The Human Solution Uplift 80 User manual

2 of 44

Contents

1. Preface ................................................................................................................ 4

1.1 Intended use................................................................................................. 4

1.2 Uplift 800 control unit functionality................................................................. 4

1.3 Target group and previous knowledge ......................................................... 5

1.4 Symbols used in safety instructions.............................................................. 5

1.5 ISP (Intelligent System Protection)............................................................... 6

1.6 Package contents......................................................................................... 7

1.7 Unpacking .................................................................................................... 7

1.8 Safety instructions ........................................................................................ 7

1.8.1 General safety instructions.................................................................... 8

1.8.2 Important notes for OEMs ................................................................... 10

1.9 Important note for service........................................................................... 10

2. Uplift 800 installation instructions ....................................................................... 11

3. Commissioning .................................................................................................. 12

3.1 Uplift 800 sockets....................................................................................... 12

3.2 Commissioning procedure.......................................................................... 13

3.2.1 Connect drives .................................................................................... 13

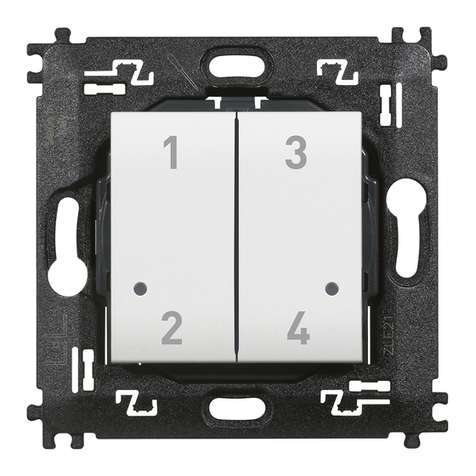

3.2.2 Connect handswitch ............................................................................ 13

3.2.3 Connect mains supply ......................................................................... 13

3.2.4 System configuration (example) .......................................................... 14

4. Operating the Uplift 800 control unit .................................................................. 16

4.1 Basic functions ........................................................................................... 16

4.1.1 Upward desktop movement................................................................. 16

4.1.2 Downward desktop movement ............................................................ 17

4.2 Advanced functions .................................................................................... 17

4.2.1 Saving a desktop position ................................................................... 17

4.2.2 Adjusting the desktop to a saved position ........................................... 18

4.2.3 Changing the desktop height displayed............................................... 19

4.2.4 Manual reset – first and second motor group ...................................... 20

4.3 Software-dependent functions.................................................................... 22

4.3.1 Key lock............................................................................................... 22

4.3.2 Slow speed ranges.............................................................................. 22

4.3.3 Container- and Shelf-Stop positions.................................................... 23

4.3.4 Automatic drive recognition ................................................................. 25

4.3.5 Drive Back........................................................................................... 26

4.3.6 Duty cycle monitoring .......................................................................... 26

4.3.7 Change the displayed desktop position (cm or inch)........................... 27

4.3.8 Cascading ........................................................................................... 27

4.3.9 Reset control unit to factory settings ................................................... 30

5. Sensor ............................................................................................................... 31

6. Programmable dongle ....................................................................................... 33

6.1 Parameterizing individual controls ......................................................... 33

7. Technical data ................................................................................................... 35

8. Appendix............................................................................................................ 37

8.1 Possible faults and remedies...................................................................... 37

8.2 Error messages on the handswitch display ................................................ 38

8.3 Click codes ................................................................................................. 40

9. Hand Switches Overview................................................................................... 41

LU – Hand Switch ................................................................................................. 41

3 of 44

Display overview ................................................................................................... 41

9.1. End of life disposal ..................................................................................... 43

9.2. Standards ................................................................................................... 44

9.3. Declarations of conformity .......................................................................... 44

9.4. Manufacturer .............................................................................................. 44

4 of 44

1. Preface

Dear Customer,

Thank you for choosing an electrically height-adjustable desk from 7KH+XPDQ 6ROXWLRQ

You are now in possession of a state-of-the-art product that compiles with all the relevant

safety requirements.

1.1 Intended use

Uplift 800 control units may only be used for the intended purpose, i.e. to control electric

height-adjustable desks. Only motors that meet 7KH+XPDQ6ROXWLRQ

specifications may be used to drive the lifting devices. The control units must

be installed, put into operation and their function checked by qualified personnel.

