Thermo King V-500 User manual

V-500 Series

TK 51859-1-MM (Rev. 1, 05/05)

Copyright© 2004 Thermo King Corp., Minneapolis, MN, USA.

Printed in USA.

This manual is published for informational purposes only and the information so provided should

not be considered as all-inclusive or covering all contingencies. If further information is required,

Thermo King Corporation should be consulted.

Sale of product shown in this manual is subject to Thermo King’s terms and conditions

including, but not limited to, the Thermo King Limited Express Warranty. Such terms and

conditions are available upon request. Thermo King’s warranty will not apply to any

equipment which has been “so repaired or altered outside the manufacturer’s plants as,

in the manufacturer’s judgment, to effect its stability.”

No warranties, express or implied, including warranties of fitness for a particular

purpose or merchantability, or warranties arising from course of dealing or usage of

trade, are made regarding the information, recommendations, and descriptions

contained herein. Manufacturer is not responsible and will not be held liable in contract

or in tort (including negligence) for any special, indirect or consequential damages,

including injury or damage caused to vehicles, contents or persons, by reason of the

installation of any Thermo King product or its mechanical failure.

The maintenance information in this manual covers unit models:

V-500-10 (920271)

V-500-20 3PH (920272)

V-500-20 1PH (920273)

V-500 MAX-10 (920274)

V-500 MAX-20 3PH (920275)

V-500 MAX-20 1PH (920276)

For further information, refer to:

V-500 Series Operating Manual TK 51878

V-500 Series Parts manual TK 52763

Diagnosing Thermo King Refrigeration Systems TK 5984

Evacuation Station Operation and Field Application TK 40612

Tool Catalog TK 5955

The information in this manual is provided to assist owners, operators and service people in the

proper upkeep and maintenance of Thermo King units. The above manuals may be purchased from

your local Thermo King dealer.

Recover Refrigerant

At Thermo King, we recognize the need to preserve the environment

and limit the potential harm to the ozone layer that can result from

allowing refrigerant to escape into the atmosphere.

We strictly adhere to a policy that promotes the recovery and limits

the loss of refrigerant into the atmosphere.

In addition, service personnel must be aware of Federal regulations

concerning the use of refrigerants and the certification of technicians.

For additional information on regulations and technician certification

programs, contact your local Thermo King dealer.

R-134a/R-404A

WARNING: Use only Polyol Ester-based refrigeration compressor oil in

R-134a/R-404A units. See Thermo King Parts Manual for part number.

Do not mix Polyol Ester and standard synthetic compressor oils. Keep Polyol

Ester compressor oil in tightly sealed containers. If Polyol Ester oil becomes

contaminated with moisture or standard oils, dispose of properly–DO NOT USE.

When servicing Thermo King R-134a or R-404A units, use only those service

tools certified for and dedicated to R134a/R-404A refrigerant and Polyol Ester

compressor oils. Residual non-HFC refrigerants or oils will contaminate R-134a

and R-404A systems.

5

About This Manual

Purpose

The purpose of this manual is to provide general maintenance information necessary to maintain the

climate control unit at peak operating standards. This includes safety information, unit information such

as bills of material and kit numbers, general unit information, maintenance procedures and related

information (such as wiring and schematic diagrams), and some diagnostic and troubleshooting

information.

NOTE: This manual may cover more than one unit. Therefore, it may contain information not

applicable to your unit.

Contents

This manual is organized into the following chapters:

Chapter Purpose

Safety Precautions Provides detailed safety information. You should be familiar with the

safety precautions before working on any unit.

Model Systems and Update

Matrices These tables list the bills of material and kit options that make up your

unit. Use them for the following purposes:

1. To determine if you have the right manual for your unit: the bill of

material (B/M) number on your unit serial plate should match one of the

bill of material numbers listed in this section. If you cannot find your unit

in the matrix, call TK Service for more information.)

