Thermo Ramsey Micro-Tech 3000 Series User manual

Serial Communications Manual

Ramsey

Micro-Tech3000

Model 3104

Loss in Weight Controller

Serial Comm-

3104 Rev

Part No.: XXXXX

Ramsey

Micro-Tech

3000

Serial Communications

Model 3104

Loss in Weight Controller

This document is confidential and is the property of Thermo Electron. It may not be

copied or reproduced in any way without the express written consent of Thermo

Electron. This document also is an unpublished work of Thermo Electron. Thermo

Electron intends to, and is maintaining the work as confidential information. Thermo

Electron also may seek to protect this work as an unpublished copyright. In the event

of either inadvertent or deliberate publication, Thermo Electron intends to enforce its

rights to this work under the copyright laws as a published work. Those having

access to this work may not copy, use, or disclose the information in this work unless

expressly authorized by Thermo Electron.

All registered and unregistered trademarks are the property of their respective

owners.

Thermo Electron,

501 90th Avenue N.W.

Minneapolis, MN 55433 U.S.A.

Tel (763) 783-2500

Fax (763) 783-2525

http://www.thermoelectron.com

eng@thermoelectron.com

2003 Thermo Electron

Revision History

Preliminary December 2003 Manual first released

Serial Communications 3104

REC XXXXX i

Table of Contents

Table of Contents ......................................................................................................................i

List of Figures ..........................................................................................................................iii

List of Tables ...........................................................................................................................iv

Chapter 1 Introduction ..................................................................................................... 1-1

1.1 General................................................................................................................... 1-1

1.2 Communication Protocols...................................................................................... 1-1

1.2.1 Protocol Rules ................................................................................................ 1-2

1.3 Printer..................................................................................................................... 1-3

1.4 Thermo Electron Warranty..................................................................................... 1-3

Disclaimer.......................................................................................................................... 1-4

Chapter 2 Installation....................................................................................................... 2-1

2.1 General................................................................................................................... 2-1

2.2 Comm A Board (Option) Installation...................................................................... 2-1

2.3 Communication Configuration (Mother Board) COMM1 ....................................... 2-6

Chapter 3 Operation ........................................................................................................ 3-1

3.1 General................................................................................................................... 3-1

3.2 Printer Scroll........................................................................................................... 3-1

3.3 Print Formats.......................................................................................................... 3-1

3.3.1 Totals .............................................................................................................. 3-2

3.3.2 Batch ............................................................................................................... 3-2

3.3.3 Alarms ............................................................................................................. 3-3

3.3.4 Audit Trails ...................................................................................................... 3-3

3.4 Communication Set-Up.......................................................................................... 3-3

3.4.1 Clock/Calendar Set-Up................................................................................... 3-4

3.4.2 COMM A and Print Scroll Set-Up ................................................................... 3-5

3.4.3 Multidrop Operator Set-Up ............................................................................. 3-7

3.4.4 Printer Set-Up ................................................................................................. 3-8

3.4.5 Define Printing Format.................................................................................. 3-10

3.5 Communication Protocols.................................................................................... 3-14

3.5.1 Registers Definition....................................................................................... 3-15

3.5.2 Type, Limits and Format of Register ............................................................ 3-16

3.5.3 Decription of Register ...................................................................................3-17

3.6 PC-Master Protocol.............................................................................................. 3-25

3.6.1 Description .................................................................................................... 3-25

3.7 Siemens 3964R.................................................................................................... 3-28

3.7.1 Write Register ............................................................................................... 3-28

3.7.2 Read Register ............................................................................................... 3-29

3.8 Modbus................................................................................................................. 3-30

3.8.1 Read Register ............................................................................................... 3-30

3.9 Allen Bradley DF1 (PLC-5) .................................................................................. 3-32

Serial Communications 3104

REC XXXXXii

3.9.1 Read Registers ............................................................................................. 3-32

3.9.2 Write Registers ............................................................................................. 3-33

3.10 Register Mapping ............................................................................................. 3-35

Chapter 4 Maintenance ................................................................................................... 4-1

4.1 General................................................................................................................... 4-1

Chapter 5 Parts................................................................................................................ 5-1

5.1 General................................................................................................................... 5-1

