Thermaltronics TMT-HA200 User manual

USER MANUAL

TMT-HA200

HOT AIR TOOL

www.thermaltronics.com

WARRANTY

All equipment and accessories are warranted by Thermaltronics to be free from

defects in materials and workmanship as follows:

Part Number Description Warranty Period

TMT-HA200 220-240V Hot Air Tool 1 Year

HE-HA200 Heating Element 30 Days

HE-PU200 Fan for TMT-HA200 30 Days

This warranty does not apply to equipment or goods which have been tampered

with, misused, damaged through improper installation or used in a manner

contrary to supplier instructions. Normal “wear and tear” of equipment or goods

is not covered by this warranty. If the product should become defective within the

warranty period, Thermaltronics will repair or replace it free of charge at its sole

option. Warranty period is from the date of purchase by the original owner. If the

date of purchase cannot be substantiated the date of manufacture will be used as

the start of the warranty period.

TABLE OF CONTENTS

TMT-HA200 SPECIFICATIONS ................................................................... 1

INTRODUCTION.......................................................................................... 1

SYSTEM FEATURES................................................................................... 1

SAFETY PRECAUTIONS............................................................................. 2

CONTROL PANEL........................................................................................ 3

UNPACKING/ASSEMBLY/OPERATION ................................................... 3-4

FREQUENTLY ASKED QUESTIONS .......................................................... 5

ORDERING GUIDE...................................................................................... 6

WARNING:

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

This tool must be placed on its stand when not in use.

1

TMT-HA200 Hot Air Tool

USER MANUAL

TMT-HA200 SPECIFICATIONS

Input Line Voltage: 220-240 VAC

Power: 600 Watts

Temperature Range: 100C - 480C

Pump: Turbine Fan

Air Flow (Max): 35L / min

Fuse: 250V 3A

Size (W x H x D): 112mm x 205mm x 117mm

Weight: 2.4 KG

Certication Marks: CE

INTRODUCTION

Congratulations on your purchase of the TMT-HA200 hot air tool. This unit

has been tested and inspected by Thermaltronics prior to shipment, and with

proper maintenance will give you years of reliable performance.

SYSTEM FEATURES

The TMT-HA200 hot air tool can be used for surface mount component

removal and reow on components such as SOIC, CHIP, QFP, PLCC and

others.

1. Auto sleep activated when hot air tool is put in the holder.

2. Adjustable, easy to use temperature control knob

3. Adjustment, easy to use air ow control knob

4. Electrostatic discharge free (ESD) safe.

5. Large selection of high quality nozzles for rework on QFP, SOP, PLCC and

SOJ components.

Functions and Features

2

SAFETY PRECAUTIONS

Warning

A fire may result if this equipment is not used with care and for intended

applications. To avoid electric shock or injury, please follow the instructions

below strictly:

1. The unit must be properly grounded.

2. The unit can reach extremely high temperatures when switched ON.

- Do not use the device near ammable materials or gases

- Do not touch heated parts, which can cause severe burns

- Do not point the nozzle towards any part of the body

3. Never operate the equipment with wet hands.

4. Always disconnect the power cord and allow the unit ample time to

cooldown before performing maintenance.

5. Use only genuine replacement parts.

Caution

1. Use this equipment in a well-ventilated area, away from combustible

equipment.

2. Disconnect the power cord if unit is not used for extended period of time.

3. Place handle in stand when not in use.

4. Handle with care.

- Never drop or sharply jolt the unit.

- The unit contains delicate parts that can be damaged if subjected to

physical force.

- Do not spill any liquids into the unit.

5. Do not operate on uneven surfaces.

6. Allow to cool down before storage.

7. Turn off the power when the unit is not in use.

8. Do not alter the unit in any manner.

9. When resting the handle in the handle holder, make sure there are no

objects within 30cm of the nozzle, as nearby objects maybe damaged.

10. Do not apply excessive force when installing and removing nozzles.

11. Do not use pliers to pull the edges of the nozzle.

12. Do not over tighten the screw when installing a new nozzle.

3

TMT-HA200 Hot Air Tool

USER MANUAL

UNPACKING/ASSEMBLY/OPERATION

Please read this manual and follow the directions before using the equipment. The carton contains:

1. TMT-HA200 Hot Air Tool

2. Handpiece Holder

3. HTN-D30, HTN-D50, HTN-D80, HTN-D100 nozzles

4. HA-HE200 Heating Element

5. IC Popper

Important: Keep all shipping materials until satisfactory operation has been veried.

