The Splash Lab TSL.420 Maintenance and service guide

Table of contents

Other The Splash Lab Dispenser manuals

The Splash Lab

The Splash Lab TSL.R.010 Series Maintenance and service guide

The Splash Lab

The Splash Lab TSL.410 Maintenance and service guide

The Splash Lab

The Splash Lab TSL-470 Maintenance and service guide

The Splash Lab

The Splash Lab TSL.R.010 Series Maintenance and service guide

The Splash Lab

The Splash Lab TSL.R.010 Series Maintenance and service guide

Popular Dispenser manuals by other brands

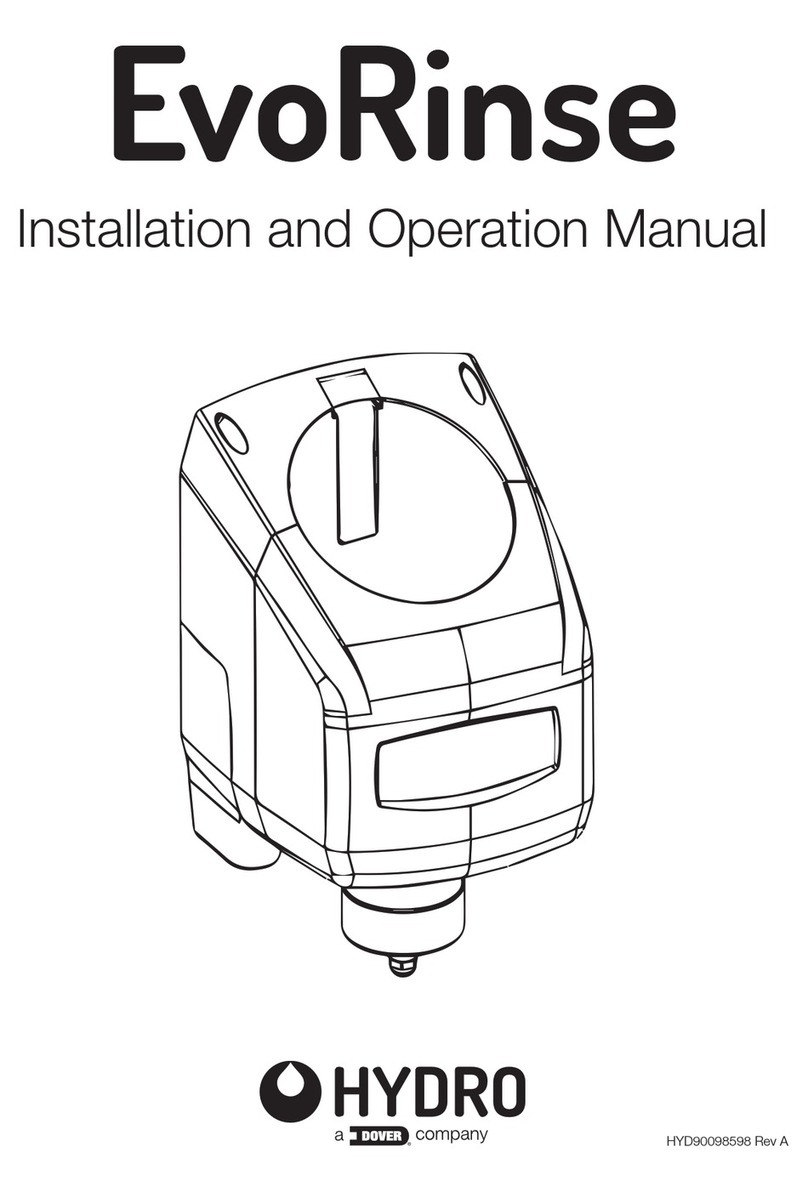

Hydro systems

Hydro systems EvoRinse Installation and operation manual

acaia

acaia AO101 user manual

Bobrick

Bobrick B-850 troubleshooting guide

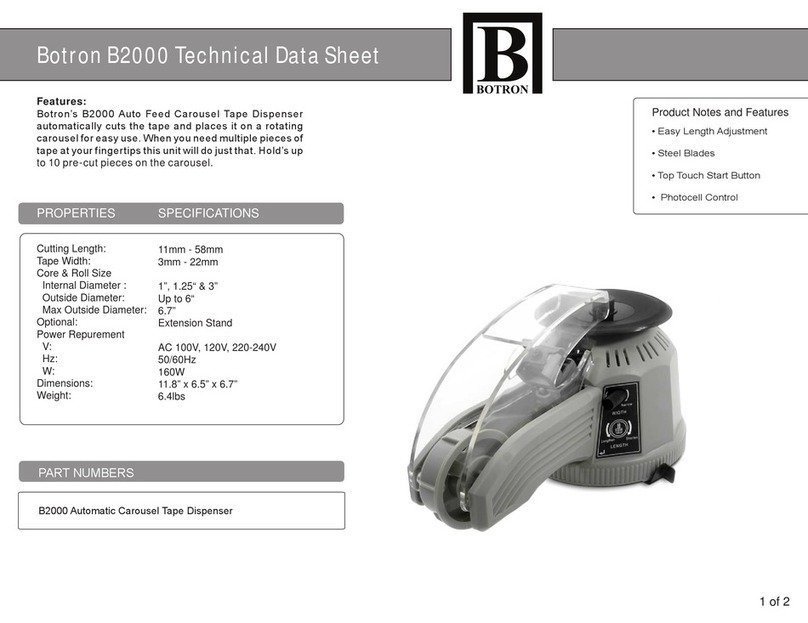

Botron

Botron B2000 quick start guide

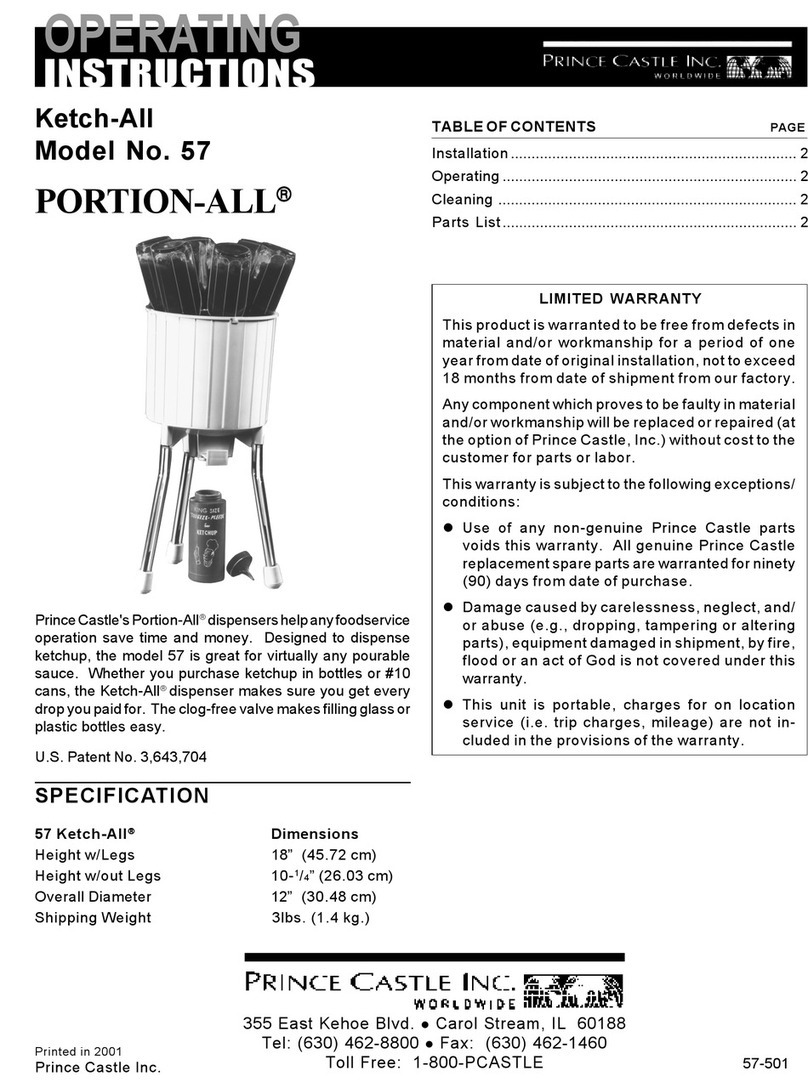

Prince Castle

Prince Castle Portion-All Ketch-All 57 operating instructions