2. To communicate with TK Service Department: If you need to call TK

Service, you must know your model number so that the service

representative to help you.

Specifications Lists unit specifications.

General Description Gives an overview description of your unit including standard and

optional features, illustrations, and general a/c theory.

Operating Instructions Provides unit operating instructions.

Maintenance Inspection Schedule Table of routine maintenance procedures.

Maintenance Chapters Provide detailed maintenance procedures required for your unit.

(Electrical, Refrigeration, Compressor, Structural, Clutch)

Refrigeration Diagnosis Provides troubleshooting information for diagnosing problems.

Wiring and Schematic Diagrams Wiring and Schematic diagrams applicable to the unit.

About This Manual

6

Before you Call Thermo King Service!

Who to call: Your Thermo King Service Representative.

Before you call Thermo King Service, have the following information on hand:

• Bill of Material (usually located on the unit serial plate)

• Model Number - found on side of the unit

Blank Pages

This manual may contain blank pages at the end of chapters. This is normal. There is no information

missing from the manual.

Roadside/Curbside Terminology

Roadside/Curbside terminology: These terms can be confusing because of differences between North

America and Europe. Please note:

Using the Model Tables in “About this Unit”

The model tables in this section (called “About this Unit,” “Model Systems and Update Matrices,” or

something similar) list important unit information that you will need to communicate with the Thermo

King Service Department. See the table on the previous page for a description of how to use these tables.

Curbside: The side of the truck to the driver’s right when the driver is in his seat and facing forward.

Roadside: The side of the truck to the driver’s left when the driver is in his seat and facing forward.

7

Table of Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before you Call Thermo King Service! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Blank Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Roadside/Curbside Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Using the Model Tables in “About this Unit” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Auto Start/Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Refrigeration Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Microprocessor Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Welding of Units or Truck Bodies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Model Systems (System Designations) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Refrigerant System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Belt Tension (Using Tool P/N 204-427) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

AC Electric Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Electric Standby Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Solder Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Control Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

In-Cab Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Oil Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Liquid Injection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Evaporator Drain Tube Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Electric Standby Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Unit Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Protection Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

P.C. Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Common Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Electric Standby Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Thermostat Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Serial Number Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table of Contents

8

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

In-Cab Control Box Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Display Return Air (Box) Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Display Setpoint Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Enter Setpoint Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Defrost Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Weekly Pretrip Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Starting the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

After Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Post Load Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Maintenance Inspection Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Refrigeration/Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Structural . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Electrical Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Maintenance Inspection Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Trouble Shooting In-Cab Control Box M-13 and M-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Defrost System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Defrost Timer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Defrost Termination Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Defrost Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Defrost Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Testing the Defrost System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Defrost Timer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Condenser Fan Pressure Switch (CFPS) R-134a Units Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Testing CFPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Liquid Injection System (R-404A Units Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Testing Liquid Injection Solenoid Valve and Metering Orifice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Electric Standby Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Refrigeration Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Maintenance Inspection Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

RCharging the Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Checking the Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Checking Compressor Oil Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

High Pressure Cutout Switch (HPCO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Low Pressure Cutout Switch (LPCO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Cleanup Procedure for Small Truck Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Structural Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Maintenance Inspection Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Evaporator Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Unit Mounting Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Table of Contents

9

Compressor Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Refrigerant Handling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Refrigerant Handling Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Refrigerant Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Compressor Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Compressor Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Compressor Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Compressor Installation Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Compressor Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Compressor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Mounting Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Adding Extra Oil To System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Major Loss Of Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Checking Compressor Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Oil Check Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Oil return procedure (System Operational) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Compressor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Draining and Replacing Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Clutch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Clutch Removal, Inspection, and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Clutch Run In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Shaft Seal Cover and Shaft Seal Removal, Inspection, and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Seal Cover Installation (When Equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Front and Rear Cylinder Head Disassembly, Inspection, and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Compressor Leak Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Belt Tensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Engine Driven Compressor Belt and Pulleys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Over-the-Road Mechanical Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Electric Standby Mechanical Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Electric Standby Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Refrigeration Diagnosis Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Wiring, Refrigeration and Schematic

