1-2 October30, 2008

POWERMASTER 400SP, 500SP AUTOMATION

WARNING

FUMES AND GASES can be hazardous to your

health.

Welding produces fumes and gases. Breathing

these fumes and gases can be hazardous to your

health.

1. Keep yourhead out of the fumes. Do not breathethe fumes.

2. If inside, ventilate the area and/oruse exhaust at the arc to

remove welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied respirator.

4. Read the Material Safety Data Sheets (MSDSs) and the

manufacturer’s instruction formetals, consumables, coatings,

and cleaners.

5. Work in a confined space only if it is well ventilated, orwhile

wearing an air-supplied respirator. Shielding gases used for

welding can displace aircausing injury ordeath. Be sure the

breathing airis safe.

6. Do not weld in locations neardegreasing, cleaning, or

spraying operations. The heat and rays of the arc can react

with vapors to form highly toxic and irritating gases.

7. Do not weld on coated metals, such as galvanized, lead, or

cadmium plated steel, unless the coating is removed from

the weld area, the area is well ventilated, and if necessary,

while wearing an air-supplied respirator. The coatings and

any metals containing these elements can give off toxic fumes

if welded.

WARNING

WELDING can cause fire orexplosion.

Sparks and spatterfly off from the welding arc. The

flying sparks and hot metal, weld spatter, hot

workpiece, and hot equipment can cause fires and

burns. Accidental contact of electrode orwelding

wire to metal objects can cause sparks, overheating,

orfire.

1. Protect yourself and others from flying sparks and hot metal.

2. Do not weld where flying sparks can strike flammable material.

3. Remove all flammables within 35 ft (10.7 m) of the welding

arc. If this is not possible, tightly coverthem with approved

covers.

4. Be alert that welding sparks and hot materials from welding

can easily go through small cracks and openings to adjacent

areas.

5. Watch forfire, and keep a fire extinguishernearby.

6. Be aware that welding on a ceiling, floor, bulkhead, orpartition

can cause fire on the hidden side.

7. Do not weld on closed containers such as tanks ordrums.

8. Connect work cable to the work as close to the welding area

as practical to prevent welding current from traveling long,

possibly unknown paths and causing electric shock and fire

hazards.

9. Do not use welderto thaw frozen pipes.

10. Remove stick electrode from holderorcut off welding wire

at contact tip when not in use.

WARNING

FLYING SPARKS AND HOT METAL can cause injury.

Chipping and grinding cause flying metal. As welds

cool, they can throw off slag.

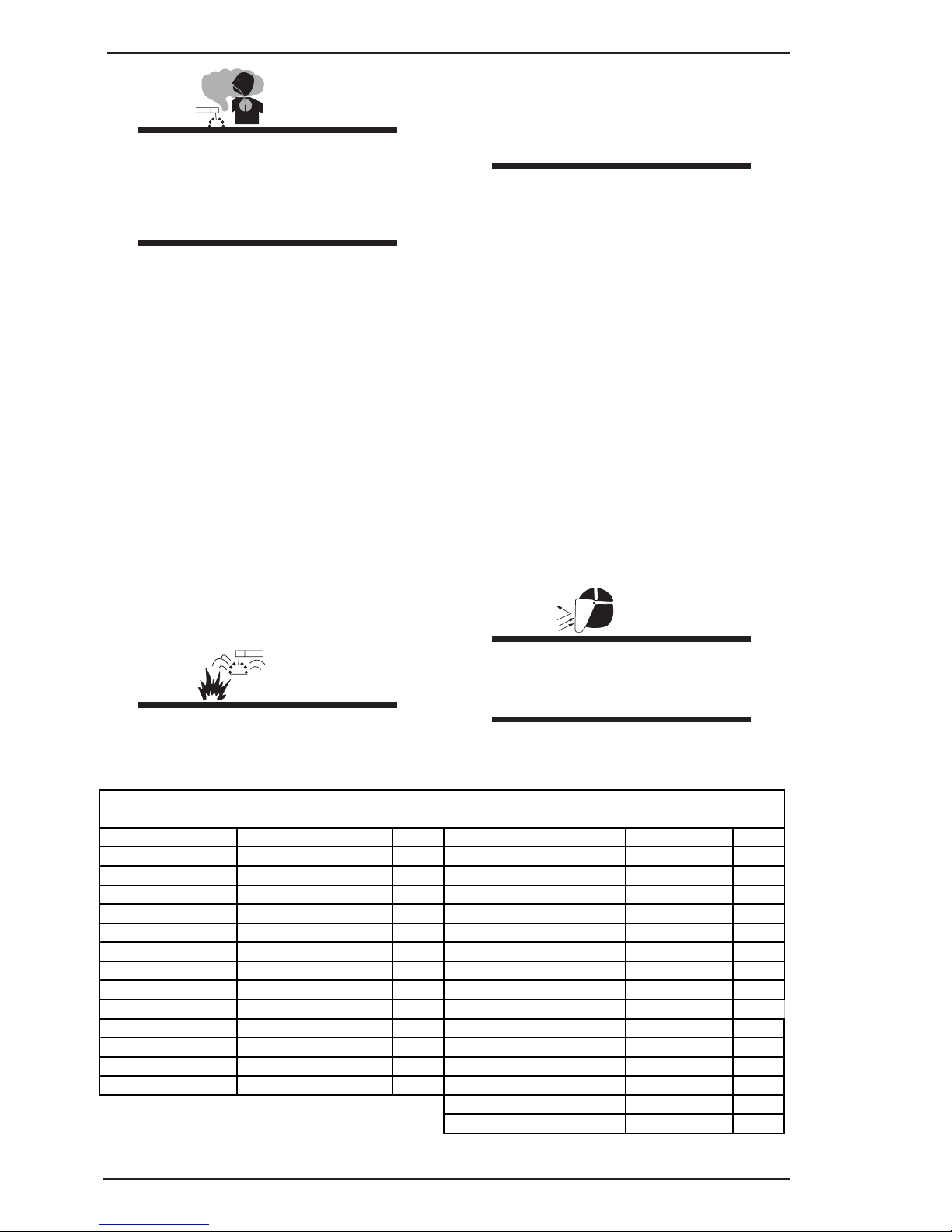

Welding orcutting Electrode Size FilterWelding orcutting Electrode Size Filter

Torch soldering 2 Gas metal-arc

Torch brazing 3 or4 Non-ferrous base metal All 11

Oxygen Cutting Ferrous base metal All 12

Light Under1 in., 25 mm 3 or4 Gas tungsten arc welding All 12

Medium 1 to 6 in., 25-150 mm 4 or5 (TIG) All12

Heavy Over6 in., 150 mm 5 or6Atomichydrogen welding All 12

Gas welding Carbon arc welding All 12

Light Under1/8 in., 3 mm 4 or5 Plasma arc welding

Medium 1/8 to 1/2 in., 3-12 mm 5 or6 Carbon arc air gouging

Heavy Over1/2 in., 12 mm 6 or8 Light 12

Shielded metal-arc Under5/32 in., 4 mm 10 Heavy 14

5/32 to 1/4 in., 12 Plasma arc cutting

Over1/4 in., 6.4 mm 14 Light Under300 Amp 9

Medium 300 to 400 Amp 12

Heavy Over400 Amp 14

Eye protection filter shade selector for welding or cutting

(goggles or helmet), from AWS A6.2-73.