Using them to control other motors or installing them in products other than electric

height-adjustable desks is only permissible with the prior written consent of 7KH+XPDQ

6ROXWLRQ. Their basic function is upwards and downwards adjustment of the desktop,

which can be controlled with all the handswitches available.

1.2 8SOLIW control unit functionality

The Uplift 800 control units incorporate the following features (the availability of some of

the features depends on the handswitch used):

• Control unit with 3 motor channels

• High efficient switch mode power supply (SMPS)

• Low standby power consumption, low field emission

• Control units with US and EU input voltage available

• Up to 2 motor groups

• ISP (Intelligent System Protection)

• Enhanced Drive Comfort

• Container- and Shelf-Stop

• Low speed area

• InBox Diagnosis

• LogicConnector DATA for sensors and cascading

• Additional functions are available, depending on the handswitch model used

(e.g. saving desktop positions, adjusting the desktop to saved positions, etc.)

• Depending on your needs, you have a choice of two switches for installation

underneath the tabletop and one tabletop switch.

5 of 44

1.3 Target group and previous knowledge

This user manual addresses the following people:

• Technicians who assemble and put electric height-adjustable desks into operation

(by installing motors and control units, configuring control units, etc.)

• Furniture assembly, service and maintenance personnel who put electric height-

adjustable desks into operation in showrooms or at the customer’s

The following is required for installing, operating and configuring electric height-

adjustable desks with Uplift 800 control units:

• Basic mechanical and electrical skills (with suitable qualifications)

• Reading the user manual

1.4 Symbols used in safety instructions

This user manual contains safety instructions with symbols to approach your

attention to possible dangers and residual risks. They indicate the following:

Danger: this warning symbol advises you of imminent danger to people’s

lives and health.

Failure to observe this warning may result in health problems, serious

injuries and damage to property.

Caution: th is w arning adv ises you of p ossible dang ers f rom el ectric

current.

Failure to observe this warning may cause injuries and damage to

property.

Note: t his sym bol adv ises you of important i nformation that m ust be

noted for operating the Uplift 800 control unit safely.

Danger: this warning advises you of a poss ible risk of body parts being

trapped or pinched in exceptional cases.

Failure to observe this warning may result in health problems, serious

injuries and damage to property.

Note: you must read the user manual.

6 of 44

1.5 ISP (Intelligent System Protection)

ISP is an electronic state-of-the-art protection system developed by 7KH+XPDQ6ROXWLRQ

It also substantially reduces the risk for fingers being trapped or pinched.

Danger: i n spi te of IS P bei ng i n p lace, there m ay sti ll be a r isk of

pinching in exceptional cases, as it is not o nly the control unit, but also

the inter action betw een th e m echanical and el ectronic syst ems that i s

responsible for cu tting ou t the m otor. In add ition, t he m echanical

components, motor and ambient conditions all affect cut-out sensitivity.

As the control unit distributer, 7KH+XPDQ6ROXWLRQ cannot therefore

eliminate this residual risk completely or accept any liability.

Note: the ISP-sensitivity and the IS P-cutoff value depend on the w hole

system (mechanical and electrical components).

Note: as soon as IS P has stopped th e el ectric he ight-adjustable desk

from moving, you can t hen o nly adj ust th e desktop in the o pposite

direction (the safety feature initially prevents you from adjusting the desk

in the same direction as triggered it).

Attention – Safety Notice: E ven w hen equi pped w ith a sensor , the

collision protection is by no m eans cons idered personal pr otection

equipment and may not be classified and described as such!

7 of 44

1.6 Package contents

The standard scope of delivery consists of one control unit.

1

Figure 1: Package contents

c Uplift 800 control unit

1.7 Unpacking

The Uplift 800 control unit comes packed in a cardboard box. To unpack, proceed as

follows:

1. Remove the cardboard.

2. Dispose of the packaging materials.

3. Keep the user manual at hand for the operators.

Note: ensure eco-friendly disposal of the packaging materials (separate

the plastic parts and cardboard for collection).