Diagrams Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table of Contents

10

11

List of Figures

Figure 1: P.C. Board Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 2: Fuse 4/1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 3: Thermostat Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 4: Unit Components (Model 20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 5: Condenser Electric and Capacitor Boxes (Model 20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 6: Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 7: Evaporator with Hot Water and Electric Heat Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 8: M13 In-Cab Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 9: On/Off Key & LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 10: Celsius/Fahrenheit LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 11: Setpoint Key & Dial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 12: Misc. LED’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 13: Defrost Key & LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 14: On/Off Key and Defrost Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 15: Setpoint Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 16: Entering Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 17: Back of Cab Control Box with Cover Removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 18: Block Diagram M-13, M-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 19: Defrost Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 20: Testing CFPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 21: Charging Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 22: High Pressure Cutout Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 23: Connecting Flushing Compressor to Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 24: Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 25: Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 26: Typical Recovery Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 27: Rotate Compressor Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 28: Compressor Installation Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 29: Loosen Cap Slowly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 30: Rotate Compressor Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 31: Shim Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 32: Oil Inspection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 33: Draining the Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 34: Typical Compressor Oil Fill Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 35: Remove Center Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 36: Remove Armature Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 37: Remove Snap Ring and Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 38: Remove Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 39: Remove Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 40: Inspect Clutch Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 41: Install Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 42: Install Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 43: Install Cover and Snap Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 44: Install Cover and Snap Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 45: Install Shims and Drive Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 46: Check Air Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 47: Shaft Seal Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 48: Remove Shaft Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 49: Inspect Shaft Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 50: Place Guide on Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

List of Figures

12

Figure 51: Place Shaft Seal on Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Figure 52: Press Seal Into Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Figure 53: Install Snap Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Figure 54: Install Shaft Seal Cover (When Equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Figure 55: Proper Shaft Seal Cover Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Figure 56: Remove Body Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Figure 57: Tap Front Cylinder Head Projections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Figure 58: Front Cylinder Head Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Figure 59: Front Valve Plate and Suction Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Figure 60: Tap Rear Cylinder Head Projections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Figure 61: Rear O-ring and Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Figure 62: Rear Valve Plate and Suction Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Figure 63: Front Cylinder and Valve Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Figure 64: Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Figure 65: Rear Suction Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Figure 66: Rear Cylinder Head Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Figure 67: Front Suction Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Figure 68: Front Cylinder Head Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Figure 69: Tightening Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Figure 70: Compressor Drain Plug Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Figure 71: Discharge and Suctions Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Figure 72: Pulley Arbor P/N 204-804 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Figure 73: Shaft Seal Kit P/N 204-805 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Figure 74: Clutch Remover P/N 204-806 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Figure 75: Compressor Holder P/N 204-807 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Figure 76: Snap Ring Pliers P/N 204-808 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Figure 77: Clutch Installation Kit P/N 204-890 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

13

Safety Precautions

General Practices

1. Always wear goggles or safety glasses.

Refrigerant liquid, refrigeration oil, and

battery acid can permanently damage the eyes.

2. Never close the compressor discharge service

valve with the unit operating.

3. Never operate the unit with the compressor

discharge valve closed.

4. Keep your hands, clothing and tools clear of

the fans and belts when the unit is running.

This should also be considered when opening

and closing the compressor service valves.

5. Make sure gauge manifold hoses are in good

condition. Never let them come in contact

with a belt, fan motor pulley, or any hot

surface.

6. Never apply heat to a sealed refrigeration

system or container.

7. Fluorocarbon refrigerants in the presence of

an open flame produce toxic gases that are

severe respiratory irritants capable of causing

death.

8. Make sure all mounting bolts are properly

torqued and are of correct length for their

particular application.

9. Use extreme caution when drilling holes in the

unit. The holes may weaken structural

components, and holes drilled into electrical

wiring can cause fire or explosion. Holes

drilled into the refrigeration system will

release refrigerant.