Gastrodomus

Gastrodomus GRANISMART 3 operating instructions

Biohit

Biohit eLINE Dispenser Pro user manual

Wilbur Curtis

Wilbur Curtis Primo Cappuccino PCGT3 user guide

Alpine

Alpine ASPEN 427-L-GRY Operation & installation manual

Dolphin

Dolphin BC633F Installation and maintenance guide

Marconi

Marconi TRIND C00011-005 Series Installation

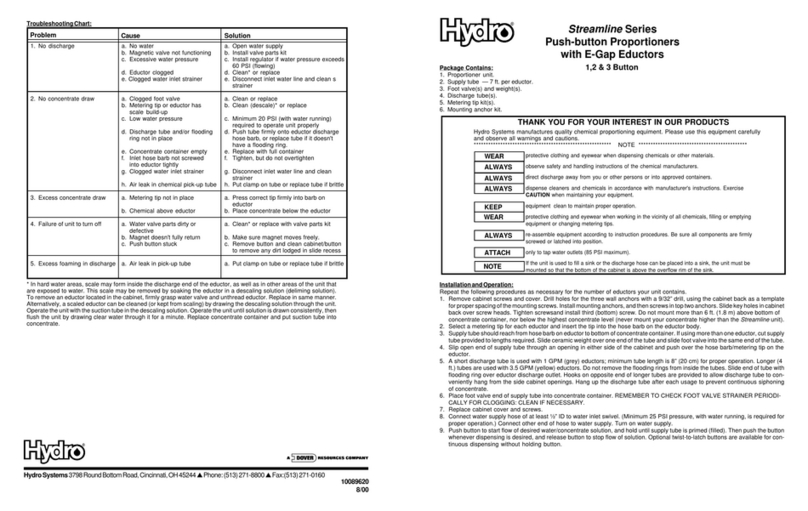

Hydro

Hydro Streamline 8691 quick start guide