Serial Communications 3104

REC XXXXX iii

List of Figures

Figure 2-1 COMM A Board 2-2

Figure 2-2 Micro-Tech 3000 Mother Board 2-3

Figure 2-3 Serial Connection RS232 2-4

Figure 2-4 Serial Connection RS485 2-5

Figure 2-5 Mother Board Area of Detail 2-8

Serial Communications 3104

REC XXXXXiv

List of Tables

Table 2-1: COMM A Board Jumpers 2-1

Table 2-2: Mother Board COMM1 Communications Wiring Config. TB3–RS485 2-6

Table 2-3: Mother Board Wiring Configuration TB3-RS232 Communications 2-6

Table 2-4: Mother Board Wiring Configuration TB3-20mA Serial Communications 2-7

Table 2-5: Mother Board Communication Jumper Setting 2-7

Serial Communications 3104

REC XXXXX 1-1

Chapter 1 Introduction

1.1 General

The Micro-Tech 3104 is a bus-based microprocessor instrument equipped with one

COMM A (on Mother Board) that can be equipped (optionally) with a second serial

communication boards. Each COMM A board has one serial channel that can be

configured according to the following standards.

!RS423/RS232C For point to point asynchronous bidirectional

communications, maximum 50 feet (15 m). Modem

capability.

!RS485/RS422 For point to point or multidrop 4 wire bidirectional

communications, maximum 4000 feet (1200 m).

!Current Loop For high immunity bidirectional asynchronous

communications. Passive only.

All of the above are optically isolated.

COMM A board (Optionally) can be installed in any available mother board expansion

slot. After installing the board and power has been restored, the instrument

automatically detects the new board and adds the communication set-up scrolls to

the Main Menu scrolls. The Micro-Tech refers to the COMM A on the Mother Board

as COM 1, and the COMM A board (if installed) as COM 2.

If two COMM A are availables; one can be set up for printing, the other one for

transferring data to and from other intelligent devices such as computers and PLC's.

The system cannot support two printers or two COMM lines.

Each COMM A contains a perpetual clock/calendar circuit with battery backup. The

battery is located on the mother board and is the same battery used for system

memory backup. The system automatically detects and uses the clock calendar

circuit of the first board and ignores the second.

Time and date set-up screens become visible after the COMM board is installed.

The Micro-Tech 3000 Integrator COMM meets the year 2000 requirements.

1.2 Communication Protocols

When a COMM line is set up for communication (not for a printer), the system is able

to send and receive data to and from another device connected to the COMM line.

The COMM option comes with the following software communication protocols

already built in:

- PC-Master A Thermo Ramsey proprietary protocol, multidrop.

- Modbus An AEG proprietary protocol, multidrop. The COMM option only

contains a subset of the protocol as specified in this manual.

- Allen-Bradley A proprietary protocol, multidrop. The COMM option only contains

a subset of the protocol in the PLC-5 version of it, as specified in

this manual.

- 3964R A Siemens proprietary protocol, single point.

Serial Communications 3104

REC XXXXX1-2

The hardware can be configured (through jumpers on the Mother Board and on the

optinally COMM board if available) to one of the three standards as listed in the

previous paragraph. However, only the RS485/RS422 standard allows multidrop

communications, RS232C and Current Loop can only be used in point to point mode.

This does not prevent the use of a protocol; it only prevents physically connecting the

Micro-Tech 3000 to more than one device.

CAUTION

The communication protocols have been implemented and tested as

described in this document or in other referenced documents. It is

the intention of Thermo Ramsey to provide all the necessary

information and help the user to connect the instrument to other

compatible devices. However, because most of the protocols are

specific to other manufacturers, Thermo Ramsey declines any

responsibility for any malfunction that may occur when connecting

the instrument to devices of other manufacturers, unless tested and

approved by Thermo Ramsey.

1.2.1 Protocol Rules

The communication protocol allows a remote intelligent device to read and

eventually write information from and to the Micro-Tech 3104. For

convenience, the information is organized in a set of registers as listed in this

document.

During the communication activity, the Micro-Tech 3104 always acts as Slave,

meaning it responds to a request from a Master device on the line, but never

attempts to send messages out.

