The Tile Doctor WTS950LN User manual

INSTRUCTION MANUAL

7 “

WE

T

TILE/ST

ONE

S

A

W

WITH

LASER AND

S

T

AND

PLEASE KEEP THIS

MANUAL FOR

FUTURE REFERENCE

CAUTION:

Read, understand, and follow all safety rules and instructions before using

this tool. These safety instructions should be followed at all times. Failure to follow these safety

instructions could result in injury to you or to others. Also, failure to read and follow these

instructions may cause damage to your equipment.

87VA

87VA CALL CUSTOMER

SERVICE

(TOLL

FREE)

1-877-845-3363

2.

3.

1 YEAR LIMITED WARRANTY

If within one year from date of purchase, this Tile Doctor product fails due to a defect in materials or workmanship, call the Ser-

vice Center at 1-877-845-3363. Please have a copy of the original receipt for all warranty claims.This warranty excludes inciden-

tal or consequential damages and failures due to misuse, abuse or normal wear and tear.This warranty gives you specific rights,

and you may also have other rights, which vary, from state to state. Please call 1-877-845-3363 for details.

TABLE OF CONTENTS

SECTION PAGE

Warranty, Technical specifications……………..………………2

General safety instructions…………………………..…………2

Specific safety instructions ……………….....…………………5

Saw features………………………………………………..……6

Unpacking major components……………..……………..……7

Unpacking accessories…………………………………..…..…7

Assembly……………………………………………….…..........8

Operation………………………………………………..….…..11

Maintenance…………………………………………….....…..13

Trouble shooting………………………………......……….…..14

Exploded drawing and parts list……………………….….…..15

TECHNICAL SPECIFICATIONS

7 “WET TILE/STONE SAW WITH LASER AND STAND

Power supply ...................................................... 120V ~, 60Hz

Motor capacity ...................................................................... 8A

No-load speed ......................................................... 7000 RPM

Diamond blade size ............................ 7 ”X 5/64”X 5/8”(Bore)

Maximum depth of cut at 0° ............................................ 2-1/4”

Maximum depth of cut at 45° .............................................. 1”

Tilting range .....................................................................0°,45°

Size of water tray ........................ 28-3/8”X 18-1/2 ”X 3-15/16”

Maximum rip cut ................................................................... 22”

Maximum square tile of diagonal cut ...................................16”

GENERAL SAFETY INSTRUCTIONS

WARNING: Some dust created by using power

tools contains chemicals known to the state of

California to cause cancer and birth defects or other

reproductive harm.

Safety is a combination of using common sense, staying

alert, and knowing how your tile saw works. Read this

manual to understand this tile saw and how to use it safely.

SAFETY SYMBOLS

The purpose of safety symbols is to attract your attention

to possible dangers. The safety symbols and the

explanations that accompany them deserve your careful

attention and understanding. The safety warnings DO

NOT, by themselves, eliminate any danger. They are no

substitutes for proper accident-prevention measures.

DANGER: Someone will be seriously injured or

killed if the safety information is not followed.

WARNING: Someone could be seriously injured or

killed if the safety information is not followed.

CAUTION: Someone may be injured if the safety

information is not followed.

DAMAGE PREVENTION AND INFORMATION

MESSAGES

These inform the user of import information and/or

instructions that could lead to equipment or other

property damage if they are not followed. Each message

is preceded by the word”NOTE,” as in the example below:

NOTE: Equipment and/or property damage may result if

these instructions are not followed.

WORK-AREA SAFETY

• KEEP THE WORK AREA CLEAN AND WELL LIT.

Cluttered benches and dark areas invite accidents.

• DON’T USE IN A DANGEROUS ENVIRONMENT. Don’t

use power tools in damp or wet locations or expose them

to rain. Don’t operate power tools in potentially explosive

environments, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks, which

may ignite the dust or fumes.

• OPERATE THE TOOL IN WELL-VENTILATED AREAS,

and provide proper dust removal. Dust generated from

some materials can be hazardous to your health. Use

dust-collection systems whenever possible.

• KEEP CHILDREN AND BYSTANDERS AWAY. All

visitors should be kept a safe distance away from the

work area.

• USE THE RIGHT TOOL. Don’t force a tool or attachment

to do a job for which it was not designed.

• MAKE THE WORKSHOP CHILD-PROOF with padlocks,

master switches, or by removing starter keys.

ELECTRICAL SAFETY

WARNING! To reduce the risk of electrocution, keep

all connections dry and off the ground. Do not touch

plug with wet hands.

• VOLTAGE: Before plugging in the tool, make sure that

the outlet voltage is within the voltage marked on the

tool’s data plate.

• DO NOT USE “AC ONLY” RATED TOOLS WITH A DC

POWER SUPPLY.

• DO NOT EXPOSE POWER TOOLS TO RAIN OR WET

CONDITIONS. Water entering a power tool will increase

the risk of electric shock.

• If operating the power tool in damp locations is

unavoidable, always use a Ground Fault Circuit

Interrupter to supply power to your tool. Always wear

electrician's rubber gloves and footwear in damp

conditions.

• DO NOT ABUSE THE CORD. Never use the cord to

carry the tools or to pull the plug from the outlet. Keep

the cord away from heat, oil, sharp edges, or moving

parts. Replace damaged cords immediately. Damaged

cords increase the risk of electric shock.

• USE THE PROPER EXTENSION CORD.

Extension Cords

Use only extension cords that are intended for outdoor

use. These extension cords are identified by a marking

“Acceptable for use with outdoor appliances, store indoors

while not in use.”

Use only extension cords having an electrical rating

equal to or greater than the rating of the product. Do not

use damaged extension cords. Examine the extension

cord before using, and replace it if it is damaged. Do not

abuse extension cords, and do not yank on any cord to

disconnect it. Keep the cord away from heat and sharp

edges. Always disconnect the extension cord from the

receptacle before disconnecting the product from the

extension cord.

•

Make sure that your extension cord is in good condition.

