THERMAL INTEGRATION DATA User manual

The DATA HIU, Installation Instructions D3 13/06/2017

The DATA HIU

Installation Instructions D3

The DATA HIU, Installation Instructions D3, 13th June 2017

The DATA HIU, Installation Instructions D3

Wiki Binder, 13th June 2017

About Thermal Integration ................................................ 3

Explanation of symbols and abbreviations .................................... 4

Overview of Components and Connections ..................................... 5

Options ............................................................. 6

Dimensions .......................................................... 7

Technical Data ........................................................ 8

Application ........................................................... 9

General Plumbing Requirements .......................................... 11

General Wiring Requirements ............................................ 12

Schematic Layout ..................................................... 13

Wiring Diagram ...................................................... 14

Installation Requirements ............................................... 16

Installation Setup ..................................................... 18

Stage 1 - Pre-Fix Bracket Positioning ....................................... 19

Stage 2 - HIU Preparation ............................................... 20

Stage 3a - Fixing HIU ................................................... 21

Stage 3b - Pipework Connections .......................................... 22

Stage 4 - Fitting a Heat Meter ............................................ 23

Stage 5 - Filling the Heating System ........................................ 24

Stage 6 - Bleeding the Unit .............................................. 25

Stage 7 - Programmer and Room Thermostat Connection ......................... 26

Stage 8 - Connect Power ................................................ 27

Adjusting Settings ..................................................... 29

Securing the Casing .................................................... 30

Service & Inspection ............................................... 31

Draining the Unit ..................................................... 32

Pump Settings (Wilo) .................................................. 33

Pump Settings (Grundfos) ............................................... 34

DHW Recirculation Pump (Optional) ........................................ 36

Differential Pressure Valve (Optional) ...................................... 37

Troubleshooting (End Users) ............................................. 38

Troubleshooting For Technicians .......................................... 39

Heat Meter ......................................................... 40

Dirt and Air Separation ................................................. 41

Guarantees and After Sales .............................................. 42

DATA EC Declaration ................................................... 44

Page 2

The DATA HIU, Installation Instructions D3, 13th June 2017

About Thermal Integration

About Us

We design and manufacture pre-fabricated Hot Water and Central Heating Cylinders, Thermal Stores, Buffer Tanks and Heat Interface

Units to suit almost any domestic or commercial application. Our range of products is the end result of over 20 years of continuous

development and improvement in heating technology. We hold to the philosophy that all customers deserve our best level of service for

the life of the product, as well as complete honesty throughout the product selection process. We hold a significant number of patents

in the fields of water storage, heat exchange, and the networking of communal heating systems, and continue to push the boundaries.

As well as the most comprehensive range of hot water systems in the UK, our headquarters in Sudbury also offers the UKs largest

renewables training centre, including the first HETAS training and test centre, with working wood, pellet and log biomass rigs, as well

as solar. There is also an extensive district heating demonstration and test facility attached to the factory, with the factory building

services running from a twin pellet biomass boiler installation, buffer storage, and HIUs to provide services. The entire facility is

controlled using our in-house IHIU Control Systems that allow any of our products to be network connected, with online monitoring and

dashboard facilities.

For a complete history of the company please read History of Thermal Integration Limited on Heatweb Wiki.

Product Range

Heat Interface Units

Standard Cylinders

Shortened Cylinders

Buffer Cylinders

Combination Cylinders

Mains Pressure Thermal Stores

Mains Hot Water Conversion Kits

Prefabricated Systems

Plate Heat Exchangers

Boiler Conversion Kits

Control Systems

Knowledge Base

To make the dissemination of technical material as simple as possible, we publish all our documentation through an online document

storage system, the Heatweb Wiki. Links to further information may be found throughout documents.

