Thermal Care TSE Instruction Manual

Table of Contents

Foreword .................................................................................................................................................................................................................. 1

Safety Guidelines .................................................................................................................................................................................................. 1

Pre-Installation....................................................................................................................................................................................................... 2

Receiving Inspection ....................................................................................................................................................................................... 2

Unit Storage........................................................................................................................................................................................................ 3

Installation - Chiller.............................................................................................................................................................................................. 3

Foundation.......................................................................................................................................................................................................... 3

Unit Location ...................................................................................................................................................................................................... 3

Rigging ................................................................................................................................................................................................................. 3

Process Fluid Piping ........................................................................................................................................................................................ 3

Condenser Water Piping ............................................................................................................................................................................... 3

Water Pressure Gauges.................................................................................................................................................................................. 4

System Temperature Sensor........................................................................................................................................................................ 4

Chiller Flow Sensor........................................................................................................................................................................................... 4

Installation - Remote Condenser.................................................................................................................................................................... 5

Location................................................................................................................................................................................................................ 5

Table 1 - Condenser Clearance Requirements ................................................................................................................................. 5

Flat Coil Condenser Foot Mounting.......................................................................................................................................................... 5

Figure 1 - Mounting Legs.......................................................................................................................................................................... 6

Lifting .................................................................................................................................................................................................................... 6

Interconnecting Refrigerant Piping........................................................................................................................................................... 6

Refrigeration Piping Design ......................................................................................................................................................................... 6

Figure 2 – Condenser Located at Chiller Level.................................................................................................................................. 7

Figure 3 – Condenser Located Below Chiller Unit........................................................................................................................... 7

Figure 4 - Condenser Located Above Chiller Unit........................................................................................................................... 7

Determining Equivalent Line Length ........................................................................................................................................................ 7

Table 2 – Equivalent Lengths of Elbows .............................................................................................................................................. 7

Liquid Line Sizing.............................................................................................................................................................................................. 7

Table 3 – Liquid Line Sizes for R410A................................................................................................................................................... 8

Discharge (Hot Gas) Line Sizing................................................................................................................................................................11

Figure 5 – Vertical Riser Traps ...............................................................................................................................................................11

Figure 6 - Double Discharge Riser.......................................................................................................................................................11

Table 4 - Horizontal or Downflow Discharge Line Sizes for R410A (inches OD) ..............................................................11

Table 5 - Upflow Discharge Line Sizes for R410A (inches OD).................................................................................................12

Calculating Refrigerant and Oil Charge.................................................................................................................................................12

Table 6 – Chiller and Condenser Refrigerant Charge...................................................................................................................13

Table 7 - Field Piping R-410A Refrigerant Charges......................................................................................................................13

Oil Charge Determination...........................................................................................................................................................................13

Installation - Electrical.......................................................................................................................................................................................13

Control Operation ..............................................................................................................................................................................................15

Screen Navigation..........................................................................................................................................................................................15

System Initialization.......................................................................................................................................................................................15

Figure 7 – Start-Up Splash Screen.......................................................................................................................................................15

Home – Chiller Home Screen.........................................................................................................................................................................16

System Overview ............................................................................................................................................................................................16

Figure 8 – Chiller Home Screen ............................................................................................................................................................16

Table 7 – System Overview Functions................................................................................................................................................16

Starting and Stopping the Chiller.................................................................................................................................................................17

Starting the Chiller .........................................................................................................................................................................................17

Figure 9 – Chiller Start ..............................................................................................................................................................................17

Stopping the Chiller ......................................................................................................................................................................................17

Figure 10 – Chiller Stop............................................................................................................................................................................17

Menu 1 - Overview.............................................................................................................................................................................................17

Figure 11 – Menu 1 Screen.....................................................................................................................................................................17

Menu 2 - Overview.............................................................................................................................................................................................17

Figure 12 – Menu 2 Screen.....................................................................................................................................................................17

Menu 1 - Alarms..................................................................................................................................................................................................18

Alarms Active ...................................................................................................................................................................................................18

Figure 13 –Alarms Active Handler .......................................................................................................................................................18

Alarms History .................................................................................................................................................................................................18

Figure 14 – Alarm History .......................................................................................................................................................................18

Warning Glycol................................................................................................................................................................................................18

Figure 15 – Warning Antifreeze............................................................................................................................................................18

Menu 1 – Diagnostics........................................................................................................................................................................................19

Diagnostics Menu...........................................................................................................................................................................................19

Figure 16 – Diagnostics Menu Screen................................................................................................................................................19

Figure 17 – Diagnostics Circuit Details Screen ...............................................................................................................................19

Figure 18 – Diagnostics Circuit Interlock Screen............................................................................................................................19

Figure 19 – Diagnostics Pumps Screen..............................................................................................................................................19

Figure 20 – Chiller Tank Screen.............................................................................................................................................................19

Figure 21 – Diagnostics Process Screen ............................................................................................................................................19

Figure 22 – Diagnostics Hardware Screen........................................................................................................................................19

Figure 23 – Diagnostics Import/Export Data Screen....................................................................................................................20

Figure 24 – Diagnostics Overview Screen.........................................................................................................................................20

Figure 25 – Diagnostics Import/Export Data Screen....................................................................................................................20

Menu 1 – Security...............................................................................................................................................................................................20

Security Menu..................................................................................................................................................................................................20

Figure 26 - Security Menu.......................................................................................................................................................................20

Figure 27 - Security – Log In Screen...................................................................................................................................................20

Figure 28 - Security – Add User Screen.............................................................................................................................................20

Figure 29 - Security – Edit User Screen..............................................................................................................................................21

Figure 30 - Security – Delete User Screen ........................................................................................................................................21

Figure 31 - Security – Change Password Screen............................................................................................................................21

Table 9 - Security – Users and Passwords ........................................................................................................................................21

Menu 1 – Inputs / Outputs .............................................................................................................................................................................21

Figure 32 - Main Inputs/Outputs Screen ..........................................................................................................................................21

Figure 33 - Inputs/Outputs – Temperature Inputs Screen.........................................................................................................22

Figure 34 - Inputs/Outputs – Pressure Inputs.................................................................................................................................22

Figure 35 - Inputs/Outputs – Analog Inputs Screen ....................................................................................................................22

Figure 36 - Inputs/Outputs – Digital Inputs Screen......................................................................................................................22

