END ARMATUREN MGM Series Technical document

Combined operated

solenoid valves

.../AX..

(version acc. to European Directive 2014/34/EU(ATEX))

Mounting and Operating Manuel

for explosion proofed solenoids

END-Automation GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7901-0 www.end.de

Art.Nr.:�MEMG2S122243050

Serie:�220885

Betriebsdruck (PS):�0,5-16 bar

Steuerdruck:�-

Temperatur (TS):�-10°C ... °HZ:50C

Größe (DN):�50 / G2"

Prüfdr

uc

k (PT):�24 bar

Fluidgruppe:�1

Herstellung:�14.02.2002

END-Automation GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7901-0

www.end.de

Art.Nr.:�MEMG2Z325665015/AX

Serie:�406390/22349-05/04

Druckbereich (PS): 0 - 16 bar Volt: 230 V�

Temperatur (TS): -20 bis +80 °C Hz: 50

Prüfdruck (PT): 24 bar 86 mA

G/DN:

1

/

2

" Magnet-Nr.: 8336

Herstellungsdatum: 01/2004 Fluidgruppe: 1

�II 2GD EEx me II T4 130°C

�Kema 02 ATEX 1218 X

0032

END-Armaturen GmbH & Co. KG

Postfach (PLZ 32503) 100 341 · Oberbecksener Str. 78 · D-32547 Bad Oeynhausen - Germany · Telefon +49-(0)5731-7900-0 · Telefax +49-(0)5731-7900-199 · http://www.end.de

2 http://www.end.de solenoid valves - 04/2016

© by END-Armaturen GmbH & Co. KG

All rights reserved. END-Armaturen GmbH & Co.KG claims copyright over this documentation.

This documentation may neither be altered, expanded, reproduced nor passed to third parties without the

written aggreement of END-Armaturen GmbH & Co. KG. This restriction also applies to the corresponding

drawings.

END-Armaturen GmbH & Co. KG has the right to change parts of the solenoid valves at any time without prior

or direct notice to the client. The contens of this publication are subject to change without notice.

This publication has been written with great care. However, END-Armaturen GmbH & Co.KG cannot be held

responsible, either for any errors occuring in this publication or for their consequences.

The products are specified by the statements in this documentation; no assurance of the properties is given.

END-Armaturen GmbH & Co. KG

Oberbecksener Straße 78

D-32547 Bad Oeynhausen

Telefon: 05731 / 7900 - 0

Telefax: 05731 / 7900 - 199

Internet: http://www.end.de

E-Mail: [email protected]

Edition: 04/2016

Impressum

solenoid valves - 04/2016 http://www.end.de 3

Contents

Contents

1 Foreword 5

2 General advice 6

2.1 Valivity 6

2.2 Inward monitoring 6

2.3 Complaints 6

2.4 Guarantee 7

2.5 Symbols and their signification 7

3 Safety advice 8

3.1. Personal protection 8

3.1.1. Safety advice for mounting 8

3.1.2 Safety advice for adjustment and initial starting 9

3.2 Device safety 10

4 Device variants 11

4.1 Device variants 11

4.2 Technical data 12

4.2.1 Technical data solenoid valve: ME(MB)..2Zxxxxxxxxx/AX 12

4.2.1 Technical data solenoid valve: MG..2Zxxxxxxxxx/AX 12

4.3 Corresponding use 12

4.4 Name-plate 13

4.5 Description of function 14

4.5.1 Combined operated solenoid valve 14

4.6 Options 15

4.6.1 Manual override 15

4.6.2 Chemical nickel-plated 16

4.6.3 Normally open 16

4.6.4 Free of oil and grease 16

4.6.5 Speed control 16

4.6.6 Electrical position indicator (contactless) 17

5 Mounting / disassembly 18

5.1 Mounting 18

5.1.1 Mounting of a solenoid valve with threaded connection 18

5.1.2 Mounting of a solenoid valve with welded connection. 19

5.1.2.2 Protection of seals / diaphragm by disassembling 19

5.2 Electrical installation 20

5.2.1 Wiring 20

5.3 Disassembly 21

5.3.1 Electrical disassembly 21

5.3.2 Mechanical disassembly 22

6. Initial operation 22

7. Faults 23

7.1 Fail causes 23

solenoid valves - 04/2016 http://www.end.de 5

1 Foreword

Dear customer, Dear assembler / user

these operation and installation manuals are intended to give you the knowledge which is

necessary for you to be able to carry out the mounting and adjustment of a solenoid valve rapidly

and correctly.