The following rules apply:

a. The Micro-Tech 3104 responds only if the message is completely

received.

b. The Micro-Tech 3104 reads the message and looks for the address,

which is contained into an address byte in the query package. The

message is then processed only if the address matches the one specified

in the set-up data of the Micro-Tech 3104, otherwise it is ignored.

c. When the system receives a message, the integrity of the message is

checked. An answer-back message is prepared if the message is

formally correct.

d. When a message containing a variable to be written in memory is

received, the system checks the correctness of the message and, if it is

correct, immediately sends the answer-back message. This does not

always mean the data is written in memory. The system first checks the

register number (which must correspond to a valid address of a variable),

then the minimum and maximum limits, and then the password. If data

can be accepted, it is stored in memory and the success flag is set to 0

(no error). If not, it is set to 1. To know if the last variables sent have

been stored, the Master checks (reads) the success flag contained in a

read only register.

The following procedure applies:

- The Host sends data to the Micro-Tech 3104.

Serial Communications 3104

REC XXXXX 1-3

- The Host waits at least 100 ms.

- The Host reads the success flag. It should be 0.

Some data is read only, some is read write, and some is write only.

WARNING

In all cases, the maximum number of words the system can transfer

is limited to 41 per time. Requests of registers in excess of 41 are

considered errors and do not generate an answer.

1.3 Printer

When a COMM line is set up for printing, the system prints out data in different ways,

depending on the set-up. Print menus become visible that allow the user to define

when and in which format the data is printed.

1. Periodical printouts at predefined intervals, as well as at predefined times of

day, or on command is possible.

2. The format of the printouts is selectable between a number of predefined

formats, plus a fully programmable user defined format. In this particular case,

the user is able to easily format the printout to fit into any pre-printed ticket or

form, without the need of special software.

1.4 Thermo Electron Warranty

The seller agrees, represents, and warrants that the equipment delivered

hereunder shall be free from defects in material and workmanship. Such

warranty shall not apply to accessories, parts, or material purchased by the

seller unless they are manufactured pursuant to seller's design, but shall apply

to the workmanship incorporated in the installation of such items in the complete

equipment. To the extent purchased parts or accessories are covered by the

manufacturer's warranty, seller shall extend such warranty to buyer.

Seller's obligation under said warranty is conditioned upon the return of the

defective equipment, transportation charges prepaid, to the seller's factory in

Minneapolis, Minnesota, and the submission of reasonable proof to seller prior

to return of the equipment that the defect is due to a matter embraced within

seller's warranty hereunder. Any such defect in material and workmanship shall

be presented to seller as soon as such alleged errors or defects are discovered

by purchaser and seller is given opportunity to investigate and correct alleged

errors or defects and in all cases, buyer must have notified seller thereof within

one (1) year after delivery, or one (1) year after installation if the installation was

accomplished by the seller.

Said warranty shall not apply if the equipment shall not have been operated and

maintained in accordance with seller's written instructions applicable to such

equipment, or if such equipment shall have been repaired or altered or modified

without seller's approval; provided, however, that the foregoing limitation of

warranty insofar as it relates to repairs, alterations, or modifications, shall not be

applicable to routine preventive and corrective maintenance which normally

occur in the operation of the equipment.

Serial Communications 3104

REC XXXXX1-4

“EXCEPT FOR THOSE WARRANTIES SPECIFICALLY CONTAINED HEREIN,

SELLER DISCLAIMS ANY AND ALL WARRANTIES WITH RESPECT TO THE

EQUIPMENT DELIVERED HEREUNDER, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE. THE SOLE

LIABILITY OF SELLER ARISING OUT OF THE WARRANTY CONTAINED

HEREIN SHALL BE EXCLUSIVELY LIMITED TO BREACH OF THOSE

WARRANTIES. THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF

THE WARRANTIES SET OUT ABOVE SHALL BE LIMITED TO THE REPAIR

OR REPLACEMENT OF ANY DEFECTIVE ACCESSORY, PART OR

MATERIAL WITH A SIMILAR ITEM FREE FROM DEFECT, AND THE

CORRECTION OF ANY DEFECT IN WORKMANSHIP. IN NO EVENT SHALL

SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES.”

Purchaser agrees to underwrite the cost of any labor required for replacement;

including time, travel, and living expenses of Thermo Electron Field Service

Engineer at closest factory base.

THERMO ELECTRON

501 90TH AVE. NW

MINNEAPOLIS, MN 55433

PHONE: (763) 783-2500

FAX: (763) 783-2525

Disclaimer

Though the information provided herein is believed to be accurate, be advised

that the information contained herein is not a guarantee for satisfactory results.