1.8 Safety instructions

This user manual contains safety instructions that draw your attention to any possible

risks, thus enabling safe operation of the Uplift 800 control unit. Please observe these

warnings and instructions at all times.

In this section you will find general safety instructions that do not refer to any

particular steps or procedures. You will find the work-specific safety instructions in

the relevant section of the manual. Additional warnings are given on the Uplift 800

control unit itself.

8 of 44

1.8.1 General safety instructions

Note: you m ust read t he us er m anual ca refully b efore installing or

operating the Uplift 800 control unit.

Caution: do not open the Uplift 800 control unit under any c ircumstances.

There is a danger of electric shock.

Caution: the Uplift 800 control unit is not designed for continuous operation.

Changing the desktop position without interruption must not ex ceed the

duty cycle indicated on the nameplate.

Caution: the Uplift 800 control unit may only be operated with mains voltage

as specified on the type plate.

Uplift 800 contro l u nits are also ava ilable fo r th e mains vo ltages used in

other countries.

Caution: only use the power cord sup plied with the contr ol unit. Check

that it is not dam aged. Do not ever ope rate the Uplift 800 control unit if the

power cord is damaged.

Danger: i t is not a llowed to connect self constructed p roducts to

7KH+XPDQ6ROXWLRQ motor co ntrols. To prev ent damage of the unit

use only components suitable for 7KH+XPDQ6ROXWLRQ

motor controls.

Caution: before connecting and disconnecting handswitches, you m ust

unplug the power cord.

Caution: i n t he event of a m alfunction ( e.g. i f the c ontrol unit keeps

adjusting the desk bec ause a m ovement key has j ammed), pl ease

unplug the unit immediately.

Danger: do not ex pose the Uplift 800 control uni t to m oisture, dr ips or

splashes.

Danger: when changing the desktop pos ition there i s a ri sk of pinching.

You must therefore ensure that no people or objects are located in the

hazardous area or can reach into it.

9 of 44

Danger: when changing the desktop position, there may i n exceptional

cases be a ri sk of p inching in sp ite of the safety featur es. Y ou must

therefore a lways ensure that no peop le or obj ects are l ocated i n the

hazardous area or reach into it.

Danger: do not m odify or m ake any c hanges to t he co ntrol un it, the

controls themselves or handswitches.

Danger: do not operate the Uplift 800 control unit in a potent ially explosive

atmosphere.

Danger: i n th e eve nt of a fault (motor or component), w henever t he

desktop attem pts to adj ust the he ight it m ay move sl ightly bef ore th e

safety cut-out is triggered. P lease note tha t there i s a pote ntial risk of

pinching in this case.

Danger: i ntelligent system pr otection (ISP) i s not ena bled dur ing a ll

resets (see 4.2.4). Please note that there is a potential risk of pinching in

this case.

Danger: thi s d evice is not intended f or us e by i ndividuals ( including

children) with limited physical, sensory or mental abilities or with a lack of

experience and/or l ack of ex pertise, un less they are sup ervised by a

person responsible for their safety or have received instructions from that

person on how to use the control unit.

Danger: children must be supervi sed at all times to ensure that they do

not play with the control unit.

Danger: if the control unit’s power cord is damaged, it must be replaced

by the m anufacturer or customer service or similarly qualified person in

order to prevent any risks.

Note: only clean the Uplift 800 control unit with a dry or sl ightly moist cloth.

Before cleaning, you must always unplug the power cord.

Note: in case of a m ains pow er breakd own or i f th e pow er cord is

plugged off during the movement of the drives, a manual reset of th e

Uplift 800 may be necessary!

10 of 44

1.8.2 Important notes for OEMs

What we mean by OEMs are companies that purchase Uplift 800 control units from

7KH+XPDQ6ROXWLRQ and install them in their own products (e.g.

electric height-adjustable desks).

Note: for reasons of EU conformity and product safety, we advise you to

provide users of your products with a manual.

Note: w hen you sh ip your f inished pr oducts, encl ose a user m anual

containing all the safety instructions that consumers need to handle your

product safely.

Note: the user m anual for your f inished product m ust contai n the

following note: you m ust read the use r m anual b efore yo u oper ate the

product (electric height-adjustable desk).

