Theiling TH-305110017 User manual

Operation Manual

ROLLERMAT

Automatic mechanical filter for fresh and saltwater aquariums and garden ponds

Fresh and saltwater aquariums from 300 to 3000 l volume and garden ponds up to a volumeof

5000 l

The Rollermat removes waste particles from the water. Biological filters and protein skimmers

are

workload is eased

and the result is crystal clear water.

1. Construction

2.

Working principle

Water with waste particles passes through the filter fleece and enters into the central drum.

From here it flows back into the

filter sump. This results in the fleece picking up waste

particles –as this happens, the flow through the fleece decreases and the water level

outside

of the drum rises. When the water level reaches the maximum level, a float switch actuates

the f l e e c e d r i v e motor and the dirty fleece roll slowly

rotates and a small part of fresh

fleece is loaded on the drum. T his res u l t s i n an inc r e a sed flow through the filter

fleece a nd thus th e w ate r level dro p s . When th e l e v e l dro ps suf f i ciently,

the float switc h is de activate d an d the moto r sto ps . This process repeats

automatically. It will take 3 –6

months until

the complete fleece is used and has

to be

replaced - this depends on the waste

production in the system.

The Fleece is very fine. Even the smallest

particles are

removed. The dirt is filtered out

of the system,

before it is metabolized

biologically. This eases the workload of

biofilters and the protein skimmers.

The pores of the fleece are even fine enough

to

retain many protozoa, like fish parasites in

fresh and

saltwater. They cannot pass

through the fleece.