Assembly and Operation

1. Remove TMT-HA200 Hot Air Tool from its box and place on a suitable work bench.

2. Install the handpiece holder onto the side of the system with a screw driver.

3. Select the proper nozzle and secure it to the handle.

4. Ensure the hot air gun is placed in the handpiece holder.

5. Connect the AC plug to a suitable AC power outlet.

6. Switch the power switch to the “on” position.

7. Adjust the air ow and temperature.

8. The unit is now in sleep mode, with the power off and both the heating element and airow off.

9. To activate the unit, lift the hot air gun from the holder.

10. After the heating element reaches temperature. The unit should then be read to use.

Power Off

1. Place the hot air gun back into the holder.

2. This will start the auto cool process, after the temperature has dropped down to safe levels, the

fan will automatically shut down and the unit will enter sleep mode.

3. Switch off the unit, unplug if not used for extended periods of time.

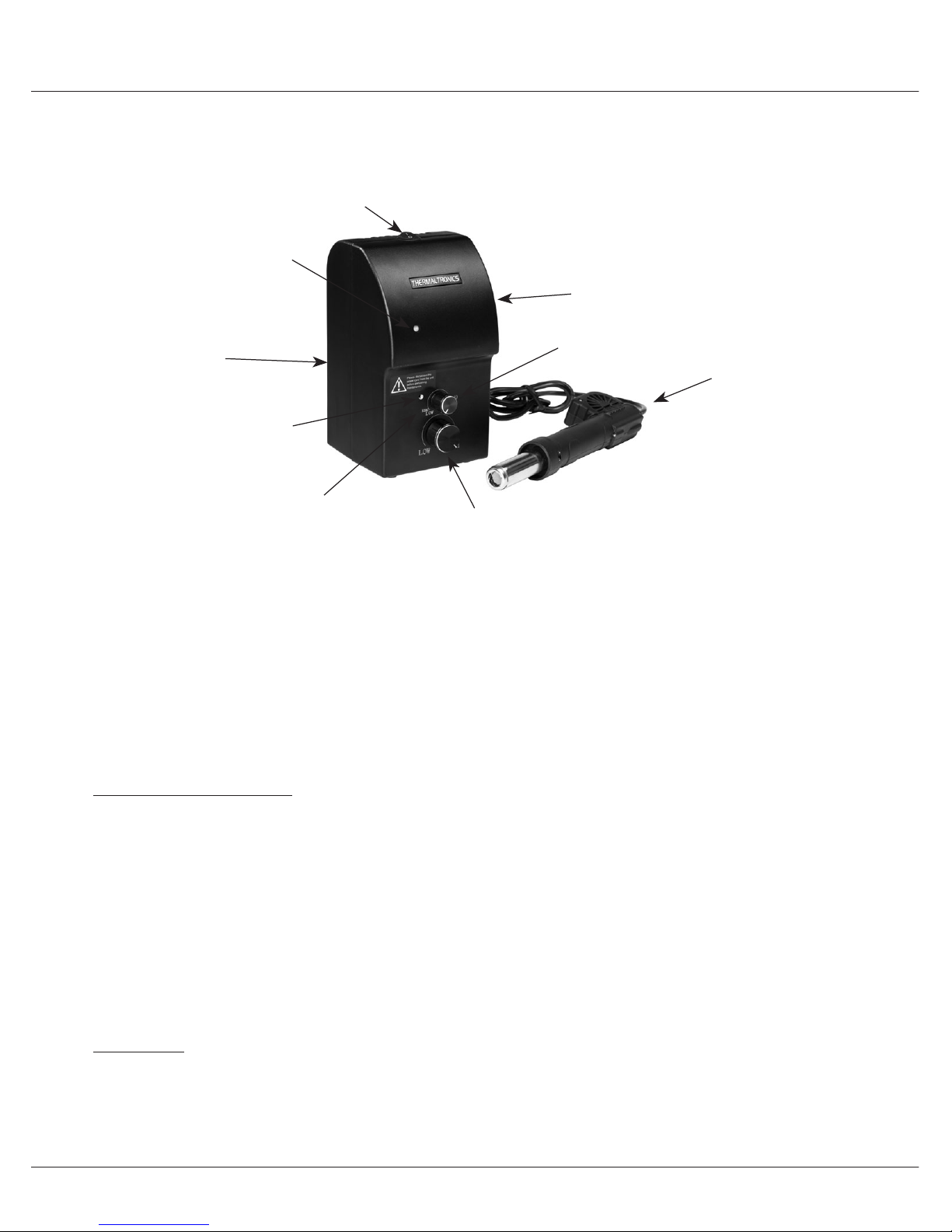

CONTROL PANEL

Temperature Knob

Air Flow Knob

Power Switch

Hot Air Gun

Handpiece Holder

ESD Paint

Power Indicator LED

Temperature

Indicator LED

Calibration

4

UNPACKING/ASSEMBLY/OPERATION

Operation - Operating Mode

Whenever the hot air gun is not placed in the holder, and the system is turned on, the unit will be in

operating mode.

Note: To prolong heating element life, always let the unit enter cool down and sleep mode

rst before turning the unit off.

Operation - Cooldown Mode

Whenever the hot air gun is placed in the holder, the system will automatically go into cooldown

mode as follows:

1. The heating element is turned off.

2. The fan will continue to blow cool air until the heating element temperature has gone down

below 100C.

3. The system goes into sleep mode.

4. Lifting the hot air gun from the holder will deactivate the cooldown mode and the system will go

back to operating mode.

Operation - Sleep Mode

Whenever the hot air gun is placed in the holder and the heating element temperature is lower than

100C.

1. The heating element is turned off.

2. The fan is turned off.

3. Lifting the hot air gun from the holder will deactivate the sleep mode.

4. In sleep mode both the power and temperature LED indicator are off.

Operation - Power off

The unit is powered down. Both the heating element and fan are off.