Useful Contacts

Commercial Sales and Operations: 0845 2411441

Specflue Sales: 0333 9997974

Web Sites

http://www.heatweb.co.uk Company Website

http://www.systemdesigner.co.uk System Designer

http://wiki.heatweb.com/wiki Heatweb Wiki

http://www.heatweb.info Monitoring software and online APIs

Page 3

The DATA HIU, Installation Instructions D3, 13th June 2017

Overview of Components and Connections

1 Primary circuit strainer

2 Back casing

3 Primary flow temperature sensor

4 Heat meter sensor pocket

5 Automatic air vent (central heating)

6 Electronics 230 V

7 Electronics 24 V

8 Heat exchanger (central heating)

9 Domestic Hot Water Temperature sensor

10 Heat exchanger (DHW)

11 Central heating pump

12 Domestic Hot Water control valve

13 Domestic Hot Water primary return temperature sensor

14 Central heating strainer

15 Filling point

16 Flow sensor

17 Pressure/temperature gauge

18 Temperature/pressure sensor central heating supply

19 Pressure relief valve (3 Bar)

20 Temperature sensor central heating primary return

21 Heat meter spool piece

22 Central heating control valve

23 Expansion vessel

24 Expansion vessel bleed valve

Page 5

The DATA HIU, Installation Instructions D3, 13th June 2017

Options

The unit has several options available depending on requirements. The basic unit can be equipped with any combination of

thefollowing:

Option A1: Spool piece, used when neither option A2 or A3 are required.

Option A2: Landlord security valve, allows the landlord to remotely isolate the unit from the district heating network if required.

Option A3: Differential pressure control valve, to balance differential pressures between the primary flow and return. Only required

where the differential pressure exceeds 250kPa. (Max 450kPa)

Option B: Water hammer arrestor, reduces water hammer within the DHW circuit.

Option C: DHW recirculation unit, to provide constant circulation of DHW throughout the property in order to allow quicker

response times at the tap where extended pipe runs are unavoidable. Note: The unit must be set to 'Comfort' Mode by the installer,

when this option is fitted.

Option D: Decorative casing, attractive white painted steel casing.

Option E1: Standard Output Domestic Hot Water, up to 65kW (at 10-60C)

Option E2: Plus output Domestic Hot Water, up to 80kW (at 10-60C)

Option F: Flushing Bypass for connecting to the primary flow and return pipework (External to the unit)

Page 6

The DATA HIU, Installation Instructions D3, 13th June 2017

Technical Data

Description Data

Nominal primary supply temperature 80C

Maximum primary supply temperature 85C

Minimum primary supply temperature 55C *

Nominal DHW supply temperature 55C

DHW Set Range 45C to 60C

Return Temp Limit Range 35C to 65C

CH Limit Range 30C to 80C

Primary connections Female / 18mm

Mains & DHW connections Female / 18mm

Central heating connections Female / 18mm

Pressure relief 15mm

Domestic Hot water heat exchanger (DHW) E8LAS40

Central heating heat exchanger (CH) E8LAS40

Maximal primary differential pressure (without dP regulator) 250kPa

Maximal primary differential pressure (with dP regulator) 450kPa

Minimal primary differential pressure 50kPa **

Pressure class DH circuit PN16

Pressure class CH circuit (3 bar safety valve) PN10

Pressure class DHW circuit PN10

CH Maximum working pressure 2.5 Bar

Casing width 490mm

Casing height 640mm

Casing depth 275mm

Casing Material EPP Expanded Polypropylene

Maximum Heat Losses 50W (1.2 kWh/day)

Typical Heat Losses (DHW Only, Keep Warm) 25W

Weight (basic version) 24kg ***

Electrical supply info 230V 50Hz

Fuse ratings 3 Amp

Sensor DHW NTC 10kohm @ 25C

Keep Warm Modes Economy / Comfort

Max Return Temperature during Keep Warm Mode DHW Setpoint - 2C

.* Minimum required DH supply temperature is DHW setpoint + 5C with a minimum of 55C.

.** Depends on requested DHW output and available DH supply temperature.

.*** Unit weight may vary depending on the optional components built into the unit

Page 8

The DATA HIU, Installation Instructions D3, 13th June 2017

Application

The Data twin plate HIU is used to provide hot water and central heating in properties connected to a district heating systemusing a

centralised boiler. Please keep the following conditions in mind during installation:

The unit must be installed in a frost free area.

