The Splash Lab TSL.410 Maintenance and service guide

TSL.410

deck mounted soap dispenser

installation + maintenance

3Safety and Warnings

4Box Contents

5Diagram

6Technical Data

8Before You Install

9Dimensions

10 How To Install

14 Commissioning & Operation

15 Troubleshooting

16 Cleaning

17 Maintenance

18 Warranty

19 Contact Details

contents

2TSL.410 MANUAL

For more information contact:

Tel: +44 (0)161 482 7000

Email: technical@thesplashlab.com

TSL.410

Read and save these instructions

WARNING !

+ Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer (see back page for more details).

TSL.410 MANUAL 3

box contents

1Body

2Bottle connector

3Flat washer

4Base collar

5Fixing nut

6Fixing nut

7Soap feed pipe

8Soap reservoir

4TSL.410 MANUAL

1

2

3

4

7

5

6

8

diagram

5TSL.410 MANUAL

5

3

7

6

4

2

1

8

1Body

2Base collar

3Flat washer

4Fixing nut

5Fixing nut

6 Bottle connector

7 Soap feed pipe

8Soap reservoir

technical data

TSL.410 MANUAL 6

Overview

Codes Power Finishes

TSL.410.CS Pump-action Brushed Stainless Steel

TSL.410.CP Pump-action Brushed Copper

TSL.410.BK Pump-action Brushed Black

TSL.410.BR Pump-action Brushed Brass

TSL.410.BZ Pump-action Brushed Bronze

Light Reflectance Values

Brushed Stainless Steel 58

Brushed Copper 19

Brushed Black 3

Brushed Brass 40

Brushed Bronze 17

Technical Data

Body Material AISI 304 Stainless Steel

Coating Type PVD (colours only)

Weight 700g

Pump Type Manual piston-type

Standard Discharge 1.0ml

Recommended Soap Type Liquid soap - <100 - 3800cPS viscosity. Not

suitable for foam soaps, alcohol gels or hand

sanitisers.

Soap Reservoir Capacity 1 Litre (standard)

5 Litres (optional remote feed)

The TSL.410 is a stainless steel deck mounted soap dispenser, available in a variety of

coloured finishes with a sleek and minimalist design.

technical data

7TSL.410 MANUAL

FRONT SIDE

Related Products

Soap Feed Systems LST1 - 5L reservoir with 2m feed pipe

LST2 - 5L reservoir with 2x 2m feed pipe

LST3 - 5L reservoir with 3x 2m feed pipe

LST4 - 5L reservoir with 4x 2m feed pipe

Sensor Operated Taps TSL.960 Deck mounted tap

TSL.990 Deck mounted tap

Related Documents

Warranty Document Email: technical@thesplashlab.com

Access Requirements

Soap reservoir must be accessible for installation, commissioning and for ongoing/

routine maintenance.

Front access: If the underside of the wash basin is tiled in, or is fixed onto a vanity

unit, a front hatch or panel(s) must be constructed below the wash basin for ongoing

maintenance access.

Installation Requirements

1. The soap dispenser is intended to be mounted in a countertop or basin

adjacent to a tap. As a guide, The Splash Lab recommends a minimum

distance of 100mm between the dispenser and a tap.

2. The TSL.410 is supplied with a single-feed reservoir fitted to the underside of

the dispenser. If a multifeed system is required, this needs to be specified

separately.

before you install

TSL.410 MANUAL 8

!

Caution

+ The TSL.410 parts must be put together correctly before installation.

+ All parts must be installed correctly before powering up the system.

TSL410 MANUAL 9

technical drawing

SIDE

FRONT

12mm Min 35mm Max

91

262 81

Soap Cap Adaptor

Ø30

Soap Bottle

Ø30

12mm Min 35mm Max

Dispenser Hole

Cut-Out 25mm

10 TSL410 MANUAL

1

Mark soap hole centres onto the surface

for installation.

how to install

Soap Installation

2

Drill 25mm diameter hole in countertop.

3

Insert dispenser through hole in basin or

countertop with the stainless steel bezel

above the counter.

4

Slide washer over mounting shank and

then tighten the fixing nut by hand.