GE

GE Cafe ENERGY STAR CFE29TSDSS Owner's Manual & Installation Instructions

SEIFOMAT

SEIFOMAT SC050 quick start guide

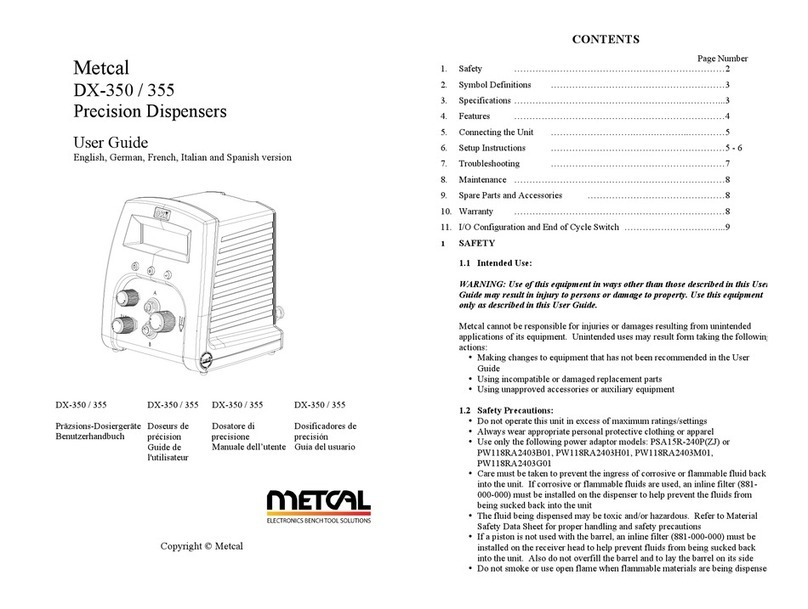

Metcal

Metcal DX-355 user guide

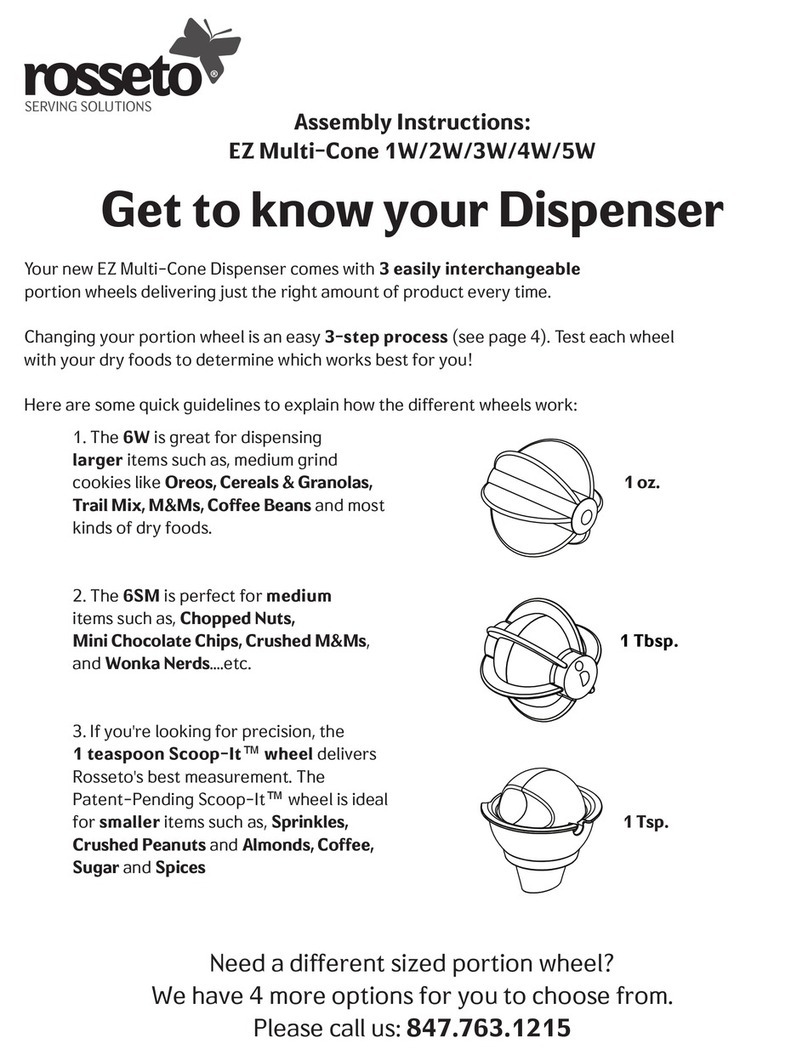

rosseto

rosseto EZ Multi-Cone 1W Assembly instructions

Schulke

Schulke touchless D1 instruction manual

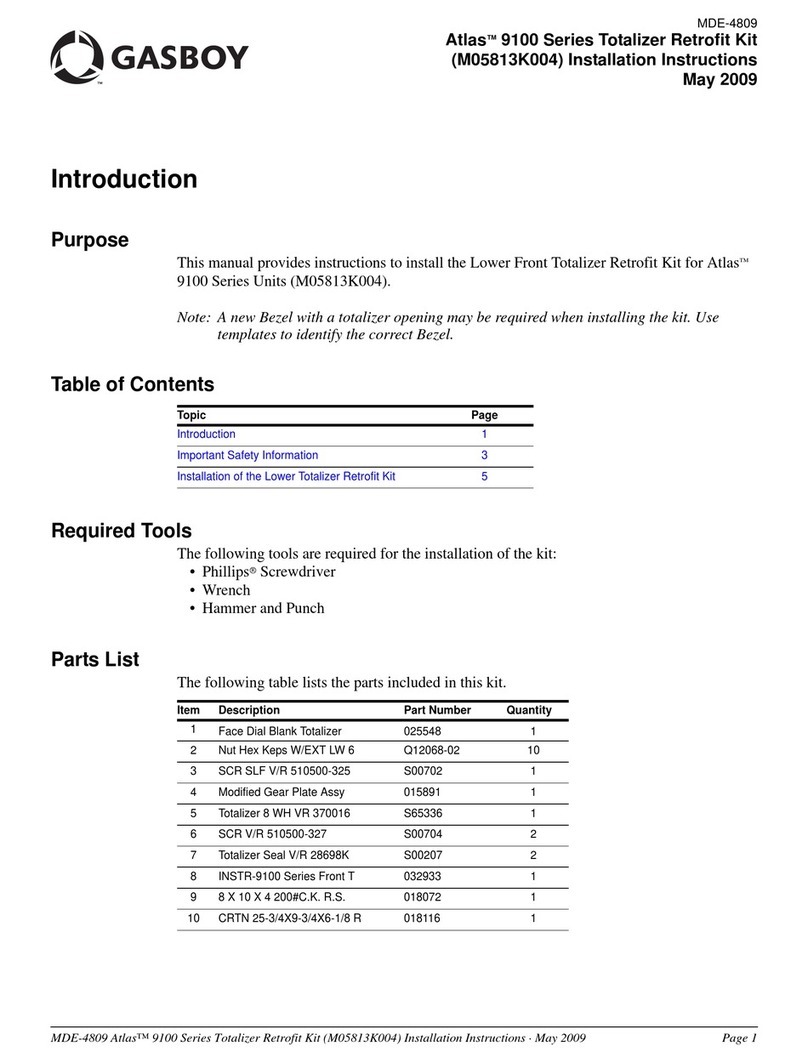

Gasboy

Gasboy Atlas 9100 series installation instructions