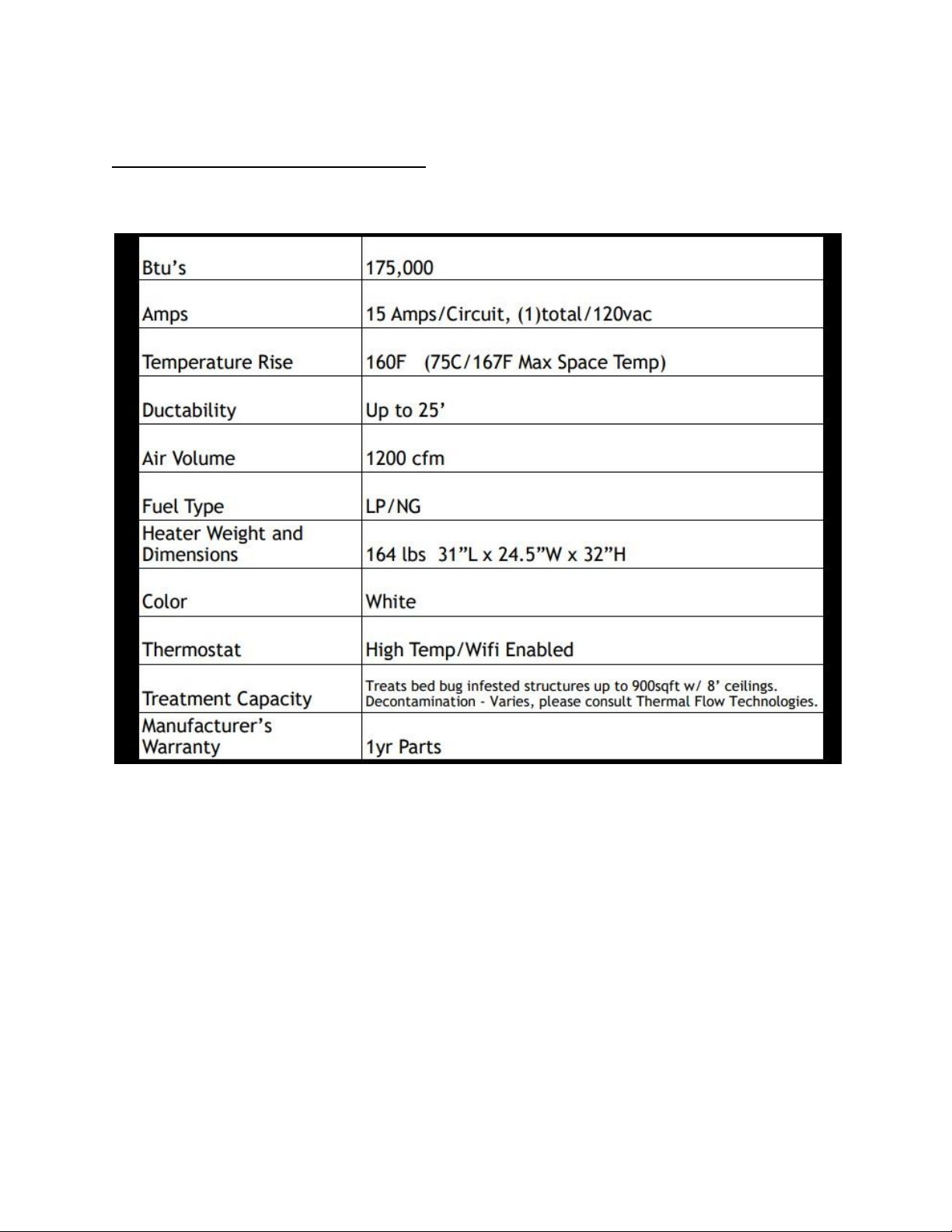

THERMAL FLOW Delta 175 Instruction Manual

Popular Heater manuals by other brands

Porter-Cable

Porter-Cable PCXH80KT Operating instructions and owner's manual

Dyna-Glo

Dyna-Glo RA18LPDG user manual

Dimplex

Dimplex PLX050E instruction manual

EOS

EOS Herkules XL S120 installation instructions

Trebs

Trebs Comfortheat 99209 manual

Biddle

Biddle STYLE2 Series Installation operation & maintenance

Vermont Castings

Vermont Castings Non-Catalytic Convection Heater 2477CE Installation and operating manual

Fagor

Fagor RA-1505 Instructions for use

GET

GET G2CH instructions

ApenGroup

ApenGroup PK Series User, installation, and maintenance manual

oventrop

oventrop Regucor Series quick start guide

Blaze King

Blaze King CLARITY CL2118.IPI.1 Operation & installation manual

ELMEKO

ELMEKO ML 150 Installation and operating manual

BN Thermic

BN Thermic 830T instructions

KING

KING K Series Installation, operation & maintenance instructions

Empire Comfort Systems

Empire Comfort Systems RH-50-5 Installation instructions and owner's manual

Well Straler

Well Straler RC-16B user guide

EUROM

EUROM 333299 instruction manual