•

When using an extension cord, be sure to use one

heavy enough to carry the current your product will

draw. An Undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

•

Table 1 shows the correct size to use depending on

cord length and ampere rating. If in doubt, use the

next heavier gauge: the smaller the gauge number, the

heavier the cord.

•

When operating a power tool outdoors, ALWAYS use

an outdoor extension cord marked “W-A” or “W.” These

cords are rated for outdoor use and reduce the risk of

electric shock.

•

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept the

tool’s plug.

Table 1

Ampere

rating

Volts Total length of cord in feet

120 V~

25ft. 50ft. 100ft. 150ft.

A. W. G.

0~6 18 16 16 14

6~10 18 16 14 12

10~12 16 16 14 12

12~16 14 12 not recommended

Ground Instruction

All grounded, cord-connected tools:

• In the event of a malfunction or breakdown, grounding

provides a path of least resistance for the electric current

to reduce the risk of electrical shock. This tool has an

electric cord with an equipment-grounding conductor

and a grounding plug. The plug must be plugged into a

matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

• Do not modify the plug provided with this tool. If it will not

fit the outlet, have a properly grounded outlet installed by

a qualified electrician.

• Improper connection of the equipment-grounding

conductor can result in electric shock. The wire covered

with green insulation is the equipment-grounding

conductor. If repair or replacement of the electric cord or

plug is necessary, do not connect the green wire to a live

terminal.

• Check with a qualified electrician or service personnel if

you do not completely understand the grounding instruc-

tions, or if there is a question as to whether the tool is

properly grounded. Use only 3-wire extension cords that

have 3-prong grounding plugs and 3-pole receptacles

that accept the tool’s plug.

• Repair or replace a damaged or worn cord immediately.

Grounded, cord-connected tools intended for use on a

supply circuit having a nominal rating less than 150 Volts:

• This tool is intended for use on a circuit with a grounded

outlet (B, Fig. A). The tool has a grounding plug (A, Fig.

A).

• A temporary adapter (D, Fig. A) may be used to connect

this plug to a 2-pole receptacle (C, Fig. A), if a properly

Fig. A

(B)

(A)

(C)

(D)

Grounding Pin

Adaptor

Grounding Means

Adaptor Is Not Permitted In Canada

Metal

Screw

Cover Of

Grounded

Outlet Box

4.

5.

grounded outlet is not available. The green-colored tab

extending from the adapter must be connected to a per-

manent ground, such as a properly grounded outlet box.

The temporary adapter should be used only until a quali-

fied electrician can install a properly grounded outlet.

Permanently connected tools

This tool can be permanently connected to a grounded,

metal, wiring system or to a system that has an equipment-

grounding conductor.

Ground-fault circuit interrupter (GFCI) protection should be

provided on the circuit or outlet to be used for the tile saw.

Receptacles are available having built-in GFCI protection

and may be used for this measure of safety.

PERSONAL SAFETY

WARNING: The operation of any power tool can

result in foreign objects being thrown into your

eyes, which can result in severe eye damage. Before

beginning power-tool operation, always wear safety

goggles or safety glasses

with side shields, and a full-

face shield when needed.

We recommend Wide Vision

Safety Mask for use over

eyeglasses or standard

safety glasses with shields.

Always use eye protection,

which is marked to comply

with ANSI Z87.1

• STAY ALERT, WATCH WHATYOU ARE DOING, and

USE COMMON SENSE when operating a power tool.

• DO NOT use the tool while tired or under the influence of

drugs, alcohol, or medication.

• WEAR PROPER APPAREL. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry.

Pull back and secure long hair. Non-slip footwear is

recommended.

• KEEP YOUR HAIR, CLOTHING, AND GLOVES AWAY

FROM MOVING PARTS.

• REMOVE ADJUSTING KEYS OR WRENCHES. Form

a habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning it on.

• ALWAYS USE SAFETY GLASSES. Everyday glasses

may have impact-resistant lenses, but they are NOT

safety glasses.

• USE A DUST OR FACE MASK, if the operation is dusty.

• WEAR HEARING PROTECTION to help prevent

hearing loss.

• NEVER TOUCH THE PINS OF THE ELECTRICAL

PLUG while inserting it into or removing it from an

electrical socket.

• NEVER STAND ON TOOL. Serious injury could occur

if the tool is tipped, or if the cutting tool is unintentionally

contacted.

TOOL SAFETY

• KEEP ALL GUARDS IN PLACE and in working order.

• AVOID ACCIDENTAL STARTING. Be sure the switch is in

the “Off” position before plugging the tool into an electrical

outlet.

FORESIGHT IS BETTER

THAN NO SIGHT

WEAR YOUR

SAFETY GLASSES

• DO NOT CARRY TOOLS WITH YOUR FINGER ON THE

SWITCH.

• DO NOT OVER REACH. Keep proper footing and balance

at all times.

• DO NOT FORCE THE TOOL. Use the correct tool and

blade for your application. The correct tool and blade will

do the job better and more safely when used at the rate

for which it is designed.

• DO NOT USE TOOL IF THE SWITCH DOES NOT TURN

IT “ON” OR “OFF.” Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

• DISCONNECT THE TOOL before servicing, when

changing accessories (such as cutting blades), or storing

the tool.

• STORE IDLE TOOLS OUT OF THE REACH OF

CHILDREN and other untrained people.

• NEVER LEAVE THE TOOL RUNNING UNATTENDED;

turn the power off. Don’t leave the tool until it comes to a

complete stop.

• ALWAYS MAINTAIN TOOLS WITH CARE. Keep cutting

tools sharp and clean. Properly maintained tools with

sharp cutting edges are less likely to bind and are easier to

control. Follow all instructions for lubricating and changing

accessories.

• CHECK FOR DAMAGED PARTS. Before further use of

the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment of

moving parts, binding of moving parts, mounting, and any

other conditions that may affect its operation. A guard or

other part that is damaged should be properly repaired or

replaced.

• USE RECOMMENDED ACCESSORIES. Consult the

product manual for recommended accessories. The use

of improper accessories may increase the risk of personal

injury.

