The Handy THPLT-A Installation and maintenance instructions

OPERATOR’S MANUAL AND PARTS LIST

PETROL LINE TRIMMER - THPLT-A

Spares & Support: 01793 333212

www.thehandy.co.uk

Before use please read & understand this manual, paying particular

attention to the safety instructions.

16/11/2012

Page 2

CONTENTS

SAFETY INSTRUCTIONS 3

SPECIFICATIONS 4

FUEL 5

ASSEMBLY AND OPERATION 6-7

REPLACEMENT OF LINE AND SPOOL 8

MAINTENANCE 9

PARTS DIAGRAM AND LIST 10-11

TROUBLESHOOTING 12

EC DECLARATION OF CONFORMITY 13

Page 3

the line trimmer. Learn its application and limitations as well

reference.

x Use sturdy footwear and a helmet with eye and ear protection.

Protect exposed parts of your body. Wear heavy duty gloves,

preferably made of leather.

x Do not wear loose clothing or jewellery. Keep hair, clothing and

gloves away from moving parts.

x Do not operate the line trimmer if you are tired, ill or under the

x Do not smoke when using the line trimmer and ensure caution

when handling fuel. We recommend you fuel the machine at least

3m away from where you wish to work in case any spilt fuel ignites

when starting the engine.

x Ensure that bystanders, children and pets keep well away when

starting or trimming - at least 15m.

x Inspect the line trimmer, and in particular the trimming head, before

use for any worn or damaged parts. Do not use until the parts are

repaired or replaced.

x Before starting the engine make sure the trimming head is not

in contact with anything and have a clear work area and secure

footing.

x The line trimmer should not be stored in direct sunlight, or

exposed to high temperatures or damp and wet conditions.

Clean the trimmer after each use and, if storing for a prolonged

period, drain down the fuel in the tank. Remove the spark plug

and put a few drops of oil into the cylinder before pulling the

starter a couple of times to distribute the oil evenly. Replace the

spark plug.

SAFETY INSTRUCTIONS

Page 4

SPECIFICATIONS

MODEL THPLT-A

Cutting Diameter 381mm

Max Output Power

Shaft Bent Shaft

Spool Type Bump Feed, twin line

Line Diameter 2mm

Line Length 2mm x 3m

Fuel Tank Capacity 0.6L

Bore and Stroke 34 x 28mm

Fuel Type Unleaded

Fuel Mixture Unleaded Petrol/Oil

Equivalent Spark Plug TORCH L7RTC

Net Weight (Empty Tank) 4.7Kg

Max Engine Idling Speed 3200/min

Min Clutch Engagement Speed 4200/min

Engine Max Speed 7800/min

Fuel Consumption at Max Engine Speed 569g/kw.h

Special Fuel Consumption at Max Engine

Speed

0.56 Kg/h

Engine Displacement 25.4cm³

Declared Sound Power Level 108 dB(A)

Vibration 8m/s²

Gear Ratio 1:1

Max Cutting Speed 7800/min

Page 5

FUEL

Do not or usenear a

fl, or while smoking

Use a ratio of 25:1 unleaded petrol to 2-stroke mineral oil, for synthetic

or semi-synthetic use the oil maker's ratio. Mix in amixing bottle.

Unscrew the fuel cap, and fuel the machine to 80% capacity. Fas-

ten the fuel cap tightly and wipe up any spillage.

Ensure that any stored petrol/oil mixture (2-stroke) is clearly

marked in separate can and only stored for 4-6 weeks. If the line

trimmer is not going to be used for a long period, drain the mixture

from the fuel tank, start the engine and drain the carburettor of

any remaining fuel.

Dispose of any unwanted 2-stroke mixture at an authorised recy-

cling point.