Figure 37 - Inputs/Outputs – Analog Outputs Screen.................................................................................................................22

Figure 38 - Inputs/Outputs – Digital Outputs Screen..................................................................................................................22

Figure 39 - Inputs/Outputs – Digital Outputs Screen..................................................................................................................22

Menu 1 – User Setup.........................................................................................................................................................................................23

Figure 40 - User Setup - Menu 1 Screen...........................................................................................................................................23

Figure 41 - User Setup - Menu 2 Screen...........................................................................................................................................23

Figure 42 - User Setup - Menu 3 Screen...........................................................................................................................................23

Figure 43 - User Setup - Menu 4 Screen...........................................................................................................................................23

Figure 44 - User Setup - Menu 5 Screen...........................................................................................................................................23

User Setup – Alarm Setup ...............................................................................................................................................................................23

Figure 45 - User Setup - Alarm Setup Screen .................................................................................................................................23

Table 10 – Alarm Setup Parameters....................................................................................................................................................24

User Setup – Hot Gas Bypass.........................................................................................................................................................................24

Figure 46 - User Setup – Hot Gas Bypass Setup Screen .............................................................................................................24

Table 11 – Hot Gas Bypass Valve Setup Parameters....................................................................................................................24

User Setup – Pump Control............................................................................................................................................................................25

Pump Control Screen....................................................................................................................................................................................25

Figure 47 - User Setup – Pumps Screen (Dedicated Backups).................................................................................................25

Figure 48 - User Setup – Pumps Screen (Dual Standby) ............................................................................................................25

Figure 49 - User Setup – Pumps VFD .................................................................................................................................................25

User Setup – EEV Control ................................................................................................................................................................................25

Figure 50 - User Setup – EEV Control Setup Screen.....................................................................................................................25

Table 12 – EEV Control Setup Parameters........................................................................................................................................25

User Setup – Compressor Staging...............................................................................................................................................................26

Figure 51 - User Setup – Compressor Staging Setup Screen ...................................................................................................26

Table 13 – Compressor Staging Setup Parameters ......................................................................................................................26

User Setup – Stage Order................................................................................................................................................................................26

Compressor Stage Order Screen..............................................................................................................................................................26

Figure 52 - User Setup – Stage Order Setup Screen....................................................................................................................26

Table 14 – Stage Order Setup Parameters .......................................................................................................................................26

User Setup – Discharge Control Setup.......................................................................................................................................................27

Discharge Control Setup Screen ..............................................................................................................................................................27

Figure 53 - User Setup – Discharge Control Setup Screen........................................................................................................27

Table 15 – Discharge Control Setup Parameters ...........................................................................................................................27

Figure 54 - User Setup – Discharge Control Setup Screen (Remote Air Cooled) .............................................................27

Table 16 – Discharge Control Setup Parameters ...........................................................................................................................27

User Setup – Dynamic Lift Setup ..................................................................................................................................................................28

Dynamic Lift Setup Screen..........................................................................................................................................................................28

Figure 55 - User Setup – Dynamic Lift Setup Screen ...................................................................................................................28

Table 17 – Dynamic Lift Parameters....................................................................................................................................................28

User Setup – Serial Communications Setup.............................................................................................................................................28

Modbus RTU Setup Screen.........................................................................................................................................................................28

Figure 56 - User Setup – Modbus RTU Setup Screen ..................................................................................................................28

User Setup – Temperature Retransmit.......................................................................................................................................................28

Figure 57 - User Setup – Temperature Retransmit Setup Screen ...........................................................................................28

User Setup – IP Address...................................................................................................................................................................................28

Figure 58 - User Setup – IP Address Setup Screen .......................................................................................................................28

User Setup – Units..............................................................................................................................................................................................28

Figure 59 - User Setup – Display Units Setup Screen ..................................................................................................................28

User Setup – Remote Setpoint......................................................................................................................................................................29

Figure 60 - User Setup – Remote Setpoint Setup Screen ..........................................................................................................29

User Setup – Primary / Secondary ...............................................................................................................................................................29

Figure 61 - User Setup – Primary / Secondary Setup Screen....................................................................................................29

User Setup – Chiller Capacity.........................................................................................................................................................................29

Chiller Capacity Screen.................................................................................................................................................................................29

Figure 62 - User Setup – Chiller Capacity Setup Screen .............................................................................................................29

User Setup – Date/Time ...................................................................................................................................................................................29

Date/Time Screen...........................................................................................................................................................................................29

Figure 63 - User Setup – Date / Time Setup Screen.....................................................................................................................29

User Setup – Pump Down ...............................................................................................................................................................................30

Pump Down Screen .......................................................................................................................................................................................30

Figure 64 - User Setup – Pump Down Setup Screen....................................................................................................................30

User Setup – Evaporator Valve......................................................................................................................................................................30

Evaporator Valve Control Screen .............................................................................................................................................................30

Figure 65 - User Setup – Evaporator Valve Control Setup Screen..........................................................................................30

User Setup – Miscellaneous Process Control...........................................................................................................................................30

User Setup – Miscellaneous Local Mode...................................................................................................................................................30

User Setup – Miscellaneous Automatic Start...........................................................................................................................................30

User Setup – Miscellaneous Current Sensors ..........................................................................................................................................30

Figure 66 - User Setup – Miscellaneous Control Setup Screen ...............................................................................................30

User Setup – Chiller Tank and Water Makeup ........................................................................................................................................31

Figure 67 - User Setup – Chiller Tank and Water Makeup Setup Screen ............................................................................31

Menu 1 – Trending.............................................................................................................................................................................................31

Figure 68 - System Trending 1 Screen...............................................................................................................................................31

Figure 69 - System Trending 2 Screen...............................................................................................................................................31

Figure 70 - System Trending 3 Screen...............................................................................................................................................31

Figure 71 - System Trending 4 Screen...............................................................................................................................................31

Menu 2 – Full Screen .........................................................................................................................................................................................32

Figure 72 - Menu 2 – Full Screen .........................................................................................................................................................32

Modbus...................................................................................................................................................................................................................33

Table 18 – Modbus Table........................................................................................................................................................................33

Start-Up ..................................................................................................................................................................................................................35

Step 1 – Connect Main Power...................................................................................................................................................................35

Step 2 – Fill Coolant Circuit ........................................................................................................................................................................35

System Fill Water Chemistry Requirements.....................................................................................................................................35