Advise you r custom ers that the use r m anual m ust be kept at hand in

close proximity to the product (electric height-adjustable desk).

Danger: conduct a r isk ana lysis of yo ur product (e lectric he ight-

adjustable desk) so that you can re spond to any potential residual risks

(e.g. by chang ing des ign feat ures or a dding notes to the user m anual

and/or placing warnings on your product).

Note: ensure that no unauthorized i ndividuals (e.g. sm all c hildren,

people under the i nfluence of drugs, et c.) can ta mper with your product

or the control unit.

1.9 Important note for service

Danger: onl y us e or iginal s pare p arts. P arts may onl y be r eplaced by

qualified service technicians, otherwise the warranty/guarantee shall be

null and void.

Danger: i n the ev ent of a fa ult, p lease contact cust omer servi ce

immediately. On ly or iginal sp are pa rts m ay be used for repa iring the

control un its. P arts m ay onl y be replaced by qua lified se rvice

technicians, otherwise the warranty/guarantee shall be null and void.

11 of 44

2. 8SOLIW installation instructions

Mount the Uplift control unit on the underside of the desktop. You will need the

following tools for mounting:

• Cross-tip screwdriver

• Pencil

• Drill (for drilling holes)

Caution: the power cord must be unplugged while the Uplift 800 control unit

is being mounted.

To mount the Uplift 800 control unit, proceed as follows:

Note: Please follow the mounting instructions carefully.

1. Position the control unit where you want it under the desktop.

2. Mark the drill holes with a pencil (See Figure 2: use the areas with the smaller

diameter).

Figure 2: Step 2

3. Pre-drill these two holes.

4. Screw the screws halfway into the 3 holes

5. Mount the control unit with the 3 screws. The screw heads fit to the bigger

diameters of the mounting holes.

6. Slide the control unit to the body stop of the 3 holes with the smaller diameter

(See Figure 2).

7. Tighten the screws properly.

Note: 7KH+XPDQ6ROXWLRQ recom mends l ens head

screws DIN7981C 4,8xL with a lens head diameter of 9,5mm. The length

L of th e screw shou ld fit to the us ed desk top. T he t ightening torque

depends on the wood, but 2Nm shall not be exceeded.

17 of 44

1.6 Package contents

The standard scope of delivery consists of one control unit.

1

Figure 1: Package contents

c Uplift 800 control unit

1.7 Unpacking

The Uplift 800 control unit comes packed in a cardboard box. To unpack, proceed as

follows:

1. Remove the cardboard.

2. Dispose of the packaging materials.

3. Keep the user manual at hand for the operators.

Note: ensure eco-friendly disposal of the packaging materials (separate

the plastic parts and cardboard for collection).

1.8 Safety instructions

This user manual contains safety instructions that draw your attention to any possible

risks, thus enabling safe operation of the Uplift 800 control unit. Please observe these

warnings and instructions at all times.

In this section you will find general safety instructions that do not refer to any

particular steps or procedures. You will find the work-specific safety instructions in

the relevant section of the manual. Additional warnings are given on the Uplift 800

control unit itself.

13 of 44

3.2 Commissioning procedure

Caution: the power cord must be unplugged while the Uplift 800 control unit

is being commissioned.

To commission a Uplift 800 control unit, proceed as follows.

3.2.1 Connect drives

Plug the motor cables into the relevant 8-pin motor sockets (M1, M2, and M3).

Note: when connecting the motor cables, you must strictly adhere to the

sequence M1, M2, M3.

3.2.2 Connect handswitch

Plug the handswitch into the 7-pin socket (HS).

Note: To o perate the tab le, w e offer the c onvenient LUD sw itch that

enables programming of di fferent settings along with a si mple Up/Down

switch, both o f w hich h ave un der t able m ounts, as w ell as a tab letop-

mounted Up/Down switch.

3.2.3 Connect mains supply

Caution: before you plug in the power cord, check the following again:

• The mains supply voltage must be as specified on the type plate

• All the components must be plugged into the right sockets

• The earthing cable must be connected

When the power cord is plugged in, the Uplift 800 control unit is operational.

Note: in case of a m ains pow er breakd own or i f th e pow er cord is

plugged off during the movement of the drives, a manual reset of th e

Uplift 800 may be necessary!