Page 6

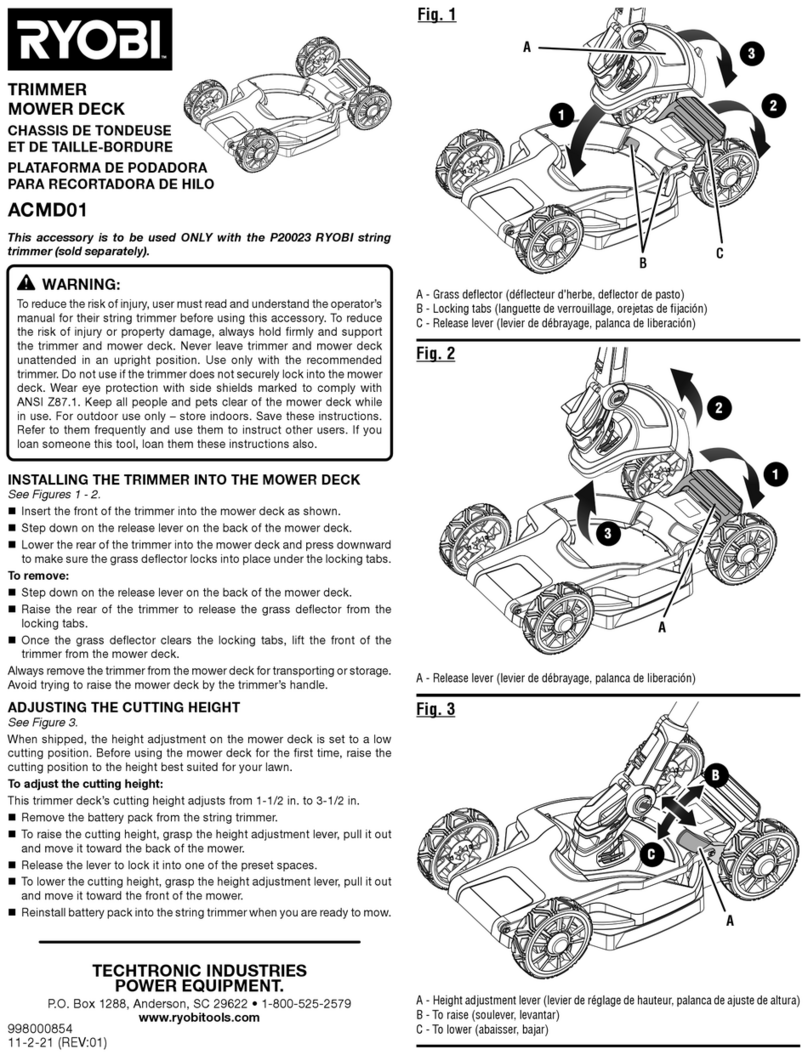

ASSEMBLY AND OPERATION

Disassemble the loop handle.

Position the upper handle over the upper shaft just in front of

-

side of the shaft and should line up with the four screw holes on

the upper handle. Secure with four screws, washers and nuts.

Connect the latch on the shoulder harness to the harness eye,

located on the upper shaft.

Adjust the strap to a comfortable position.

Bnt

The attachment connects to the power unit by means of a

coupler device.

Loosen the knob on the coupler of the upper shaft.

Push in the button on the bent shaft.

Align the button with the guide recess on the coupler and slide

the two shafts together.

Rotate the lower shaft until the button locks in the positioning

hole.

Tighten the knob securely.

Note: If the button does not release completely in the positioning

hole, the shafts are not locked in place. Slightly rotate from side to

side until the button locks.

bracket.

Fix the bolt through the holes in the tabs on the shield and the

slots in the bracket on the attachment shaft.

Tighten securely and remove the protective packaging from the

line cut-off blade.

A

djusting the Throttle Cable:

• After releasing the throttle lever, pull the throttle cable.

• The normal play is 1 or 2 mm when measured at the

carburettor side end.

• If the play is too short or long, take off the air cleaner

cover, loosen the locknut (1) and adjust (2).

Page 7

Place the machine on the floor, as this may make it easier to start.

• Move the ignition switch to the “on” or I position.