Table 19 – Fill Water Chemistry Requirements...............................................................................................................................36

Table 20 - Recommended Glycol Solutions.....................................................................................................................................37

Step 3 - Check Condenser ..........................................................................................................................................................................37

Water-Cooled Condenser Check..........................................................................................................................................................37

Remote Air-Cooled Condenser Check...............................................................................................................................................37

Step 4 – Check Refrigerant Valves...........................................................................................................................................................37

Step 5 – Check Low Temperature Alarm...............................................................................................................................................37

Step 6 – Turn On Control Power ..............................................................................................................................................................37

Step 8 – Initial Unit Operation...................................................................................................................................................................38

Preventive Maintenance...................................................................................................................................................................................38

Once a Week ....................................................................................................................................................................................................38

Once a Month..................................................................................................................................................................................................39

Once Every 6 Months....................................................................................................................................................................................39

Once a Year.......................................................................................................................................................................................................39

Cleaning the Operator Interface...................................................................................................................................................................40

General Troubleshooting.................................................................................................................................................................................41

Preventive Maintenance Checklist ...............................................................................................................................................................42

Drawings.................................................................................................................................................................................................................42

1

Foreword

The central chiller consists of a refrigeration circuit to

provide cooling water to coolant.

This manual is to serve as a guide for installing,

operating, and maintaining the equipment. Improper

installation, operation, and maintenance can lead to

poor performance and/or equipment damage. Use

qualified installers and service technicians for all

installation and maintenance of this equipment.

This manual is for our standard product and is

general in nature. Unit-specific drawings and

supplemental documents are included with the

equipment as needed. Additional copies of

documents are available upon request.

Due to the ever-changing nature of applicable

codes, ordinances, and other local laws pertaining to

the use and operation of this equipment, we do not

reference them in this manual.

The equipment uses a hydrofluorocarbon (HFC),

trade named R-410A, as a chemical refrigerant for

heat transfer purposes. This chemical is sealed and

tested in a pressurized system containing ASME

coded vessels; however, a system failure will release

it. Refrigerant gas can cause toxic fumes if exposed

to fire. Place these units in a well-ventilated area,

especially if open flames are present. Failure to

follow these instructions could result in a hazardous

condition. We recommend the use of a refrigerant

management program to document the type and

quantity of refrigerant in the equipment. In addition,

we recommend only licensed and EPA certified

service technicians work on our refrigeration circuits.

Safety Guidelines

Observe all safety precautions during installation,

start-up, and service of this equipment. The

following is a list of symbols used in this manual and

their meaning.

General Warning

Electricity Warning

Sharp Element Warning

Hot Surface Warning

Flammable Material Warning

Explosive Material Warning

General Mandatory Action

Wear Eye Protection

Wear Protective Gloves

Wear Ear Protection

Disconnect Before Carrying Out Maintenance or

Repair

Connect an Earth Terminal to Ground

2

Only qualified personnel should install, start-up, and

service this equipment. When working on this

equipment, observe precautions in this manual as

well as tags, stickers, and labels on the equipment.

WARNING: Any use or misuse of this equipment

outside of the design intent may cause injury or harm.

WARNING: Vent all refrigerant relief valves in

accordance to ANSI/ASHRAE Standard 15, Safety Code

for Mechanical Refrigeration. Locate this equipment in

a well-ventilated area. Inhalation of refrigerant can be

hazardous to your health and the accumulation of

refrigerant within an enclosed space can displace

oxygen and cause suffocation.

WARNING: This equipment contains hazardous

voltages that can cause severe injury or death.

WARNING: This equipment contains refrigerant under

pressure. Accidental release of refrigerant under

pressure can cause personal injury and or property

damage.

WARNING: This equipment may contain fan blades or

other sharp edges. Make sure all fan guards and other

protective shields are securely in place.

WARNING: The exposed surfaces of motors, refrigerant

piping, and other fluid circuit components can be very

hot and can cause burns if touched with unprotected

hands.

CAUTION: Disconnect and lock out incoming power

before installing, servicing, or maintaining the

equipment. Connecting power to the main terminal

block energizes the entire electric circuitry of the unit.

Shut off the electric power at the main disconnect

before opening access panels for repair or

maintenance.

CAUTION: Wear eye protection when installing,

maintaining, or repairing the equipment to protect

against any sparks, debris, or fluid leaks.

CAUTION: The equipment will exceed 70 dBA sound

pressure at 1 meter distance and 1 meter elevation

when operating. Wear ear protection as required for

personal comfort when operating or working in close

proximity to the chiller.

CAUTION: Wear protective gloves when installing,

maintaining, or repairing the equipment to protect

against any sparks, debris, or fluid leaks.

Pre-Installation

Receiving Inspection

When the unit arrives, verify the information on the

unit nameplate agrees with the order

acknowledgement and shipping papers. Inspect the

equipment for any visible damage and verify all

items shown on the bill of lading are present. If

damage is evident, document it on the delivery

receipt by clearly marking any item with damage as

“unit damage” and notify the carrier. In addition,

notify our Customer Service Department and they

will provide assistance with preparing and filing

freight damage claims, including arranging for an

estimate on repair costs; however, filing the shipping

damage claim is the responsibility of the receiving

party. Do not install damaged equipment without

getting the equipment repaired.

Shipping damage is the responsibility of the carrier.

To protect against possible loss due to damage

incurred during shipping and to expedite payment

for damages, it is important to follow proper

procedures and keep records. Photographs of

damaged equipment are excellent documentation

for your records.

Start unpacking the unit, inspect for concealed

damage, and take photos of any damage found.

Once received, equipment owners have the

responsibility to provide reasonable evidence that

the damage did not occur after delivery. Photos of

the equipment damage while the equipment is still

partially packed will help in this regard. Refrigerant

lines can be susceptible to damage in transit. Check

for broken lines, oil leaks, damaged controls, or any

other major component torn loose from its

mounting point.

Record any signs of concealed damage and file a

shipping damage claim immediately with the

shipping company. Most carriers require concealed

damages be reported within 15 days of receipt of

the equipment. In addition, notify our Customer

Service Department and they will provide assistance

with preparing and filing freight damage claims,

including arranging for an estimate on repair costs;

however, filing the shipping damage claim is the

responsibility of the receiving party.