Specifically, this information is neither a warranty nor guarantee, expressed or

implied, regarding performance, merchantability, fitness, or any other matter

with respect to the products, and recommendation for use of the product/process

information in conflict with any patent. Please note that Thermo Electron

reserves the right to change and/or improve the product design and

specifications without notice.

Serial Communications 3104

REC XXXXX 2-1

Chapter 2

Installation

2.1 General

This chapter describes the installation procedure and hardware configuration for the

communications (on Mother Board and on Comm A Board option). If the

communication option was installed at the factory, it may not be necessary to

continue with this chapter. Proceed to Chapter 3.0, Operation.

2.2 Comm A Board (Option) Installation

To install the COMM A board, proceed as follows:

1. Select the jumper positions on the COMM A board for the desired

communication standard. Below is a table which summarizes the jumper

positions for selection of the electrical interface. Refer to Figure 2-1 for jumper

locations.

TABLE 2-1

COMM A BOARD JUMPERS

JUMPERS

Mode

OP1

OP2

OP3

OP4

OP5

OP6

RS-232

"A"

"A"

"A"

"A"

"A"

"B"

RS-485

"B"

"A"

"B"

"B"

"MDP"

"TRM"

[Default)

20 mA

"B"

"B"

"A"

"A"

"A"

"C"

TABLE "MDP" TABLE "TRM"

FOR RS-485 ONLY FOR RS-485 ONLY

OP5 OP6

"A" NORMAL "A" TERMINATED

"B" MULTIDROP "B" NOT TERMINATED

2. Open the Micro-Tech wall mount enclosure and turn power off at the mains,

or remove panel mount enclosure from the panel and remove top cover

allowing access to the mother board.

3. Remove the field mating connector. Wire the connector per the supplied

field wiring diagram or install field terminal board cable (wall mount only).

4. Remove the hex head mounting screw from the connector end of the COMM

board.

5. Insert the COMM board in any available expansion slot on the mother board

(see Figure 2-2).

Serial Communications 3104

REC XXXXX2-2

Figure 2-1 COMM A Board

Serial Communications 3104

REC XXXXX 2-3

-SLOT # N CHANGED

Acquire new

configuration?

YES NO

Figure 2-2 Micro-Tech 3000 Mother Board

EXPANSION

SLOT

6. Insert the hex head screw through the chassis and tighten.

7. Install the wired mating connector on the COMM board connector.

8. Reinstall panel mount enclosure in the panel.

9. Turn power back on. The following screen appears when power is applied

and remains on for 10 seconds.

The screen disappears after 10 seconds if the question is not answered, and

the Micro-Tech 3104 assumes the answer is NO. "HW CONFIG. CHANGED"

alarm is on and cannot be reset. The above screen appears each time power

is cycled if the question is not answered.

Answer YES because this is a hardware configuration change.

10. This completes the installation procedure.

11. Set-up data for the newly installed COMM board must now be

entered. Proceed to Chapter 3.0, Operation.

Serial Communications 3104

REC XXXXX2-4

Figure 2-3 Serial Connection RS232

Serial Communications 3104

REC XXXXX 2-5

Figure 2-4 Serial Connection RS485

Serial Communications 3104

REC XXXXX2-6

2.3 Communication Configuration (Mother Board) COMM1

This section describes the setup procedure and hardware configuration for the

communications from the motherboard. Use the following steps to configure

the communications:

Select the jumper positions for the desired communication standard. Refer to

Table 2-5 for jumper locations.

Wire to the Terminal Block 3 on the motherboard for the communication

standard selected, RS-485, RS-232c, 20 mA current loop.

