FRONT PANEL EDITOR PARAMETERS

Parameter As Shown On Display

Day:month:year,

hour:minute:seconds

Oil Pressure Low Shutdown

(When Enabled)

Oil Pressure Low Pre Alarm

(When Enabled)

Coolant Temperature High Pre Alarm (When

Enabled)

Coolant Temp High Controlled Shutdown

(When Enabled)

Coolant Temperature High Shutdown (When

Enabled)

Pre Heat Temperature (When Enabled)

Post Heat Temperature (When Enabled)

Under Speed Shutdown

(When Enabled)

Under Speed Warning (When Enabled)

Over Speed Warning (When Enabled)

Battery Under Voltage Warning

Battery Under Voltage Warning Delay (When

Enabled)

Battery Under Voltage Warning

Battery Over Voltage Warning

Battery Over Voltage Warning Delay (When

Enabled)

Battery Over Voltage Warning

Charge Alternator Failure Warning

Charge Alternator Warning Delay

(When Enabled)

Charge Alternator Failure Warning

Charge Alternator Failure Shutdown

Charge Alternator Shutdown Delay

(When Enabled)

Charge Alternator Failure Shutdown

(When Enabled)

Reset Default Speed on Start-up

FRONT PANEL EDITOR PARAMETERS (CONTINUED)

Parameter As Shown On Display

Engine Speed Transient Delay

Selectable Speed Transfer Time

Engine Pre Heat Timer (When Enabled)

Engine Overspeed Overshoot

Engine Fail To Stop Delay

Battery Under Voltage Warning Delay

Battery Over Voltage Warning Delay

On Load / Off Load / Auto Start Inhibit, Week,

Start Time, Run Time and Day

Selection (1-8)

Press to begin

editing then up or down

when selecting the

different parameters.

