THERMAL INTEGRATION DATA Extra HIU User manual

The DATA Extra HIU, Installation Instructions DE2 12/08/2021

The DATA Extra HIU

Installation Instructions DE2

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

The DATA Extra HIU, Installation Instructions DE2

Wiki Binder, 12th August 2021

Explanation of symbols and abbreviations .................................... 3

Introduction .......................................................... 4

Key Components ....................................................... 5

Available Options ...................................................... 6

Dimensions .......................................................... 7

Technical Data ........................................................ 8

Description .......................................................... 9

Operation ........................................................... 10

Adjusting Settings ..................................................... 11

Factory Settings ...................................................... 12

General Plumbing Requiremenrts ......................................... 13

General Wiring Requirements ............................................ 14

HIU Schematic ....................................................... 15

Installation Schematic .................................................. 16

Wiring Schematic ..................................................... 17

Important Installation Requirements ....................................... 18

Service and Inspection .................................................. 20

DHW Performance .................................................... 21

Central Heating Temperature Curves ....................................... 25

Installation Set-up .................................................... 27

Adjusting Temperatures and Settings ....................................... 35

Troubleshooting for End users ............................................ 39

Troubleshooting (for Technicians) ......................................... 40

Guarantees and After Sales Backup for HIUs .................................. 41

Page 2

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

Introduction

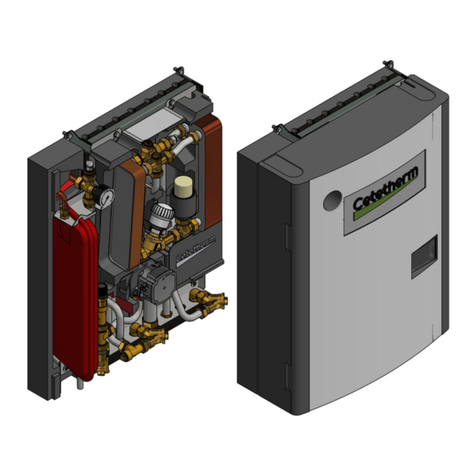

The DATA Extra HIU enables us to take the functions of our flagship twin plate DATA HIU and increase the heating output to cater for

commercial or industrial applications. The basis of this HIU is our SLIM hot water only HIU and then we add a heating plate heat

exchanger and Danfoss pressure independent control valve with a Novocon Actuator for the heating side of the HIU. Both the heating

and hot water controls are linked to our Node-iHIU system and can be accessed remotely for monitoring and adjustment.

The fully insulated HIU is enclosed within a white steel enclosure designed to keep the overall footprint of the HIU to an absolute

minimum. If required, the expansion vessel, safety relief valve, filling loop and pump are mounted external to the casing, allowing the

HIU to be fitted out of the way, with key components mounted in a more accessible location.

The heating installation must be equipped with a correctly sized expansion vessel and safety relief valve fitted between the HIU

and any isolation valve on the heating circuit. It is also advisable to fit a filling loop and pressure gauge to the heating system, in

a location convenient for the end user to access and top-up the central heating system. Refer to the chapter on "Installation

Requirements" for more information. Contact Thermal Integration for more information on parts availability and advice on

system safety.

Page 4

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

Key Components

Parts List

Item No. Description Pt. No.

1 SLIM HIU 70TILSLIM

2 Node-iHIU Control 70DATA-Extra-Control

3 CH Plate Heat Exchanger 7028768

4 CH Control Valve 70610

5 CH Control Valve Actuator 70NOVO003Z8500

6 Heat Meter 70HM403-2.5-G1B-130

7 Primary Flow Temperature Sensor 70HSF51862

8 Primary Return Temperature Sensor 70HSF51862

9 CH Flow Temperature Sensor 70HSF51862

10 Manual Air Vent N/A

11 Heat Meter Flow Temperature Sensor N/A

12 DHW Plate Heat Exchanger 7066561

13 DHW Stepper Control Valve 70HSF51495

14 Universal HIU Controller 70HSFCONTROL

15 DHW Flow Sensor 70HSF50274

16 DHW Temperature Sensor 70HSF52727

17 Primary Return Temperature Sensor 70HSF52726

18 Primary Flow Temperature Sensor 70HSF52727

Not Shown Optional Differential Pressure Sensor 70200216-2

Page 5

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

Available Options

The unit has several options available depending on requirements. The basic unit can be equipped with any combination of the

following:

Landlord security valve, allows the landlord to remotely isolate the unit from the district heating network if required.