3

A full refrigerant charge is included in chillers with an

integral water-cooled condenser. Chillers designed

for use with a remote air-cooled condenser and the

remote condensers themselves ship with a nitrogen

holding charge. Check the remote condenser for

signs of leaks prior to rigging. This will ensure no coil

damage has occurred after the unit left the factory.

The condenser ships with the legs removed. Mount

the legs to the condenser using the provided nuts,

bolts, and washers.

Unit Storage

When storing the unit it is important to protect it

from damage. Blow out any water from the unit;

cover it to keep dirt and debris from accumulating or

getting in, and store in an indoor sheltered area that

does not exceed 145°F.

Installation - Chiller

Foundation

Install the unit on a rigid, non-warping mounting

pad, concrete foundation, or level floor suitable to

support the full operating weight of the equipment.

When installed the equipment must be level within

¼ inch over its length and width.

Unit Location

The unit is available in many different configurations

for various environments. Refer to the proposal and

order acknowledgement document for the

equipment to verify the specific design conditions in

which it can operate.

To ensure proper airflow and clearance space for

proper operation and maintenance allow a minimum

of 36 inches of clearance between the sides of the

equipment and any walls or obstructions. Avoid

locating piping or conduit over the unit to ensure

easy access with an overhead crane or lift to lift out

heavier components during replacement or service.

In addition, ensure the condenser and evaporator

refrigerant pressure relief valves can vent in

accordance with all local and national codes.

Rigging

The chiller has a frame to facilitate easy movement

and positioning with a crane or forklift. Follow

proper rigging methods to prevent damage to

components. Avoid impact loading caused by

sudden jerking when lifting or lowering the chiller.

Use pads where abrasive surface contact may occur.

Process Fluid Piping

Proper insulation of chilled process fluid piping is

crucial to prevent condensation. The formation of

condensation adds a substantial heat load to the

chiller.

The importance of properly sized piping cannot be

overemphasized. See the ASHRAE Handbook or

other suitable design guide for proper pipe sizing. In

general, run full size piping out to the process and

reduce pipe size at connections as needed. One of

the most common causes of unsatisfactory chiller

performance is poor piping system design. Avoid

long lengths of hoses, quick disconnect fittings, and

manifolds wherever possible as they offer high

resistance to water flow. When manifolds are

required, install them as close to the use point as

possible. Provide flow-balancing valves at each

machine to assure adequate water distribution in the

entire system.

Condenser Water Piping

(Water-Cooled Condenser Units Only)

The performance of a water-cooled condenser is

dependent on the flow and temperature of the

cooling water used. Insufficient cooling of the

condenser will result in the reduction of cooling

capacity of the chiller and under extreme conditions

may result in the chiller shutting down due to high

refrigerant pressure. Allowing the condenser to plug

up from contaminants in the condenser water

stream adversely affects performance. In order to

reduce maintenance costs and chiller downtime, a

water treatment program is highly recommended for

the condenser cooling water. Contact our Customer

Service Department for assistance in the proper

procedure for cleaning out any plugged condenser.

The nominal water-cooled condenser is design for

85°F condenser cooling water supply. Under normal

operation there will be about a 10°F rise through the

condenser resulting in 95°F exiting water. To ensure

proper water flow through the condenser, ensure the

condenser water pump provides at least 25 psi or

water at a flow rate of 3 gpm per ton of chiller

capacity.

4

Each condenser has a two-way condenser water-

regulating valve. The condenser water-regulating

valve controls the amount of water allowed to pass

through the condenser in order to maintain proper

refrigeration pressures in the circuit.

To prevent damage to the condenser and/or water-

regulating valve, the water pressure should not

exceed 150 psig.

Water Pressure Gauges

Install pressure gauges in the inlet and outlet of both

the condenser and evaporator chilled water piping

to provide the ability to read the pressure drop

across the chiller and aid in preventive maintenance

and troubleshooting.

WARNING: Vent all refrigerant relief valves in accordance

to ANSI/ASHRAE Standard 15, Safety Code for Mechanical

Refrigeration. Locate this equipment in a well-ventilated

area. Inhalation of refrigerant can be hazardous to your

health and the accumulation of refrigerant within an

enclosed space can displace oxygen and cause suffocation.

WARNING: This equipment contains hazardous voltages

that can cause severe injury or death.

WARNING: This equipment contains refrigerant under

pressure. Accidental release of refrigerant under pressure

can cause personal injury and or property damage.

WARNING: This equipment may contain fan blades or

other sharp edges. Make sure all fan guards and other

protective shields are securely in place.

WARNING: The exposed surfaces of motors, refrigerant

piping, and other fluid circuit components can be very hot

and can cause burns if touched with unprotected hands.

CAUTION: Disconnect and lock out incoming power before

installing, servicing, or maintaining the equipment.

Connecting power to the main terminal block energizes

the entire electric circuitry of the unit. A power supply

provides 24 VDC control power. Shut off the electric power

at the main disconnect before opening access panels for

repair or maintenance.

CAUTION: Wear eye protection when installing,

maintaining, or repairing the equipment to protect against

any sparks, debris, or fluid leaks.

CAUTION: The equipment will exceed 70 dBA sound

pressure at 1 meter distance and 1 meter elevation when

operating. Wear ear protection as required for personal

comfort when operating or working in close proximity to

the chiller.

CAUTION: Wear protective gloves when installing,

maintaining, or repairing the equipment to protect against

any sparks, debris, or fluid leaks.

System Temperature Sensor

This section only applies to installations where

multiple chillers are in a common system where one

chiller is the primary chiller with the other chillers

serving as secondary chillers. In those situations, a

field-installed fluid-temperature sensor is required in

the common process fluid supply and return piping.

Install the sensor downstream of all individual chilled

water supply streams. Position the temperature

sensor to read the mixed supply temperature. The

supply temperature sensor is normally the control

sensor for the chiller system set point and

determines the loading/unloading of the

compressors of the system.

The temperature sensor comes from the factory with

a ½” NPT male fitting thermowell for direct

mounting in the field piping. Mount the temperature

sensor in a minimum pipe size of 3”. Wire the

temperature sensor to the designated primary chiller

electrical enclosure and land at the appropriate

terminal blocks within the enclosure. See the chiller

electrical schematic for further details.