Please read these instructions carefully and pay particular attention to the advice and warning

notes.

Only instructed and qualified mechanics should mount, adjust or maintain the solenoid valves.

The solenoid valves will be deliver in several versions relative to

- ways

- operations

- material

- type of voltage and rated voltage

- connection type and connection size

There are also several options available.

With accessories

- speed control

- electric position indication

- manual override

could take place.

If you have any question concerning to the solenoid valves we shall be pleased to answer them.

The telephone number will be found on the inside cover of this operation and installation manual.

Yours

END-Armaturen GmbH & Co. KG

Foreword

6 http://www.end.de solenoid valves - 04/2016

2 General advice

2.1 Valivity

These mounting and operating manual is valid for the explosion proofed version of the solenoid

valves:

MGMx2Zxxxxxxxxx/AX..

MEMG2Zxxxxxxxxx/AX..

MEMF2Zxxxxxxxxx/AX..

MBxx2Zxxxxxxxxx/AX..

also before mentioned solenoid vavles with welded connections

and their variants:

- with X as a perface to the type

- and a appendage to the type (e.g. /A05).

2.2 Inward monitoring

Please check

- directly after delivery the solenoid valve for any transport damages and deficiencies.

- with reference to the accompanying delivery note the number of parts.

Do not leave any parts in the package.

2.3 Complaints

Claims for replacement or goods which relate to transport damage can only be considered valid if

the parcel service / forwarder has notified without delay.

In case of returns (because of transport damage / repairs), please make a damage protocol and

send the parts back to END-Armaturen, if possile in the orginal packaging.

In case of a return, please mention the following:

• Name and address of the consignee

• Order-/ article-number

• Description of the defect.

General advice

Advice

The products descript in this documentation in the conditions of our delivery are partly completed

machinery according to annex 2 paragraph g of the directive 2006/42/EC on machinery, which must

not be put into service until the final machinery into which it is to be incorporated has been declared

in conformity with the provisions of the Directive 2006/42/EC on machinery, where appropriate.

Please take notice to the Declaration of incorporation and the assembly instruction.

solenoid valves - 04/2016 http://www.end.de 7

2.4 Guarantee

For our solenoid valve we give a guarantee period in accordance with the sales contract.

The end of the normal duration of life of the wearing parts represents no defect.

The warrently and guarantee rules of END-Armaturen GmbH & Co. KG are applicable.

2.5 Symbols and their signification

Paragraphs which are idntified with this symbol contain very important advices, this also includes

advices for averting health risks. Observe these paragraphs without fail!

Paragraphs which are identified with this symbol contain very important advices, this also includes

how to avoid damage to property. Observe these paragraphs without fail!

This symbols indicates paragraphs which contain comments / advices or tips.

This spanner identifies the description of actions which you should carry out.

Symbols and their signification

8 http://www.end.de solenoid valves - 04/2016

3 Safety advice

Depending on the technical circumstances and the time under and at which the solenoid valve

is mounted, adjusted and commissioned, in each case you have to take into account particular

safety aspects

If, for example, the valve works in an operational chemical plant, the potential hazards of commis-

sioning have another dimension in case this is carried out for test purposes on a „dry“ part of the

plant in the assembly room.

Since we do not know the circumstances at the time of mounting / adjusting / commissioning you

may find advice on hazards in the following description which are not relevant to you.

Please observe (only) the advice which applies to your situation!

3.1. Personal protection

3.1.1. Safety advice for mounting

We wish to point out expressly that the mounting, the electrical installation and the adjustment of

the solenoid valves and the accesories must be carried out only by trained specialised personnel

having mechanical and electrical knowledge.

Don`t move off the coil from the tube by switched on power supply.

At first switch off all the devices / machines / plant affected by mounting or repair.

If appropriate, isolate the devices / machines / plant from the main.

Check (for example in chemical plants) whether the switching off of the devices / machines /

plant will causes potential danger.

If appropriate, in case of a fault in the solenoid valve (in a system which is in operation) inform

the shift foreman / safety engineer or the works manager without delay about the fault, in order,

for example, to avoid an outflow / overflow of chemicals or the discharge of gases in good time

by means of suitable measures!

