product due to

ongoing product development.

14

A SELECTION OF QUALITY PRODUCTS FROM OUR VAST RANGE

A SELECTION OF QUALITY PRODUCTS FROM OUR VAST RANGE

HAND PUSH LAWN MOWERS

HAND PUSH LAWN MOWERS

ELECTRIC & PETROL BLOW VACS

ELECTRIC & PETROL BLOW VACS

ELECTRIC & PETROL SHREDDERS

ELECTRIC & PETROL SHREDDERS

ELECTRIC, PETROL & MANUAL

ELECTRIC, PETROL & MANUAL

LOG SPLITTERS

LOG SPLITTERS

LAWN SWEEPERS

LAWN SWEEPERS

PETROL LINE TRIMMERS

PETROL LINE TRIMMERS

PETROL BRUSHCUTTERS

PETROL BRUSHCUTTERS

PETROL MULTICUTTERS

PETROL MULTICUTTERS

ELECTRIC & PETROL CHAINSAWS

ELECTRIC & PETROL CHAINSAWS

LOG SAW HORSES

LOG SAW HORSES

CORDLESS & PETROL

CORDLESS & PETROL

HEDGETRIMMERS

HEDGETRIMMERS

ELECTRIC & PETROL TILLERS

ELECTRIC & PETROL TILLERS

AERATORS & DETHATHERS

AERATORS & DETHATHERS

GARDEN & SALT SPREADERS

GARDEN & SALT SPREADERS

PUSH & TOWED ROLLERS

PUSH & TOWED ROLLERS

SNOW CLEARANCE TOOLS

SNOW CLEARANCE TOOLS

SPRAYERS

SPRAYERS

SACK TRUCKS

SACK TRUCKS

TROLLEYS & TRAILERS

TROLLEYS & TRAILERS

LIGHT CONSTRUCTION

LIGHT CONSTRUCTION

FIND OUT MORE AT WWW.THEHANDY.CO.UK

FIND OUT MORE AT WWW.THEHANDY.CO.UK

15

To order spare parts and see the complete range of garden

machinery and garden equipment from Handy, visit:

www.thehandy.co.uk

Spares & Support: 01793 333212

Other manuals for THSSWB

1

Table of contents

Other The Handy Paper Shredder manuals

The Handy

The Handy THIS User manual

The Handy

The Handy THSS User manual

The Handy

The Handy THHSWB Installation and maintenance instructions

The Handy

The Handy THPDS65 User manual

The Handy

The Handy THIS Installation and maintenance instructions

The Handy

The Handy THIS User manual

The Handy

The Handy THSSWB User manual

The Handy

The Handy THISWB User manual

Popular Paper Shredder manuals by other brands

EBA

EBA 430 E operating instructions

Andrew James

Andrew James Electric Garden Shredder & Ear Protectors manual

Fellowes

Fellowes POWERSHRED 73Ci manual

Q-Connect

Q-Connect CROSS-CUT 10 instruction manual

Lervia

Lervia KH 4402 Operating and safety instructions

QShred

QShred SENTIN-L PROW operating instructions