Differential pressure control valve, to balance differential pressures between the primary flow and return. Only required where the

differential pressure exceeds 250kPa. (Max 450kPa)

Flushing Bypass for connecting to the primary flow and return pipework (External to the unit)

External DHW recirculation unit, to provide constant circulation of DHW throughout the property in order to allow quicker response

times at the tap where extended pipe runs are unavoidable.

Heat Meter. It is possible to fit most brands of heat meter into the HIU, contact Thermal Integration for further information.

Page 6

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

Technical Data

Primary

Nominal primary supply temperature 85°C

Maximum primary supply temperature 90°C *

Minimum primary supply temperature 55°C **

Maximum primary differential pressure 250kPa

Minimum primary differential pressure 50kPa ***

Pressure class DH circuit PN16

Domestic Hot Water

Nominal DHW supply temperature 55°C

DHW Set Range 45°C to 60°C

Domestic Hot water heat exchanger (DHW) E8LAS40

Keep Warm Modes Economy / Comfort

Keep Warm Temperature 25°C to 60°C

Keep Warm Duration 0 to 120 mins or Always On

Max Return Temperature during Keep Warm Mode DHW Setpoint -2°C

DHW Max pressure 6 Bar

Pressure class DHW circuit PN10

DWH Priority Multi-Stage ****

Central Heating

Maximum flow temperature Primary T -5°C

Return Temp Limit Range 35°C to 55°C

CH Limit Range 30°C to 80°C

Central heating heat exchanger (CH) B25TH30

Pressure class CH circuit (3 bar safety valve) PN16

CH working pressure N/A (By Installer)

Nominal pump pressure 20 kPa (Adj. 0-70)

Maximum recommend flow rate 750 l/hr

General

Primary connections DN32 Female

Mains & DHW connections ¾” Female

Central heating connections ¾” Female

Casing width 653mm

Casing height 900mm

Casing depth 225mm

Casing Material Steel

HIU Insulation Material EPP Expanded Polypropylene

Pipework Insulation Material Grey Polyethylene Foam

Maximum Heat Losses <50W (1.2 kWh/day)

Weight (basic version) 35kg Approx

Electrical supply info 230V 50Hz - 0.64A

Power consumption per year circa 45kWh

Fuse ratings 3 Amp

Sensors NTC 10kohm @ 25°C

.* Maximum primary supply temperature 100°C for momentary spikes.

.** Minimum required DH supply temperature is DHW setpoint + 5°C with a minimum of 55°C.

.*** Depends on requested DHW output and available DH supply temperature.

.**** See Multi-Stage DHW Priority example below.

Page 8

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

Description

The HIU is for use in properties connected to a district heating system using a centralised boiler and is suitable for both central heating

and domestic hot water. Each hydraulic circuit to which the HIU is connected, must meet minimum water quality standards as stated in

document "Requirements on water quality" available on our Wiki Site at www.heatweb.co.uk/w.

Please keep the following conditions in mind during installation:

The unit must be installed in a frost free area.

The unit must not be exposed to direct sunlight.

Ambient temperature should be between +5°C and +40°C.

Humidity should be between 10% and 85%.

The unit must be connected to a fused double pole isolator.

The unit uses 230 VAC. Use caution when handling. Contact may lead to shock, burns or electrocution.

Components in the unit and connected to the unit can reach high temperatures. Contact may lead to burns.

DHW Status Indicator LED

Green blinking slowly (about 1x per second): HIU is at rest; there is no heat demand and all control valves are closed.

Blue blinking: HIU is in Hot water mode; there is a water draw-off and the control valve is open.

Red blinking: Error

White continuous (only for engineers): HIU is in service mode

No LED: HIU is switched off

Page 9

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

Operation

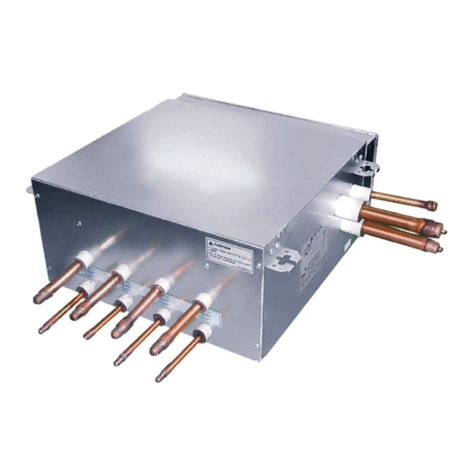

The HIU is equipped with two heat exchangers, the left hand heat exchanger transfers the heat from the district heating system to the

DHW circuit and the right hand heat exchanger transfers the heat from the district heating system to the CH circuit. These heat

exchangers ensure hydraulic separation between the property and the district heating network. The hot water in the district heating

network does not come into contact with the hot water or heating circuit of the property. Heat is transferred from the district heating

network via the heat exchangers to the domestic hot water system and central heating system.