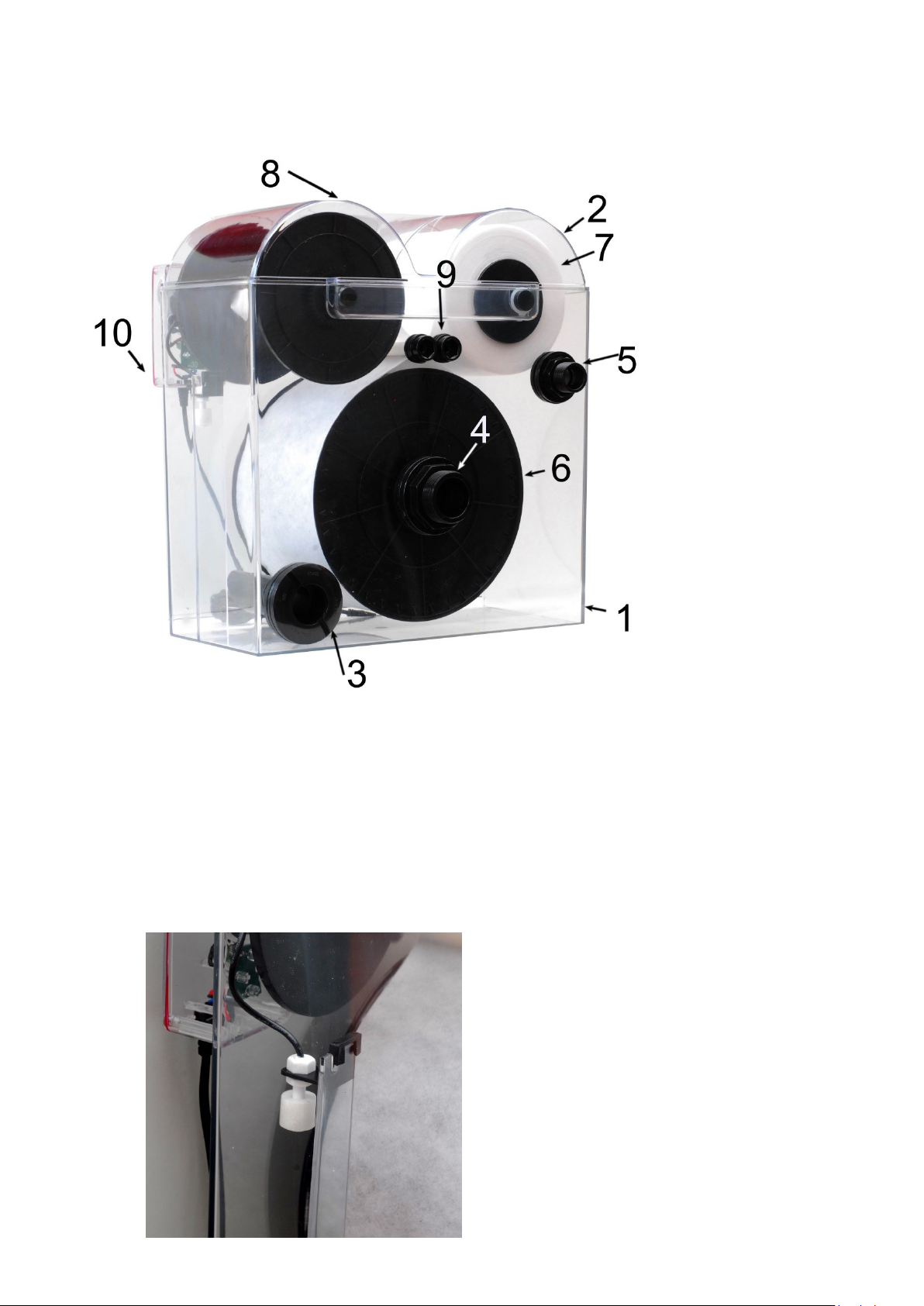

1.

1

.

1. Filter

2. Lid

3. Water inlet

4. Water outlet

5. Overflow

6. Filter Drum

7. New Fleece Roll

8. Dirty Fleece Roll

9. Directing Rolls

10. Level Switch

3. Features of the Rollermat:

Efficient mechanical filtration by fine filter

fleece

Automatic transport of the fleece.

The rolls are easy to change, up to 100 m length.

The roll is 15 cm wide, for flow rates up to 2700l/h, depending on the water quality.

Minimum power uptake. Average below 0.1w.

12V voltage –low safe voltage

The fleece is transported from the releasing roll to the

accepting roll. The rolls are driven by gear wheels .

If the accepting roll is full –or the releasing roll empty,

it

can be taken out of the filter easily. Both parts can

be

separated and the fleece can be discarded .Inserting a new

fleece roll.

Care must be taken when replacing the fleece roll –please

ensure the O-rings on the left and right side of the new roll are

mounted in the correct way - see the arrow on the figure at

the left. These O –rings prevent the roll from turning freely -

this keeps the fleece always taut.

The fleece is directed from the fresh roll over the first

directing

roll (see item 9). The end of the fleece can now be fixed to the

drum (by a tape) or just

pressed into the drum. The drum is

rotated carefully anti clockwise until the fleece can be reached

from the other

side.

Now, it is directed over the second directing roll and fixed on the accepting roll. This can be done

with

tape as well. If the accepting roll is in place and the transformer is plugged into the mains, thelevel

switch

can be lifted lightly by hand. The motor starts and the fleece is pulled taut.

4. Warning

When initially installing, the Rollermat will slowly increase the internal volume until filled to the normal

operating level –this will require approximately 20 litres of water. Please make sure you have enough

water to add to your aquarium/pond to replace this water (not ATO water! - disable any ATO device

until the Rollermat is filled to the bottom of the float switch.

During normal operation, the increase in water volume required to trigger the float switch and advance

the filter fleece, is only around 1 litre (when roll advances, this additional 1 litre is then returned to the

aquarium/pond). Therefore the impact on salinity/ATO operation is insignificant on tank sizes of 300

litres or more. On tanks volumes below this, the salinity/water level may be impacted and the

Rollermat is not recommended.

5.

Set Up

Aquarium: The Rollermat must be positioned so that the water outlet (which must not be reduced below

the 40mm)) can return water to the aquarium by gravity.

The Rollermat can be placed into the filter sump below the aquarium. Alternatively, it can be placed above

the water level, so that the purified water can flow freely back

into the aquarium.

Garden pond: The Rollermat is placed above the water level and is supplied with water by a pump.

The purified water flows freely back into the pond.