The unit must not be exposed to direct sunlight.

Ambient temperature should be between +5C and +40C.

Humidity should be between 10% and 85%.

The unit must be connected to a fused double pole isolator.

The unit uses 230 VAC. Use caution when handling. Contact may lead to shock, burns or electrocution.

Temperatures of components in the unit and connected to the unit can reach high temperatures. Contact may lead to burns.

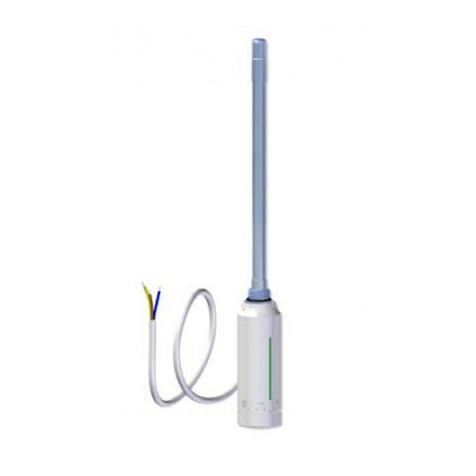

Status indicator LED

Green blinking (slow): Normal condition

Green blinking (fast): Heating demand

Blue blinking: Domestic Hot Water Mode / Tap draw-off

Red blinking: Error

White continuous: Service mode (installer only)

No LED: HIU is switched off

Page 9

The DATA HIU, Installation Instructions D3, 13th June 2017

Operation

Central Heating

The heat exchanger physically separates the district heating network and the central heating circuit. The application minimises the

riskof contamination of district heating water as well as the risk and consequences of leakage in the central heatingsystem.

Components, pipes and radiators in, and connected to the unit may be hot. The DATA heat interface unit is designed for use with

centralised heating systems up to 85C. The pipes and components in the unit and the pipes and radiators in the central heating

installation can reach temperatures of 80C and contact may lead to burns.

Domestic Hot Water

The unit is equipped with single walled plate heat exchangers. The front heat exchanger transfers the heat from the district

heatingsystem to the DHW. The electronics within the unit, together with domestic hot water control valve, temperature sensors and

flowsensor, regulate the temperature of the hot water to it's set point (As Standard 55C).

Each HIU has two domestic hot water keep hot modes, Eco or Comfort mode. These can only be selected during commissioning or by a

trained engineer.

The default setting is Eco mode, and this can be specified to run for 0 minutes (which turns the feature off all together), 15, 30, 60 or

120 minutes after the last hot water draw off. In Eco mode the heat exchanger is kept to a specified temperature (between 25 and 60

Deg C) for the selected period of time and after this period of inactivity has elapsed the stepper motor closes completely and the

temperature in the domestic hot water circuit is allowed to drop through natural dissipation to minimize energy consumption. If a hot

water draw off is made any time throughout the Eco mode function the unit will deliver hot water as usual and the Eco mode function

will begin counting down for the selected time once again.In Comfort mode the heat exchanger is continuously supplied with a trickle of

primary water for quicker hot water delivery, however energy consumption will be slightly higher than if the unit was set in Eco mode.

To prevent legionella from growing the heat exchanger is heated to 57C for at least 30 minutes every 24 hours. (it is not possible to

specify the time at which this occurs)

The hot water temperature is regulated to approximately 55C. If there is a power outage during DHW draw off, units not fitted

with a landlord security valve will stop regulating the hot water temperature. This may lead to a hot water temperature that is

higher or lower than 55C. Hot water can cause burns.

Priority Switching

The unit is fitted with domestic hot water priority switching. When hot water is drawn off, the central heating control valve will

close,diverting all primary flow to heat the domestic hot water circuit. Primary flow to the central heating is cut off during hot water

delivery.Primary flow to the central heating is resumed after the hot water draw off has finished.