Press to begin

editing then up or down

when selecting the

different configurations

*Electronic Engines Only

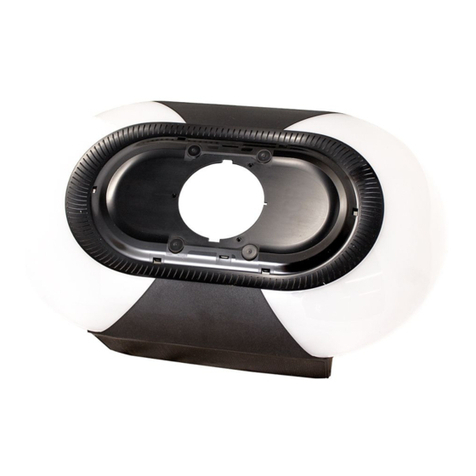

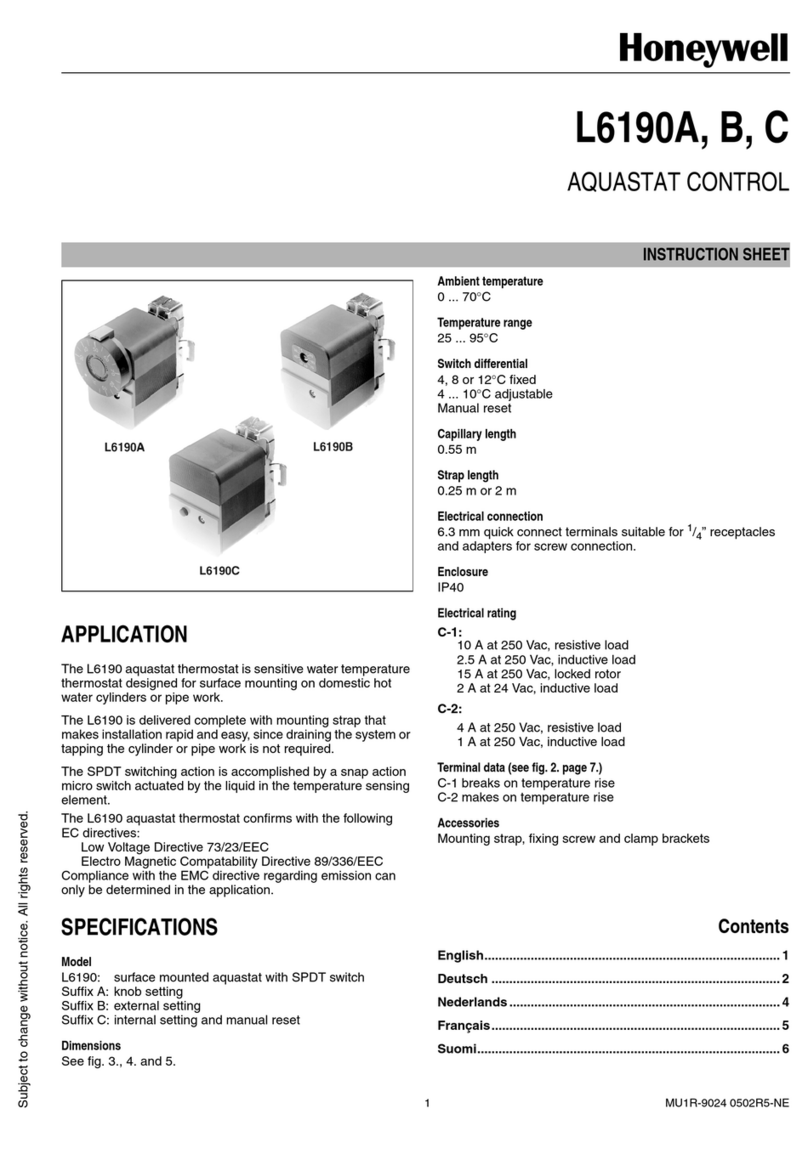

FIXING CLIPS

NOTE: In conditions of excessive vibration, mount the module on suitable

anti-vibration mountings.

The module is held into the panel fascia using the supplied fixing clips.

•Withdraw the fixing clip screw (turn anticlockwise) until only the pointed

end is protruding from the clip.

•Insert the three ‘prongs’ of the fixing clip into the slots in the side of the

module case.

•Pull the fixing clip backwards (towards the back of the module) ensuring all

three prongs of the clip are inside their allotted slots.

•Turn the fixing clip screws clockwise until they make contact with the panel

fascia.

•Turn the screws a little more to secure the module into the panel fascia.

Care should be taken not to over tighten the fixing clip screws

ACCESSING THE ‘RUNNING’ CONFIGURATION EDITOR

•The ‘running’ editor can be entered while the engine is running. All protections

remain active if the engine is running while the running editor is entered.

•Press and hold the (Tick) button to enter the running editor.

RUNNING CONFIGURATION EDITOR PARAMETERS

Parameter As Shown On Display

DIMENSIONS

240.0 mm x 181.1 mm x 42. mm

(9.4” x 7.1” x 1.6”)

WEIGHT

0.7 kg

(1.4 Ib)

PANEL CUTOUT

220 mm x 160 mm (8.7” x 6.3”)

TEMPERATURE

Operating: -40 ºC to +70 ºC

(-40 ºF to +158 ºF)

Storage: -40 ºC to +80 ºC

(-40 ºF to +176 ºF)

REQUIREMENTS FOR UL CERTIFICATION

WARNING!: More than one live circuit exists, see diagram overleaf for further information.

Screw Terminal Tightening Torque

•Terminals suitable for connection of conductor size 13 AWG to 20 AWG (0.5 mm² to 2.5 mm²).

•Conductor protection must be provided in accordance with NFPA 70, Article 240

•Low voltage circuits (35 V or less) must be supplied from the engine starting battery or an isolated secondary circuit.

•Must be connected through UL Listed or Recognized isolating current transformers with the secondary rating of 5 A max.

•Must be connected to communication circuits of UL Listed equipment

•Suitable for flat surface mounting in Type 1 Enclosure Type rating with surrounding air temperature -22 ºF to +122 ºF (-30 ºC to +50 ºC)

•Suitable for pollution degree 3 environments.