6. Connection

Water inlet

40 mm tank union/glue fitting

Water outlet

40 mm tank union/glue fitting

overflow

25 mm tank union/glue fitting

Water inlet

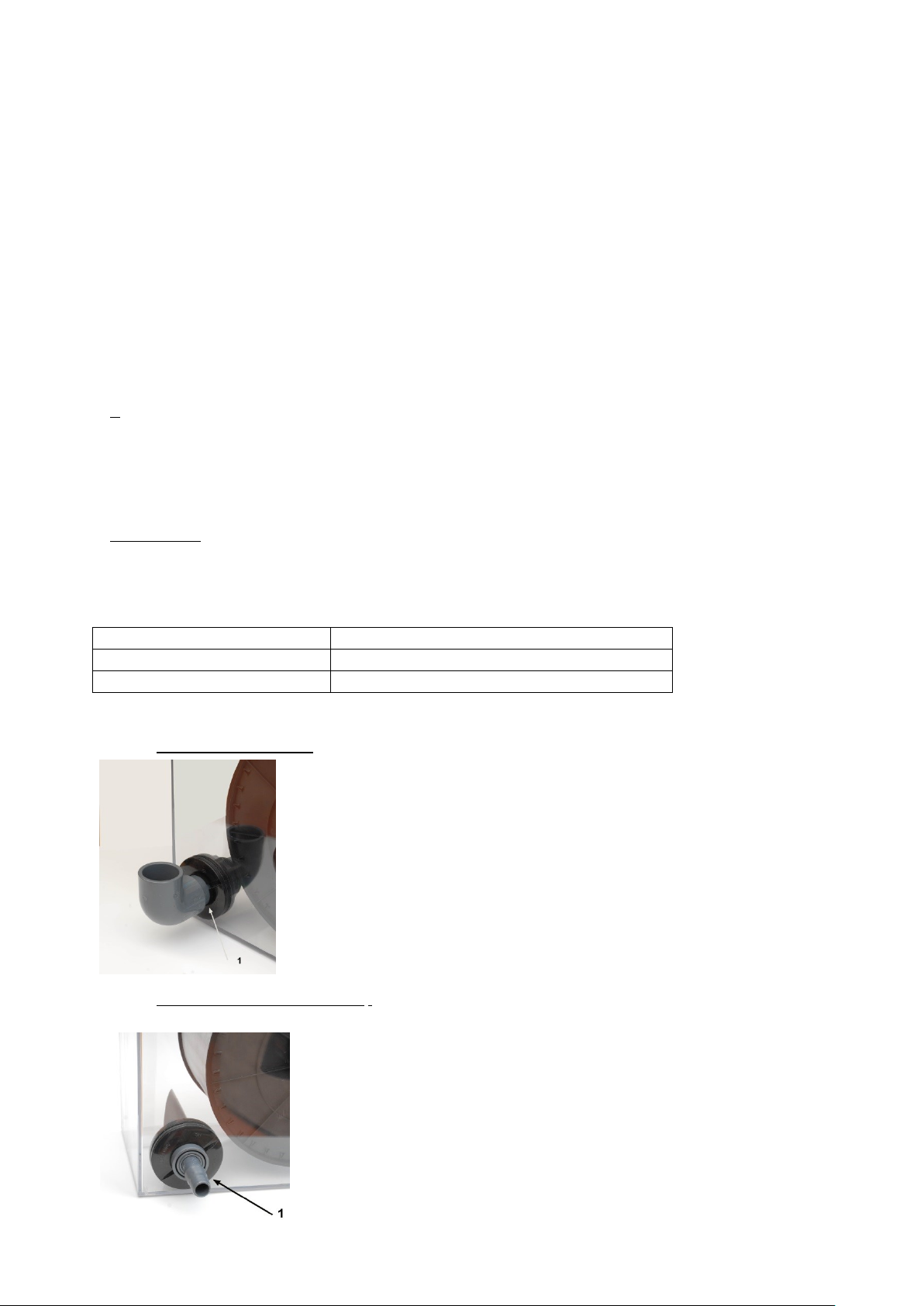

1. Water inlet by Gravity

If operated by gravity, the Rollermat is placed below the aquarium or below the

water level of the pond in the filter sump.

From the overflow chamber of the aquarium or from the skimmer of the pond a

pipe with a diameter of 40 mm is connected to the water inlet of the Rollermat

(1).

It is important, that the 40 mm pipe is just pressed into the tank union. If it is

glued, it the Rollermat cannot be disassembled for maintenance.