Central heating

The temperature of the property's heating system is controlled automatically by the HIU, with the temperature set-point being

adjustable via the Modbus interface. When heating demand finishes, the heating pump will be switched off after a defined pump over-

run time (default: 15 minutes).

Domestic Hot Water

The electronics within the unit, together with domestic hot water control valve, temperature sensors and flow sensor, regulate the

temperature of the hot water to it's set point (As Standard 55°C). The HIU has a very low switching point, recognising DHW flow rates as

low as 1 l/min.

Each HIU has two domestic hot water keep hot modes, 'Eco' or 'Comfort' mode. These can only be selected during commissioning or by a

trained engineer.

'Eco' mode can be specified to run for 0 minutes (which turns the feature off all together), 15, 30, 60 or 120 minutes after the last hot

water draw off. In 'Eco' mode the heat exchanger is kept to a specified temperature (between 25 and 60°C) for the selected period of

time and after this period of inactivity has elapsed the control valve closes completely and the temperature in the domestic hot water

circuit is allowed to drop through natural dissipation to minimize energy consumption. If a hot water draw off is made any time

throughout the Eco mode function the unit will deliver hot water as usual and the 'Eco' mode function will begin counting down for the

selected time once again.In 'Comfort' mode the heat exchanger is continuously supplied with a trickle of primary water for quicker hot

water delivery, however energy consumption will be slightly higher than if the unit was set in 'Eco' mode.

To prevent legionella from growing the heat exchanger is heated to 60°C for at least 60 minutes every 24 hours. (it is not possible to

specify the time at which this occurs)

The hot water temperature is regulated to temperatures as high as 60°C. If there is a power outage during DHW draw off, units

not fitted with a landlord security valve will stop regulating the hot water temperature. This may lead to a hot water temperature

that is higher or lower than the setpoint. Hot water can cause burns.

Page 10

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

Adjusting Settings

The DATA Extra requires connection to either a PC running the commissioning software, or by the use of an iHIU Controller, in order to

adjust settings.

End users cannot adjust settings, unless an iHIU Controller is used.

PC Software

The software is made freely available, along with training, to registered commissioning engineers. Please contact Thermal Integration

for further information.

The software allows one to adjust the following settings:

Setting Options Default

Domestic Hot Water Temperature 45°C to 60°C 50°C

Primary Differential Pressure Auto or Manual from 0.3 to 2.0 bar Auto

Warmup Boost Flow Rate 8 to 20 l/min 20 l/min

Return Temperature Limit Disabled or Enabled from 35°C to 65°C Enabled 50°C

Maximum Central Heating Temperature 30°C to 80°C 80°C

Central Heating Pump Timeout 0 to 30 minutes 15 minutes

iHIU Controller

The iHIU Controller is a miniature Linux web server that can be supplied separately to provide more advanced control and monitoring of

the Data HIU. The controller is typically mounted within the casing of the HIU, with an option for a display on the front of the HIU.

The controller provides a WiFi zone, and can log onto existing networks through either WiFi or Ethernet to gain access to the internet.

The HIU can then be controlled directly from other devices on the local network, such as smartphones. Once connected to the internet

the system can provide remote control and monitoring services, as well as many other features, some of which are listed below:

Browser based cross platform interface that adjusts to screen size

Allows setting of all the parameters available to the PC software, except via a browser

Control over central heating as well as other settings via Google Calendar

Remote commissioning

Remote fault alarms and message forwarding via email or SMS

Voice control over services via Android app

Connection to Energy Saving Trust's Embed Database for free and secure online storage of all system data

Page 11

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

Factory Settings

DHW Settings

The DHW settings are factory set, and these can only be changed by connecting a laptop directly to the SLIM HIU communication cable

and using the HIU Monitor Application Software available from Thermal Integration. If the DATA Extra HIU is connected to a BMS, it is

possible to alter the settings through the BMS ModBus interface.

