The Handy THHC22DB User manual

Page 1

OPERATOR’S MANUAL AND PARTS LIST

PETROL HEDGE TRIMMER - THHC22DB

Sales & Helpline 01793 333220

www.thehandy.co.uk

Before use please read & understand this manual, paying particular

attention to the safety instructions.

2010 v1

Page 2

CONTENTS

SAFETY INSTRUCTIONS 3

SPECIFICATIONS 4

MAJOR PARTS 4

FUEL 5

OPERATION 6

HINTS AND TIPS 7

MAINTENANCE 8

PARTS DIAGRAMS 10-13

EC DECLARATION OF CONFORMITY 14

Page 3

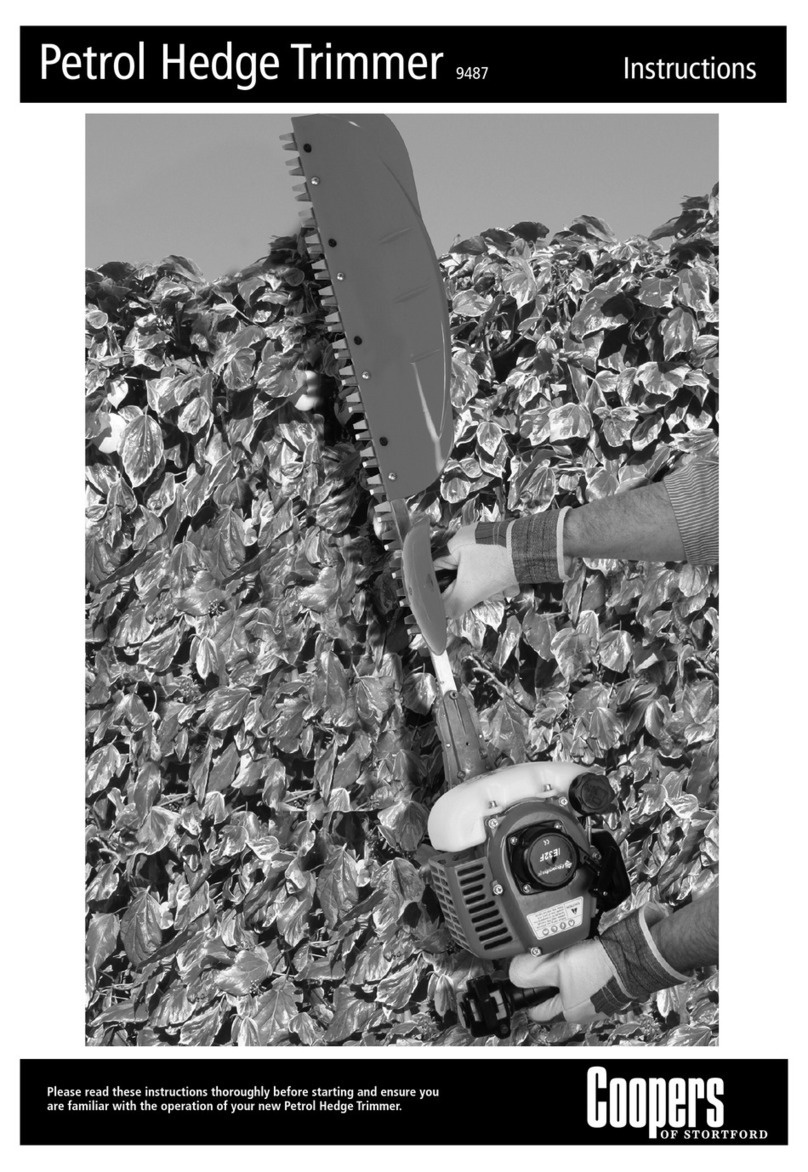

SAFETY INSTRUCTIONS

Read and understand the owner’s manual and labels afxed to the hedge

trimmer. Learn its application and limitations as well as the specic potential

hazards. Retain these instructions for reference.

• Use sturdy footwear and a helmet with eye and ear protection.

Protect exposed parts of your body. Wear heavy duty gloves, preferably

made of leather.

• Do NOT operate the hedge trimmer if you are tired,ill or under the inuence

of alcohol or drugs.

• Do NOT smoke when using the hedge trimmer and ensure caution when

handling fuel. We recommend you fuel the machine at least 3m away from

where you wish to work in case any spilt fuel ignites when starting the engine.

• Ensure that bystanders, children and pets keep well away when starting or

cutting - at least 15m.

• Inspect the hedge trimmer, and in particular the cutter blade, before use

for any worn or damaged parts. Do not use until the parts are repaired or

replaced.

• Before starting the engine make sure the cutter blade is not in contact with

anything and have a clear work area and secure footing.

• Hold the hedge trimmer rmly with both hands when using and keep all parts

of your body away from the machine. Always ensure a safe rm footing and

do not over-reach.

• Always carry the hedge trimmer with the engine stopped and the cutter blade

covered.