Before mounting or repair, remove the pressure from pneumatic / hydraulic devices / machines

/ plant!

Drain the conduit from medium.

If necessary, set up warning signs in order to prevent the inadvertent starting up of the device /

machine / plant.

Observe the respective relevant professional safety and accident prevention regulations when

carrying out the mounting / repair.

Check the correct functioning of the safety equipment ( for example the emergency push off

buttons / safety vales, etc).

Safety advice

solenoid valves - 04/2016 http://www.end.de 9

Safety advice

3.1.2 Safety advice for adjustment and initial starting

As a result of the starting a solenoid valve the flow of gases, stem. liquids, etc. may be enabled or

interrupted!

By starting the device / machine observe that the solenoid valve may be in an undefinied opera-

ting position. By this uncontrollable movements could happen.

Assure yourself that, as the result of the starting or the test adjustment of the solenoid valve, no

potential hazard will be produced for the personnel or the invironment.

If necessary, set up warning signs in order to prevent the inadvertent starting up or shutting down

of the devices / machine / plant!

By ending mounting check the correct function and the tightness of the solenoid valve.

Check the right position and correct function of perhaps mounted accessories.

Check the right function of all safety devices (for example emergency push off buttons; etc.)!

Carry out the starting and the adjustment only in accordance with the instructions discribed in this

documentation.

10 http://www.end.de solenoid valves - 04/2016

3.2 Device safety

The solenoid valve

- is a quality product which is produced in accordance with the recognized industrial regulations.

- left the manufacturer`s work in a perfect condition!

In order to maintain this condition, as installer / user you must carry out your task in accordance

with the descriptions in these instructions, technically correctly and wirh the greatest possible

precision!

We assume that you have, as a trained specialist, sound mechanical and electrical knowledge.

The solenoid valve must be used only for a purpose corresponding to its construction.

The solenoid valve must be used within the values specified in the technical data.

Satisfy yourself that, as a result of the mounting, the commissioning or as a result of the test adjus-

tments of the solenoid valve, no potential hazards will be produced for devices / machine / plant!

Warning! Danger of burns.

In case of the working conditions, a extrem heating up of the coils will be possible.

At explosion proofed solenoid valves the max. permitted surface temperature of the equipment is

classified in temperature classes. The temperatures won`t be exceeded in the respective tempe-

rature class:

T1: max. 450°C;

T2: max. 300°C;

T3: max. 200°C;

T4: max. 135°C;

T5: max. 100°C;

T6: max. 85°C.

Open the solenoid valve only to such an extant as described in this documentation!

Don`t mount the solenoid valve, start the solenoid valve or carry out any adjustments on it, if the

solenoid valve, the supply lines or the part of the plant on which it is mounted is damaged.

By ending mounting check the correct function and the tightness of the solenoid valve.

At installation in the open or moist ambient you have to take special measures to protect the

solenoid valve against moisture.

Safety advice

solenoid valves - 04/2016 http://www.end.de 11

Device variants

4 Device variants

4.1 Device variants

The solenoid valves can be delivered in various applications.

The following table explains the composition of the article number to you. These article numbers

will be mentioned on the name plate:

For example: MGMG2Z126247015/AX

Solenoid valve with B.S.P. thread acc. to DIN ISO 228T1, 2/2-ways,

combiend operated, body: brass, seals: NBR, explosion proofed solenoid,

24V DC, solenoid size 21 watts, connecting size G 1/2“

1. - 2. Digit

Product

3. Digit

Type

4. Digit

Connection

5. Digit

Ways

6. Digit

Operation

7. Digit

Body material

ME

MG

MG= B.S.P thread

acc. to

DIN ISO 228 T1

A= welded connetion

DIN 3293

L= welded connection

ISO 4200

M = welded connection

DIN 11850-R2

F= flanges acc. DIN

2531 / 2533 / 2545

2= 2/2-ways Z= combiend operated 1= brass

3= stainless steel

8. Digit

Seals material

9. Digit

Type of voltage

10. Digit

Voltage

11. - 12. Digit

Solenoid type

2= NBR

3= FKM

4= EPDM

5= EEx me II T4 (AC)

6= EEx me II T4 (DC)

7= EEx md II T4 (AC)

8= EEx md II T4 (DC)