SERVICE SAFETY

• If any part of this we-tile/stone saw is missing or should

break, bend, or fail in any way; or should any electrical

component fail to perform properly: ALWAYS shut off the

power switch and remove the plug from the power source,

and have the missing, damaged, or failed part replaced

BEFORE resuming operation.

• When servicing a tool, ALWAYS use only identical

replacement parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow Maintenance Instructions may create a

risk of electric shock or injury.

SPECIFIC SAFETY INSTRUCTIONS

FOR WET TILE/STONE SAW

SAFETY INSTRUCTIONS FOR WET TILE/STONE SAW

WARNING: BE SURE to read and understand all

instruction in this manual before using this Wet Tile/

Stone Saw with Laser Guide and Stand. Failure to

follow all instructions may result in electric shock, fire

and/or serious personal injury

WARNING: To reduce the risk of mistakes that

could cause serious, permanent injury, do not plug the

tile saw into an electrical receptacle until the following

steps have been satisfactorily completed:

• Completely assemble the saw (See “Assembly”

section).

• Learn the use and function of the ON-OFF switch,

blade guard, laser-adjustment-knob, overload protector,

spindle lock, depth-stop-adjustment knob, depth-

adjustment knob, bevel-cut-adjustment knob, universal

guide etc. (See “Getting to Know Your Tile Saw” section).

• Review and understand all safety instructions and

operating procedures in this manual.

• Review the maintenance methods for this saw (See

“Maintaining Your Saw” section).

• Never put your fingers or hands in the path of the saw

blade or other cutting tool.

• Never reach behind the cutting tool with either hand for

any reason. Do not reach behind the blade to hold down

the work piece, support the work piece, remove scraps,

or for any other reason.

• Never use a hand position where a sudden slip could

cause the fingers or the hand to move into a saw blade.

• Find and read all the warning labels found on the tool

(shown below).

The labels on your tool may include the following symbols.

V.................................... Volts

A.................................... Amperes

Hz.................................. Hertz

W................................... Watts

min................................ Minutes

~

.................................... Alternating current

no.................................. No-load speed

RPM.............................. Revolutions or Strokes per minute

................................. Indicates danger, warning or

caution. It means attention! Your

safety is involved.

WARNING! Use of this tool can generate dust-

containing chemicals known to the state of California

to cause cancer, birth defects, or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other

masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending

upon how often do this type of work.To reduce your

exposure to these chemicals:

• Work in a well-ventilated area.

• Work with approved safety equipment, such as

those dust masks that are specially designed to filter

out microscopic particles.

Avoid prolonged contact with dust from power

sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and

wash exposed areas with soap and water.

Allowing dust to get into your mouth or eyes or to lie on

the skin may promote absorption of harmful chemicals.

Use of accessories that are not recommended for use

with this tool may create hazardous conditions.

• DIRECTION OF FEED: Always feed work into the blade

against the rotational direction of the blade.

• LET THE BLADE COME TO A COMPLETE STOP

before removing any jammed or off-cut material from

around the blade area.”

• POSITION OF TILE SAW: To avoid the possibility of the

appliance plug or receptacle getting wet, position the tile

saw to one side of a wall-mounted receptacle.The user

should arrange a “drip loop” in the cord connecting the

saw to a receptacle. (Fig. B)

Fig. B Tile Saw

Power Supply

Cord

Drip Loop

Water Tray

Tile Saw

Support

Esta bomba no se hainvestigado para el uso

en lapiscinani áreas marinas.

Utilice sólo con aguadulce.

PRECAUCION

1.

2.

3.

CAUTION

LASER RADIATION-

DO NOT STARE INTO BEAM

AVOID EXPOSURE--Laser radiation is

emitted through this aperture

Wavelength:635nm

Complies with 21 CFR 1040.10 and 1040.11

Max output: 2.5mW

Class IIIa Laser Product

RADIACION LASER-

NO MIRE FIJAMENTE EL RAYOLÁ SER

EVITE LA EXPOSICION-RADIACION LASER.

EVITE EXPOSICION DIRECTADE LOS OJOS

6.

7.

The “drip loop” is a section of the cord that hangs below the

level of the receptacle or below the connector, if an exten-

sion cord is used, to keep the water that travels along the

cord from coming into contact with the receptacle. (Fig. B)

If the plug or receptacle does get wet, DON’T unplug the

cord. Disconnect the fuse or circuit breaker that supplies

power to the tool. Then unplug the tool and examine the

receptacle for water. Do not use the receptacle until it is

completely dry.

SAFETY INSTRUCTIONS FOR LASER

This saw has a built-in laser light. The laser is class IIIa

and emits output power of a maximum

2.5mW and 635nm wavelengths. The laser doesn’t

normally present an optical hazard.

CAUTION: The following label is on

your saw. It indicates where the laser

light is emitted by the saw.

CAUTION: Avoid exposure.

Laser radiation is emitted through

this aperture.

CAUTION: The use of controls or

adjustments or the performance of

procedures other than those directed in this manual

may result in hazardous radiation exposure.

WARNING: Laser radiation Avoid direct eye

exposure. Do not stare into the beam.Turn the laser on

only when the tool is operated.

WARNING: Be sure to read and understand all

instructions. Always follow the following safety rules

when using this saw:

• NEVER aim the beam at any person or at any object

other than the work piece.

• DO NOT look directly into the laser-beam output

aperture during operation. The laser beam can be

harmful to the eyes.

• ALWAYS keep the laser out of the reach of children.

The laser on the saw is not a toy.

• Using optical instruments with this product will

increase eye hazard.

DON’T ATTEMPT TO REPAIR OR DISASSEMBLE

the laser. If unqualified persons attempt to repair

this product, serious injury may result. Any repair

required on this laser product should be performed by

authorized service-center personnel.