Note: To prolong heating element life, always turn the temperature knob fully counter

clockwise and airow knob to the midpoint after each use.

Calibrating the hot air gun

In some cases, it may be necessary to synchronize the amount of heat delivered by the hot air gun

with an external temperature sensing device. This can be achieved by the following steps:

1. Turn the temperature knob to maximum.

2. Place an external temperature sensing device near the tip of the hot air gun nozzle.

3. Wait for the temperature LED indicator to start ickering and the external temperature readout

has stabilized.

4. Unscrew the calibration screw. Insert a small screw driver into the hole and slowly turn the

calibration utility until the approximate temperature on both devices are synchronized.

Operating Cooldown Sleep Power off

5

TMT-HA200 Hot Air Tool

USER MANUAL

FREQUENTLY ASKED QUESTIONS

Q: The unit has no power.

A: Check if the unit is switched on and the power cord is plugged in. Verify that the

fuse has not blown out. Pick up the hot air gun, the unit may just be in sleep mode.

Q: The actual temperature is not increasing

A: Pick up the hot air gun, the unit may just be in sleep mode. The overheat protection

may be engaged, power off unit to cooldown and then power back on. Lastly, check if

the heating element is damaged, replace if damaged.

Q: Replacing the heating element.

Q: No air is coming out of the hot air gun

A: Check if the fan is damaged, replace if damaged.

Q: Replacing the fan.

Caution: Disconnect power before replacing the fan.

1. Remove the screws holding the hot air tool together and open the cover.

2. Disconnect and remove the heater pipe.

3. Pull back the heat shrink tube and disconnect the fan by unsoldering the power

wires. Remember the wire order (one wire is positive, one wire is negative)

4. Insert a new fan (HA-PU200).

5. Reassemble the hot air gun in the reverse order it was disassembled.

Q: Other problems

Caution: Disconnect power before replacing heater element.

1. Remove the six screws holding the hot air tool together and

open the cover.

2. Disconnect and remove the heater pipe.

3. Disconnect the heater connector, pull back the heat shrink

tube and desolder thermocouple wires.

4. Insert a new heating element (HA-HE200).

5. Reassemble the hot air gun in the reverse order it was

disassembled.