Move the choke lever upwards to the “start” position (for cold start only).

Squeeze the safety lever, then the throttle, finally push in the throttle lock button with

your thumb.

Push the choke lever down to the “run” position and pull the starter again until the

Warning: failure to push the choke to the "run" position after the engine has fired will

flood the engine.

Allow the engine to run idle for about 10 seconds to warm it up.

prime the primer bulb.

Release the throttle trigger and allow the engine to idle for a few moments.

Move the ignition switch to the “off” position.

stopped.

securely tightened.

Always position the unit on the operator’s right side. Using it on the left side will expose

the user to the exhaust and hot surfaces which can result in burns.

Hold the trimmer with your right hand on the rear handle and your left hand on the loop

position with the trigger handle about hip height.

Cut tall grass from the top down to prevent the grass wrapping around the shaft housing

and string head which may cause damage from overheating. If grass becomes entangled

stop the engine completely, disconnect the spark plug wire and remove the grass.

Page 8

To replace the line or spool:

Stop the engine.

Remove the bump knob/retaining cap by turning it anti-clockwise.

Remove the empty spool being careful not to lose the spring behind

the head.

Clean the head thoroughly and inspect for any worn or damaged

parts.

To reload the spool with line:-

Cut two lengths of spare line 3 metres long.

Position each line in the two holes located in the centre of the spool,

as in Fig. 13, and wind in the direction of the arrow on the spool

(see Fig. 12) keeping the line tight at all times, as in Fig. 14.

Wind the line on until you have about 15cm left then secure the lines

into the slots on the tabs, as shown in Fig. 15.

Insert the lines on the spool into the eyelets on the trimmer head as

in Fig. 16

Place the spool on the drive shaft.

Release the lines from the tabs by sharply pulling each line while

pushing down on the spool.

Push down on the spool to reveal the drive shaft then place the

bump knob/retaining cap onto the drive shaft as in Fig. 17.

Secure the knob/retaining cap by turning it clockwise.

If you need to replace the whole spool, follow the instructions above,

REPLACEMENT OF SPOOL AND LINE

Page 9

MAINTENANCE

Before carrying out any maintenance, ensure that the trimmer

engine is at a complete standstill.

increase fuel consumption and allow abrasive particles to pass

into the engine.

e-

formance.

the it

Heavy deposits should be washed out in soapy water. Allow

the filter to dry completely.

to

to enter the fuel tank.

end of the fuel pipe and can be extracted by using a piece of

hooked wire.

it

If the inside of the fuel tank is dirty rinse out with petrol.

Check the spark plug after every 10-15 hours of use.

Remove the spark plug cover.

Using the plug spanner supplied, remove the spark plug by

turning it anti-clockwise.

Clean and adjust the gap to 0.6-0.7mm.

Replace the spark plug if it is damaged or visibly worn.

then

tighten fully with the spanner.

We recommend that your petrol line trimmer is serviced after

15 hours of use and thereafter every 2 years.