• Never lay the hot hedge trimmer down on dry grass or any combustible

material where there is a re risk from the hot engine.

• Only use the hedge trimmer in good light and visibility. During cold weather be

aware of slippery or wet areas.

• NEVER operate the hedge trimmer in a tree or from a ladder.

• NEVER feed twigs or other material to be cut into the cutter blade with your

hands. Do not lift the hedge trimmer by the cutter blades and be aware that

the blades may run on after the engine has stopped.

• Please recycle the cardboard packaging in which the hedge trimmer is

delivered.

Always shut off the engine before setting it down.

Page 4

SPECIFICATIONS

Model No THHC22DB

Weight ( with blade cover) 5.2kg

Fuel Tank Capacity 600 ml

Engine Displacement 22.5 cm³

Handle 5 Position Twist Grip Handle

Cutting Length 510 mm

Maximum Engine Performance 0.65 Kw

Maximum Blade Speed 1.53 m/s

Idling Speed 3000 per min

Clutch Engagement Speed 3800 per min

Carburettor Type Ruixin/huayi

Ignition System Hic

Spark Plug BPM6A

Electrode Gap 0.6~0.7

Mixture Ratio 25:1

Gear Ratio 14:58

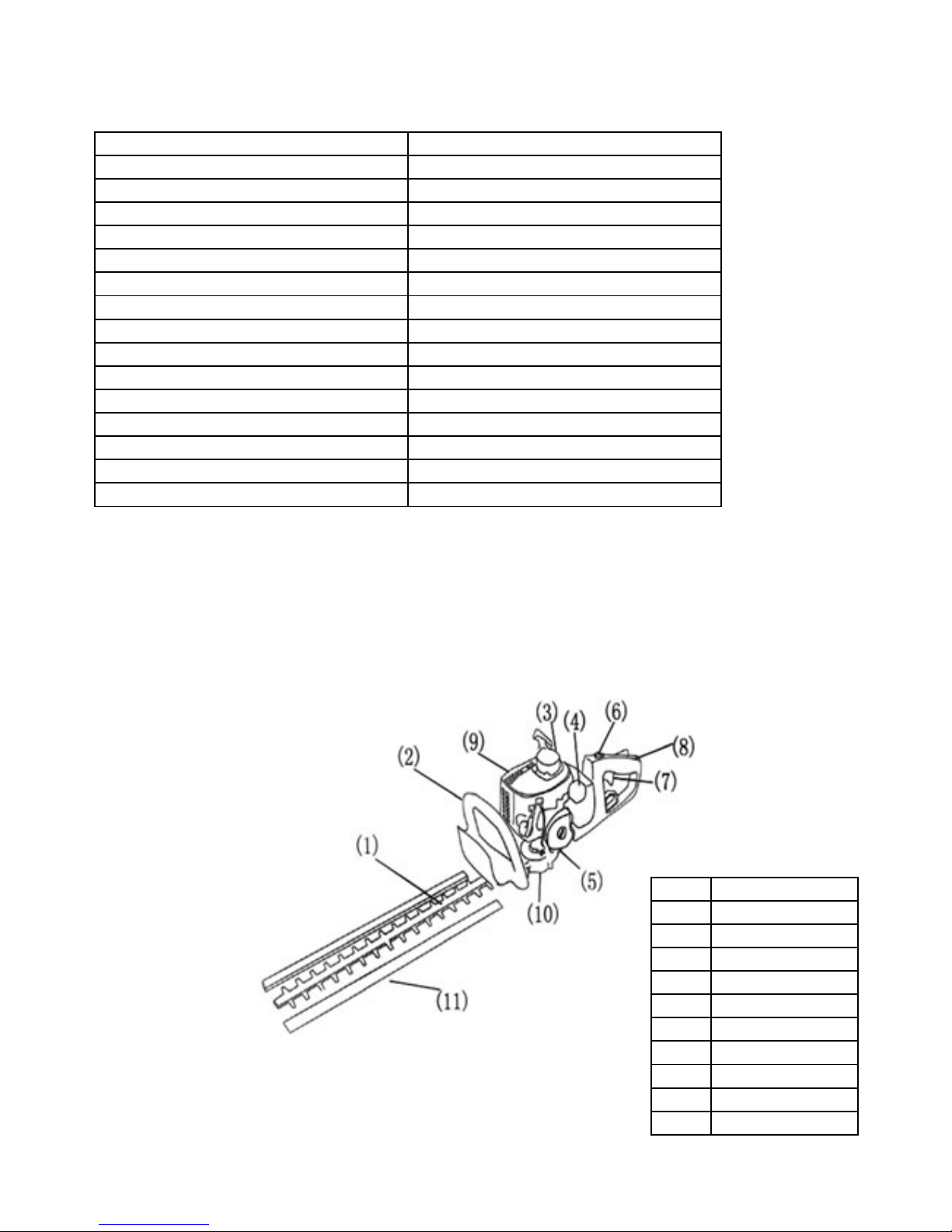

MAJOR PARTS

1 Blade

2 Front Handle

3 Recoil Starter

4 Fuel Tank Cap

5 Carburettor

6 On/Off Switch

7 Throttle Lever

8 Rear Handle

9Mufer

10 Gearbox

11 Blade Cover

Page 5

FUEL

Petrol is very ammable. Avoid smoking or fuelling the hedge

trimmer anywhere near a ame or sparks. Allow the engine to cool be-

fore re-fuelling. Fuel the engine at least 3m away from your work area.