Page 10

The DATA HIU, Installation Instructions D3, 13th June 2017

General Plumbing Requirements

NEW COMPLETE SYSTEM INSTALLATIONS When carrying out a completely new heating system installation in a new build property

or a first time installation in an existing property, then the heating system must conform to current building regulations Part L1a. All

new domestic heating systems must have a minimum of two heating zones. Each of these zones should be controlled by a thermostat

and zone valve. Alternatively individual electronically controlled Thermostatic Radiator Valves may be fitted. If domestic hot water is

provided by a storage system then the storage system or cylinder will require separate time and temperature control.

All radiators must have TRV's fitted in all rooms except bathrooms and any rooms where a thermostat is located. The exception to this

are single storey, open plan dwellings where the living area is more than 70% of the total usable floor area. Then this type of dwelling

can be controlled as one zone.

EXISTING INSTALLATIONS: When carrying out boiler replacements on an existing system, the regulations do not require separate

zoning of the upstairs and downstairs and compliance with the regulations can be achieved by a single room thermostat or

programmable room thermostat. It is however recommended that TRV's are fitted to all rooms except the bathrooms and the room

where a thermostat is located.

The appliance must be installed in accordance with, and comply to, the current: IEE Regulations, Building Regulations, Building

Standards (Scotland) (Consolidation), Building Regulations (Northern Ireland), local water by-laws, Health & Safety Document

635 (The Electricity at Work Regulations 1989) and any other local requirements.

BRITISH & IRISH STANDARDS Where no specific instruction is given, reference should be made to the relevant British and/or Irish

Standard codes of Practice.

BS7074:1 Code of practice for domestic and hot water supply

EN12828 Central heating for domestic premises

BS7593 Treatment of water in domestic hot water central heating systems

ECTI National rules for electrical installations

Potable water: All seals, joints and compounds (including flux and solder) and components used as part of the secondary domestic

water system must be approved by WRAS.

CH Water: Artificially softened water must not be used to fill the central heating system.

FITTING AND MODIFICATIONS: Fitting the appliance and any controls to the appliance may only be carried out by a competent

engineer. Any misuse or unauthorised modifications to the appliance or associated components and systems could invalidate the

guarantee and may lead to serious injury or even death. The manufacturer accepts no liability arising from any such actions, excluding

statutory rights.

SERVICING: The end user should be advised to have the system serviced annually by a competent engineer. Contact Thermal

Integration Ltd for a list of approved engineers. Approved spares must be used to help maintain the economy, safety and reliability of

the appliance. The service engineer must complete the Service Record after each service.

Page 11

The DATA HIU, Installation Instructions D3, 13th June 2017

General Wiring Requirements

These instructions apply in the UK and Ireland only and must be followed except for any statutory obligations. Component specific

electrical information may also be supplied in support of these instructions, however if there is any doubt please contact Thermal

Integration Ltd. (Tel: 0845 2411441)

FAILURE TO INSTALL APPLIANCES CORRECTLY COULD LEAD TO PROSECUTION.

The appliance must be installed in accordance with, and comply to, the current: IEE Regulations, Building Regulations, Building

Standards (Scotland) (Consolidation), Building Regulations (Northern Ireland), local water by-laws, Health & Safety Document

635 (The Electricity at Work Regulations 1989) and any other local requirements.

BRITISH & IRISH STANDARDS: Where no specific instruction is given, reference should be made to the relevant British and/or Irish

Standard codes of Practice.

BS7074:1 Code of practice for domestic and hot water supply

EN12828 Central heating for domestic premises

BS7593 Treatment of water in domestic hot water central heating systems

ECTI National rules for electrical installations

Potable water: All seals, joints and compounds (including flux and solder) and components used as part of the secondary domestic

water system must be approved by WRAS.

CH Water: Artificially softened water must not be used to fill the central heating system.

CAUTION: ISOLATE THE MAINS SUPPLIES BEFORE STARTING ANY WORK AND OBSERVE ALL RELEVANT SAFETY

PRECAUTIONS.

Danger of short circuit: When connecting the cables ensure that no cable pieces fall inside the control panel.

The Mains supply to the appliance must be through a fused double pole isolator situated next to the appliance. The isolator must have a

contact separation of 3mm minimum in all poles and should isolate the appliance and all associated controls.