2= 24V

3= 42V

4= 110V

5= 205V

6= 230V

82 = 10 watts

47 = 23 watts

51 = 30 watts

54 = 47 watts

65 = 22 watts

13. - 15. Digit

Connection size

16. - 20. Digit

Options

NO = Normally open

OF = Free of oil and grease

SR = Speed control

Flanged and, Threaded

welded connection connection

006 = = G ⅛

008 = = G ¼

010 = = G ⅜

015 = DN 15 = G ½

020 = DN 20 = G ¾

025 = DN 25 = G 1

032 = DN 32 = G 1¼

040 = DN 40 = G 1½

050 = DN 50 = G 2

065 = DN 65 = G 2½

080 = DN 80 = G 3

100 = DN 100 = G 4

125 = DN 125

150 = DN 150

Explanation of article number composition for direct acting solenoid valves

Art. MGxxxx / MExxxx

AX = Version acc. to ATEX (obligatory)

CN = Chemical nickel-plated

HN = Manual override

12 http://www.end.de solenoid valves - 04/2016

4.2 Technical data

4.2.1 Technical data solenoid valve: ME(MB)..2Zxxxxxxxxx/AX

The below table shows the technical data of the solenoid for explosion proofed solenoid valves

with explosion proof identification:

II 2GD bzw. II 2 G

EEx m (e) II T3/T4

T = 140°C bzw. T = 110°C

- dimensioning current

- Each solenoid operator has to be protected by a fuse according to the rated current

(max. 3x rated current according DIN 41571 or IEC 127) resp. Motor protection switch with

short-circuit and fast thermal tripping protection. The fuse can be accommodated in the

associated device or must be added separately.

The fuse voltage has to be equal or higher than the rated soleniod voltage. The shutdown

capability has to be equal or higher than the max. assumed short-circuit current at the

installation point.

4.3 Corresponding use

The soleniods are only licensend in connection with the supplied valves. The combination of valves

and solenoid must be selected by the manufacturer or his representative.

The solenoid coil is an encapsulated safe electrical work equipment group II, designed for applica-

tion in atmospheres according to category 2G (zone 1+ zone 2) / 2D (zone 21 + zone 22).

By using the described solenoid valve, observe , that the flow rate of explosive media inside the

valve will be less than:

v≤2m/sforexplosiveliquidmediaand

v≤20m/sforexplosivegases.

Device variants

Series K05932.. K05924.. K05927..

Rated voltage [V] 12 - 230 V 12 - 230 V 24 - 230V

Rated current [mA]2000 - 100 2700 - 140 2100 - 220

Rated power [W] 23 30 47

Ambient temperature

-20°C ... +40°C -20°C ... +40°C -20°C ... +40°C

4.2.1 Technical data solenoid valve: MG..2Zxxxxxxxxx/AX

The below table shows the technical data of the solenoid for explosion proofed solenoid valves

with explosion proof identification:

II 2 G em II T4

II 2 D IP65 T130°C

Series 8336 ... 8345 8436 ... 8445 9236 ... 9245 9336 ... 9345

9350 ... 9360

Rated voltage [v] 12 - 440 V DC

24 - 400 V AC

Rated current [mA]50 - 1830 90 -3330 30 - 1000 41 - 1500

Rated power [W] 22 40 12 18

Ambient temperature

-20°C ... +40°C -20°C ... +40°C -20°C ... +40°C -20°C ... +40°C

solenoid valves - 04/2016 http://www.end.de 13

Name-plate

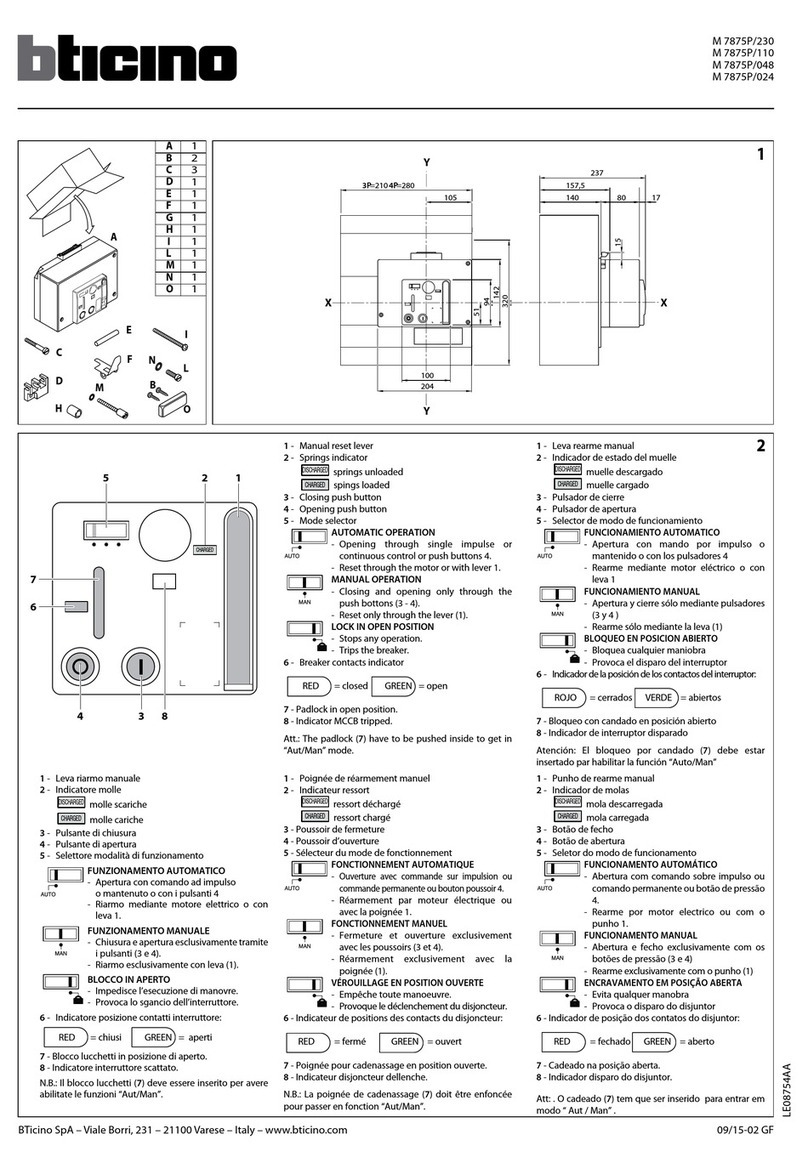

4.4 Name-plate

The solenoid valves will be provided with a name-plate, which permitts a definite identification

of the valve and shows the most important technical data to you. The name-plate should not dis-

placed or changed.

Fig. 4.1 - Name-plate

Art.Nr. article number of the valve (see also chapter 4 „device variants“)

Serie serial or production number

Betriebsdruck (PS) max. pressure range of the valve [bar]

Temperatur (TS) max. temperature range of the valve

Größe (DN) connection size of the valve

Prüfdruck (PT) testing pressure of the valve and the solenoid system

Fluidgruppe allowed fluid group of the valve

Herstellung date of manufacturing

Typ / NR.: description of the solenoid system

UN: 24V: rated voltage [V]

Hz.: DC: direct current

IN: 0,94 A: rated current [A]

PN: 23 W: rated power [W]

PTB 03 ATEX 2095 X: number of the certificate issued by a registration entity

II 2G EEx em II T4

II 2D IP65 T130°C: explosion proof identification

100%ED: duty cycle

END-Automation GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7901-0 www.end.de

Art.Nr.: MEMG2S122243050

Serie: 220885

Betriebsdruck (PS): 0,5-16 bar

Steuerdruck: -

Temperatur (TS): -10°C ... +80°C

Größe (DN): 50 / G2"

Prüfdruck (PT): 24 bar

Fluidgruppe: 1

Herstellung: 14.02.2002

END-Armaturen GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7900-0 www.end.de

Art.Nr.: MGMG2Z126247015

Serie: 220885

Betriebsdruck (PS): 0 - 16 bar

Steuerdruck: -

Temperatur (TS): -10°C ... +50°C

Größe (DN): G 1/2"

Prüfdruck (PT): 24 bar

Fluidgruppe: 1

Herstellung: 18.08.2003

END-Automation GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7901-0 www.end.de

Art.Nr.: MEMG2S122243050

Serie: 220885

Betriebsdruck (PS): 0,5-16 bar

Steuerdruck: -

Temperatur (TS): -10°C ... +80°C

Größe (DN): 50 / G2"

Prüfdruck (PT): 24 bar

FluidgEDrEDuppe: 1

END-Armaturen GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7900-0 www.end.de