Chiller Flow Sensor

This section only applies to installations when the

flow sensor option is present. In those situations, a

field-installed chiller flow sensor is required. Mount

the flow sensor in the process fluid supply piping in

an area of pipe with a minimum of 10 pipe diameters

of straight run after any valves or pipefittings. This

ensures the stream of fluid is solid and stable for

accurate flow measurement.

The flow sensor comes from the factory with a ½”

NPT compression fitting for direct mounting in the

field piping. Mount the flow sensor in a minimum

pipe size of 2”. Insert the stem of the sensor into the

compression fitting so the tip of the sensor is at the

approximate center of the pipe. The sensor requires

five pipe diameters of straight run piping on both

sides of the sensor. Wire the flow sensor to the

chiller electrical enclosure and land at the

appropriate terminal blocks with the enclosure. See

the chiller electrical schematic for further details.

5

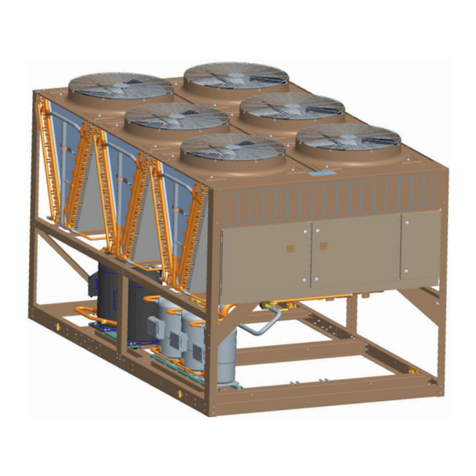

Installation - Remote Condenser

Chillers designed for use with a remote air-cooled

condenser include a factory-selected remote

condenser. The remote air-cooled condenser

typically ships separately from a different location

than the chiller.

Location

The remote air-cooled condenser is for outdoor use.

Locate the remote condenser in an accessible area.

The vertical air discharge must be unobstructed.

When locating the condenser it is important to

consider accessibility to the components to allow for

proper maintenance and servicing of the unit. Avoid

locating piping or conduit over the unit to ensure

easy access with an overhead crane or lift to lift out

heavier components during replacement or service.

Proper ventilation is another important

consideration when locating the condenser. In

general, locate the unit in an area that will not rise

above 110°F.

Install the unit on a firm, level base no closer than its

width from walls or other condensers. Avoid

locations near exhaust fans, plumbing vents, flues, or

chimneys. Fasten the mounting legs at their base to

the steel or concrete of the supporting structure. For

units mounted on a roof structure, the steel support

base holding the condenser should be elevated

above the roof and attached to the building.

Avoid areas that can create a “micro-climate” such as

an alcove with east, north, and west walls that can be

significantly warmer than surrounding areas. The

condenser needs to have unrestricted airways so it

can easily move cool air in and heated air away.

Consider locating the condenser where fan noise

and vibration transmission into nearby workspaces is

unlikely.

Table 1 - Condenser Clearance Requirements

Nominal Cooling Capacity (ton)

From

Ends

(in)

From

Sides

(in)

10 to 80 single-circuit (flat coil)

48

48

100 single-circuit (V-coil)

36

63

120 single-circuit (V-coil)

36

80

20 to 160 ton dual-circuit (flat coil)

48

48

200 ton dual circuit (V-coil)

36

47

240 ton dual-circuit (V-coil)

36

62

The clearance requirements are to ensure proper

airflow and to provide space for maintenance. Due

to the nature of their design, the flat coil units

require a minimum of 48 inches all around each

condenser. If two condensers are side-by-side, the

total clearance requirement is 96 inches. For the V-

coil units, the 36-inch clearance at the ends is only

for maintenance access, all of the air entered the

coils from the sides. The clearances shown in the

chart for the V-coils are for ground mounting;

however, if the V-coil units are elevated 12 inches or

more above the ground to allow airflow under the

coils, they can be place 12 inches apart. We

recommend a minimum of 36 inch clear between V-

coil units when elevated the 12 inches or more just

to leave room for maintenance access.

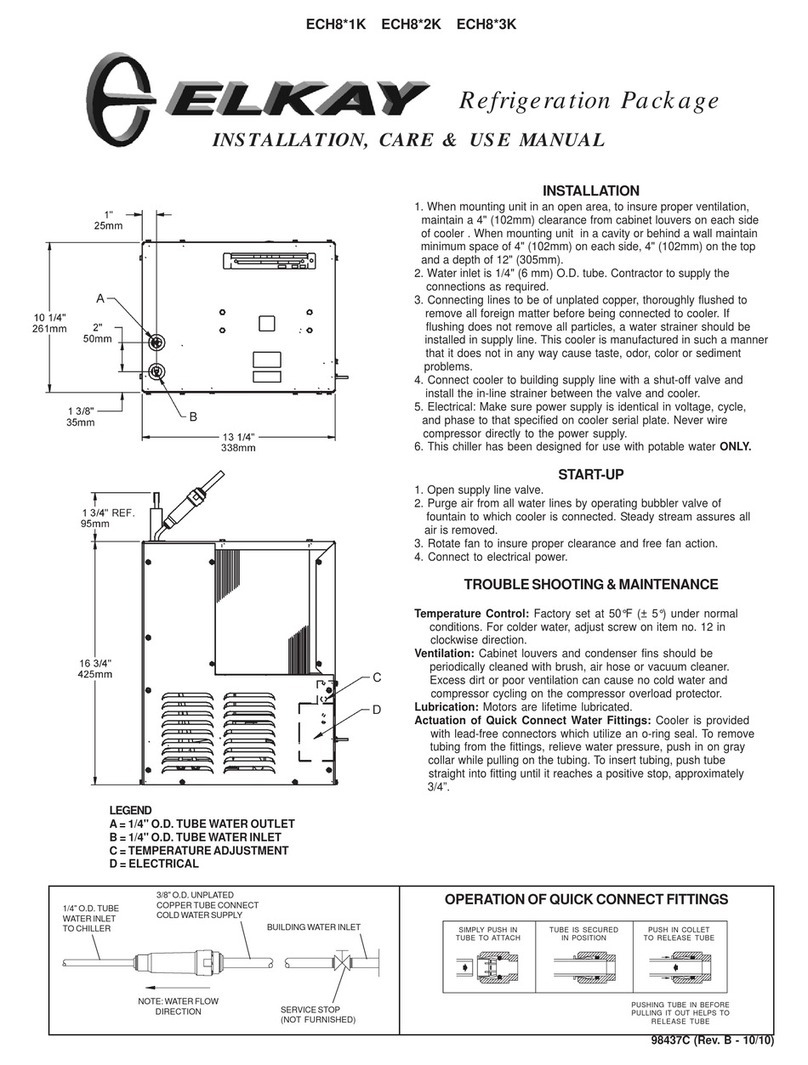

Flat Coil Condenser Foot Mounting

The 10 through 80-ton single-circuit and 20 through

160-ton dual-circuit condensers are a flat or

horizontal coil design and ship on their sides with

the legs removed to reduce shipping dimensions

and provide more protection to the coil from

possible damage caused by impact loading over

rough roads and transit conditions.