SAW FEATURES

1. Stand handle

2. Water tray

3. Worktable

4. Table locking knob (Fig. 38)

5. Blade

6. Right-laser-beam adjustment knob (Fig. 35, Fig. 37)

7. Blade guard

8. Pump plug receptacle (Fig. 19)

9. Blade-guard wing nut (Fig. 21)

10. Anti-splash rubber guard

11. Water hose

12. Cutting-depth-adjustment knob (Fig. 11, Fig.48)

13. Motor/upper arm assembly (Fig. 10, Fig. 11)

14. 0°,45°bevel-cut adjustment knob (Fig. 47)

15. On/Off switch

16. Laser-battery-compartment release button (Fig. 32)

17. Laser-battery compartment (Fig.33)

18. Laser on/off switch

19. Left-laser-beam-adjustment knob (Fig. 35,Fig. 37)

20. Blade-guard locking knob (Fig. 20)

21. Lubrication port (Fig. 50)

22. Water pump

23. Lower arm assembly (Fig. 8, Fig. 9)

24. Parallel/angle guide

25. Spindle-lock button (Fig. 26)

WARNING! The use of any accessory or attachment

or performance of any operation with this tool other than

those recommend in this instruction manual may present a

risk personal injury.

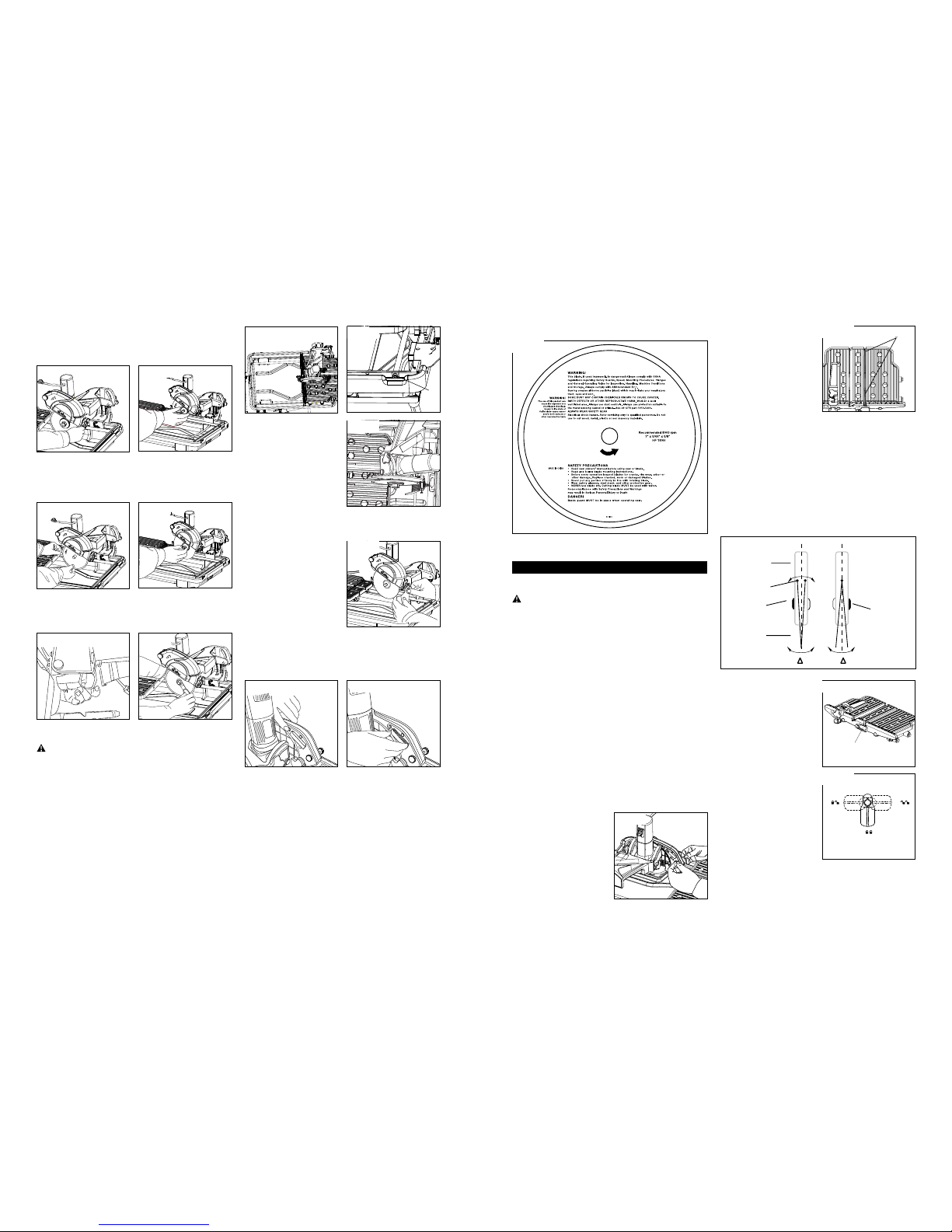

UNPACKING MAJOR COMPONENTS

The contents of the carton are as follows:

Motor/upper arm

assembly (Includes blade

guard and water hose)

1 set

Frame assembly and

table(Includes slip bar)

1 set

Lower arm assembly 1 pc

Instruction manual 1 set

Accessories (see below) 1 set

UNPACKING ACCESSORIES

1. Telescoping, foldable

stand (Fig. 1, Fig. 2)

1 PC

2. Parallel/angle guide

(Fig. 44, Fig. 42)

1 PC

3. Saw blade 1 PC

4. Water pump (Fig. 5) 1 PC

5. Lower arm assembly

bolts with spring

washers (Fig. 9)

2

sets

6. Water tray 1 PC

7. Blade wrench (Fig. 27) 1 PC

8. Anti-splash rubber

guard (Includes

locking wing nut and

washer) (Fig. 31)

1 set

9. Lubricant (Fig. 50) 1 PC

10. Cutting-depth-

adjustment Knob

(Fig. 11, Fig. 48)

1 PC

11. Lower-arm-assembly

Hex wrench (Fig. .9)

1 PC

12. Lower-arm-assembly

cap (Fig.12)

1 PC

8

9

10

11

1

2

4

3

5

6

7

15

14 16

17

18

19

20

21

24

22

12

13

23

25

CAUTION

LASER RADIATION-

DO NOT STARE INTO BEAM

AVOID EXPOSURE--Laser radiation is

emitted through this aperture

Wavelength:635nm

Complies with 21 CFR 1040.10 and 1040.11

Max output: 2.5mW

Class IIIa Laser Product

RADIACION LASER-

NO MIRE FIJAMENTE EL RAYOLÁSER

EVITE LA EXPOSICION-RADIACION LASER.