Table 2-2: Mother Board COMM 1 Communications Wiring Configuration - TB3 – RS-485

Motherboard

RS-485 Communications

TB 3

25 Shield

29 -RX

28 +Rx

24 Common

21 +TX

20 -TX

Maximum cable length 4000 ft

Use Beldon 9830 or equivalent

Table 2-3: Mother Board Wiring Configuration TB 3 – RS-232 Communications

Motherboard

RS-232 Communications

TB 3

25 Shield

23 CTS

24 Common

22 RxD

21 TxD

20 RTS

Maximum cable length 50 ft

Use Beldon 9538 or equivalent

Serial Communications 3104

REC XXXXX 2-7

Table 2-4: Mother Board Wiring Configuration TB 3 – 20mA Serial Communications

Motherboard

20 mA Serial

Communications

TB 3

25 Shield

26 +20 mA (out)

27 -20 mA (out)

28 +20 mA (in)

24 -20 mA (in)

Maximum cable length 4000 ft

Use Beldon 9829 or equivalent

Table 2-5: Mother Board Communication Jumper Settings

JUMPERS

Mode OP1 OP2 OP3 OP10 OP13 OP11

RS-485 “A” “A” “A” “A” “A” Normal

”B” Multi-drop

“A” Terminated

‘B” Not Terminated

Default

RS-232 “B” “B” “B” “A” “A” Normal “B” Not Terminated

”A” Terminated

Default

20 mA “A” “A” “A” “B” “A” “C”

Serial Communications 3104

REC XXXXX2-8

Figure 2-5: Mother Board Area of Detail

.

This manual suits for next models

1

Table of contents

Other Thermo Controllers manuals

Popular Controllers manuals by other brands

HP

HP HSG80 - StorageWorks RAID Array Controller Maintenance and service guide

Mitsubishi Electric

Mitsubishi Electric M800VS Series Connection and set up manual

Compac

Compac DCA Installation & service manual

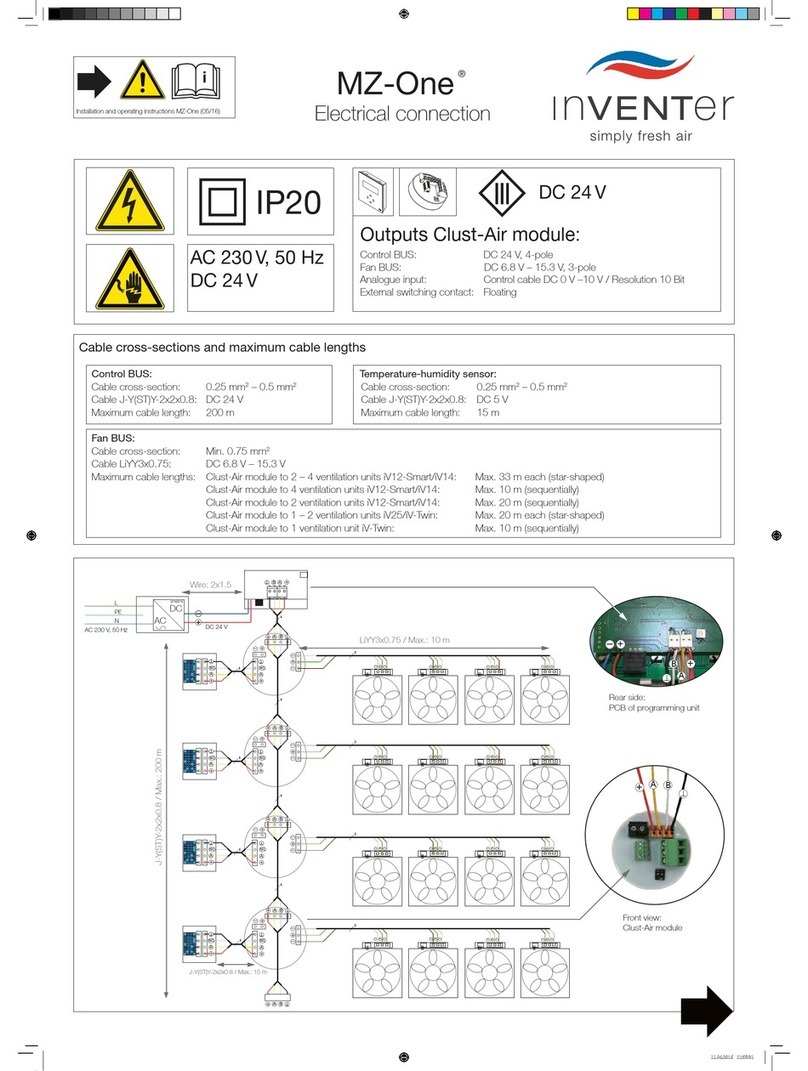

inVENTer

inVENTer MZ-One manual

Toro

Toro VISION II Series owner's manual

AWELCO

AWELCO THOR 45 user manual