• Use a mixture of 25 parts unleaded petrol to 1 part 2-stroke engine oil (25:1)

and mix in the mixing bottle provided. Agitate well.

• Unscrew the fuel cap, and fuel the machine to 80% capacity. Fasten the fuel

cap tightly and wipe up any spillage.

• Ensure that any stored petrol/oil mixture ( 2-stroke) is clearly marked in sepa-

rate can and only stored for 4-6 weeks. If the hedge trimmer is not going to

be used for a long period, drain the mixture from the fuel tank, start the engine

and drain the carburettor of any remaining fuel.

• Dispose of any unwanted 2-stroke mixture at an authorised recycling point.

Page 6

OPERATION

Before use, check that the cutter blade is not damaged, the handles controls

are easy to use and that the STOP On/Off switch operates correctly.

The idling speed should be set so that the blades do not move whilst the en-

gine is idling.

1. Pull the STOP switch backwards.

2. Squeeze lock lever A and then the throttle lever B.

3. Keeping throttle lever B depressed, press throttle lock C inward.

4. Keeping throttle lock C depressed, release throttle lever B - this will lock

throttle lever B in position.

5. Gently depress the primer pump 7-10 times until fuel comes into the primer

pump.

6. Move the choke lever to ‘open’.

7. Holding the unit down rmly, slowly pull the starter cord until resistance is

felt and continue with a sharp pull until the engine res.

8. Move the choke lever to ‘closed’ and pull the starter cord again until the

engine res.

9. As soon as the engine starts, squeeze and release the throttle, thus releas-

ing the throttle lever B so that the engine can idle.

10. Run the engine for approximately one minute at moderate speed before

applying full speed.

• If starting a warm engine, try procedures 1, 7 and 8. If the engine does not

start repeat the whole procedure from step 1.

To Stop the Machine:-

• Release the throttle lever completely and push the STOP switch forward.

Page 7

Always hold the hedge trimmer rmly with both hands when using.

Before cutting ensure that the blades are running at full speed and be aware that

the blades may keep moving after you have released the throttle.

This hedge trimmer has a twist handle which rotates through 180 degrees and is

ideal for cutting shaped hedges.

It is advisable to cut a hedge from the bottom up sweeping the cutter bar in an arc

as you move along the hedge. The double edged cutter blades allows use by left or

right handed operators.

To cut the top of the hedge, hold the cutter bar at an angle of 0-10 degrees as you

swing the hedge trimmer horizontally. Sweep the cutter bar in an arc towards the

outside of the hedge so that the cuttings are swept onto the ground.

Pay special attention when cutting hedges which are laid out along a wire fence. If

the blades makes contact with the wire damage may occur.

Do not use the hedge trimmer for long periods at a time - take a break of 10-15

mins after 50 mins use or after using one tank of fuel.

If the blades hit a stone, wire or other foreign object, turn off the engine and check

for any damage immediately. Replace any damaged blades before continuing.

Do not attempt to remove any twigs or branches jammed in the cutter blades with-

out rst turning the machine off.

HINTS AND TIPS

Page 8

MAINTENANCE

To ensure a long service life and to avoid any damage to the hedge trimmer. per-

form the following maintenance at regular intervals.