EVITE EXPOSICION DIRECTADE LOS OJOS

8.

9.

INSTALL THE WATER PUMP

1. Attach the water pump in

the indent the tray wall, as

shown in Fig. 5.

2.

Place the water pump

power cord in the bottom of

the water tray as shown in

Fig. 5.

Note:The four suction cups

on the water pump should be

attached to the side of the water tray.

INSTALL THE FRAME ASSEMBLY AND TABLE

1. Align the water tray and the frame assembly and table

so that the plug hole in the water tray is on the same

side as the water drain opening in the frame assembly.

2. Place the frame assembly and table into the water tray

(Fig. 6.).

3. Locate the water plug on the frame and insert the water

plug into the drain hole (Fig. 7).

INSTALL THE MOTOR AND ARM ASSEMBLY

1. Place the lower-arm assembly onto the frame assembly

(Fig. 8).

2. Insert the bolts with the spring washers (supplied) into

the lower-arm assembly and thread them into the table

frame. The Lower-arm-assembly hex wrench supplied

can be used to assist in this process.

3. Firmly tighten both bolts (Fig. 9).

Fig. 1

Brake

Fig. 2

Ensure that you have checked the contents in the carton

with the Major Components and Accessories lists before

discarding carton or packing materials.

REPLACEMENT BLADES

We recommend the use of genuine Tile Doctor

replacement blades. Specify Cat. No.: HF180H Blade size:

7” x 5/64” x 5/8” Arbor size: 5/8”

A 7” blade may be used as a replacement.

ASSEMBLY

WARNING! For your own safety and protection, do

not attempt to operate this tile saw until it is completely

assembled and all components and accessories are

properly installed according to this instruction manual.

Read and understand the capability of the tile saw and the

hazards associated with its operation.

WARNING!

To avoid injury from unexpected starting

or electrical shock, the tool must remain unplugged

whenever your are performing an assembly, adjustments

or changing accessories.

WARNING! Read all instructions prior to use. Failure to

follow the safety rules listed in this manual and other basic

safety precautions may result in serious personal injury.

SET UP THE STAND

1. Pull one stand leg out of its sleeve, and then pull the

other stand leg out of its sleeve (Fig. 1).

2. Unfold the stand fully and make sure that it is firmly

seated (Fig. 2).

INSTALL THE WATER TRAY

1. Align the water tray on the stand as shown in Fig. 3: the

tray cutout and the stand wheels are on the same side.

2. The water tray will snap into place inside the four pins

on the stand.

3. Make sure that the water tray is securely seated in the

stand (Fig. 4).

Fig. 3

Cutout

Fig. 4

Cutout

Fig. 5

Fig. 6 Fig. 7

Fig. 8 Fig. 9

4. Slide the motor/upper-arm assembly onto the arm-

assembly shaft. The motor must be tilted down towards

the water tray to insure that the motor/upper-arm

assembly can slide fully into place (Fig. 10).

5.

Make sure that the motor/upper arm assembly fits snug

with the lower-arm assembly and that you are unable to

see the arm-assembly shaft.

6. Rotate the motor to the vertical position and secure the

motor/upper-arm assembly to the lower-arm assembly

with the depth-adjustment knob (Fig. 11).

7. Fit the lower-arm-assembly cap supplied onto the

lower-arm assembly (Fig. 12).

INSTALL THE WATER HOSE

1. Locate the water hose attached to the motor/upper arm

assembly. Route the water hose from the back of the

blade guard (where it is permanently affixed) to the water

pump, as illustrated by the thick black line in Fig. 13

2. Clips are located on the motor/upper-arm assembly

and lower-arm assembly to secure the water hose (Fig.

14, Fig. 15).

3. Insert the water hose through the hole on the lower-

arm assembly (Fig. 16), and then insert the water hose

into the pump’s intake hole (Fig. 17).

4. Route the pump’s electrical cord through the clip on

the back of the lower-arm assembly and plug it into the

shorter of the two electrical cords attached to the motor

(Fig. 18, Fig. 19).

INSTALL THE BLADE

1.

Loosen the wing nut on the blade guard (Fig. 21).

2. Loosen the locking knob on the front inside area of the

blade guard to release the blade guard (Fig. 20).

Fig. 13

Clips for water

hose of pump

Pump

Fig. 12a Fig. 12b

Fig. 10 Fig. 11

Fig. 14 Fig. 15

Fig. 16 Fig. 17

Fig. 18 Fig. 19

Fig. 20 Fig. 21

10.

11.

3.

Lift up the blade guard, and then tighten the wing nut

(Fig. 22).

4. Remove the motor-shaft nut and the outer flange. Only the

inner flange should remain on the blade shaft (Fig. 23).

5.

Fit the blade supplied onto the motor shaft (Fig. 24).

Caution: Make sure that the arrow on the blade points in

the same direction as the arrow marked on the blade guard.

6. Replace the outer flange and the motor-shaft nut (Fig. 25).

7. Press the spindle-lock button while tightening the

motor-shaft nut on the motor shaft with the wrench

supplied until the motor-shaft nut is screwed securely

(Fig. 26, Fig. 27).

8.

Lower

the blade guard and tighten the wing nut and the

locking knobs.

WARNING:

To reduce the risk of injury, use only

accessories rated at least 8000rpm.

ADJUST THE WORKTABLE

NOTE: It’s unnecessary to adjust the worktable before use,

because the positions of the worktable and the blade are

adjusted properly in the factory. If adjustment becomes

necessary, follow the worktable adjustment instructions

below.

1.

Push the worktable until one “∆” mark is under the blade.