10. Use caution when working around exposed

coil fins. The fins can cause painful

lacerations.

11. Use caution when working with a refrigerant

or refrigeration system in any closed or

confined area with a limited air supply (for

example, a truck body or garage). Refrigerant

tends to displace air and can cause oxygen

depletion resulting in suffocation and possible

death.

12. When using ladder or scaffolding, use caution

and follow manufacturer recommendations.

Auto Start/Stop

Refrigerant

When removing refrigerant from a unit, a

recovery process that prevents or minimizes

refrigerant loss to the atmosphere is required by

law.

When a refrigerant is exposed to the atmosphere

in the liquid state, it evaporates rapidly, freezing

anything it contacts. If refrigerant contacts the

skin, severe frostbite can result.

First Aid

In the event of frostbite, the objectives of First

Aid are to protect the frozen area from further

injury, to warm the affected area rapidly and to

maintain respiration.

•Eyes: For contact with liquid, immediately

flush eyes with large amounts of water and get

prompt medical attention.

•Skin: Flush area with large amounts of

lukewarm water. Do not apply heat. Remove

contaminated clothing and shoes. Wrap burns

with dry, sterile, bulky dressing to protect

from infection/injury. Get medical attention.

Wash contaminated clothing before reuse.

•Inhalation: Move victim to fresh air and use

cardiopulmonary resuscitation (CPR) or

mouth-to-mouth ventilation if necessary. Stay

with victim until arrival of emergency medical

personnel.

CAUTION: The unit may start

automatically and at any time when the

unit On/Off switch is in the On position.

Units with CYCLE-SENTRYTM start

automatically in both CYCLE-SENTRY

mode and Continuous mode. Be sure to

turn the On/Off switch Off before opening

doors or inspecting or working on any part

of the unit.

Safety Precautions

14

Refrigeration Oil

Observe the following precautions when working

with or around synthetic or polyol ester refrigerant

oil:

• Do not allow refrigerant oil to contact your

eyes.

• Do not allow prolonged or repeated contact

with skin or clothing.

• To prevent irritation, you should wash

thoroughly immediately after handling

refrigerant oil. Rubber gloves are

recommended when handling polyol ester oil.

First Aid

•Eyes: Immediately flush eyes with large

amounts of water for at least 15 minutes while

holding the eyelids open. Get prompt medical

attention.

•Skin: Remove contaminated clothing. Wash

thoroughly with soap and water. Get medical

attention if irritation persists.

•Inhalation: Move victim to fresh air and

restore breathing if necessary. Stay with

victim until arrival of emergency personnel.

•Ingestion: Do not induce vomiting. Contact a

local poison control center or physician

immediately.

Electrical Hazards

Microprocessor Service

Precautions must be taken to prevent electrostatic

discharge when servicing the microprocessor

controller and related components. Potential

differences considerably lower than those which

produce a small spark from a finger to a door

knob can severely damage or destroy solid-state

integrated circuit components.

The following procedures must be rigidly adhered

to when servicing units to avoid microprocessor

damage or destruction.

1. Disconnect all power to the unit.

2. Avoid wearing clothing that generates static

electricity (wool, nylon, polyester, etc.).

3. Do wear a static discharge wrist strap (see

Tool Catalog) with the lead end connected to

the microprocessor’s ground terminal. These

straps are available at most electronic

equipment distributors. Do not wear these

straps with power applied to the unit.

4. Avoid contacting the electronic components

on the circuit boards of the unit being

serviced.

5. Leave the circuit boards in their static proof

packing materials until ready for installation.

6. If a defective controller is to be returned for

repair, it should be returned in the same static

protective packing materials from which the

replacement component was removed.

7. After servicing the controller or any other

circuits, the wiring should be checked for

possible errors before restoring power.