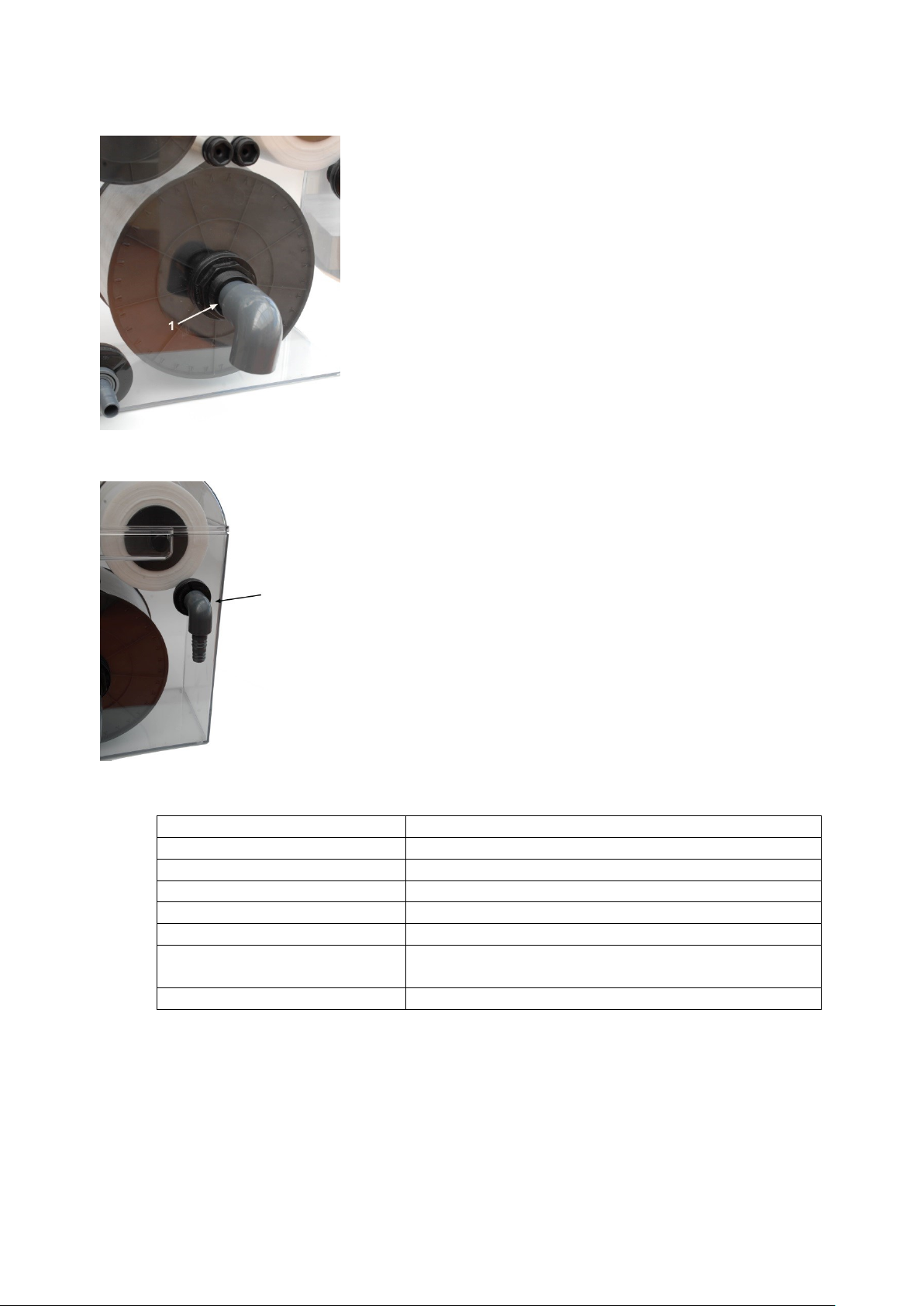

2. Water inlet by pump pressure.

If the Rollermat is supplied with water by a pump, the maximum flow is 2700l/h

(e.g. River 2700). The water inlet has to be reduced by a reduction fitting to a

¾” hose connector. This connections should be glued.

The Rollermat is placed above the water level of the aquarium or pond. The

water flows back by gravity into the aquarium or the pond.

Water outlet

The water outlet may not be reduced. A 40 mm PVC pipe should be

presses into the tank union. From here a PVC pipe can be directed to the

filter sump or pond. The pipe should not be glued into the tank union. If

it is glued, the Rollermat cannot not be disassembled.

Alternatively a 40 mm hose fitting can be pressed into the tank union

and a hose may be directed to the pond or aquarium.

In any case, the water must flow freely away from the outlet. Neither a

PVC pipe nor a flexible hose may be directed higher than the outlet of

the Rollermat.

Overflow

The emergency overflow is a 25 mm tank union. Here, you can press in a 25 mm

PVC pipe. From here the pipe is directed downwards in a free flow pipe.

Alternatively a 25 mm hose connection can be pressed into the tank union and a

hose can be directed to the pond or aquarium.

6.

Technical data

Power supply motor

12V, 50/60Hz , 4 Watts

Transformer

230V/50 Hz

Water inlet

D 40 glue connection, 1 ¾“ thread

Water outlet

D 40 glue connection, 1 ¾“ thread

overflow

D 25 glue connection, 1 “ thread

Width of the fleece roll

15 cm

Maximum water level, if placed

in a filter sump

12,5 cm above the bottom of the Rollermat

Dimensions (L x W x H)

42 x 25 x 45 cm

7.

