iom-clicsa-cf-eng www.clima-ex.com

6

EFFICIENCY

Our units are designed to meet the needs of any project.

Our intelligent process controllers and smart temperature sensors

provide maximum performance and energy savings.

The system automatically modifies the operating mode to maintain

optimum system conditions, making it very easy to operate.

All temperature sensors are calibrated and adjusted at the factory

prior to shipment. Start-up should be performed by a qualified

technician, during initial start-up the unit will be adjusted to local

conditions and all operating points will be checked.

Once the unit has been set up, operation is a matter of pressing

the start/stop button until it is certain that the unit is operating

properly.

After this the unit will operate automatically, turning itself on

according to the demand of the refrigeration system and local

conditions.

The units feature intelligent processors and sensors that

automatically control the temperature at optimum operating

conditions.

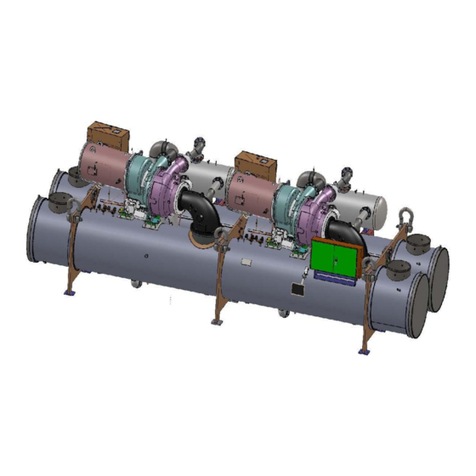

The units were designed to be coupled with each other and

combined to meet different load variations (Tandem Installation).

Up to 10 modules can be combined; these combinations can be

made with Water Chiller Units of different capacities ranging from

25 to 250 tons. Capacities vary depending on the number and

type of units.

SAFETY

All structures are made of galvanized sheet steel, coated with

electrostatic baked-on paint to ensure long durability and freedom

from corrosion under all weather conditions, such as direct

sunlight, rain and wind.

All units are designed to fit into a small installation space, thus

eliminating large installation areas. We use only high quality

components to ensure durability and safety even in harsh

environmental conditions.

NOTE: For applications in tropical climates our units are

coated inside and out with corrosion protection

Our products have AHRI efficiency certifications and ETL safety

certifications, in addition to meeting all industry safety standards.

We are members of the American Society of Heating,

Refrigerating and Air-Conditioning Engineers (ASHRAE). To

show our commitment to our customers and stakeholders; our

equipment comes with a 1 year major warranty after start-up.

Our units use R410A refrigerant, which is harmless to the ozone

layer and is non-toxic and non-flammable, even in case of leakage.

Finally, the efficiency of the heat exchanger and its modular

design allow for quick and easy installation.

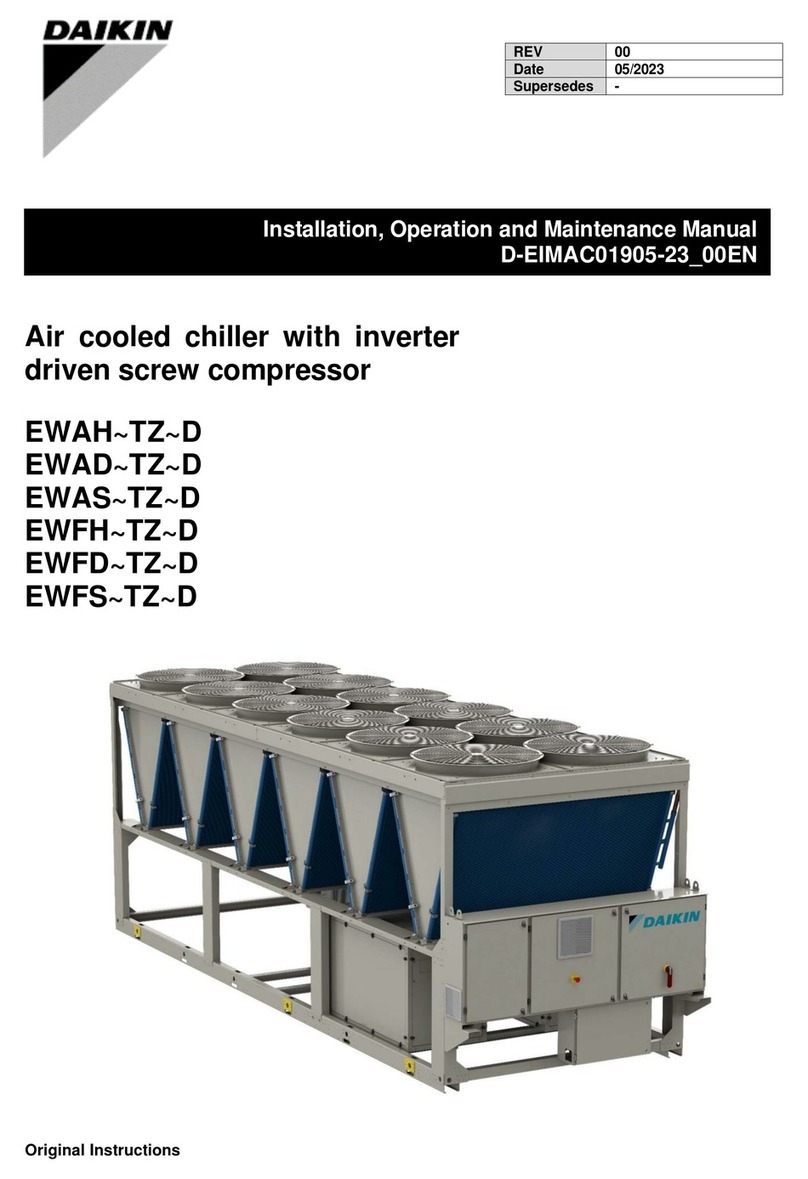

DESIGN

Research conducted by the Engineering Department has resulted

in units with high design efficiency and optimum performance.

The selection of the main components, our quality and control

system guarantee high performance and safety.

All major components are rigorously tested and qualified before

installation. Each designed unit has undergone long hours of

rigorous testing to ensure the safety, durability and quality of the

entire system.

COMMUNICATION

The units can be controlled in tandem mode and/or can be

connected to a central control unit. Operation and user access

will be through a 7” color touch screen.

Our units can be managed through different communication

protocols; such as Modbus and BACnet, the most commonly used

protocols in the Air Conditioning industry.

Our units keep track of all programmable variables in real

time, such as performance monitoring, specific alarms of the

refrigeration cycle and the electrical system; as well as detection

of external factors such as fire or flood (optional sensors).

The control and monitoring system ensures the correct operation

of the unit by monitoring in real time the condition of the major

components (high or low refrigerant pressure, compressor and

fan motor conditions, etc.).

In case of failure, the event will be recorded for later analysis,

facilitating the localization of a possible failure and its solution.

INSTALLATION

The units have been designed for easy installation. Screw

connections provide easy installation of the water piping, which

are located on both sides of the unit, so that the piping can be

connected to either side of the unit.

The individual assembly of the units reduces installation cost, the

units have a rigid base that balances the weight of the unit and

allows for easy installation.

MAINTENANCE

The simplicity in the design of each unit allows for maximum

ease of maintenance. All major components are available to

maintenance personnel by simply opening the service panel.

If an emergency shutdown occurs, the control section will indicate

in detail the cause of the failure, helping to facilitate and accelerate

troubleshooting.