8. Never use testers consisting of a battery and a

light bulb to test circuits on any

microprocessor based equipment.

9. Before connecting or disconnecting the

battery, the Microprocessor Power On/Off

switch must be turned to the Off position. It is

located on the roadside of the unit, lower left

corner.

Safety Precautions

15

Welding of Units or Truck Bodies

When electric welding is to be performed on any

portion of the temperature control unit, truck or

truck chassis when the temperature control unit is

attached, it is necessary to ensure that welding

currents are not allowed to flow through the

electronic circuits of the unit.

These procedures must be rigidly adhered to when

servicing units to avoid damage or destruction of

the controller.

1. Disconnect all power to the unit.

2. Disconnect all wire harnesses from the

controller.

3. Switch all of the electrical circuit breakers in

the control box to the Off position.

4. Weld unit or container per normal welding

procedures. Keep ground return electrode as

close to the area to be welded as practical.

This will reduce the likelihood of stray

welding currents passing through any

electrical or electronic circuits.

5. When the welding operation is completed, the

unit power cables, wiring and circuit breakers

must be restored to their normal condition.

High Voltage

When servicing or repairing a temperature control

unit, the possibility of serious or even fatal injury

from electrical shock exists. Extreme care must be

used when working with a refrigeration unit that

is connected to a source of operating power, even

if the unit is not operating. Lethal voltage

potentials can exist at the unit power cord, inside

the control box, at the motors and within the

wiring harnesses.

Precautions

1. Be certain the Unit On/Off switch is turned

Off before connecting or disconnecting the

standby power plug. Never attempt to stop the

unit by disconnecting the power plug.

2. Be certain the unit power plug is clean and dry

before connecting it to a power source.

3. When working on high voltage circuits on the

temperature control unit, do not make any

rapid moves. If a tool drops, do not grab for it.

People do not contact high voltage wires on

purpose. It occurs from an unplanned

movement.

4. Use tools with insulated handles that are in

good condition. Never hold metal tools in

your hand if exposed, energized conductors

are within reach.

5. Treat all wires and connections as high

voltage until a meter and wiring diagram show

otherwise.

6. Never work alone on high voltage circuits on

the temperature control unit. Another person

should always be present to shut off the

temperature control unit and to provide aid in

the event of an accident.

7. Have electrically insulated gloves, cable

cutters and safety glasses available in the

immediate vicinity in the event of an accident.

First Aid

Immediate action must be initiated after a person

has received an electrical shock. Obtain

immediate medical assistance if available.

The source of shock must be immediately

removed by either shutting down the power or

removing the victim from the source. If it is not

possible to shut off the power, the wire should be

cut with either an insulated instrument (e.g., a

wooden handled axe or cable cutters with heavy

insulated handles) or by a rescuer wearing

electrically insulated gloves and safety glasses.

Whichever method is used do not look at the wire

while it is being cut. The ensuing flash can cause

burns and blindness.

Safety Precautions

16

If the victim must be removed from a live circuit,

pull the victim off with a non-conductive material.

Use the victim’s coat, a rope, wood, or loop your

belt around the victim’s leg or arm and pull the

victim off. Do not touch the victim. You can

receive a shock from current flowing through the

victim’s body. After separating the victim from

the power source, check immediately for the

presence of a pulse and respiration. If a pulse is

not present, start CPR (Cardiopulmonary

Resuscitation) and call for emergency medical

assistance. If a pulse is present, respiration may be

restored by using mouth-to-mouth resuscitation,

but call for emergency medical assistance.

Low Voltage

Control circuits used in the temperature control

unit are low voltage (12 Vdc). This voltage

potential is not considered dangerous, but the

large amount of current available (over 30 amps)

can cause severe burns if shorted or ground.

Do not wear jewelry, watch or rings when

working on the unit. If these items contact an

electrical circuit, severe burns may result.