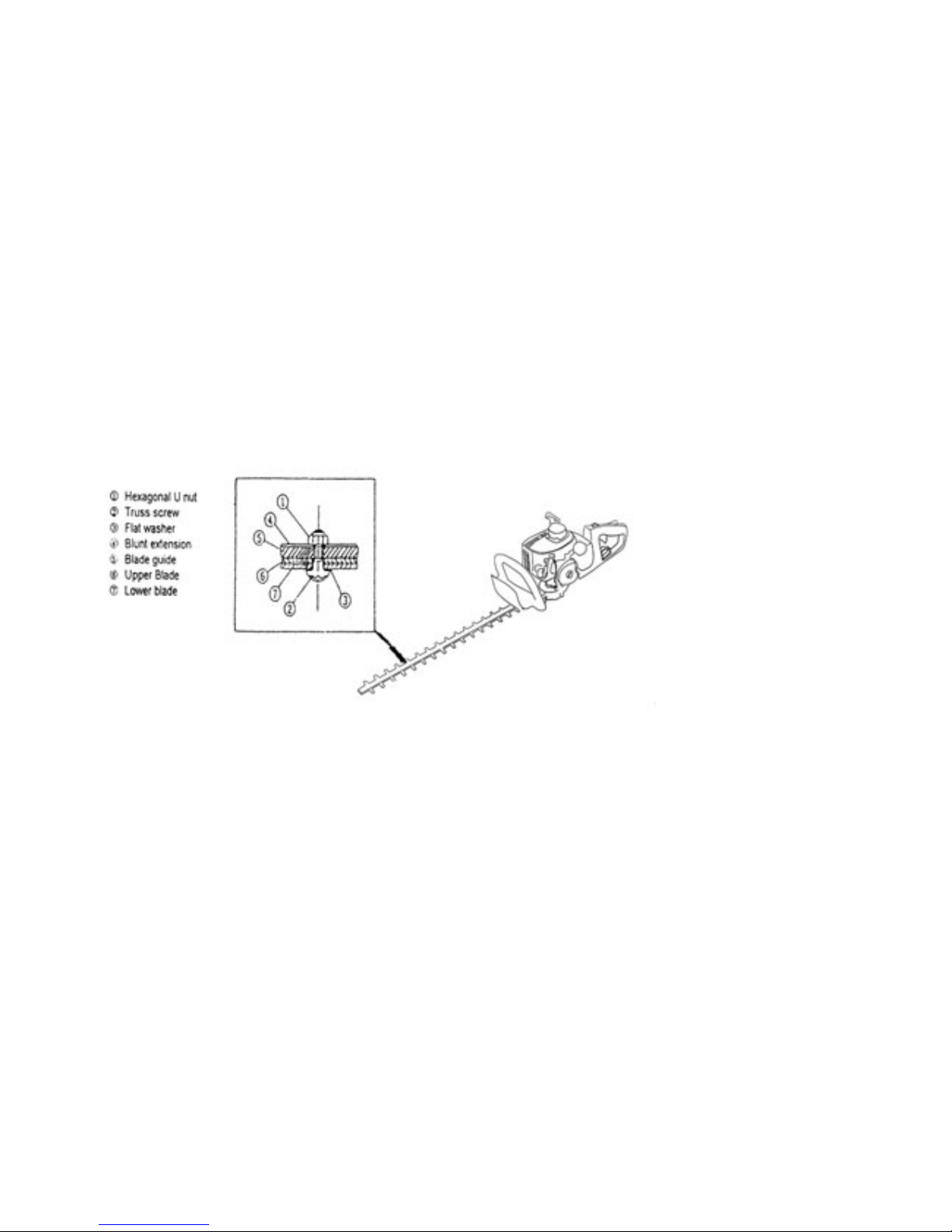

Blade Adjustment:

After a period of time the blades may need adjusting.

Refer to the diagram below and follow these guidelines:

1. Loosen nut 1.

2. Turn screw 2lightly until it stops turning and the turn back ¼ -½ turn.

3. Tighten nut 1whilst holding screw 2.

4. Lubricate blades with light oil after adjustments.

5. Start the engine and operate throttle on and off for a minute making sure the

blades run freely.

Page 9

STORAGE

When storing the hedge trimmer for any length of time it is important to drain

down the fuel, both in the tank and the carburettor. Either drain the fuel manually

or run the engine until it uses up all the fuel.

Remove the spark plug and add a few drops of oil into the spark plug hole.

Pull the starter cord gently to conrm that a lm of oil covers the engine inside.

Tighten the spark plug.

Clean dirt or dust from the cutter blade and the outside of the machine and wipe

with an oily cloth.

Store in a dry place.

Air Filter:

Check and clean the Air Filter regularly to ensure optimum performance.

Remove the air lter cover, take out the sponge element and wash in lukewarm

water. Allow to dry completely and then replace. Clean off any excessive dirt and

dust.

Spark Plug:

Check the spark plug periodically and ensure that the gap between the electrodes

is between 0.6 and 0.7mm. Adjust where necessary using the universal wrench

supplied. If the spark plug is clogged with carbon, clean thoroughly or replace.

Grease:

Supply grease to the gear case through the grease hole every 10 to 20 hours

using a good quality grease.