Typ: KO593210

NR.: 6.2261.002

UN: 24 V Hz.: DC

IN: 0,94A PN: 23 W Dat.: 06/03

PTB 03 ATEX 2095 X Prüf.: 010

II2G EEx em II T4

II2D IP65 T130°C

100% ED

ACHTUNG: Betriebsanleitung beachten

0102

END-Automation GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7901-0 www.end.de

Art.Nr.: MEMG2S122243050

Serie: 220885

Betriebsdruck (PS): 0,5-16 bar

Steuerdruck: -

Temperatur (TS): -10°C ... +80°C

Größe (DN): 50 / G2"

Prüfdruck (PT): 24 bar

Fluidgruppe: 1

Herstellung: 14.02.2002

END-Armaturen GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7900-0 www.end.de

Art.Nr.: MGMG2Z126247015

Serie: 220885

Betriebsdruck (PS): 0 - 16 bar

Steuerdruck: -

Temperatur (TS): -10°C ... +50°C

Größe (DN): G 1/2"

Prüfdruck (PT): 24 bar

Fluidgruppe: 1

Herstellung: 18.08.2003

END-Automation GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7901-0 www.end.de

Art.Nr.: MEMG2S122243050

Serie: 220885

Betriebsdruck (PS): 0,5-16 bar

Steuerdruck: -

Temperatur (TS): -10°C ... +80°C

Größe (DN): 50 / G2"

Prüfdruck (PT): 24 bar

FluidgEDrEDuppe: 1

END-Armaturen GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7900-0 www.end.de

Typ: KO593210

NR.: 6.2261.002

UN: 24 V Hz.: DC

IN: 0,94A PN: 23 W Dat.: 06/03

PTB 03 ATEX 2095 X Prüf.: 010

II2G EEx em II T4

II2D IP65 T130°C

100% ED

ACHTUNG: Betriebsanleitung beachten

0102

Fig. 4.2 - Additional name-plate for explosion proofed solenoid valves

14 http://www.end.de solenoid valves - 04/2016

Description of function

4.5 Description of function

4.5.1 Combined operated solenoid valve

This type of valves does not require any pressure difference for opening and shutting the main

closing element. According to the indecated pressure diagrams they work from 0 bar upwards.

The plunger is connected to the diaphragm witch is fitted with a pilot nozzle. The attraction of the

plunger therefore causes the pilot nozzle to open, and the ensuing pressure lifts the diaphragm;

this action is further reinforced by the opening stroke of the plunger. Thus a combination of direct

(plunger) and indirect (diaphragm) operations ensure full passage even at low pressures, and ope-

rations and seal remain regular even at 0 bar pressure.

By taking advantage of the surface differences, this type of valves enables operating big-size

vavles with high pressure, the actuators being comparatively small as against direct-acting valves.

The actuator stroke must be at least as high as the valve lift. The force must be sufficient for ope-

ning the pilot bore and the main closing element against the spring force.

Fig. 4.3 -Combined operated solenoid valve: standard- application

solenoid valves - 04/2016 http://www.end.de 15

Description of function

Fig. 4.4 - description of function:Manual override

4.6 Options

4.6.1 Manual override

At the option „manual override“ the combined operated solenoid valve will be actuated by a hand

wheel. The main closing element of the combined operated solenoid valve will be lift up by turning

round a spindle with a hand wheel.

16 http://www.end.de solenoid valves - 04/2016

Options

4.6.2 Chemical nickel-plated

The body of the solenoid valve will be nickel-plated to protect the surface against aggressive

media.

4.6.3 Normally open

In this case the de-energized solenoid valve will be hold in the open position by spring force, the

energized solenoid closes the valve.

These solenoid valves should only be used with DC - coils.

4.6.4 Free of oil and grease

All part of the solenoid valve which can come into contact with pure oxygen will be clean up of oil

and grease to avoid the formation of explosive gases.

4.6.5 Speed control

With the speed control you can change the diameter of the pilot drilling at a combined operated

solenoid valve. Therefore a control of the closing time will take place. This option isn`t available for

solenoid valves with a connection size ½“and smaller sizes.

Fig. 4.5 - Description of function: speed control

+

-

+

-

solenoid valves - 04/2016 http://www.end.de 17

Options

4.6.6 Electrical position indicator (contactless)

The electrical position indicator is needed to show the operation condition of a solenoid valve over

a great distance. It is also possible to indicate a signal to a control device. Therefore are different

types of limit switches available: Reed contact or inductive proximity limit switches.

