Thermo Scientific i

C

Chapter 1 Safety Notes

Basic Operating Precautions.............................................................................................1-1

Safety Consideration. ........................................................................................................ 1-2

Warranty............................................................................................................................ 1-2

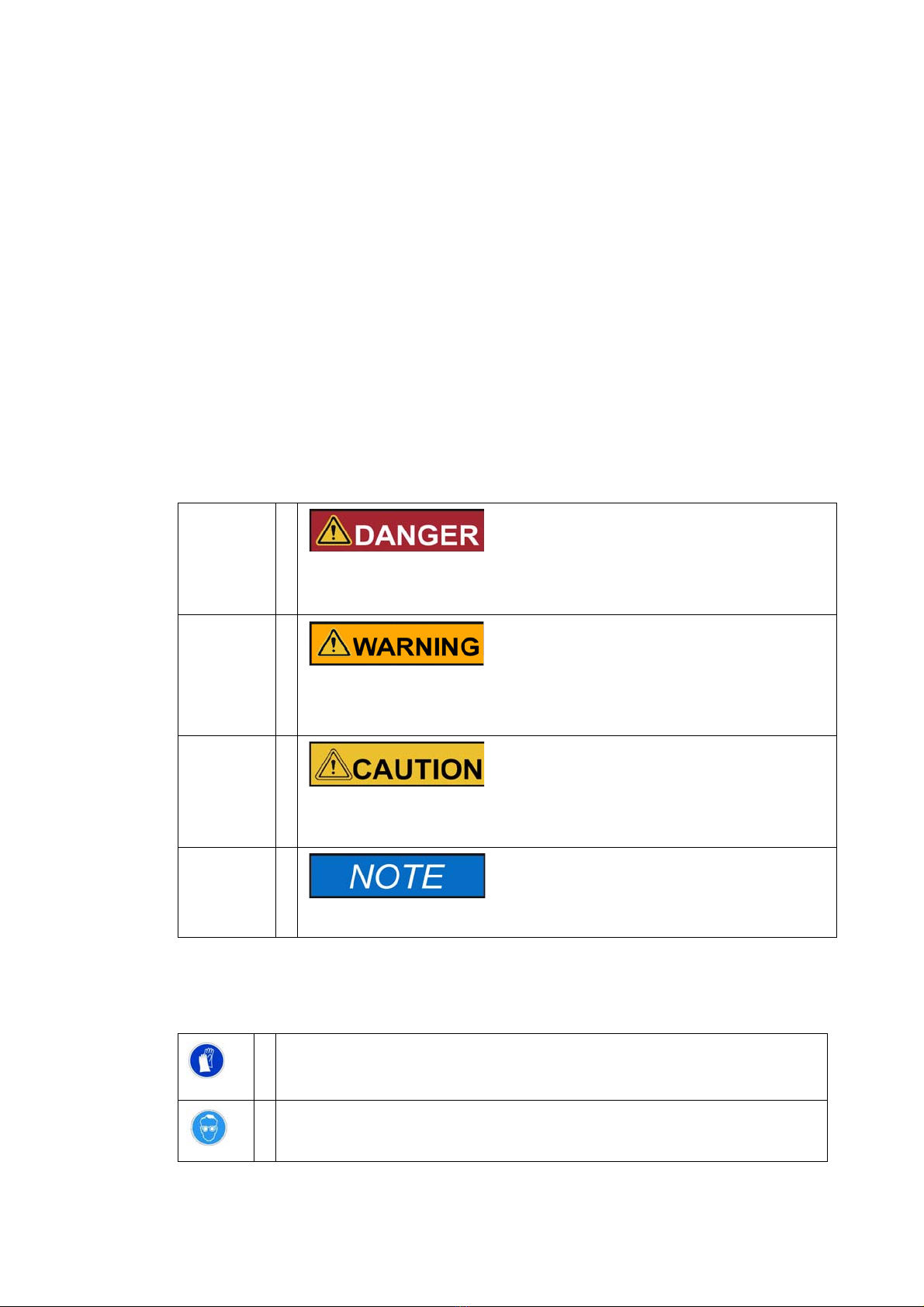

Explanation of Safety Information and Symbols................................................................1-3

Additional symbols for safety information..........................................................................1-3

Standards and Directives................................................................................................... 1-4

Chapter 2 Introduction...................................................................................................................... 2-1

Chapter 3 Unpacking ........................................................................................................................ 3-1

Chapter 4 Installation

Location............................................................................................................................. 4-1

Power Wiring. .................................................................................................................... 4-1

Furnace and Control Console Connection Diagram..........................................................4-2

Furnace Thermocouple Connection- Single and Double Controller. ................................. 4-3

Power Wiring Procedure....................................................................................................4-4

Thermocouple Wiring Installation................................................................................................. 4-5

Chapter 5 Initial Start-Up.................................................................................................................. 5-1

Chapter 6 Operation - UT150 Controller

UP150 Controller Overview...............................................................................................6-2

Single Setpoint Operation.................................................................................................. 6-7

Programming Operation: Entering a Program...................................................................6-8

Usinh the Hold Function .................................................................................................. 6-13

Using the Advance Function............................................................................................6-14

Auto Tuning UP150 Controller.........................................................................................6-15

Temperature Offset Procedure........................................................................................ 6-15

Changing Temperature Scale Between °C and °F..........................................................6-16

Chapter 7 Communication Option

Cable Installation. .............................................................................................................. 7-1

UT150 Communications Setpu Parameters...................................................................... 7-1

Software Installation. .........................................................................................................7-2

Communications Test........................................................................................................ 7-3

Troubleshooting.................................................................................................................7-4

Decimal Point Adjustment..................................................................................................7-4

Addresses for Multiple Controller.......................................................................................7-4

Table of Contents