14 of 44

3.2.4 System configuration (example)

The figure below shows the socket assignment for a configuration example. This

configuration consists of:

c 1 Uplift 800 control unit

d 3 motors (shown inside the columns)

e HSC-KB-OD-2 handswitch

2

1

3

Figure 4: Configuration example

15 of 44

3.2.5 Reset

At initial start-up the product must be reset in order to commence operation.

When used in a table, the reset function facilitates moving all columns to the same

level at the bottom-most table position. This ensures that the desktop moves in

parallel to the ground level.

Additionally the standard version of the control saves the connected components,

such as columns or an optional sensor, in its memory. After the reset, changes in the

configuration will be recognized and classified as errors. The system will not move

before the saved condition has been restored.

Danger: During reset the collision protection is deactivated so that

there is no detection activity. This entails a higher risk of crushing.

Please make sure that there are no objects or persons in the danger

zone (defined as the entire lifting or moving range of all components)

and the danger zone is kept free.

3.2.6 Reset (manual reset)

To perform a reset, the U p and D own keys of the sw itch need to be pressed l ong

enough to cause the system to move downwards and reach the bottom position.

and

As the contro l automatically sh ifts into energy-saving mode after a

few seconds, thi s mode must be deacti vated first. To do t his, briefly

press the Up or Down key.

Press and hold the Up and Down keys at the same time immediately

after the previous step.

After 2 seconds the reset beg ins, th e tab le m oves dow nward and

needs to be kept moving until it reaches its bottom position.

A successful reset operation is followed by a double clicking sound

from the control.

Note: In order to reset the control to the factory setting you will need an

LUD switch or a dong le that has be en programmed with the respect ive

basic setting!

16 of 44

4. Operating the 8SOLIW control unit

To ensure safe operation of the Uplift 800 control unit, please observe the following

safety instructions:

Note: in case of a m ains pow er breakd own or i f th e pow er cord is

plugged off during the movement of the drives, a manual reset of th e

Uplift 800 may be necessary!

Caution: keep ch ildren aw ay from el ectric hei ght-adjustable d esks,

control units and handswitches. There is risk of injury and electric shock.

Caution: unplug the p ower cord d uring a thunderstorm or i f you do not

intend to use the desk f or a longer period. Th e cont rol u nit m ight

otherwise be damaged by power surges.

4.1 Basic functions

Note: the Uplift 800 control unit offers an ex tensive range of functions. The

availability of some functions depends however on the handswitch used.

This sect ion desc ribes the bas ic f unctions ava ilable w ith every

handswitch designed for use with Uplift 800 control units.

Note: the 2 bas ic func tions upw ard a nd downward m ovement are

available for both motorgroups separately. Please read the manual of the

used handswitch to see which buttons are linked to which motor group!

4.1.1 Upward desktop movement

This function enables you to adjust the desktop upwards. To change its position,

proceed as follows:

Press the desktop up key.

Keep pressing the key until the required desktop height is reached.

Note: the desktop will continue moving upwards until you release the key

or the maximum height is reached.

17 of 44

4.1.2 Downward desktop movement

This function enables you to adjust the desktop downwards. To change its position,

proceed as follows:

Press the desktop down key.

Keep pressing the key until the required desktop height is reached.

Note: the desktop will continue moving downwards until you release the

key or the minimum height is reached.

4.2 Advanced functions

Note: you can only use the following functions of the Uplift 800 control unit if

you have a handswitch with memory position keys and a memory key.

4.2.1 Saving a desktop position

This function allows you to save a defined desktop height. One desktop height can

be saved per memory position key. To save a position, proceed as follows:

Note: if you are switching on the Uplift 800 control unit for the f irst time, all

the save d pos itions a re s et t o th e lowest desktop he ight (minimum

desktop position).

1.

Adjust the desktop to the position you want to save.

The display will show the desktop height (e.g. 73cm).

2.

Press the memory key.

The display will read S –.

3.

Press the required memory position key (e.g. 2).

The display will read S 2.

4. The set deskt op position w ill now be saved to the se lected m emory

position key.

You will hear an audi ble double click and after about 2 seconds the

saved desktop position will be displayed.