Accessories: Spare fleece rolls

Article number: 3051100171 spare roll Aquarium “Fine“, 40g/m², 45m long

Article number: 3051100172 spare roll Pond “Standard“, 20g/m², 90m long

9. Failures

The fleece is not transported. This may have different reasons:

-The fleece is not lying straight on the drum; there is a gap between fleece and drum. Unfiltered

water can pass through this gap. The water level inside of the Rollermat will not rise high enough to

touch the level switch. Action: tear the fleece straight and set up the Rollermat straight (water

balance)

-The motor turns, however the fleece is not transported. The gear wheel on the shaft of the motor

does not turn. Reason: The gear wheel is broken and has to be changed. It is only pressed on the

shaft and can be removed by hand or with the help of a lever.

-The motor does not turn although the water level in the Rollermat is above the level switch and

already flows through the emergency overflow. This may have different reasons:

-If the red LED in the electric compartment is off, the transformer or the PCB are broken.

-The red LED is on, however the motor does not react on the level switch. In this case either the

motor or the level switch are broken. If the motor is broken, the electric compartment should be

warm, because the motor tries to turn. If the level switch is broken, the compartment will be cold,

because the motor is not switched on.

-All parts can be changed easily.

10.Warranty

Should any defect in material or workmanship be found within 12 months of the date of purchase,

Theiling GmbH undertakes to repair or, at our option, replace the defective part free of charge–

always provided the product has been installed correctly, is used for the purpose that was intended

by us, is used in accordance with the operating instructions and is returned to us carriage paid. The

warranty term is not applicable on the all consumable products. Proof of Purchase is requiredby

presentation of an original invoice or receipt indicating the dealer’s name, the model number and

date of purchase, or a Guarantee Card if appropriate. This warranty may not apply if any model or

production number has been altered, deleted or removed, unauthorized persons ororganisations

have executed repairs, modifications or alterations, or damage is caused by accident, misuseor

neglect. We regret we are unable to accept any liability for any consequential loss. Please notethat

the product is not defective under the terms of this warranty where the product, or any of its

component parts, was not originally designed and / or manufactured for the market in which it is

used. These statements do not affect your statutory rights as a customer. If your TheilingGmbH

product does not appear to be working correctly or appears to be defective, please contact your

dealer in the first instance. Before calling your dealer, please ensure you have read andunderstood

the operating instructions. If you have any questions your dealer cannot answer, please contact us.

Our policy is one of continual technical improvement and we reserve the right to modify and adjust

the specification of our products without priornotification.

Spare parts list

art no

name

3051100180

lid

3051100181

Roll

(delivering)

3051100182

Roll

/(receiving)

3051100183

Direction roll

for fleece

3051100184

Drum

3051100185

Rung for the

drum

3051100186

Screw

3051100187

Nut

3051100203

Square ring

3051100204

washer

3051100205

Tank Union

25 mm

(overflow)

3051100206

Tank Union

(40mm) for

inlet and

outlet

art no

/name

3051100207

Deckel

Elektro-

modul

Lid for

electric

module

3051100208

Screws for

the lid

3051100209

Sealing for

the lid

3051100174

Motor

3051100188

Gear wheel

3051100189

Sealing for

motor

3051100178

Level switch

3051100190

Sealing for

level switch

3051100200

Holder for

level switch

3051100201

Circuit plate

3051100202

Connection

cable

3051100177

Transformer

Theiling GmbH, Maschweg 49, D-49324 Melle - 10/2016

- Technical changes reserved –

This manual suits for next models

1

Other Theiling Water Filtration System manuals

Popular Water Filtration System manuals by other brands

SteriPEN

SteriPEN Adventurer user guide

Ispring

Ispring DF1 Series user manual

Laica

Laica Fast Disk FD03A Instructions and warranty

Trigano

Trigano J-PSC064 Instruction and maintenance manual

Danfoss

Danfoss AHF 005 operating instructions

Acqua Brevetti

Acqua Brevetti BravoMAX M Installation and operating manual

Beko

Beko CLEARPOINT Series operating manual

SkyJuice

SkyJuice SkyHydrant Set up and operating instructions

Graco

Graco 213-062 instructions

UV Pure Technologies

UV Pure Technologies UPSTREAM instruction manual

amiad

amiad SAF X Series Installation, operation & maintenance instructions

HEISSNER

HEISSNER FPU24000-00 Instructions for use