2. Use a hex wrench(not provide) to loosen the two

nuts(M8 socket hexagon screw) (the other nut is at the

other end of the slip bar) to adjust the slip bar until the

blade is vertically aligned with the “

∆

” mark (Fig. 28, Fig.

29).

3. Push the worktable until another “

∆

” mark is under

the blade. Use a wrench to loosen the two nuts to adjust

Fig. 22 Fig. 23

Fig. 24 Fig. 25

Fig. 26 Fig. 27

the slip bar until the blade is

vertically aligned with the “

∆

”

mark (Fig. 30).

4. Follow steps 1 and 3 to

adjust the worktable three

times.

NOTE: Be sure to adjust the

worktable following steps 1

and 3 three times or more to

ensure that the worktable is

adjusted in the best position.

INSTALL THE ANTI-SPLASH RUBBER GUARD

Fit the rubber guard in place

and tighten it with the wing nut

and washer supplied (Fig. 31).

INSTALL THE LASER

BATTERIES

1. Press the gray button

to release the battery

compartment on the back

blade guard (Fig. 32).

2. Install two AAA batteries (not supplied) in the

compartment.

3. Push the battery compartment back into the blade

guard (Fig. 33).

Fig. 30

Fig. 31

Fig. 32 Fig. 33

WARNING ON BLADE

OPERATION

FILLING THE WATER TRAY

WARNING!

Lack of cooling water may damage the

saw blade. Never turn on the machine without enough

water in the tray or without plugging in the water pump.

To insure proper operation, check to make sure that the

pump is always fully immersed in the water tray.

SWITCH ON AND OFF

Connect the unit to a power source with the correct

voltage and frequency (120V, 60Hz).

1. To start the motor, turn the switch knob to the “ON”

position.

2. To stop the motor, turn the switch knob to the “OFF”

position.

NOTE: Providing the pump’s plug is inserted into the

pump plug receptacle on the motor (see Figs 18 and 19),

the pump will be turned on when the motor is turned on.

SAFETY FEATURE ON SWITCH

Pull out the switch knob (the yellow part) after the switch

has been set at the “OFF” position. This safety feature

prevents accidentally starting the machine.

CALIBRATING THE LASER LINE

1. Press the laser switch

button to turn on the laser,

press the button again to

turn off the laser. ALWAYS

shut off the laser light when

you are finished cutting

(Fig. 35).

2. Position the laser beam

across the two

“∆”

marks

engraved in the slot of the

Fig. 34

worktable and the table

fence by adjusting one or

both knobs on the sides of

blade guard. (Fig. 35, Fig.

36).

3.

If the laser line will not line

up with the two

“∆”

marks.

follow the instructions that

follow under Adjusting the

Angle and/or Alignment of

the Laser.

ADJUSTING THE ANGLE AND/OR ALIGNMENT

OF THE LASER

1. To adjust the alignment of the laser, turn the knob on

the left of the blade guard. Set the laser beam to align

with the

“∆”

marked on the slot on the table fence.

2. To adjust the angle of the laser beam, turn the knob

on the right side of the blade guard. Set laser beam to

align with the

“∆”

marked on the slot of the worktable.

3. For best result knobs should be adjusted

simultaneously.

EXTENDING THE TABLE

1. When the knob is on

the position A, both the

worktable and table fence

are locked and cannot move

on the slip bar (Fig. 39).

2. When the knob is on

the position B, the table

fence is locked, but it can

move on the slip bar with

worktable.(Fig. 39).

3. When the knob is on the

position C, both the worktable

and table fence are unlocked

and they can move on the

slip bar (Fig. 39).

Fig. 35

" "mark

Fig. 36 “∆” mark

Blade guard

Right adjustment

(ANGLE).

Left

adjustment

knob

(ALIGNMENT).

Laser beam

Laser (inside

blade guard)

knob

" " " "

Fig. 37

knob

Fig. 38

A( )

B( ) C( )

Fig. 39

Fig. 28 Fig. 29

Nut

12.

13.

PULLING THE TABLE FENCE

Put the locking knob on

Position C (Fig. 39), and then

pull the table fence out (Fig. 40).

CUTTING OPERATION

WARNING!

Turn the switch

knob to the “OFF” position

when adjusting the motor.

WARNING!

Do not attempt

to cut very small pieces. Avoid awkward hand positions

where a sudden slip could cause your hand or finger to

come in contact with the diamond blade. When cutting

any material, make sure that it is fully supported. Hold

workpiece firmly. Do not force the material into the

blade.

CAUTION!

Make sure that the cutting-depth-

adjustment knob and the bevel-cut-adjustment knob are

tightened before operating the saw.

PARALLEL

CUT

1. Loosen the knob on the

parallel/angle guide,

2. Using the window in

parallel/angle guide and

scale rules on the table

surface for reference,

adjust the parallel/angle

guide to the desired

distance from the blade as

indicated in the window in

the guide.

3. Tighten the knob (Fig. 41).

4. Ensure that the angle arrow on the parallel/angle guide

points to 0° (Fig. 45).

Left-side alignment:

1. Align the appropriate measurement on the scale on the

table with indicator above the window on the parallel/

angle guide. For example, in Fig. 42, the indicator

points to “3” on the scale; the width between blade and

left edge of tile is 3 inch.

2. Position and press the tile

firmly against the parallel/

angle guide and move the

table evenly with two hands

during cutting. Do not force

the work piece or move the

table too quickly (Fig. 43).

Fig. 40

Fig. 41

Right-side alignment:

1. The parallel/angle guide cannot be used for right-side

alignment, but the scale of the table fence may be used

to measure on the right side of the workpiece.

2.

At this side, the zero scale is the

“∆”

mark.

3.

The distance between the blade and the right edge of

the workpiece is marked “L” in Fig. 44.

FLAT 0°~ 45°ANGLE CUT

1. Loosen the knob on the parallel/angle guide.

2.

Adjust the parallel/angle guide to the desired angle and

tighten the knob (Fig. 45).

3.