1

2

3

Fan Wires

6

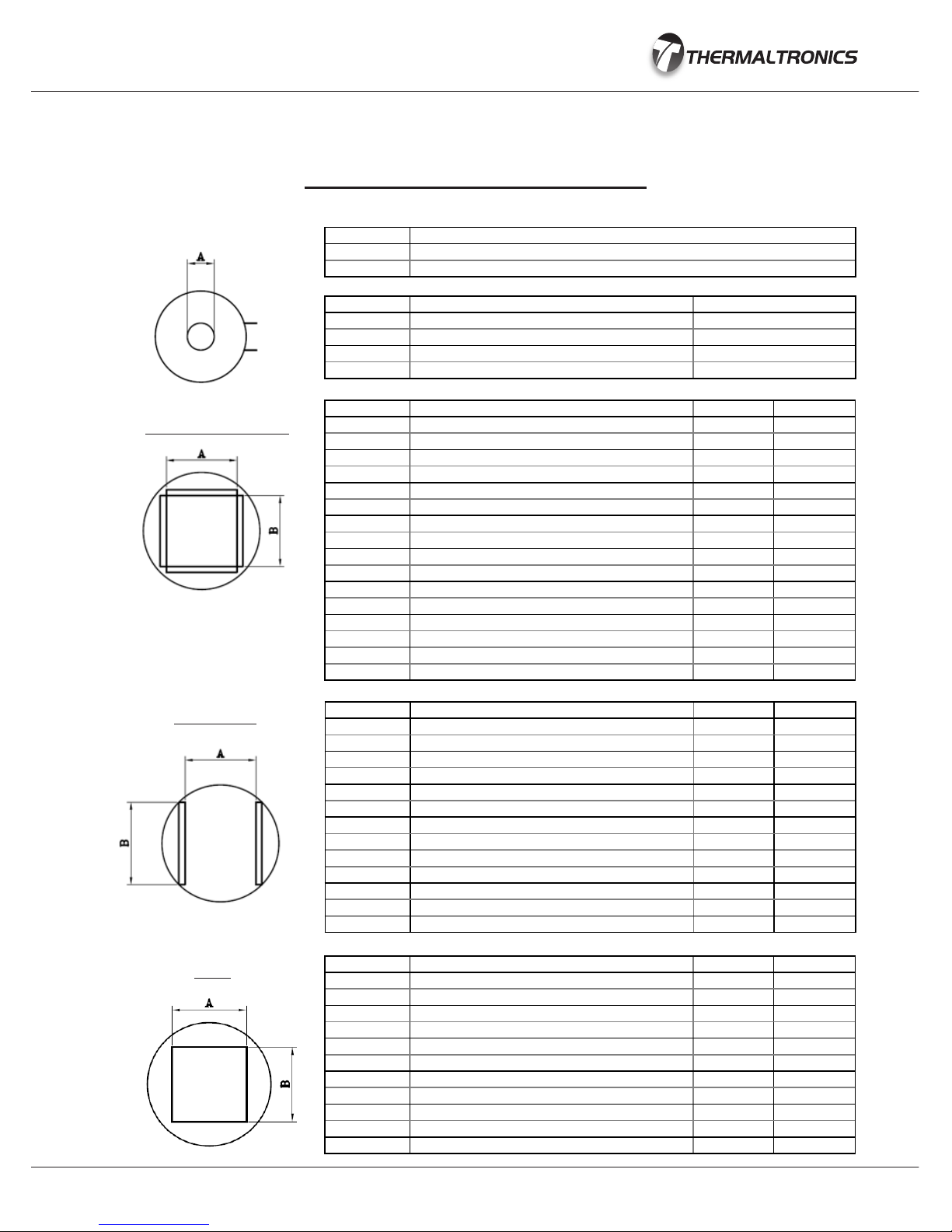

ORDERING GUIDE

PART# DESCRIPTION A mm (in) B mm (in)

