Calibrating the Speed Sensor ............................................2-16

Determining Values to Use for Initial Setup........................2-16

Determining Belt Speed...................................................2-17

Determining Clip Delay....................................................2-17

Determining Timed Delay................................................2-17

Chapter 3 Operating the TMD ..............................................3-1

Overview..............................................................................3-1

Operator Interface................................................................3-1

Operating Modes...............................................................3-2

Menu Structure.....................................................................3-2

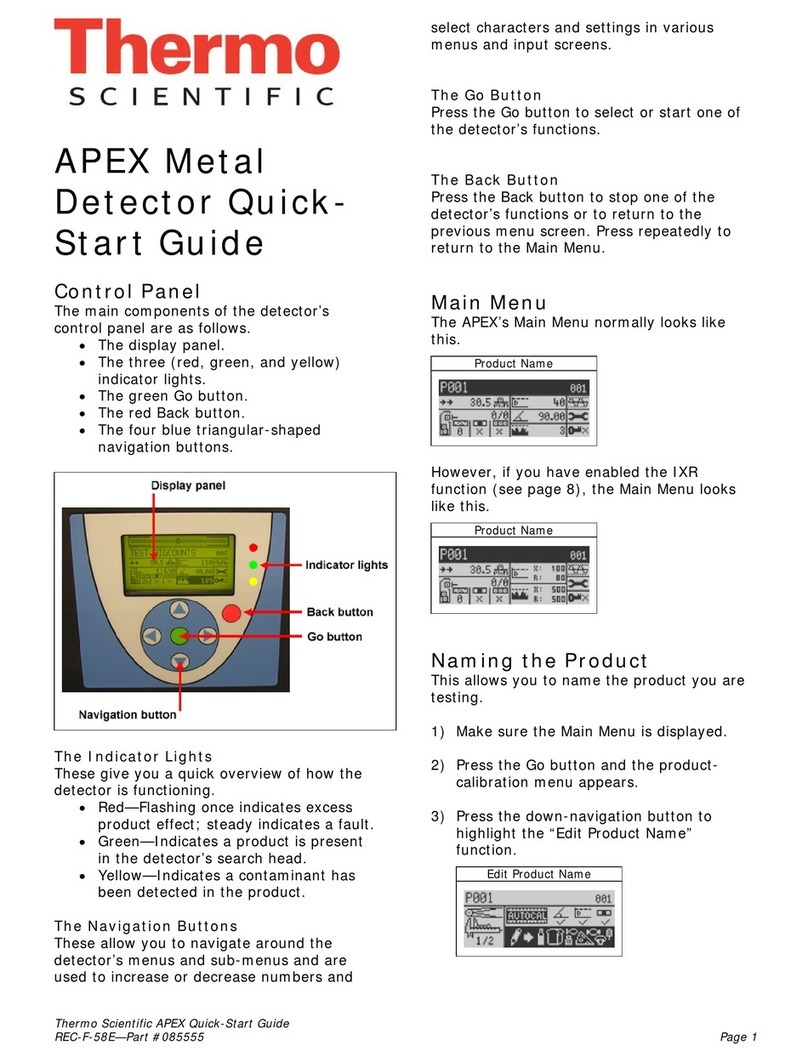

Front Panel Keypad...........................................................3-4

SCROLL Keys ................................................................3-4

VALUE Keys...................................................................3-4

ENTER Key ....................................................................3-4

RESET Key.....................................................................3-5

Front Panel LED Indicators ...............................................3-5

NORMAL ........................................................................3-5

ALARM ...........................................................................3-5

BYPASS .........................................................................3-5

CALIB .............................................................................3-5

Bar Graph.......................................................................3-5

Front Panel Displays .........................................................3-6

Run Screen.....................................................................3-6

Password Protection Screen...........................................3-7

Calibration Screens ........................................................3-8

Coil Balance....................................................................3-8

Calibrate for Metal ..........................................................3-9

Calibrate for Clip.............................................................3-9

EST Cal ........................................................................3-10

Test...............................................................................3-10

Exit................................................................................3-11

Setup Screens..............................................................3-11

Clip Delay .....................................................................3-11

Bar/Rod Sensitivity .......................................................3-11

Bar/Rod Length.............................................................3-12

Belt Speed....................................................................3-12

Timed Delay..................................................................3-12

Timed Duration.............................................................3-12

Audit Int.........................................................................3-12

Material Code ...............................................................3-12

Time Constant ..............................................................3-12

Filter..............................................................................3-13

Operating Frequency....................................................3-13

Remote Front Panel......................................................3-13

Modbus Communications .............................................3-13

Switch Settings.............................................................3-13