Page 10

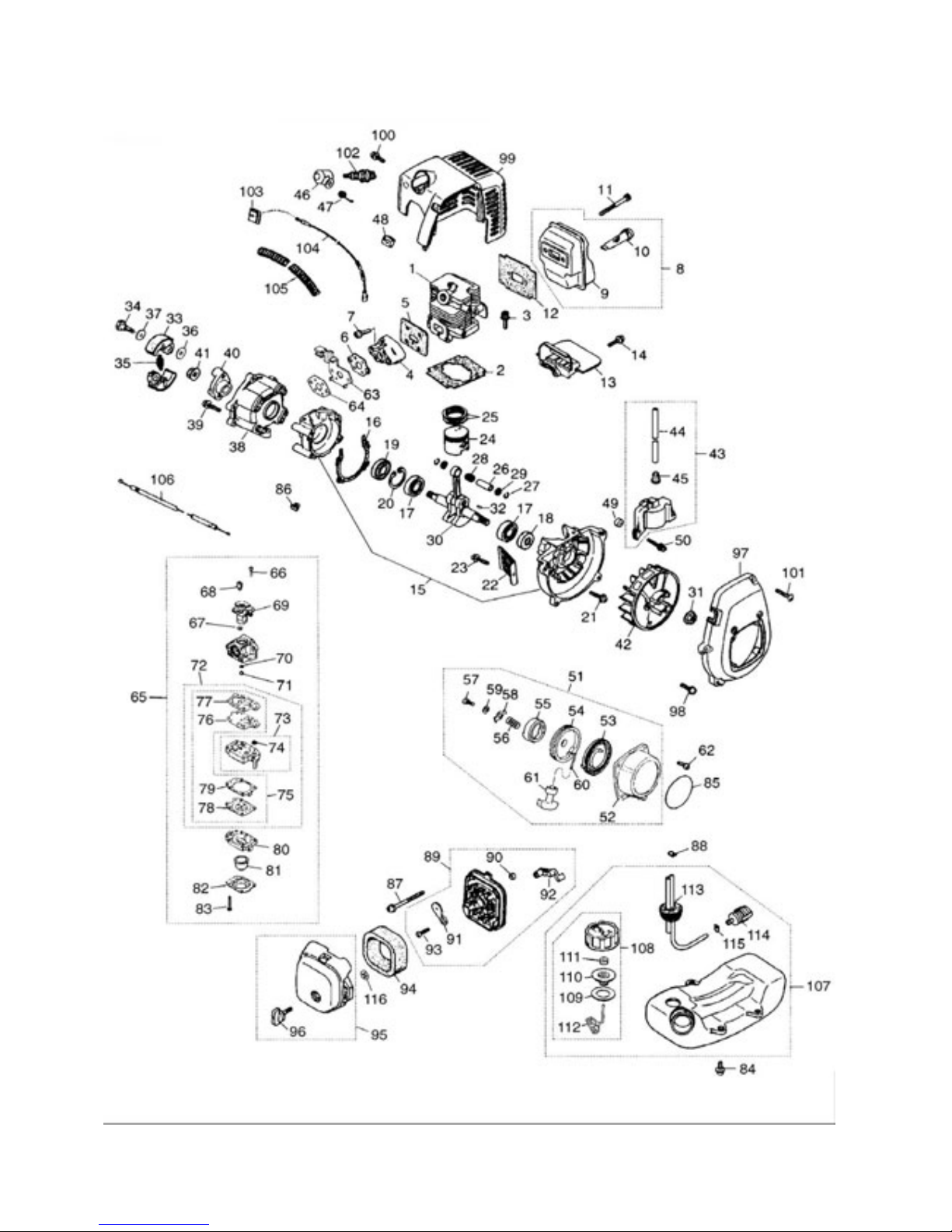

PARTS - ENGINE

Page 11

PARTS - ENGINE

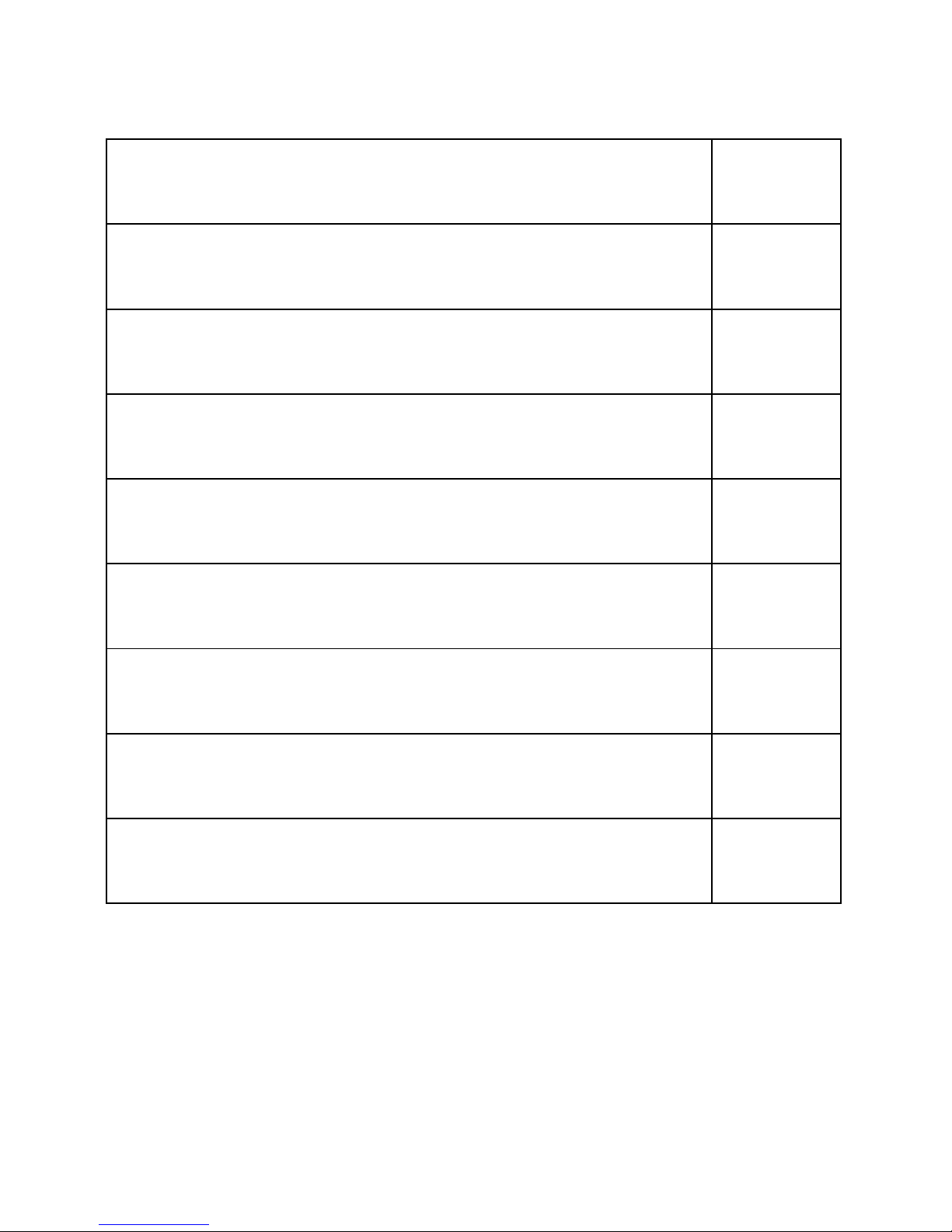

No Part No Desc Qty No Part No Desc Qty No Part No Desc Qty

1 TH118-1 Cylinder 1 2 TH118-2 Gasket, base 1 3 TH118-3 Bolt M5x22 2

4 TH118-4 Insulator 1 5 TH118-5 Gasket, insula-

tor

1 6 TH118-6 Gasket, carb 1

7 TH118-7 Screw M5x20 2 8 TH118-8 Mufer Assy 1 9 TH118-9 Mufer 1

10 TH118-10 Spark Arrester 1 11 TH118-11 Bolt M5x50 2 12 TH118-12 Gasket, mufer 1

13 TH118-13 Plate, mufer 1 14 TH118-14 Screw M4x16 1 15 TH118-15 Crankcase,

comp

1

16 TH118-16 Gasket, case 1 17 TH118-17 Bearing 2 18 TH118-18 Oil Seal 1

19 TH118-19 Oil Seal 1 20 TH118-20 Snap Ring 1 21 TH118-21 Bolt M5x30 4

22 TH118-22 Guard 1 23 TH118-23 Screw M5x14 1 24 TH118-24 Piston 1

25 TH118-25 Ring, piston 2 26 TH118-26 Pin, piston 1 27 TH118-27 Snap Ring 2

28 TH118-28 Bearing 1 29 TH118-29 Washer 2 30 TH118-30 Crankshaft

comp

1

31 TH118-31 Nut 1 32 TH118-32 Key 1 33 TH118-33 Shoe 2

34 TH118-34 Screw 2 35 TH118-35 Spring 1 36 TH118-36 Washer 2

37 TH118-37 Washer 2 38 TH118-38 Case, clutch 1 39 TH118-39 Screw M5x16 4

40 TH118-40 Plate, clutch 1 41 TH118-41 Nut 1 42 TH118-42 Rotor 1

43 TH118-43 Coil Assy 1 44 TH118-44 Cord 1 45 TH118-45 Cap 1

46 TH118-46 Cap, spark plug 1 47 TH118-47 Spring 1 48 TH118-48 Grommet 1

49 TH118-49 Spacer 2 50 TH118-50 Bolt M4x25 2 51 TH118-51 Recoil Assy 1

52 TH118-52 Case, recoil 1 53 TH118-53 Spring, spiral 1 54 TH118-54 Reel 1

55 TH118-55 Ratchet 1 56 TH118-56 Spring 1 57 TH118-57 Screw 1