Assemble the corner legs to the bottom flanges on

the unit side panels and end panels using the

hardware provided and the matching mounting

hole-patterns. All corner legs are the same. For units

that are longer than three fans, assemble the center

leg. Remove two bolts from the bottom flange of the

unit side panels that match the hole-pattern on the

top flanges of both legs. Attached the center legs

using the hardware provide at the center-divider

panel location. Replace the bolts removed from the

side panels to secure the leg assembly to the bottom

flanges of the condenser side panels.

6

Figure 1 - Mounting Legs

Lifting

Use only qualified personnel using the proper

equipment when lifting and positioning the

condenser. Lift the remote condenser using the leg

support channels or the side lifting brackets. Use

spreader bars when lifting to apply the lifting force

vertically. Under no circumstances use the coil

headers or return bends in the lifting or moving of

the condenser.

Interconnecting Refrigerant Piping

The chiller and remote condenser ship with a

nitrogen holding charge. Evacuation of this charge is

required before charging with refrigerant. The chiller

is for use only with the air-cooled condenser

provided with the unit. The following section covers

the required piping between the chiller and the

provided air-cooled condenser.

The discharge and liquid lines leaving the chiller

have caps. These line sizes do not necessarily reflect

the actual line sizes required for the piping between

the chiller and the air-cooled condenser.

Refrigerant piping size and piping design have a

significant impact on system performance and

reliability. All piping should conform to the

applicable local and state codes.

CAUTION: Use refrigerant grade copper tubing ASTM

B280 only and isolate the refrigeration lines from

building structures to prevent transfer of vibration. All

copper tubing must have a pressure rating suitable for

R-410A: tubing that is 3/4” OD or larger must be Type

K rigid tubing. ACR annealed tubing coil may be used

for sizes 5/8” ODS or smaller.

Do not use a saw to remove end caps. This might

allow copper chips to contaminate the system. Use a

tube cutter or heat to remove the caps. When

sweating copper joints it is important to evacuate all

refrigerant present and flow dry nitrogen through

the system. This prevents the formation of toxic

gases, corrosive acids, and scale.

CAUTION: Do not use soft solders. For copper-to-

copper joints use a copper-phosphorus braze alloy

(BCuP per the American Welding Society) with 5%

(BCuP-3) to 15% (BCuP-5) silver content. Only use a

high silver content brazing alloy (BAg per AWS) for

copper-to-brass or copper-to-steel joints such as a

45% (BAg-5) silver content. Only use oxy-acetylene

brazing.

WARNING: The POE oil contained within the

compressor is hygroscopic and has the ability to

absorb water vapor from the atmosphere. Take

necessary steps to prevent an open system from

exposure to the atmosphere for extended periods

while installing the interconnecting refrigerant

tubing.

Refrigeration Piping Design

The system is configurable in any of the

arrangements as shown in Figure 2, Figure 3, and

Figure 4. The configuration and its associated

elevation, along with the total distance between the

chiller and the air-cooled condenser are important

factors in determining the liquid line and discharge

line sizes. This will also affect the field refrigerant

charges. Consequently, it is important to adhere to

certain physical limitations to ensure the system

operates as designed.

General design considerations are:

1. The total distance between the chiller and the

air-cooled condenser must not exceed 200

actual feet or 300 equivalent feet. Keep the

distance as short as possible.

2. Liquid line risers must not exceed 15 feet in

height from the condenser liquid line

connection.

3. Discharge line risers cannot exceed an elevation

difference greater than 100 actual feet without a

minimum of 2% efficiency decrease.

4. To form a proper liquid seal at the condenser,

immediately drop at least 15 inches down from

the liquid outlet before routing the piping to the

chiller. Make the drop leg before any bends or

angles connecting to the remainder of the liquid

connection piping.

5. Pipe condensers with dual circuits to assure

equal refrigerant flow to each circuit.

Corner Leg

Center Leg

(Right-hand Side Facing Header)

7

Figure 2 – Condenser Located at Chiller Level

Figure 3 – Condenser Located Below Chiller Unit

Figure 4 - Condenser Located Above Chiller Unit

Caution: Liquid line sizing for each chiller capacity is

in Table . These line sizes are listed per circuit and

apply where leaving water temperature (LWT) is 40°F

or higher. For applications where the LWT is below

40°F, size lines using the ASHRAE Refrigeration

Handbook or other suitable design guide.

Determining Equivalent Line Length

To determine the appropriate size for field installed

liquid and discharge lines, it is first necessary to

establish the equivalent length of pipe for each line.

The equivalent length is the approximate friction loss

from the combined linear run of pipe and the

equivalent feet of elbows, valves, and other

components in the refrigeration piping. The sum

total is the equivalent length of pipe that would have

the same pressure loss. See the ASHRAE

Refrigeration Handbook for more information.

Follow these steps when calculating line size:

1. Start with an initial approximation of equivalent

length by assuming that the equivalent length of

pipe is 1.5 times the actual pipe length.

2. Determine approximate line sizes by referring to

Table 3 for liquid lines, Table 4 and Table 5 for

the discharge lines.

3. Check the line size by calculating the actual

equivalent length using the equivalent lengths

as shown in Table 2.

CAUTION: When calculating the equivalent length,

do not include piping of the chiller unit. Only field

piping must be considered.

