Air Conditioner Service Manual

TABLE OF CONTENTS

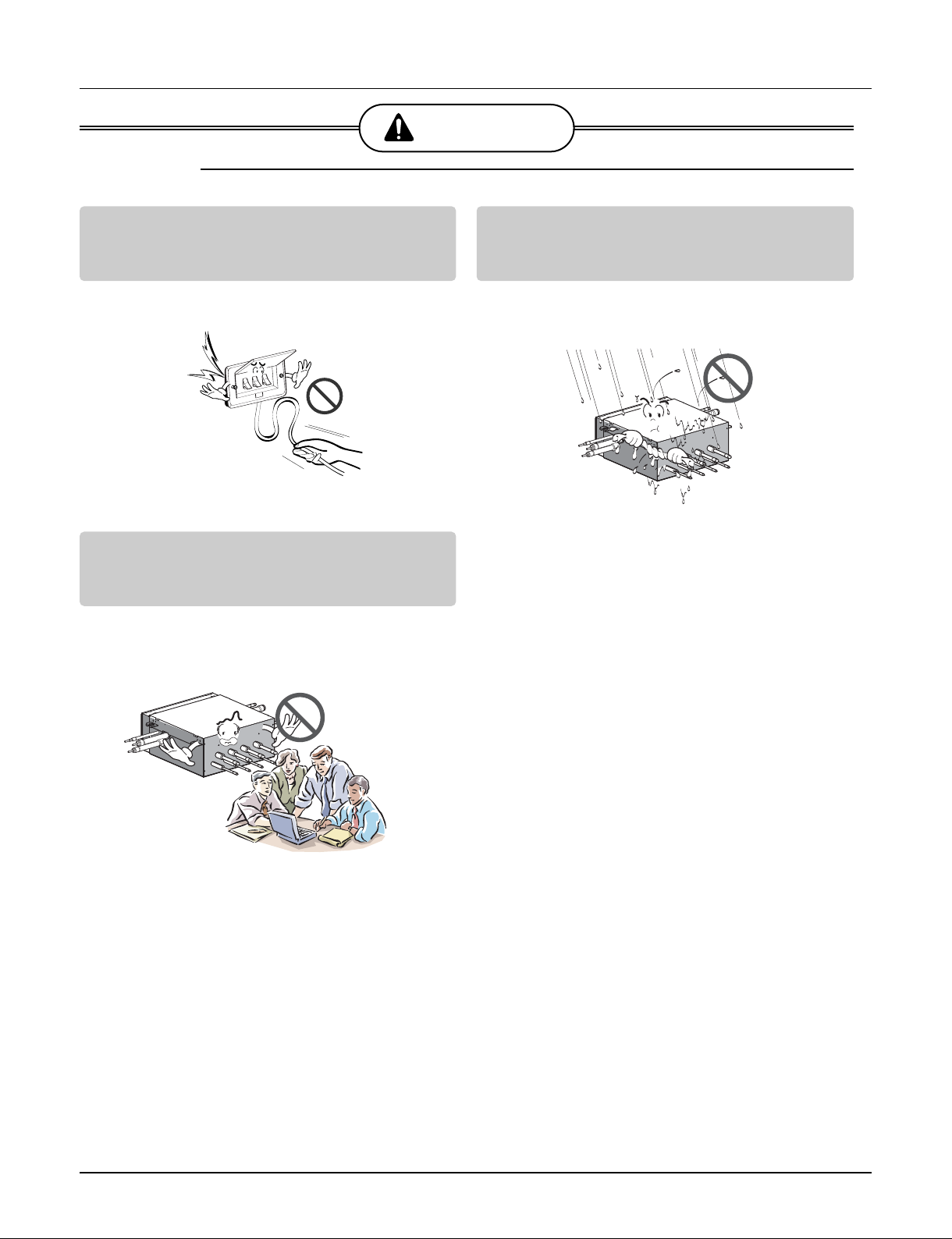

Safety Precautions .....................................................................................................3

Part 1 General Information ........................................................................................5

Model Names ...............................................................................................................................6

External Appearance ...................................................................................................................7

Nomenclature ...............................................................................................................................8

Part 2 HR Units ...........................................................................................................9

Part 3 PCB Setting....................................................................................................19

Part 4 Trouble shooting guide................................................................................ 35

Copyright ©2011 LG Electronics. Inc. All right reserved.

Only for training and service purposes LGE Internal Use Only

- 2 -