3

Chillers with an integral water-cooled or air-cooled

condenser ship with a full refrigerant charge. Chillers

designed for use with a remote air-cooled condenser

and the remote condensers themselves ship with a

nitrogen holding charge. Check the remote

condenser for signs of leaks prior to rigging. This will

ensure no coil damage has occurred after the unit

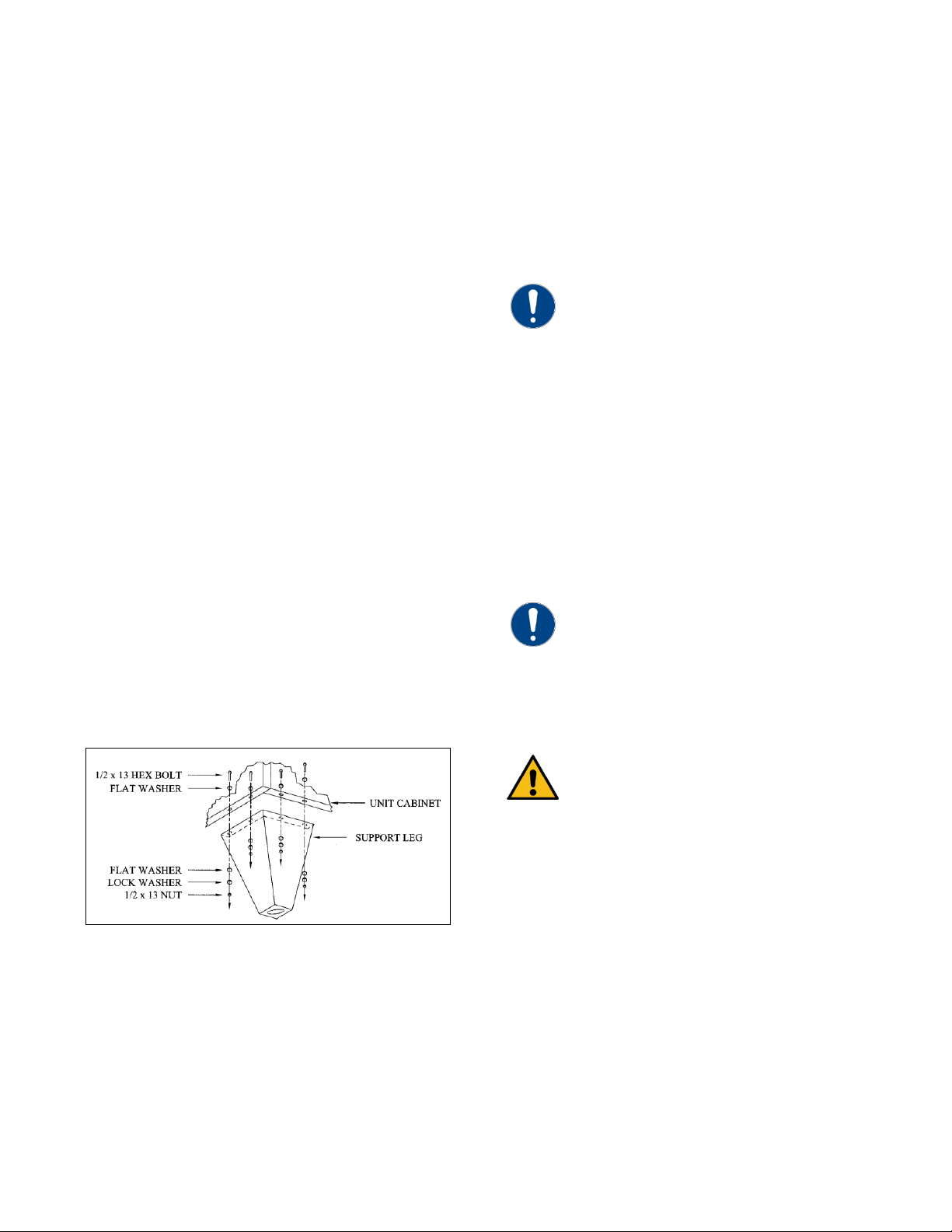

left the factory. The condenser ships with the legs

removed. Mount the legs to the condenser using the

provided nuts, bolts, and washers.

Unit Storage

If the chiller is stored prior to installation, it is

important to protect it from damage. Blow out any

water from the evaporator and water-cooled

condenser circuits to protect the unit from damage

from freezing. Close any open refrigerant valves.

Cover the equipment to keep dirt and debris from

accumulating on it. Units charged with refrigerant

should not be stored in areas warmer than 145°F.

Installation - Chiller

Foundation

Install the chiller on a rigid, non-warping mounting

pad, concrete foundation, or level floor suitable to

support the full operating weight of the equipment.

When installed the equipment must be level within

¼ inch over its length and width.

Unit Location

The chiller is available in many different

configurations for various environments. Refer to the

proposal and order acknowledgement document for

the equipment to verify the specific design

conditions in which it can operate.

Allow a minimum of 48 inches of clearance between

the chiller and any walls or obstructions. For

installations with multiple chillers, allow a minimum

of 96 inches between chillers placed side-by-side or

48 inches for chillers placed end-to-end.

When locating the chiller it is important to consider

accessibility to the components to allow for proper

maintenance and servicing of the unit. In general,

allow a minimum of 36 inches of clearance around

and above the unit. Avoid locating piping or conduit

over the unit to ensure easy access with an overhead

crane or lift to lift out heavier components during

replacement or service.

Proper ventilation is another important

consideration when locating the chiller. In general,

locate the unit in an area that will not rise above

110°F. In addition, ensure the condenser and

evaporator refrigerant pressure relief valves can vent

in accordance with all local and national codes.

Chillers with an integral air-cooled condenser require

a minimum of 36 inches of clearance at both the

condenser air inlet and condenser air discharge, they

are not, as standard, designed to have the condenser

air discharge ducted. Improper clearance or poor

ventilation will reduce the cooling capacity of the

chiller and may cause high refrigerant pressure

problems. In order to avoid possible low refrigerant

pressure safety trips during start-up, maintain the

inlet air temperature above 50°F. If outside air is

ducted into an indoor chiller with an integral air-

cooled condenser, there is an option for low ambient

heat pressure controls which allow for incoming air

temperatures down to 0°F. Cooler temperatures than

this require custom modifications.

Rigging

The chiller has a frame to facilitate easy movement

and positioning with a crane or forklift. Follow

proper rigging methods to prevent damage to

components. Avoid impact loading caused by

sudden jerking when lifting or lowering the chiller.

Use pads where abrasive surface contact may occur.

Chilled Process Fluid Piping

Proper insulation of chilled process fluid piping is

crucial to prevent condensation. The formation of

condensation adds a substantial heat load to the

chiller.

The importance of properly sized piping between

the chiller and process cannot be overemphasized.

See the ASHRAE Handbook or other suitable design

guide for proper pipe sizing. In general, run full size

piping out to the process and reduce pipe size at

connections as needed. One of the most common

causes of unsatisfactory chiller performance is poor

piping system design. Avoid long lengths of hoses,

quick disconnect fittings, and manifolds wherever

possible as they offer high resistance to water flow.

When manifolds are required, install them as close to

the use point as possible. Provide flow-balancing

valves at each machine to assure adequate water

distribution in the entire system. Typically, when