Unless otherwise stated, all Heat Interface Units should be connected to a mains 230V 50Hz Supply fused at 3 Amps.

All electrical connections with the Heat Interface Unit control panel are clearly marked as follows:

L = Live 230V

N = Neutral

E = Earth

Any additional mains cable should comply fully with the current I.E.E. wiring regulations. It must have a minimum section of 0.75mm2

and be capable of withstanding a minimum of 85C.

Page 12

The DATA HIU, Installation Instructions D3, 13th June 2017

Installation Requirements

Components, pipes and radiators in, and connected to the unit may be hot. The DATA heat interface unit is designed for use with

centralised heating systems up to 85C. The pipes and components in the unit and the pipes and radiators in the central heating

installation can reach temperatures of 80C and contact may lead to burns.

To ensure the life expectancy of the unit, the system must meet certain requirements. Keep following conditions in mind during

installation:

Maximum pressure supplied by the district heating network is 10 bar.

Maximum differential pressure supplied by the district heating network is 250 kPa. (450 kPa when differential pressure valve is

fitted)

Maximum supplied temperature by the distict heating network is 90C.

Minimal supply temperature is setpoint DHW + 5C.

Central heating

Before the unit is commissioned, the central heating circuit must be fitted with an automatic bypass valve to maintain a minimal

flowrate and regulate pressure across the system. The valve must be installed between the central heating supply and return, noting

thedirection of flow.

ABV = Automatic Bypass Valve

NOTE For optimal energy efficiency and comfort, it is of the utmost importance to hydraulically balance the CH system correctly. For

the same purpose it is advisable to design the CH system in such a way that the CH return temperatures are as low as possible.

* Artificially softened water must not be used to fill the central heating system

Page 16

The DATA HIU, Installation Instructions D3, 13th June 2017

DHW Recirculation Unit

The DHW recirculation unit is an available option within the unit. The circulation system connected to the unit must not contain

anyclosable valves. Applying valves to the system can cause the pump to overheat due to insufficient flow.

Keep following condition in mind during installation:

Maximum pressure supplied by the domestic water circuit is 10 bar.

All seals, joints and compounds (including flux and solder) and components used as part of the secondary domestic water system

must be WRAS approved.

Page 17

The DATA HIU, Installation Instructions D3, 13th June 2017

Stage 1 - Pre-Fix Bracket Positioning

The following dimensions for for the extended pre-fix kit.If a flushing by-pass is to be fitted, please refer to the relevant page.

1.Mark out the wall with the fixing points using the dimensions shown below.

2.Drill holes using a suitable drill bit to suit wall plugs provided in accessory pack.

3.Using a level, fit first fix brackets to wall.

4.Continue with external pipework as required. With isolating valves closed the systems can be filled for testing.

Mounting to a plywood wall:Minimal plywood thickness must be 18 mm. Make sure that the back wall is at least 50 mm wider than

the unit to ensure a proper support. Make sure the drill markings are aligned and leveled. Drill holes of 4 mm on the markedlocations

40 mm deep. 4 holes are drilled for the fix rail unit and another 4 for the unit. Mount the fix rail firmly to the wall using the enclosed

screws.

Mounting to a concrete wall:Make sure the wall is robust and of good quality. Avoid hollow walls and make sure that the screws are

not placed in the flushings of a brick wall. Drill holes of 10 mm on the marked locations 60 mm deep. 4 holes are drilled for the fix rail

unit and another 4 for the unit. Mount the fix rail firmly to the wall using the enclosed screws and plugs.

Page 19

Table of contents

Other THERMAL INTEGRATION Heating System manuals

Popular Heating System manuals by other brands

Solaire

Solaire R4 user guide

System air

System air SAVE VTC 700 user manual

ComfortHeat

ComfortHeat CTAV-10 installation instructions

System air

System air fantech SHR450 installation manual

weinor

weinor Tempura Instructions for assembly maintenance and use

Armstrong

Armstrong 3760 ProDose Series Installation and operating instructions