17

Model Systems (System Designations)

Thermo King Model V-500 Truck Refrigeration Systems

NOTE: When calling the dealer or factory for information or parts please have the Bill of Material

number for your particular unit handy.

System Designation System

Number Power Pack Install Kit Refrig Schematic, Wiring

Diagrams

V-500-10 920387 8800002 R-134a 1E24520, 1E24518

V-500-20 3PH 920388 085060 8800002 R-134a 1E18884, 1E24443

V-500-20 1PH 920388 085014 8800002 R-134a 1E24519, 1E24517

V-500 MAX-10 920390 8800002 R-404A 1E24520, 1E24518

V-500 MAX-20 3PH 920391 085060 8800002 R-404A 1E18884, 1E24443

V-500 MAX-20 1PH 920391 085014 8800002 R-404A 1E24519, 1E24517

Model Systems (System Designations)

18

19

Specifications

Electrical System

Fuses

Fuse 1: Evaporator Fan Motor (EF1) 15 amps

Fuse 2: Evaporator Fan Motor (EF2) 15 amps

Fuse 3: Engine-driven Compressor Clutch Coil, Condenser

Solenoid Valve Coil (heating option), Hot Gas Solenoid Valve Coil 15 amps

Fuse 5: Condenser Fan Motor (CFM1) 15 amps

Fuse 6: Condenser Fan Motor (CFM2) 15 amps

Fuse 7: Evaporator Fan Motor (EF3) 15 amps

Fuse 4: Cab Control Box when in Electric Standby 3amps

Fuse 4/1: Cab Control Box 3 amps

Condenser Fan Motors

Voltage Full Load rpm Full Load Current

13 Vdc 3000 9.2 Amps

Evaporator Fan Motors

Voltage Full Load rpm Full Load Current

13 Vdc 2700 6.2 Amps

Coils for Hot Gas Solenoids, Condenser Solenoids, and Liquid Line Solenoids

Voltage Current Resistance

12 Vdc 2.3 amps 5.2 ohms

Specifications

20

Refrigerant System

R-134A REFRIGERATION SYSTEM (V-500)

Refrigerant Charge V-500 7.93 lbs (3.6 kg) R-134a

Defrost Termination Switch: Opens 48.0 ± 5.4 F (8.9 ± 3.0 C)

Closes 36.0 ± 5.4 F (2.2 ± 3.0 C)

High Pressure Cutout Switch: Opens 300 ± 10 psi (2068 ± 69 kPa)

Closes 200 ± 20 psi (1378 ± 69 kPa)

Low Pressure Cutout: Opens 5 to 11 in. Hg vacuum (-17 to -34 kPa)

Closes 4 to 7 psi (28 to 48 kPa)

Condenser Fan Speed Control (CFSC) Pressure Cutout Switch:Opens 200 ± 7 psi (1379 ± 48 kPa)

Closes 160 ± 7 psi (1103 ± 48 kPa)

R-404A REFRIGERATION SYSTEM (V-500 Max)

Refrigerant Charge V-500 Max 8.15 lbs (3.7 kg) R-404A

Defrost Termination Switch: Opens 48.0 ± 5.4 F (8.9 ± 3.0 C)

Closes 36.0 ± 5.4 F (2.2 ± 3.0 C)

Liquid Injection Switch: Opens 200 ± 5 F (93 ± 3 C)

Closes 230 ± 5 F (110 ± 3 C)

High Pressure Cutout Switch: Opens 450 ± 10 psi (3100 ± 69 kPa)

Closes 375 ± 10 psi (2585 ± 69 kPa)

Low Pressure Cutout: Opens 5 to 11 in. Hg vacuum(-17 to -34 kPa)

Closes 4 to 7 psi (28 to 48 kPa)

Condenser Fan Speed Control (CFSC) Pressure Cutout Switch:Opens 300 + 20 psi/-0 psi (2068 ± 138 kPa)