58 TH118-58 Retainer 1 59 TH118-59 Washer 1 60 TH118-60 Rope 1

61 TH118-61 Knob 1 62 TH118-62 Screw 4 63 TH118-63 Bracket 1

64 TH118-64 Gasket, carb 1 65 TH118-65 Carburettor

Assy

1 66 TH118-66 Screw 1

67 TH118-67 Ring 1 68 TH118-68 Swivel 1 69 TH118-69 Valve Assy 1

70 TH118-70 O-Ring 1 71 TH118-71 Jet No 37 1 72 TH118-72 Rebuild Kit 1

73 TH118-73 Body Assy 1 74 TH118-74 Screen 1 75 TH118-75 Gasket Kit 1

76 TH118-76 Diaphragm, pump 1 77 TH118-77 Gasket, pump 1 78 TH118-78 Diaphragm 1

79 TH118-79 Gasket, dia-

phragm

1 80 TH118-80 Body, purge 1 81 TH118-81 Pump, priming 1

82 TH118-82 Cover, pump 1 83 TH118-83 Screw 4 84 TH118-84 Screw 3

85 TH118-85 Label, recoil 1 86 TH118-86 Cap 1 87 TH118-87 Screw M5x60 2

88 TH118-88 Clip 1 89 TH118-89 Body Assy 1 90 TH118-90 Sleeve 2

91 TH118-91 Plate, choke 1 92 TH118-92 Lever, choke 1 93 TH118-93 Screw 1

94 TH118-94 Element 1 95 TH118-95 Cover Assy 1 96 TH118-96 Knob 1

97 TH118-97 Cover, fan 4 98 TH118-98 Screw M5x20 4 99 TH118-99 Cover, engine 1

100 TH118-

100

Screw M5x12 1 101 TH118-

101

Screw 1 102 TH118-

102

Spark Plug 1

103 TH118-

103

Grommet 1 104 TH118-

104

Cord, comp 1 105 TH118-

105

Tube 1

106 TH118-

106

Cable, comp 1 107 TH118-

107

Tank Assy 1 108 TH118-

108

Cap Assy 1

109 TH118-

109

Packing 1 110 TH118-

110

Holder 1 111 TH118-

111

Filter 1

112 TH118-

112

Stopper 1 113 TH118-

113

Pipe, comp 1 114 TH118-

114

Filter Assy 1

115 TH118-

115

Clip 1 116 TH118-

116

Clip 1

Page 12

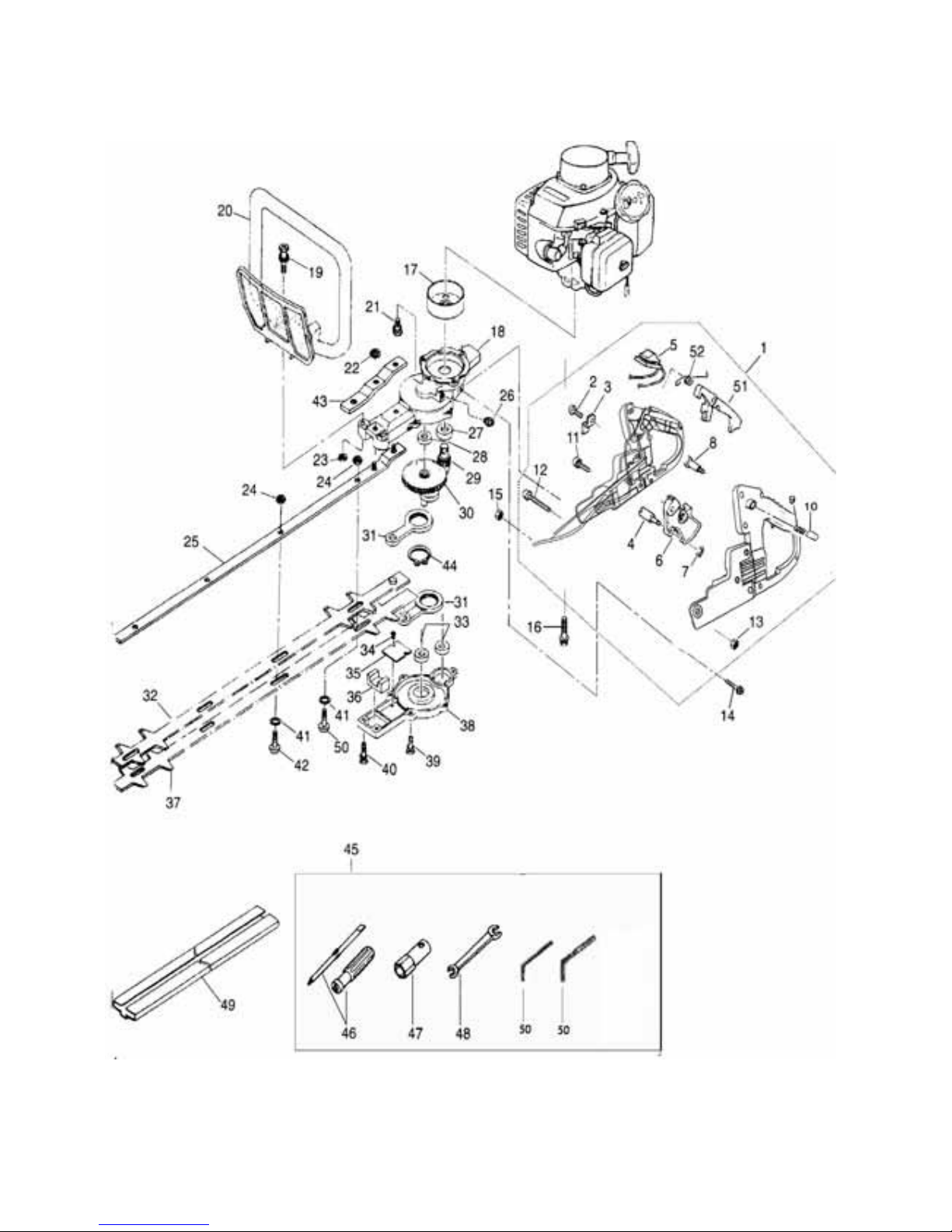