Using the parallel/angle guide to align the material for

angle cutting, position and press the tile firmly with two

hands

4. Move the table evenly with two hands during cutting.

Do not force the work piece or move the table too

quickly(Fig. 46).

45° BEVEL CUT

1. Loosen the bevel-cut adjustment knob and adjust the

angle from 0°to 45°.

2. Tighten the knob before cutting.

3. Position and press the

tile firmly with two hands

during cutting (Fig. 47).

4. Move the table evenly with

two hands during cutting.

Do not force the work

piece or move the table too

quickly

3

8

Fig. 42a

3

8

Fig. 42b

Fig. 43

Fig. 44a Fig. 44b

Zero Scale

Right Edge of

Workpiece

Fig. 45 Fig. 46

Fig. 47

CUTTING DEPTH ADJUSTMENT

1.

Loosen the cutting-depth-

adjustment knob (Fig. 48)

2. Raise the cutting head to

the height desired.

3. Retighten the cutting-depth

adjustment knob.

MAKING A PLUNGE CUT

1. Loosen the cutting-depth-

adjustment knob.

2. Raise the saw to the full,

upright position.

3. Align the tile under the saw

blade by moving the table

to the desired position

(Fig49)

4.

Plunge the saw into the

material. Do not force the

saw or move the saw too

quickly into the material.

CHANGING THE BLADE

When the blade is worn out, it should be changed. Please

follow the procedure illustrated in previously in Blade

Installation.

HOW TO USE LUBRICANT SUPPLIED

When the movement of the

table is not smooth, a small

amount lubricant may be

injected.

1. Loosen the cap on the

lubrication port.

2. Cut the end of the injection

tube attached to the bottle

of lubricant.

3. Inject a small amount of lubricant into the bar cylinder

under the table (Fig. 50).

4. Replace the lubrication port cap.

MAINTENANCE

CAUTION! For your safety, turn off the switch and

unplug saw from the power source before performing

any maintenance or cleaning. If the power cord becomes

damaged in anyway, replace it immediately with the

approved cord. When cleaning the saw, do not expose the

motor to direct water. If excessive water is introduced into

the motor, electric shock and/or damage to the motor can

occur.

Do not service the electric motor’s internal components

yourself. Contact an authorized service center.

Never use water or any other chemical liquids to cleaning

the electrical parts of the machine.

Use a soft cloth to clean the water and dust on the

machine.

Keep the ventilation slots of the motor clean to prevent

overheating of the motor

Periodic maintenance of your tile saw allows for long

Fig. 48

Fig. 49

Fig. 50

life and trouble-free operation. The cutting residue that

the saw generates could be considerable. A cleaning,

lubrication, and maintenance schedule should be

maintained.

As a common sense and preventative maintenance

practice, follow these recommended steps:

•

Clean the entire saw with fresh water after each use.

•

Pump clean/fresh water for 1 minute through the water

pump and blade guard assembly to safeguard against

slurry build-up and clogging.

• Keep the slip bar lubricated.

• If the table is not sliding easily, inject the lubricant into

the bar cylinder under the table (Fig. 50)

.

•

Inspect the diamond blade for it’s overall integrity. Check

the rim for wear or damage.

MOTOR REPLACEMENT

WARNING! Disconnect the plug from the power source

before performing any assembly, adjustment, or repair to

avoid possible injury.

Remove the motor unit from the accessory pack and

remove the hex nut and two

flanges on the motor shaft.

Replacement Procedure:

1. Loosen the 0°-45°bevel-

cut-adjustment knob and

swing the support plate of

the motor unit 0°to 45°(Fig.

51a).

2. Raise the blade guard

to its highest position by

loosening the locking knob.

3.

Loosen the 4 mounting screws and remove the motor.

4. Insert the new motor unit

into the support plate in

the direction shown by the

arrow in Fig. 51a.

5. Attach the motor unit with

the four screws supplied.

6. The screws shall be

screwed into the gear box

of the motor unit through

the support plate and firmly

tightened with a screwdriver (Fig. 51b.)

NOTE: After motor replacement, a slight misalignment

may have occurred. Check the following settings and

adjust, if necessary, prior to using the saw.

Fig. 51a

Fig. 51b

14.

15.

TROUBLE SHOOTING

WARNING! For your safety, turn “ON/OFF” switch

OFF and unplug the saw from the power source before

performing any troubleshooting procedures.

1. The motor is too hot:

•

Turn off the machine and let it cool down to room

temperature.

•

Check and clean the ventilation.

• If the above recommendations do not work, please

call the Service Center at 1-877-845-3363.

2. Motor stops turning:

•

Verify that all electrical connections are secure.

•

Check that the power-source voltage is 120V.

•

Verify that the switch is on the “ON” position.

• Contact Consumer Services at 1-877-845-3363

if the

one of above steps does not solve the problem.

3. The pump cannot inject water:

•

The water in the tray is not deep enough.

•

The water hose is loose or has come off.

•

The pump electrical cord is not firmly connected to

the receptacle.

•

The filter foam in inlet of the pump is too dirty.

4. Laser line projection is hard to see:

•

The work area is too brightly lit.

•

Batteries are weak.

•

Check that if any dust or water drop is on the glass

cover at the laser aperture.

5. Laser does not work:

•

The laser switch is not in turned on.

•

Batteries are depleted.

6. The movement of whole table and table fence is not

smooth:

•

Remove the mud or tile debris on the table and bars.

•

Inject a little lubricant into the lubricant injection

intake and spread some on the bars of table fence.

7. The blade is not aligned with the mark “

∆

”

•

Refer to the ADJUST THE WORKTABLE section,

and adjust follow step 1 through 3.

CLEANING THE PUMP

Remove the front plate and the impeller, and use a small

brush or stream of water to clean up any debris.

CAUTION: The pump shaft cannot be removed.

WARNING! If the water from the pump is reduced or

has stopped, replace the pump or have it repaired by the

qualified personnel.

WARNING! Some dust created by power sanding,

sawing, grinding, drilling, and other construction activities

contains chemicals known [to the State California] to

cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

•

Lead from lead-based paints.

•

Crystalline silica from bricks and cement and other

masonry products.