A separate Declaration of conformity and the user`s manual of the switch will be sent to you with

the solenoid valve.

18 http://www.end.de solenoid valves - 04/2016

5 Mounting / disassembly

5.1 Mounting

The mounting of the solenoid valves ristricts to

- the mechanical mounting into the prescribed pipes

- the electrical mounting of the solenoid valves and perhaps the mounting of accessories.

The installation of direct acting solenoid valves can be according your needs.

The installation with a vertical standing coil should be prefered.

In the following description we assume that you have read the former chapters attentive. We also

assume that you will observe the safety advices and warnings from chapter 3 „Safety advices“

during the mounting / disassembly.

If you have not read chapter 3 „safety advices“ until now, read these important advices now and

turn back to this page.

The mounting and the electrical installation must be carried out only by trained specialised per-

sonel with mechanical and electrical knowledge.

The mechanical installation are the same by all applications. It differs only by the type of connec-

tion.

Observe the flow direction, specified on the valve body.

Before mounting the solenoid valve clean up the pipes. Pollution will reduce the safety and the

duration of life of the valve. If necessary mount a Y-strainer upstream the valve.

Avoid strains of the body by non align pipes.

At installation in the open or moist ambient you have to take special measures to protect the

solenoid valve against moisture.

5.1.1 Mounting of a solenoid valve with threaded connection

Before lay on sealing compounds, check the hardly screwing of the pipes into the valve body.

Lay on the correct sealing compounds on the pipes end. By using PTFE-ribbon or hemp sealings

observe the screw direction . Don`t use sealing compounds which are not prescribed for your

employment.

Screw the pipes into the connection ends of the valve body. Don`t use the solenoid as a lever.

Strike up the pipes with pressure after that time the manufacturer of the sealing compounds pre-

tends for harden it.

Check the tightness of all connections.

Mounting / disassembly

solenoid valves - 04/2016 http://www.end.de 19

5.1.2 Mounting of a solenoid valve with welded connection.

By welding the valve body with the pipes observe appropriate demands and guide lines.

The safety demands by welding are depending on the place and the position of the point of weld.

Welding the parts at a serviceable device / machine / plant the potential of danger is as higher

as welding the parts in a welding room.

If appropriate, inform the shift foreman / safety engineer or the works manager and the fire bri-

gade of your factory.

By welding observe your own national guide lines about safety and prevention of accidents.

Before welding the solenoid body between the pipes you have to take measures to prevent the

damage of the sealings or diaphragm.

5.1.2.2 Protection of seals / diaphragm by disassembling

Clamp the valve between a vice carefully. By using guard plates you can prevent the damage of

the ends of the body.

Loosen the screws of the cap by using a fit spanner.

Turn out the screws of the valve body and take the cap byside carefully. Remove the diaphragm

from the valve body. If you should disassemble some solenoid valves, places marks on the body,

diaphragm and the caps that you will be able to join the correct parts by a subsequent mounting

of the solnoid valves.

Mounting / disassembly

20 http://www.end.de solenoid valves - 04/2016

5.2 Electrical installation

At the explosion proofed version the connecting cable is spilt with the soleniod body. It should

not be open on no account.

If connecting the lead wires make ensure the wire ends or the leads are properly inserted to the

electrical terminal.

Connecting cable and wires should be free of sharp bends in order to avoid short circuits and

interruptions.

Before initial operation of the device make sure that the overall equipment or unit respectively

meets the requirements of the EMC directive.

Each solenoid operator has to be protected by a fuse according to the rated current (max. 3x

rated current accord. DIN 41571 or IEC 127) resp. Motor protection switch with short-circut and

fast thermal tripping protection. The fuse can be accommodated in the associated device or must

be added separately.

The fuse voltage has to be equal or higher than the rated solenoid voltage. The shutdown capa-

bility has to be equal or higher than the max. assumed short-circut current at the installation

point.

5.2.1 Wiring

Mounting / disassembly

Fig. 5.1 - Mounting / disassembly - wiring

Spulenschaltung - Gleichstrom

blau

braun

gelb

Spulenschaltung - Wechselstrom

blau

braun

gelb

Wiring - DC

blue

brown

yellow

Wiring - AC

blue

brown

yellow

This manual suits for next models

3

Table of contents

Other END ARMATUREN Control Unit manuals