3

MBRELL

-

-

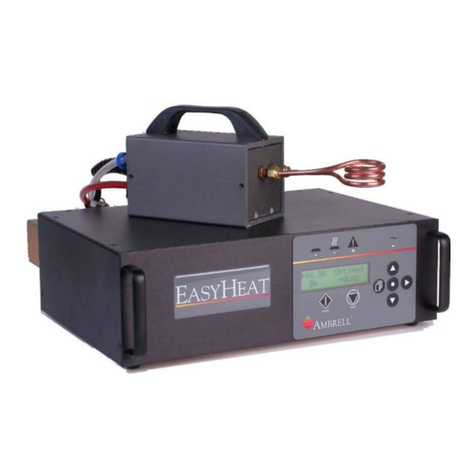

Precision Induction Heating

Table of Contents

1Introduction ..........................................................................................................................5

1.1Safety Considerations........................................................................................................6

1.2Front and Rear Panels .......................................................................................................8

1.3Work Head ......................................................................................................................10

1.4Assembly.........................................................................................................................11

1.5Installation.......................................................................................................................14

2How Your EASYHEAT Works ........................................................................................17

2.1Home Zone......................................................................................................................18

2.2Control Zone ...................................................................................................................24

2.3Detailed EASYHEAT Operation ....................................................................................29

2.4Equipment Maintenance..................................................................................................32

2.5Before You Call Service… .............................................................................................34

2.6Calibration.......................................................................................................................36

2.7Smartburst Technology ...................................................................................................36

3Customizing Your EASYHEAT .......................................................................................39

3.1Rear Panel Connections ..................................................................................................39

3.2Serial Port (RJ45 modular)..............................................................................................45

3.3Optional Equipment ........................................................................................................53

3.4eVIEW Induction Heating Software ...............................................................................55

3.5Tap Adjustment ...............................................................................................................57

3.6Re-selecting Mains Voltage Range .................................................................................59

4Storing the System..............................................................................................................61

4.1System Disposal ..............................................................................................................61

4.2Sorting .............................................................................................................................61

5Regulation, Efficiency and Power Measurement ............................................................61

5.1RF Regulation and Efficiency .........................................................................................61

5.1.1Primary regulation techniques not used in EASYHEAT products:.........................62

5.1.2Power Measurement.................................................................................................64

6Technical Information .......................................................................................................66

6.1Mechanical ......................................................................................................................66

6.2Electrical..........................................................................................................................67

6.3Auxiliary Output Modes and Scaling Examples.............................................................69

6.4Environmental .................................................................................................................71

6.5Contact Information ........................................................................................................72

7Theory of Coil Design ........................................................................................................75