•

Arsenic and chromium from chemically treated lumber.

Your risk from these exposure varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

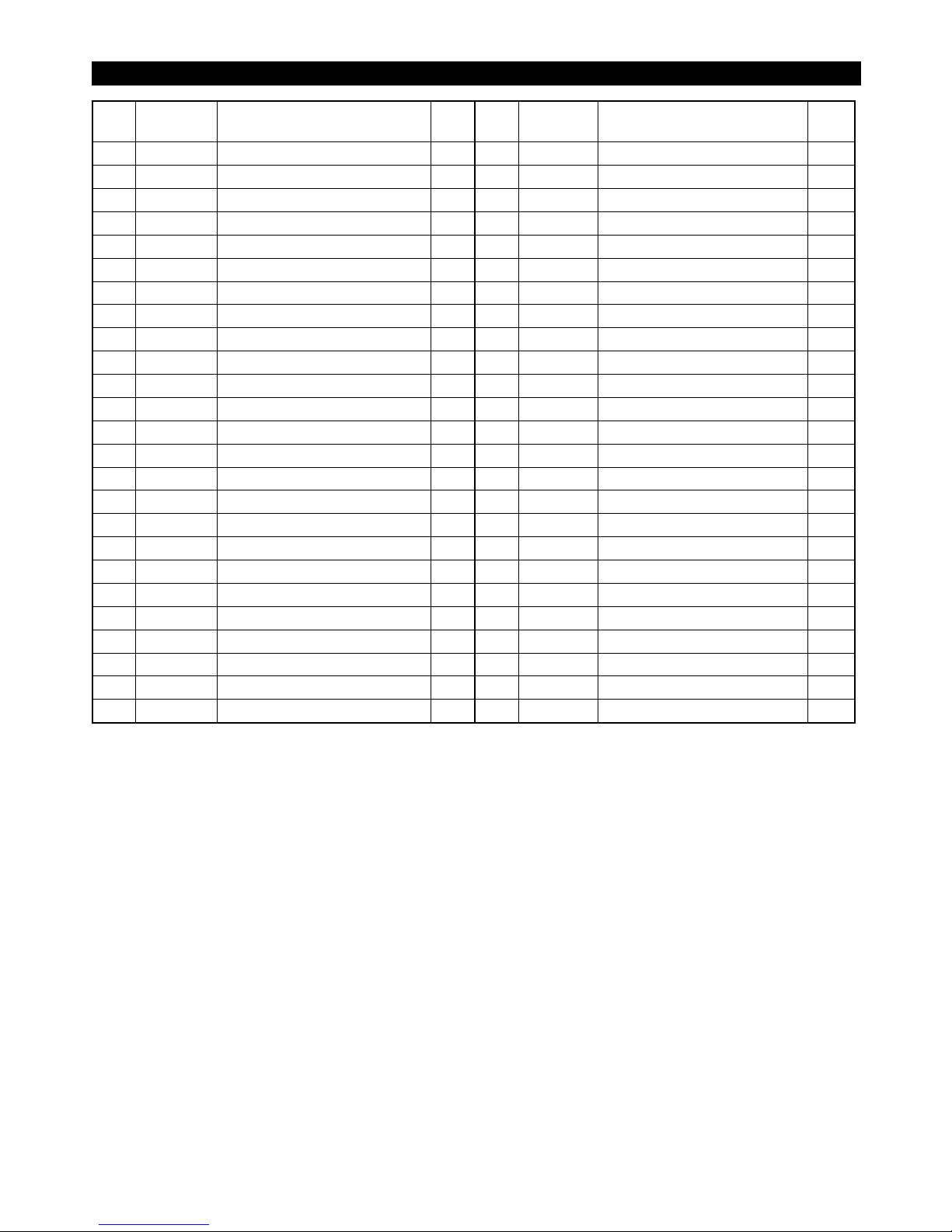

EXPLODED DRAWING (NOT INCLUDING STAND)

16.

PARTS LIST FOR WTS950LN(NOT INCLUDING STAND)

KEY

NO

PART NO. DESCRIPTION QTY KEY

NO

PART NO. DESCRIPTION QTY

1 6108001 Stopper for slip bar 2 26 6111046A Knob 2

2 6108055A Table fence 1 27 6108027A Wing nut 1

3 6108003 Spring pin 2 28 6108028A Anti-splash rubber guard 1

4 6108056 worktable 1 29 6108029 Washer 5

5 6108049A Right laser beam adjustment knob 1 30 6108030 Wing nut M8 1

6 6108058A Water tray 1 31 6108031 Nut 2

7 6108007 Water pump 1 32 6108032 Flange 2

8 6108008 Tie-in 1 33 6108033A Blade 7”×5/64”×5/8” 1

9 6108009 Water plug 1 34 6108059 Support plate 1

10 6108010 Chain for water plug 1 35 6108035 Tie-in 1

11 6108011A Steel frame 1 36 6108036 Spring 1

12 6108012 Bolt 2 37 6111015 Water hose 1

13 6108013 Spring washer 7 38 6108038A Battery compartment 1

14 6108014 Square flat washer 2 39 6108039 “O” ring 1

15 6108015 Lower arm assembly cap 1 40 6108040 AAA battery (not supplied) 2

16 6108016 Slip bar 1 41 6108041A Left laser beam adjustment knob 1

17 6108017A Lower arm assembly 1 42 6108042A Guard 1

18 6108018 Screw 3 43 6108043A Blade wrench 1

19 6108019 Clip 3 44 6108044 Lower arm assembly hex wrench 1

20 6108020 Spring washer 2 45 6108045 Lubricant 1

21 6108021 Lower arm assembly Bolt 2 46 6108046A Parallel/angle guide 1

22 6108022A Cutting depth adjustment knob 1 47 6108047A Guide knob 2

23 6108023 Bolt 1 48 6108048 Nut M6 3

24 6108024 Swivel pin 2 49 6108034 Motor unit 1

25 6108025A Upper arm assembly 1 50 6108050 Washer 1

Table of contents