Closes 200 ± 20 psi (1379 ± 138 kPa)

Condenser Fan Pressure Cutout Switch (CFPS): Opens 130 ± 10 psi (896 ± 69 kPa)

Closes 180 ± 10 psi (1241 ± 69 kPa)

Compressors

Main Compressor SELTEC TM-16XD, Engine Driven, Swash Plate, 6

Cylinder

Electrical Compressor FRASCOLD D211Y, Reciprocating, 3 Cylinder,

System Oil Capacity Main: 15.1 oz (150 cc)

Standby Operation: 40.1 oz (1200 cc)

Compressor Oil Type Polyol Ester P/N 203-515

Refrigerant 8.1 lbs (3.7 kg) R-404A

8.0 lbs (3.6 kg) R-134a

Defrost Method: Hot gas

Defrost Timer: Initiation Interval Adjustable, 1 hour to 10 hours

Termination Interval Termination is not timed.

Defrost is terminated by Klixon switch.

CAUTION: Failure to use correct Thermo King recommended oil will invalidate your warranty.

This manual suits for next models

12

Table of contents

Popular Control Unit manuals by other brands

TECH FASS

TECH FASS APS mini Plus MREM 65 Series user guide

Hi-Tec

Hi-Tec SPECTRA PRO instruction manual

Timeguard

Timeguard TS800B operating instructions

WindowMaster

WindowMaster WCC 103 MotorController Installation instruction

Ublox

Ublox MAX-M10M Integration manual

Krom Schroder

Krom Schroder DG 17VC operating instructions

CSW

CSW RECTORSEAL EZ TRAP EZT180 Product data sheet

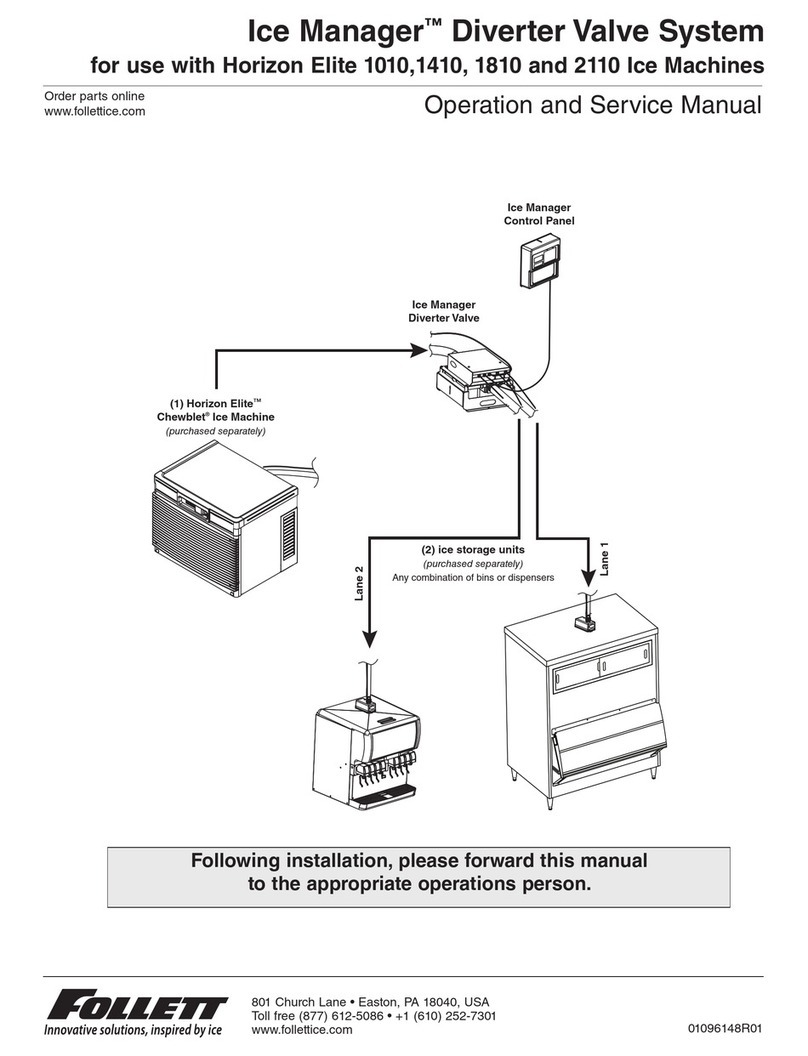

Follett

Follett Ice Manager Operation and service manual

EB TECHNOLOGY

EB TECHNOLOGY START S10 manual

3Com

3Com NETBuilder II FDDILink Installing

Steady State Fate

Steady State Fate DivKid RND manual

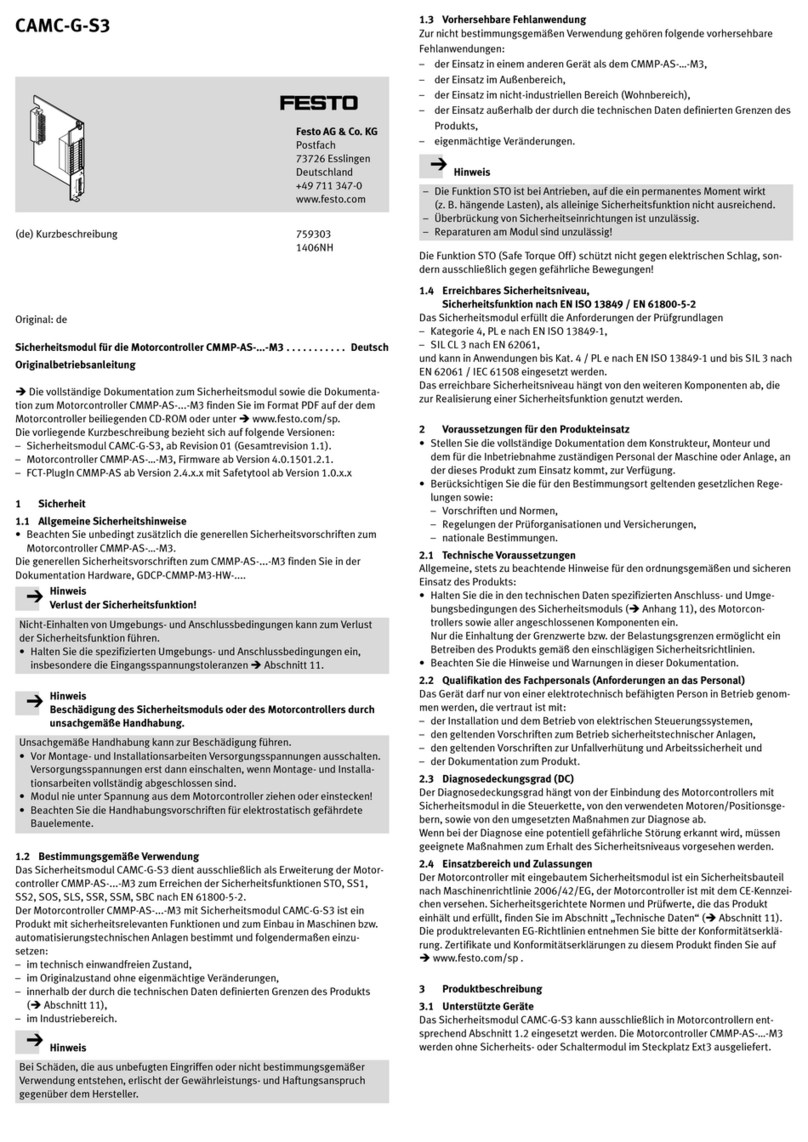

Festo

Festo CAMC-G-S3 Translation of the original instructions