Page 10

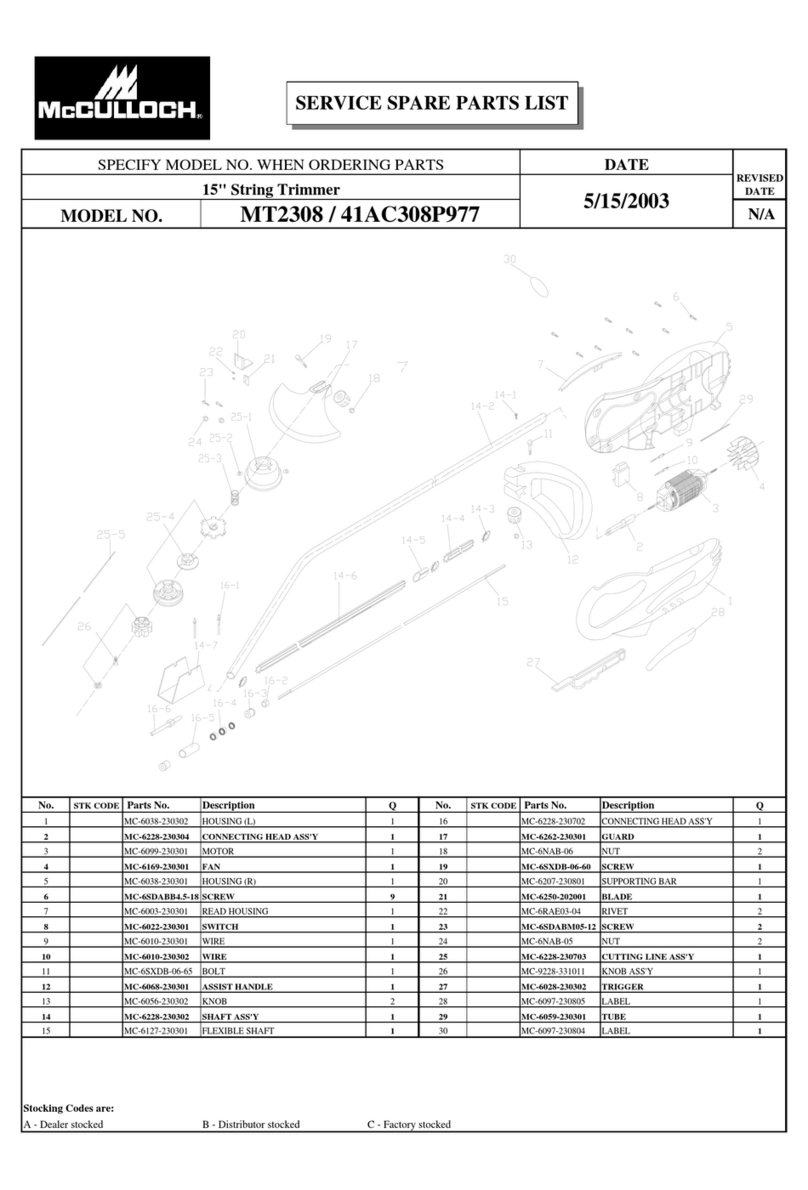

PARTS DIAGRAM

Page 11

PARTS LIST

No Part No Description Qty

1 TH142-1 Hand Wheel 1

2 TH142-2 Coupling 1

3 TH142-3 Throttle Lock 1

4 TH142-4 Throttle Trigger 1

5 TH142-5 Handle Left Side 1

6 TH142-6 Handle Right Side 1

7 TH142-7 Safety Throttle Lever 1

8 TH142-8 On/Off Switch 1

9 TH142-9 “D” Handle 1

No Part No Description Qty

2 TH131-2 Bracket 1

3 TH131-3 Screw 1

4 TH131-4 Nut 1

6 TH131-6 Spool & Cap Assembly 1

7 TH131-7 Shield 1

8 TH131-8 Knob 1

9 TH131-9 Washer 1

Page 12

PARTS DIAGRAM AND LIST - ENGINE

No Part No Desc Qty No Part No Desc Qty

1 TH132-1 Screw 2 25 TH132-25 Flat Washer 2

2 TH132-2 Spring Washer 2 26 TH132-26 Heat Shield 1

3 TH132-3 Flat Washer 2 27 TH132-27 Exhaust 1

4 TH132-4 Filter Housing 1 28 TH132-28 Exhaust Gasket 1

5 TH132-5 Carburettor 1 29 TH132-29 Clips 1

6 TH132-6 Gasket 1 30 TH132-30 Screw 3

7 TH132-7 Screw 2 31 TH132-31 Spring Washer 3

8 TH132-8 Spring Washer 2 32 TH132-32 Flat Washer 3

9 TH132-9 Flat Washer 2 33 TH132-33 Fuel Tank 1

10 TH132-10 Insulator 1 34 TH132-34 Fly Wheel Key 1

11 TH132-11 Gasket 1 35 TH132-35 Fly Wheel 1

12 TH132-12 Spark Plug (ngkbpmr7a) 1 36 TH136-36 Nut 1

13 TH132-13 Engine Cowl 1 37 TH132-37 Spring 2

14 TH132-14 Flat Washer 1 38 TH132-38 Clutch Shoes (Pair) 1

15 TH132-15 Spring Washer 1 39 TH132-39 Washer 2

16 TH132-16 Screw 1 40 TH132-40 Bolt 2

17 TH132-17 Short Engine 1 41 TH132-41 Clutch Drum 1

18 TH132-18 Starter Pawl 1 42 TH132-42 Cir Clip 1

19 TH132-19 Recoil Assy 1 43 TH132-43 Bearing 1

20 TH132-20 Flat Washer 4 44 TH132-44 Screw 2

21 TH132-21 Spring Washer 4 45 TH132-45 Spring Washer 2

22 TH132-22 Screw 4 46 TH132-46 Flat Washer 2

23 TH132-23 Screw 2 47 TH132-47 Coil1

24 TH132-24 Spring Washer 2

Page 13

TROUBLE SHOOTING

PROBLEM

Power loss or sudden stop-

ping

Fuel Tank Empty

Mixture not reaching car-

burettor

Water in mixture

Carbon deposits in cyl-

inder, exhaust pipe or

Add fuel

Drain and rinse out fuel

system

Clean all affected parts or

Engine runs but blade will not

turn

Jammed in gearbox Take to authorised repair

agent

Unit is smoking Unit is Faulty - Take to authorised repair

agent

Line will not advance when