TSL.410 MANUAL 11

5

Assemble the 2nd nut on the mounting

shank and then tighten this against the

1st nut. (Use 2 spanners for this)

Soap Installation

6

Connect the soap feed pipe to the spigot

below the countertop

7

Screw the bottle connector onto the

mounting shank so that 1 turn of thread

is visible below the connector.

8

Tighten the locking grub screw using a

2mm hex wrench.

how to install

11

Once all nuts are tightened, use the

pump action to dispense soap.

WARNING:Ensure all connections are

fully tightened to ensure full seal of the

soap dispenser.

TSL.410 MANUAL 12

9

Screw the reservoir onto the connector.

Soap Installation

10

Ensure all parts of the product are tight

and do not move unintentionally.

how to install

13 TSL.410 MANUAL

+ Fill the reservoir with liquid soap of viscosity in the range of 100 - 3800 cPs

+ Screw the reservoir onto the connector

+ Pump the dispenser head until soap is dispensed from the spout

commissioning

operation

The dispenser is depressed by the user, which draws a measured amount of soap (1ml)

from the reservoir and is then dispensed from the spout onto the user’s hands.

TSL.410 MANUAL 14

cleaning

+ Take extra care when cleaning decorative surfaces.

+ For surface cleaning of the soap dispenser use ONLY soap and water, then wipe

dry with a clean cloth or towel.

+ DO NOT use steel wool or cleaning agents containing alcohol, acid, abrasives or

the like.

+ Use of any prohibited cleaning or maintenance products or substances could

damage the surface of the tap.

+ When cleaning bathroom tiles, the soap dispensers should be protected from any

splattering of harsh cleansers.

All grades of stainless steel will stain or discolour if due care and attention is not

taken. The surface must be regularly cleaned to ensure a long service life of the soap

dispenser.

Use a soft cloth or sponge with a mild solution of soapy water as part of the regular

washroom janitorial routine. Do not use abrasive or cream cleaners as these will

damage the surface finish.

If further information is required, contact The Splash Lab technical team for more

detailed stainless steel care guidelines.

soap

A good quality liquid soap of viscosity 100 – 3800 cPs units should be used. Hand

cleaners containing abrasive particles should not be used as this will cause damage to

the pump mechanism. The dispenser mechanism is not compatible with alcohol gels or

hand sanitisers.

TSL.410 MANUAL 15

maintenance

Occasionally purge the dispenser by pumping warm water (hand warm) through the

unit. This will remove any congealed soap.