PARTS - CUTTER

Page 13

PARTS - CUTTER

No Part No Description Qty No Part No Description Qty

1 TH116-1 Rear Handle Assy 1 2 TH116-2 Screw M4x10 1

3 TH116-3 Plate 1 4 TH116-4 Cable End 1

5 TH116-5 Switch Assy 1 6 TH116-6 Throttle Lever 1

7 TH116-7 Snap Ring 1 8 TH116-8 Pin 1

9 TH116-9 Spring 1 10 TH116-10 Cap 1

11 TH116-11 Screw M4x16 5 12 TH116-12 Screw M4x30 1

13 TH116-13 Nut M6 6 14 TH116-14 Bolt M6x50 1

15 TH116-15 Nut M6 1 16 TH116-16 Bolt M6x40 1

17 TH116-17 Clutch Drum 1 18 TH116-18 Middle Case 1

19 TH116-19 Bolt M6x35 2 20 TH116-20 Front Handle 1

21 TH116-21 Bolt M6x14 2 22 TH116-22 Nut M5 2

23 TH116-23 Nut M6 2 24 TH116-24 Nut M6U 4

25 TH116-25 Guide Plate 1 26 TH116-26 Grease Fitting 1

27 TH116-27 Bearing 6001 2RS 1 28 TH116-28 Bearing 608Z 1

29 TH116-29 Pinion 1 30 TH116-30 Gear Comp 1

31 TH116-31 Rod Assy 2 32 TH116-32 Upper Blade 1

33 TH116-33 Bearing 608Z 2 34 TH116-34 Screw M3x5 2

35 TH116-35 Plate 1 36 TH116-36 Felt 1

37 TH116-37 Lower Blade 1 38 TH116-38 Lower Case 1

39 TH116-39 Bolt M5x16 5 40 TH116-40 Bolt M5x20 2

41 TH116-41 Washer 4 42 TH116-42 Screw M6x19 3

43 TH116-43 Plate 1 44 TH116-44 Snap Ring 1

45 TH116-45 Tool Set 1 46 TH116-46 Screwdriver 1

47 TH116-47 Socket Hex ¾” 1 48 TH116-48 Spanner 8x10 1

49 TH116-49 Cover, blade 1 50 TH116-50 Screw M6x22 1

51 TH116-51 Spanner 1

Page 14

EC DECLARATION OF CONFORMITY

Declaration of Conformity

Pursuant to the regulations of the following EC Directives:

- Electromagnetic Compatibility Directive 2004/108/EC

- Machinery Directive 2006/42/EC