restarting engine

Line is welded to itself

Not enough line on spool

Line has worn too short

Line is tangled on spool

Lubricate with silicone

spray

Add more line

Pull lines whilst alternately

pressing down on and

releasing the bump button

Remove line from the

spool and rewind

Cutting head is hard to turn Grass wrapped or built up

around head

Clean affected parts

Grass wraps round

attachment shaft and head

assembly

Cutting tall grass at ground

level

Cut tall grass from the top

down.

Page 14

EC DECLARATION OF CONFORMITY

Declaration of Conformity

Pursuant to the regulations of the following EC Directives:

- Electromagnetic Compatability Directive 2004/108/EC

- Machinery Directive 2006/42/EC

- Engine Emission Directive 2002/88/EC

Handy Distribution Ltd hereby declares that the product:

Machine Type: 25cc Line Trimmer

Machine Model: THPLT-A

Engine Displacement: 25.4 cm³

Max Motor Power: 0.75Kw

Max Engine Speed:

Mass in Kg:

Cutting Capacity:

Conforms to the main safety requirements of the EC Directives listed above.

This conformity is based on the following standards and normative documents:

2006/42/EC/Annex I

EN ISO 11806: 2008

EN ISO 14982: 1998

Measured Sound Power Level: 107.3dB(A)

Guaranteed Sound Power Level: 108dB(A)

Name: Mr Simon Belcher

Title: Managing Director

Company: Handy Distribution Ltd

Address: Hobley Drive, Stratton St Margaret, SWINDON, SN3 4NS

Signature: Date: 15th Feb 2010

To order spare parts and see the complete range of garden

machinery and garden equipment from Handy, visit:

www.thehandy.co.uk

Spares & Support: 01793 333212

Table of contents

Other The Handy Trimmer manuals

The Handy

The Handy THEPHT User manual

The Handy

The Handy THPKLRT User manual

The Handy

The Handy THHC22DB User manual

The Handy

The Handy THPLT Installation and maintenance instructions

The Handy

The Handy THLRT2600 Installation and maintenance instructions

The Handy

The Handy THBC26 Installation and maintenance instructions

The Handy

The Handy THMC-A User manual

The Handy

The Handy THEPHT500 User manual

The Handy

The Handy THGSS User manual

The Handy

The Handy THHC30SB Installation and maintenance instructions