Note: using saved desktop positions is only available for handswitches

with memory keys. The desi gn of the m emory posi tion keys var ies,

depending on the handswitch model used.

18 of 44

Note: i t is sof tware param eter de pendent w hich m otor grou p can

save/recall memory positions. If both motor groups are capable of saving

memory posi tions, the cur rent pos ition of both groups w ill be stored

(even if they are different). When recalling a stored position in this case,

both groups sta rt the ir m ovement at the same ti me, even i f thei r

movement direction is different.

4.2.2 Adjusting the desktop to a saved position

You can use this function to adjust the desktop to a saved height. To change to a

saved position, proceed as follows:

Note: av ailability of the double c lick fu nction depends on the so ftware

configuration of the control unit.

Option A (without double click function)

1.

Press the required memory position key (e.g. 2) and hold it down.

The desktop w ill m ove unti l it reac hes the saved posi tion. If you

release the key before the saved position is reached, the desktop will

stop and the saved desktop position will not be reached.

2. The deskt op has r eached t he saved p osition. N ow re lease t he

memory position key.

The display will read the current (saved) desktop position.

Option B (with double click function)

1.

Double click the required memory position key (e.g. 2).

2. After the double click, the desktop will automatically adjust to the saved

position.

The display will show the current (saved) desktop position.

Danger: w hen you c hange the deskto p pos ition autom atically

(especially w ithout us ing p inch p rotection), there is a hi gher r isk of

pinching. Y ou m ust there fore ensu re that no peo ple o r o bjects are

located in the hazardous area or reach into it.

Note: if you pre ss anothe r key w hile th e desktop i s cha nging

automatically to a saved pos ition, it w ill sto p i mmediately. Y ou then

have to reactivate automatic desktop adjustment to a preset position.

19 of 44

4.2.3 Changing the desktop height displayed

This function enables you to change the height shown on the display, but not the

actual position of the desktop. Proceed as follows:

1.

Press the memory key.

The display will read S –.

2.

Press the Down key (down arrow) for approx. 5 seconds.

The display will start flashing.

3.

Adjust the hei ght d isplayed by p ressing t he Down (dow n

arrow) or Up key (up arrow).

4.

Press the memory key.

The he ight d isplay is now set to the new desktop pos ition

entered.

Note: this function is available for both motorgroups separately. Please

read the manual of the used handsw itch to see which buttons are linked

to which motor group!

Note: please note that this procedure does not alter the actual position of

the desktop. It only changes the height displayed.

Note: th is f unction i s on ly available for ha ndswitches w ith i ntegrated

display.

20 of 44

4.2.4 Manual reset – first and second motor group

The LUD switch is designed to control two motor groups. This function is required for

controlling, for example, a tab le base, t he movement of which is being done via the

first tw o motor channe ls, and a screen lift, that i s contro lled vi a the th ird m otor

channel. In standa rd conf iguration the f irst motor group i s moved vi a the U p and

Down keys to the right, while the second motor group is controlled via the left Up and

Down keys on the LUD switch.

When the actual desktop position no longer corresponds to the height displayed or

you wish to use a configured control unit on another identical electric height-

adjustable desk, you have to reset the lowest desktop position to the minimum

height.

To reset the first motor group, proceed as follows.

1.

As the control automatically shifts into energy-saving mode after a

few seconds, this mode must be deactivated first. To do this, briefly

press the Up or Down key.

2.

and

Press and ho ld the U p and D own keys at the sam e ti me

immediately after the previous step.

After 2 seconds the r eset begins, the table moves do wnward and

needs to be kept moving until it reaches its bottom position.

3. Release the button(s). The electric height-adjustable desk can now

be used again normally.

Note: this function is available for the first motor group only.

Table of contents

Popular Control Unit manuals by other brands

Sony

Sony RM-450 Service manual

END ARMATUREN

END ARMATUREN MGM Series Mounting and operating manual

Belden

Belden GRASS VALLEY ADX-1901 Guide to installation and operation

Omnitronic

Omnitronic ALT-105 user manual

Schnick-Schnack-Systems

Schnick-Schnack-Systems DMX-Recorder user guide

Seav

Seav BeSUN 433 manual