HTN-PL20 Nozzle 11.9mm x 11.9mm, PLCC-20 11.9 11.9

HTN-PL28 Nozzle 14.5mm x 14.5mm, PLCC-28 14.5 14.5

HTN-PL32 Nozzle 16.9mm x 14.3mm, PLCC-32 16.9 14.3

HTN-PL44 Nozzle 19.5mm x 19.5mm, PLCC-44 19.5 19.5

HTN-PL52 Nozzle 22.0mm x 22.0mm, PLCC-52 22.0 22.0

HTN-PL68 Nozzle 27.0mm x 27.2mm, PLCC-68 27.0 27.2

HTN-PL84 Nozzle 32.4mm x 32.4mm, PLCC-84 32.4 32.4

HTN-QF48 Nozzle 8.4mm x 8.4mm, QFP-48 8.4 8.4

HTN-QF44 Nozzle 13.4mm x 13.4mm, QFP-44 13.4 13.4

HTN-QF80 Nozzle 17.3mm x 17.3mm, QFP-52,80 17.3 17.3

HTN-QF100 Nozzle 23.4mm x 18.1mm, QFP-64,80,100 23.4 18.1

HTN-QF160 Nozzle 31.2mm x 31.2mm, QFP-120,128,144,160 31.2 31.2

HTN-BQ100 Nozzle 22.4mm x 22.4mm, BQFP-100 22.4 22.4

HTN-QF240 Nozzle 34.5mm x 34.5mm, QFP-240 34.5 34.5

HTN-BQ196 Nozzle 37.7mm x 37.7mm, BQFP-196 37.7 37.7

HTN-QF208 Nozzle 29.8mm x 29.8mm, QFP-208 29.8 29.8

PART# DESCRIPTION A mm (in)

HTN-D30 Nozzle 3.0mm 3.0

HTN-D50 Nozzle 5.0mm 5.0

HTN-D80 Nozzle 8.0mm 8.0

HTN-D100 Nozzle 10.0mm 10.0

HTN-SC16 Nozzle 6.8mm x 10.2mm, SOIC 14, 16 6.8 10.2

HTN-SL16 Nozzle 10.6mm x 10.8mm, SOL 14, 16 10.6 10.8

HTN-SL20 Nozzle 10.6mm x 13.3mm, SOL 20, 20J 10.6 13.3

HTN-SL24 Nozzle 10.6mm x 15.9mm, SOL 24, 24J 10.6 15.9

HTN-SL28 Nozzle 10.6mm x 18.4mm, SOL 28 10.6 18.4

HTN-SL44 Nozzle 16.0mm x 27.9mm, SOL 44 16.0 27.9

HTN-SJ32 Nozzle 13.5mm x 20.6mm, SOJ 32 13.5 20.6

HTN-SJ40 Nozzle 13.5mm x 25.4mm, SOJ 40 13.5 25.4

HTN-TS24 Nozzle 17.0mm x 7.1mm, TSOP 20-24 PIN 17.0 7.1

HTN-TS32 Nozzle 21.0mm x 9.1mm, TSOP 28-32 PIN 21.0 9.1

HTN-TS40 Nozzle 21.0mm x 10.8, TSOP 40 PIN 21.0 10.8

HTN-TS48 Nozzle 21.0mm x 13.3mm, TSOP 48 PIN 21.0 13.3

HTN-TS24B Nozzle 10.2mm x 18.4mm, TSOP 20-24 PIN 10.2 18.4

HTN-TS44 Nozzle 12.7mm x 19.8mm, TSOP 24-28/40-44 PIN 12.7 19.8

SO, TSOP

PLCC, QFP, BQFP

PART# DESCRIPTION

HA-HE200 Heating Element for TMT-HA200

HA-PU200 Replacement Fan for TMT-HA200

SPARE PARTS & NOZZLES

HTN-B1010 Nozzle 10.0mm x 10.0mm 10.0 10.0

HTN-B1313 Nozzle 13.0mm x 13.0mm 13.0 13.0

HTN-B1616 Nozzle 16.0mm x 16.0mm 16.0 16.0

HTN-B1919 Nozzle 19.0mm x 19.0mm 19.0 19.0

HTN-B2828 Nozzle 28.0mm x 28.0mm 28.0 28.0

HTN-B3030 Nozzle 30.0mm x 30.0mm 30.0 30.0

HTN-B3232 Nozzle 32.0mm x 32.0mm 32.0 32.0

HTN-B3636 Nozzle 36.0mm x 36.0mm 36.0 36.0

HTN-B3939 Nozzle 39.0mm x 39.0mm 39.0 39.0

HTN-B4141 Nozzle 41.0mm x 41.0mm 41.0 41.0

HTN-B4343 Nozzle 43.0mm x 43.0mm 43.0 43.0

HTN-B4545 Nozzle 45.0mm x 45.0mm 45.0 45.0

BGA

Table of contents

Other Thermaltronics Power Tools manuals