The factory settings are as follows:-

Setting Limits Set Value

Temperature - DHW 45 - 60C 55C

Pressure Manual / Auto Auto

Ecoheat Time (keep warm) Off,15, 30, 60, 120, Always Off

Ecoheat Temperature 25 - 60C N/A

Legionella Prevention Cycle On / Off Off

District Heating Warmup Boost 8 - 20 l/min 20 l/min

Central Heating Settings

Setting Limits Set Value

Temperature - CH 20 - 80C 60C

Pump Over-run any 60 secs

Return Temperature Monitoring On / Off Off

Return Temperature Limit 30 - 55C 55C*

CH Control Valve Pre-set 10 - 100% 100%

If the Return Temperature Monitoring function is set to 'Off' the Return Temperature Limit is irrelevant.

Multi-Stage DHW Priority

If DHW priority is not suitable for the installation location (for instance in a restaurant or hair dressers, where hot water draw-offs may

be frequent and therefore hold off the heating output), the primary flow rate available for the HIU to operate simultaneously in both

DHW and CH modes, does not need to be the sum of the two circuits. This is due to the Multi-Stage DHW Priority feature built into the

HIU software.

This feature allows peek or multi-staged flow limits to be set, which enables the DHW priority to be off-set against a proportion of the

heating flow. Although it is possible to set specific flow rates and reductions, An example of the basic principle is explained below:-

DHW primary flow rate =

0 to 25%, no effect on the heating output

25 to 50%, heating output reduced by 25%

50 to 75%, heating output reduced by 50%

75 100%, heating off completely.

Page 12

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

General Plumbing Requiremenrts

NEW COMPLETE SYSTEM INSTALLATIONS: When carrying out a completely new heating system installation in a new build

property or a first time installation in an existing property, then the heating system must conform to current building regulations Part

L1a. All new domestic heating systems must have a minimum of two heating zones. Each of these zones should be controlled by a

thermostat and zone valve. Alternatively individual electronically controlled Thermostatic Radiator Valves may be fitted. If domestic

hot water is provided by a storage system then the storage system or cylinder will require separate time and temperature control.

All radiators must have TRV's fitted in all rooms except bathrooms and any rooms where a thermostat is located. The exception to this

are single storey, open plan dwellings where the living area is more than 70% of the total usable floor area. Then this type of dwelling

can be controlled as one zone.

EXISTING INSTALLATIONS: When carrying out boiler replacements on an existing system, the regulations do not require separate

zoning of the upstairs and downstairs and compliance with the regulations can be achieved by a single room thermostat or

programmable room thermostat. It is however recommended that TRV's are fitted to all rooms except the bathrooms and the room

where a thermostat is located.

The appliance must be installed in accordance with, and comply to, the current: IEE Regulations, Building Regulations, Building

Standards (Scotland) (Consolidation), Building Regulations (Northern Ireland), local water by-laws, Health & Safety Document

635 (The Electricity at Work Regulations 1989) and any other local requirements.

BRITISH & IRISH STANDARDS Where no specific instruction is given, reference should be made to the relevant British and/or Irish

Standard codes of Practice.

BS7074:1 Code of practice for domestic and hot water supply

EN12828 Central heating for domestic premises

BS7593 Treatment of water in domestic hot water central heating systems

ECTI National rules for electrical installations

POTABLE WATER: All seals, joints and compounds (including flux and solder) and components used as part of the secondary domestic

water system must be approved by WRAS.

FITTING AND MODIFICATIONS: Fitting the appliance and any controls to the appliance may only be carried out by a competent

engineer. Any misuse or unauthorised modifications to the appliance or associated components and systems could invalidate the

guarantee and may lead to serious injury or even death. The manufacturer accepts no liability arising from any such actions, excluding

statutory rights.

SERVICING: The end user should be advised to have the system serviced annually by a competent engineer. Contact Thermal

Integration Ltd for a list of approved engineers. Approved spares must be used to help maintain the economy, safety and reliability of

the appliance. The service engineer must complete the Service Record after each service.

Page 13

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

General Wiring Requirements

These instructions apply in the UK and Ireland only and must be followed except for any statutory obligations. Component specific

electrical information may also be supplied in support of these instructions, however if there is any doubt please contact Thermal

Integration Ltd. (Tel: 0345 2411441)

FAILURE TO INSTALL APPLIANCES CORRECTLY COULD LEAD TO PROSECUTION.

The appliance must be installed in accordance with, and comply to, the current: IEE Regulations, Building Regulations, Building

Standards (Scotland) (Consolidation), Building Regulations (Northern Ireland), local water by-laws, Health & Safety Document

635 (The Electricity at Work Regulations 1989) and any other local requirements.

BRITISH & IRISH STANDARDS: Where no specific instruction is given, reference should be made to the relevant British and/or Irish

Standard codes of Practice.