Handy Distribution Ltd hereby declares that the product

Machine type: Petrol Hedge Trimmer

Machine model: THHC22DB

Engine Displacement: 22.5cm³

Max Motor Power: 0.65KW

Max Engine Speed: 7500/min

Cutting Speed: 1800/min

Mass in kg: 5.2kg

Cutting Length: 510mm

conforms to the main safety requirements of the EC Directives listed above.

This conformity is based on the following standards and normative documents:

EN 774

EN ISO 14982:1998

Measured Sound Power Level: 103.8dB(A)

Guaranteed Sound Power Level: 108dB (A)

The responsible person, based within the EC, is identied below

Name: Mr. Simon Belcher

Title: Managing Director

Company: Handy Distribution Ltd

Address: Hobley Drive, Stratton St Margaret, Swindon, Wiltshire, SN3 4NS

Signature : Date: 15th Nov 2009

Page 15

To order spare parts and see the complete range of garden

machinery and garden equipment from Handy, visit:

www.thehandy.co.uk

Table of contents

Other The Handy Trimmer manuals

The Handy

The Handy THEPHT User manual

The Handy

The Handy THPLT Installation and maintenance instructions

The Handy

The Handy THBC26 Installation and maintenance instructions

The Handy

The Handy THPLT-A Installation and maintenance instructions

The Handy

The Handy THHC30SB Installation and maintenance instructions

The Handy

The Handy THEPHT500 User manual

The Handy

The Handy THGSS User manual

The Handy

The Handy THMC-A User manual

The Handy

The Handy THLRT2600 Installation and maintenance instructions

The Handy

The Handy THPKLRT User manual