Table 2 – Equivalent Lengths of Elbows

Line

Size OD

(in)

Equivalent Lengths of Refrigerant Pipe (feet)

90°

Standard

90°Long

Radius

90°

Street

45°

Standard

45°

Street

7/8

2.0

1.4

3.2

0.9

1.6

1 1/8

2.6

1.7

4.1

1.3

2.1

1 3/8

3.3

2.3

5.6

1.7

3.0

1 5/8

4.0

2.6

6.3

2.1

3.4

2 1/8

5.0

3.3

8.2

2.6

4.5

2 5/8

6.0

4.1

10.0

3.2

5.2

3 1/8

7.5

5.0

12.0

4.0

6.4

3 5/8

9.0

5.9

15.0

4.7

7.3

4 1/8

10.0

6.7

17.0

5.2

8.5

Liquid Line Sizing

The liquid line diameter should be as small as

possible while maintaining acceptable pressure drop.

This is necessary to minimize refrigerant charge. The

total length between the chiller unit and the air-

cooled condenser must not exceed 200 actual feet

or 300 equivalent feet. It is best to pipe the liquid

line so that there is an immediate drop of at least 15

inches at the condenser outlets to make a liquid seal.

Liquid line risers in the system will require an

additional 0.5 psig pressure drop per foot of vertical

rise. When it is necessary to have a liquid line riser,

make the vertical run immediately after the

condenser before any additional restrictions. The

liquid line risers must not exceed 10 feet in height

from the condenser liquid line connection. The liquid

line does not require pitching. Install a pressure tap

valve at the condenser to facilitate measuring

pressure for service.

8

Liquid lines do not typically require insulation.

However, if exposing the lines to solar heat gain or

temperatures exceeding 110 °F, there is a negative

effect on sub-cooling. In these situations, insulate

the liquid lines.

Table 3 – Liquid Line Sizes for R410A

10 Ton Circuit (R410A) Liquid Line Size (Inch OD)

15 Ton Circuit (R410A) Liquid Line Size (Inch OD)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

0 to 5

6 to 10

11 to 15

25

3/4

3/4

3/4

3/4

25

7/8

7/8

7/8

7/8

50

3/4

3/4

3/4

3/4

50

7/8

7/8

7/8

7/8

75

3/4

3/4

3/4

3/4

75

7/8

7/8

7/8

7/8

100

3/4

3/4

3/4

7/8

100

7/8

7/8

7/8

1 1/8

125

3/4

3/4

3/4

7/8

125

7/8

7/8

7/8

1 1/8

150

3/4

3/4

3/4

7/8

150

7/8

7/8

7/8

1 1/8

175

3/4

3/4

3/4

7/8

175

7/8

7/8

7/8

1 1/8

200

3/4

3/4

7/8

1 1/8

200

7/8

7/8

1 1/8

1 1/8

225

3/4

3/4

7/8

1 1/8

225

7/8

7/8

1 1/8

1 1/8

250

3/4

3/4

7/8

1 1/8

250

7/8

7/8

1 1/8

1 1/8

275

3/4

3/4

7/8

1 1/8

275

7/8

7/8

1 1/8

1 1/8

300

3/4

7/8

7/8

1 1/8

300

7/8

7/8

1 1/8

1 1/8

20 Ton Circuit (R410A) Liquid Line Size (Inch OD)

25 Ton Circuit (R410A) Liquid Line Size (Inch OD)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

0 to 5

6 to 10

11 to 15

25

1 1/8

1 1/8

1 1/8

1 1/8

25

1 1/8

1 1/8

1 1/8

1 1/8

50

1 1/8

1 1/8

1 1/8

1 1/8

50

1 1/8

1 1/8

1 1/8

1 1/8

75

1 1/8

1 1/8

1 1/8

1 1/8

75

1 1/8

1 1/8

1 1/8

1 1/8

100

1 1/8

1 1/8

1 1/8

1 1/8

100

1 1/8

1 1/8

1 1/8

1 1/8

125

1 1/8

1 1/8

1 1/8

1 1/8

125

1 1/8

1 1/8

1 1/8

1 1/8

150

1 1/8

1 1/8

1 1/8

1 1/8

150

1 1/8

1 1/8

1 1/8

1 3/8

175

1 1/8

1 1/8

1 1/8

1 1/8

175

1 1/8

1 1/8

1 1/8

1 3/8

200

1 1/8

1 1/8

1 1/8

1 3/8

200

1 1/8

1 1/8

1 1/8

1 3/8

225

1 1/8

1 1/8

1 1/8

1 3/8

225

1 1/8

1 1/8

1 1/8

1 3/8

250

1 1/8

1 1/8

1 1/8

1 3/8

250

1 1/8

1 1/8

1 1/8

1 3/8

275

1 1/8

1 1/8

1 1/8

1 3/8

275

1 1/8

1 1/8

1 1/8

1 3/8

300

1 1/8

1 1/8

1 1/8

1 3/8

300

1 1/8

1 1/8

1 3/8

1 3/8

9

Table 3 – Liquid Line Sizes for R410A (continued)