BS7074:1 Code of practice for domestic and hot water supply

EN12828 Central heating for domestic premises

BS7593 Treatment of water in domestic hot water central heating systems

ECTI National rules for electrical installations

CAUTION: ISOLATE THE MAINS SUPPLIES BEFORE STARTING ANY WORK AND OBSERVE ALL RELEVANT SAFETY

PRECAUTIONS.

Danger of short circuit: When connecting the cables ensure that no cable pieces fall inside the control panel.

The Mains supply to the appliance must be through a fused double pole isolator situated next to the appliance. The isolator must have a

contact separation of 3mm minimum in all poles and should isolate the appliance and all associated controls.

Unless otherwise stated, all Heat Interface Units should be connected to a mains 230V 50Hz Supply fused at 3 Amps.

All electrical connections with the Heat Interface Unit control panel are clearly marked as follows:

L = Live 230V

N = Neutral

E = Earth

Any additional mains cable should comply fully with the current I.E.E. wiring regulations. It must have a minimum section of 0.75mm2

and be capable of withstanding a minimum of 85C.

Page 14

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

Important Installation Requirements

Components in the HIU, pipes and radiators may reach high temperatures. The HIU is designed for heat distribution networks

with water temperatures up to 95°C. The pipes and parts in the HIU as well as pipes and radiators in the heating system can also

reach this temperature. Contact can lead to burns.

Central Heating

When installing the HIU, the following conditions must be observed (see the following diagrams):

1. The heating installation must be equipped with a correctly sized expansion vessel and safety relief valve fitted between the HIU and

any isolation valve on the heating circuit.

2. It is advisable to fit a filling loop and pressure gauge to the heating system, in a location convenient for the end user to access and top

up the central heating system.

3. The heating system must be equipped with a WRAS approved over pressure safety relief valve (rated to 3 bar), fitted between the HIU

and any isolation valve on the heating circuit.

4. A heating control valve must not be installed in the heating circuit. The room thermostat should, if used, be connected to the room

thermostat cable of the HIU.

5. Before the unit is commissioned, the central heating circuit must be fitted with an automatic bypass valve to maintain a minimal flow

rate and regulate pressure across the system. The valve must be installed between the central heating flow and return, noting the

direction of flow. The automatic bypass must be fitted before any isolation valve on the heating circuit.

NOTE For optimal energy efficiency and comfort, it is of the utmost importance to hydraulically balance the CH system correctly. For

the same purpose it is advisable to design the CH system in such a way that the CH return temperatures are as low as possible.

* Artificially softened water must not be used to fill the central heating system

.

.

DHW Recirculation Unit

Page 18

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

The DHW recirculation unit is an available option for fitting external to the HIU. The recirculation system must not contain any

isolation valves. Applying valves to the system can cause the pump to overheat due to insufficient flow.

Keep the following conditions in mind during installation:

Maximum pressure supplied by the domestic water circuit is 10 bar.

All seals, joints and compounds (including flux and solder) and components used as part of the secondary domestic water system

must be WRAS approved.

Page 19

The DATA Extra HIU, Installation Instructions DE2, 12th August 2021

Service and Inspection

Components in the HIU, pipes and radiators may reach high temperatures. The HIU is designed for heat distribution networks

with water temperatures up to 95°C. The pipes and parts in the HIU as well as pipes and radiators in the heating system can also

reach this temperature. Contact can lead to burns.

To ensure the unit functions properly, it is advised to periodically inspect the installation.

Maintenance and repairs should be carried out by recognised personnel only.

Remove the power from the unit when performing maintenance and/or repairs.

Connect the flow and return valve from the district heating network.

Connect the flow and return valve on the unit.

Check the unit for leaks.

Check the primary and central heating strainer for debris and clean if necessary.

Check valves for debris and clean if necessary.

Check the unit operates satisfactorily in domestic hot water and central heating modes.

The casing can be cleaned with a damp cloth. Do not use detergents of any kind.

The unit uses electrical components (230Vac, 24Vdc & 5Vdc). These components must stay dry at all times. Contact with these

energised components can result in an electrical shock, burn, or electrocution.

Prolonged Absence or Holiday

Do not switch the unit off during periods of prolonged absence or holiday. To prevent frost damage within the unit or the distribution

network, the radiator and shutoff valves MUST remain open. Radiators can be switched to the frost protection position (slightly

opened) and/or the room thermostat lowered to a MINIMUM of 10°C. It is recommended to flush all water tapping points and showers

for at least 2 minutes after a long period of absence.

Page 20

Table of contents

Other THERMAL INTEGRATION Heating System manuals