5

System B – solar system with 1 collector (roof) sensor, 2 tank sensors and gas

booster

IP 20

T4A

100 ... 240 V~

50-60 Hz

Temp. Sensor Pt1000

S1 S2 S3 S4 NR2R1VBus

1234 56789101213141516 17 18 19 20

NNL

R1 1 (1) A 100 ... 240 V~

R2 1 (1) A 100 ... 240 V~

Sensors and actuators required:

S1 Collector (roof) sensor

S2 Tank sensor, bottom, height of coil

S3 Tank sensor, top, height of gas booster coil / inlet

R1 Solar pump / auxiliary relay in case of big pumps

R2 Gas booster pump /

auxiliary relay for potential-free contact activation of gas booster

Additional sensor:

S4 Additional temperature monitoring, e. g. solar return piping

5. System Layout

Adjustment range: 1 … 3

Factory setting: 1

ÎChoose Arr 2

5. Maximum tank temperature

Adjustment range: 4 … 95

Factory setting: 60 °C

ÎChange to suit your needs.

Loading will stop when this temperature is

reached at tank sensor (S2).

Factory setting is 60 °C [140 °F] to avoid

scald risk or system damage.

6. Minimum pump speed

Adjustment range: 30 … 100%

Factory setting: 30 °C

ÎChange to suit your needs.

Change to 100 %, if pump speed control is

forbidden or not necessary (e. g. auxiliary

relay connected to solar pump (R1).

In order to complete the commissioning

menu, press button 3.

Further adjustments can be carried out in

the adjustmen menu.

Press and hold button 1 for approx. 3 s to

enter the adjustment menu.Use Button 1 to

scroll to the parameter you wish to adjust.

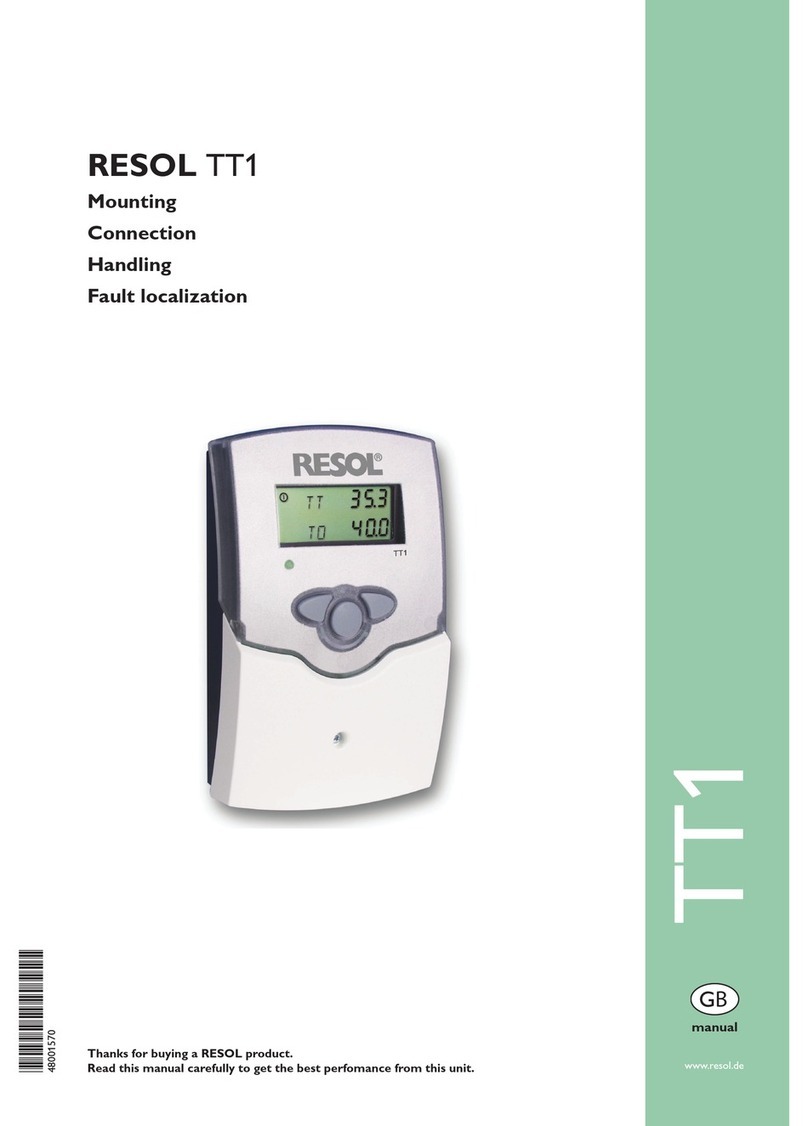

7.AfterHeating (backup heating)

Adjustment range 0.0 … 95.0 °C

[30.0 … 200.0 °F]

Factory setting 40.0 °C

ÎChange to suit your needs.

Arr 2