30 Ton Circuit (R410A) Liquid Line Size (Inch OD)

40 Ton Circuit (R410A) Liquid Line Size (Inch OD)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

0 to 5

6 to 10

11 to 15

25

1 1/8

1 1/8

1 1/8

1 1/8

25

1 3/8

1 3/8

1 3/8

1 3/8

50

1 1/8

1 1/8

1 1/8

1 1/8

50

1 3/8

1 3/8

1 3/8

1 3/8

75

1 1/8

1 1/8

1 1/8

1 1/8

75

1 3/8

1 3/8

1 3/8

1 3/8

100

1 1/8

1 1/8

1 1/8

1 3/8

100

1 3/8

1 3/8

1 3/8

1 3/8

125

1 1/8

1 1/8

1 1/8

1 3/8

125

1 3/8

1 3/8

1 3/8

1 3/8

150

1 1/8

1 1/8

1 1/8

1 3/8

150

1 3/8

1 3/8

1 3/8

1 5/8

175

1 1/8

1 1/8

1 1/8

1 3/8

175

1 3/8

1 3/8

1 3/8

1 5/8

200

1 1/8

1 1/8

1 1/8

1 3/8

200

1 3/8

1 3/8

1 3/8

1 5/8

225

1 1/8

1 1/8

1 3/8

1 3/8

225

1 3/8

1 3/8

1 3/8

1 5/8

250

1 1/8

1 1/8

1 3/8

1 5/8

250

1 3/8

1 3/8

1 3/8

1 5/8

275

1 1/8

1 1/8

1 3/8

1 5/8

275

1 3/8

1 3/8

1 3/8

1 5/8

300

1 1/8

1 1/8

1 3/8

1 5/8

300

1 3/8

1 3/8

1 3/8

1 5/8

50 Ton Circuit (R410A) Liquid Line Size (Inch OD)

60 Ton Circuit (R410A) Liquid Line Size (Inch OD)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

0 to 5

6 to 10

11 to 15

25

1 3/8

1 3/8

1 3/8

1 3/8

25

1 5/8

1 5/8

1 5/8

1 5/8

50

1 3/8

1 3/8

1 3/8

1 3/8

50

1 5/8

1 5/8

1 5/8

1 5/8

75

1 3/8

1 3/8

1 3/8

1 3/8

75

1 5/8

1 5/8

1 5/8

1 5/8

100

1 3/8

1 3/8

1 3/8

1 5/8

100

1 5/8

1 5/8

1 5/8

1 5/8

125

1 3/8

1 3/8

1 3/8

1 5/8

125

1 5/8

1 5/8

1 5/8

1 5/8

150

1 3/8

1 3/8

1 3/8

1 5/8

150

1 5/8

1 5/8

1 5/8

1 5/8

175

1 3/8

1 3/8

1 3/8

1 5/8

175

1 5/8

1 5/8

1 5/8

2 1/8

200

1 3/8

1 3/8

1 3/8

1 5/8

200

1 5/8

1 5/8

1 5/8

2 1/8

225

1 3/8

1 3/8

1 5/8

1 5/8

225

1 5/8

1 5/8

1 5/8

2 1/8

250

1 3/8

1 3/8

1 5/8

2 1/8

250

1 5/8

1 5/8

1 5/8

2 1/8

275

1 3/8

1 3/8

1 5/8

2 1/8

275

1 5/8

1 5/8

1 5/8

2 1/8

300

1 3/8

1 3/8

1 5/8

2 1/8

300

1 5/8

1 5/8

1 5/8

2 1/8

10

Table 3 – Liquid Line Sizes for R410A (continued)

80 Ton Circuit (R410A) Liquid Line Size (Inch OD)

100 Ton Circuit (R410A) Liquid Line Size (Inch OD)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

0 to 5

6 to 10

11 to 15

25

2 1/8

2 1/8

2 1/8

2 1/8

25

2 1/8

2 1/8

2 1/8

2 1/8

50

2 1/8

2 1/8

2 1/8

2 1/8

50

2 1/8

2 1/8

2 1/8

2 1/8

75

2 1/8

2 1/8

2 1/8

2 1/8

75

2 1/8

2 1/8

2 1/8

2 1/8

100

2 1/8

2 1/8

2 1/8

2 1/8

100

2 1/8

2 1/8

2 1/8

2 1/8

125

2 1/8

2 1/8

2 1/8

2 1/8

125

2 1/8

2 1/8

2 1/8

2 1/8

150

2 1/8

2 1/8

2 1/8

2 1/8

150

2 1/8

2 1/8

2 1/8

2 1/8

175

2 1/8

2 1/8

2 1/8

2 1/8

175

2 1/8

2 1/8

2 1/8

2 1/8

200

2 1/8

2 1/8

2 1/8

2 1/8

200

2 1/8

2 1/8

2 1/8

2 1/8

225

2 1/8

2 1/8

2 1/8

2 1/8

225

2 1/8

2 1/8

2 1/8

2 1/8

250

2 1/8

2 1/8

2 1/8

2 1/8

250

2 1/8

2 1/8

2 1/8

2 5/8

275

2 1/8

2 1/8

2 1/8

2 1/8

275

2 1/8

2 1/8

2 1/8

2 5/8

300

2 1/8

2 1/8

2 1/8

2 1/8

300

2 1/8

2 1/8

2 1/8

2 5/8

120 Ton Circuit (R410A) Liquid Line Size (Inch OD)

Equivalent

Length (Ft)

Horizontal or

Down Flow

Up Flow (Feet of Run)

0 to 5

6 to 10

11 to 15

25

2 1/8

2 1/8

2 1/8

2 1/8

50

2 1/8

2 1/8

2 1/8

2 1/8

75

2 1/8

2 1/8

2 1/8

2 1/8

100

2 1/8

2 1/8

2 1/8

2 1/8

125

2 1/8

2 1/8

2 1/8

2 1/8

150

2 1/8

2 1/8

2 1/8

2 1/8

175

2 1/8

2 1/8

2 1/8

2 5/8

200

2 1/8

2 1/8

2 1/8

2 5/8

225

2 1/8

2 1/8

2 1/8

2 5/8

250

2 1/8

2 1/8

2 1/8

2 5/8

275

2 1/8

2 1/8

2 1/8

2 5/8

300

2 1/8

2 1/8

2 1/8

2 5/8

11

Discharge (Hot Gas) Line Sizing

The discharge line sizes depend on the velocity

needed to obtain sufficient oil return. It is very

important to minimize line length and restrictions to

reduce pressure drop and maximize capacity.

Upflow hot gas risers need to have a trap at the

bottom and reverse trap at the top. In addition, a

trap and reverse trap arrangement needs to be

spaced every 15 feet in the rise for oil management

(see Figure 5).

The discharge lines should pitch downward, in the

direction of the hot gas flow, at the rate of ½ inch

per each 10 foot of horizontal run. If the chiller unit

is below the condenser, loop the discharge line to at

least 1 inch above the top of the condenser. Install a

pressure tap valve at the condenser to facilitate

measuring pressure for service. Take careful

consideration in the design of the discharge gas

riser.

Check the oil-level sight glass in the compressor to

ensure it is at the appropriate level to verify there is

no trapping of oil in the piping. Use a double riser

system to ensure proper oil return. See Figure 6 and

Table for double riser constructions.

Figure 5 – Vertical Riser Traps

Figure 6 - Double Discharge Riser

Note: Discharge line sizing shown in Table 4 and

Table 5 are listed per circuit and applies where

leaving water temperature (LWT) is 40°F or higher.

For applications where LWT is below 40°F, size lines

using the ASHRAE Refrigeration Handbook or other

suitable design guide.

Table 4 - Horizontal or Downflow Discharge Line Sizes for R410A (inches OD)

Circuit

Tons

Total Equivalent Length (Ft)

25

50

75

100

125

150

175

200

225

250

275

300

10

7/8

7/8

7/8

7/8

7/8

7/8

7/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

15

7/8

7/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

20

7/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

25

1⅛

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

30

1⅛

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

40

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

50

1 5/8

1 5/8