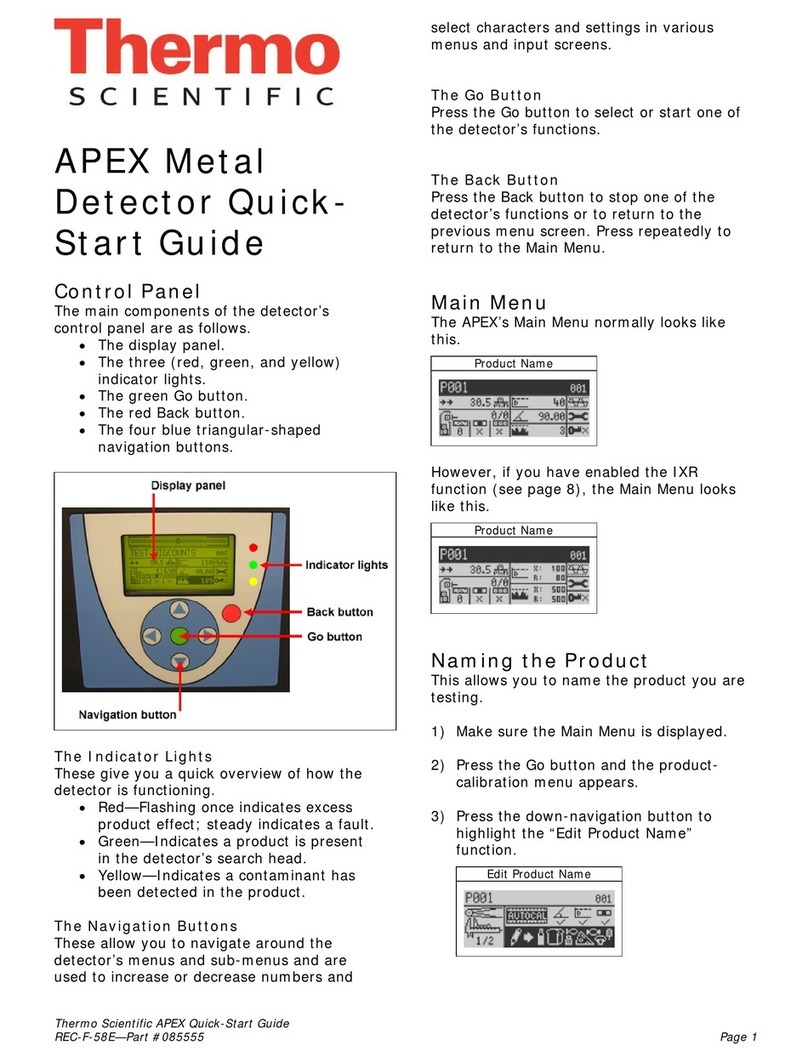

Thermo Scientific APEX 500 Rx User manual

Other Thermo Scientific Metal Detector manuals

Thermo Scientific

Thermo Scientific Apex User manual

Thermo Scientific

Thermo Scientific Oretronic III Instruction and safety manual

Thermo Scientific

Thermo Scientific Apex User manual

Thermo Scientific

Thermo Scientific APEX 100 User manual

Thermo Scientific

Thermo Scientific DSP2 Owner's manual

Thermo Scientific

Thermo Scientific Ramsey Oretronic IV User manual

Popular Metal Detector manuals by other brands

Steinberg Systems

Steinberg Systems SBS-MD-12 user manual

GOLDEN MASK

GOLDEN MASK 5 user guide

Grizzly

Grizzly YM 203 manual

Fisher Research Labs

Fisher Research Labs 1280-X Aquanaut operating manual

Treasure Cove

Treasure Cove Vibra-Probe 560 quick guide

Accurate Locators

Accurate Locators XL16 IMAGER user guide