refilling

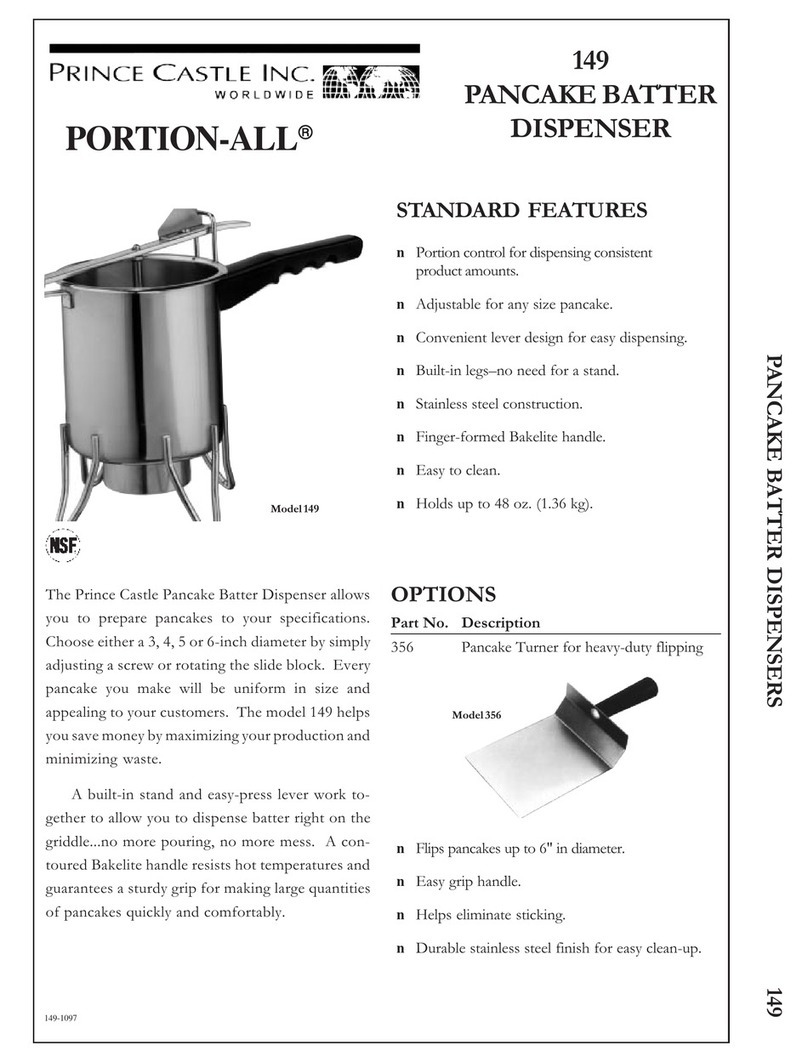

Single feed reservoir

1. Unscrew the reservoir from the connector cap.

2. Fill the reservoir with liquid soap of viscosity in the range 100 – 3800 cPs.

3. Screw reservoir onto the connector,

4. Pump the dispenser head until soap is dispensed from the spout.

Multi-feed pipe system

1. Remove the support clips and pipes from the neck of the soap reservoir,

2. Fill reservoir with soap until desired level is reached.

3. Replace the feed pipes in the reservoir, ensuring the ends of the soap pipes

are beneath the surface of the soap.

4. Alternatively, the feed pipes can be inserted into a replacement container of

soap.

5. Pump the dispenser head until soap is dispensed from the spout

The level of soap in the reservoirs should be checked regularly to ensure the soap feed

pipes are always dipped into the soap. If it does happen that the soap level is allowed

to fall below the minimum required, there will be an airlock introduced into the pipe,

which will then need to be re-primed. Priming of the system is achieved by depressing

the pump until soap is dispensed consistently.

THE SOAP DISPENSERS CONTAIN NO USER-SERVICABLE PARTS.

TSL.410 MANUAL 16

warranty

We believe the future is personal. With a global mindset, we challenge conventional

restroom norms via product innovation to create considered washroom solutions for

corporate, public and hospitality spaces. We use rich raw materials, cutting-edge

automation and considered washroom design to powerfully and positively influence the

lives of people.

Demonstrating our commitment to quality and our belief in the strength of our designs,

we offer the following warranties.

The Splash Lab warrant that its products will be free of manufacturing and material

defects during normal use and environmental conditions as detailed below:

TSL.410: 2 years parts & labour

If a defect is found in normal use, The Splash Lab will, at their discretion, repair, provide

a replacement part or product, or make appropriate adjustments. Damage caused by

accident, misuse, or abuse is not covered by this warranty. Improper care and cleaning

will void the warranty.

Non-operation of the product due to environmental conditions beyond our control,

installation error, incorrect maintenance, water quality, fair wear and tear, incorrect or

inappropriate installation, misuse and abuse is not covered by the warranty.

Proof of purchase (original sales receipt) must be provided to The Splash Lab with all

warranty claims.

The above warranty is valid for goods supplied within the United Kingdom.

For goods supplied outside of the United Kingdom, The Splash Lab will honour the

above stated warranty periods for the parts only.

THE SPLASH LAB DISCLAIM ANY LIABILITY FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

TSL.410 MANUAL 17

contact

General information

+44 (0) 161 482 7000

Technical support

technical@thesplashlab.com

For further contact information visit:

www.thesplashlab.com

TSL.410 • (EUR) • REV 1-24/08/20

Table of contents

Other The Splash Lab Dispenser manuals

The Splash Lab

The Splash Lab TSL.420 Maintenance and service guide

The Splash Lab

The Splash Lab TSL.R.010 Series Maintenance and service guide

The Splash Lab

The Splash Lab TSL.R.010 Series Maintenance and service guide

The Splash Lab

The Splash Lab TSL-470 Maintenance and service guide

The Splash Lab

The Splash Lab TSL.R.010 Series Maintenance and service guide