Thermoheat RMC-FA60/L Manual

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 877-447-4768 8:30 a.m. – 4:30 pm CST, Monday – Friday

www.ghpgroupinc.com

USER’S MANUAL AND OPERATING INSTRUCTIONS

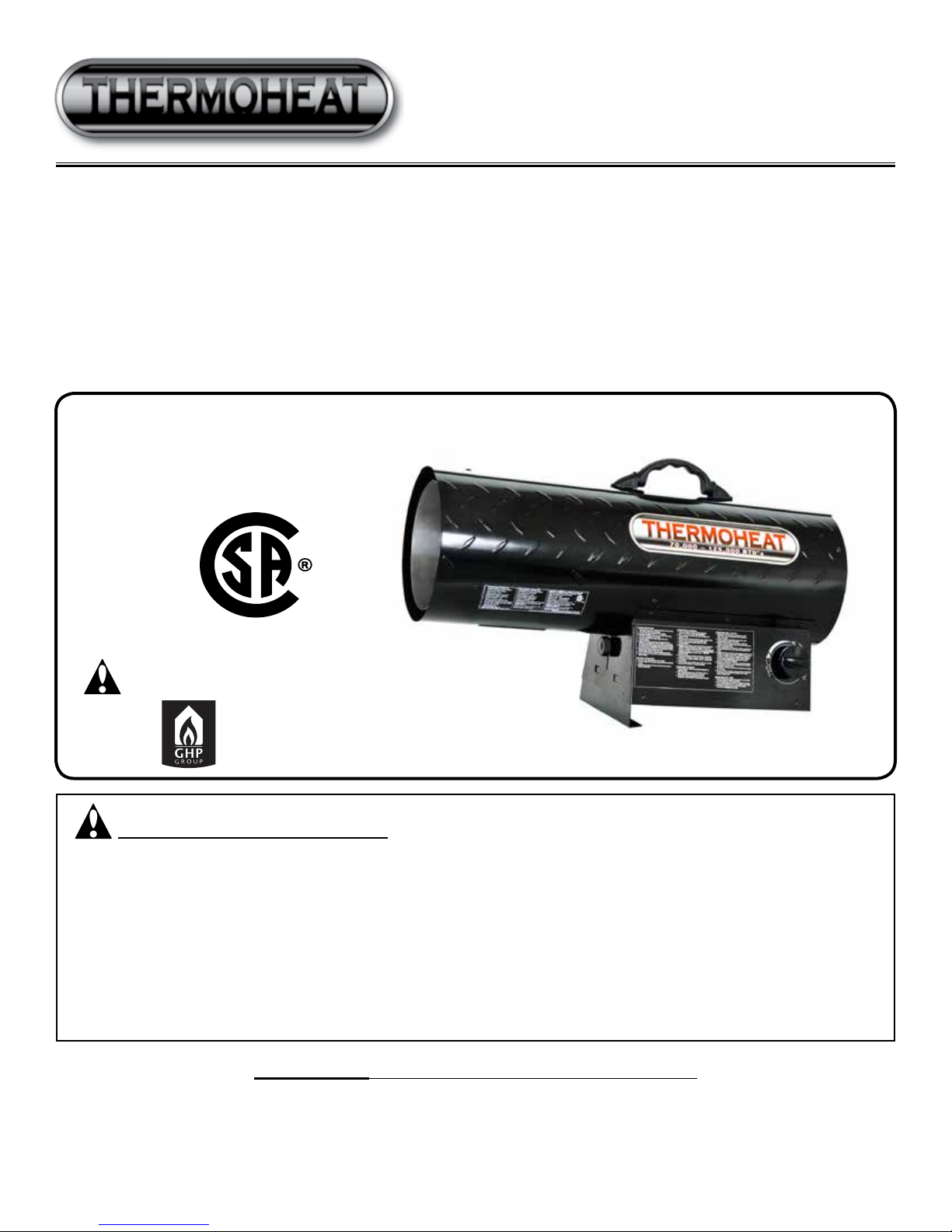

PROPANE

CONSTRUCTION HEATER

GENERAL HAZARD WARNING

FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS PROVIDED WITH

THIS HEATER, CAN RESULT IN DEATH, SERIOUS BODILY INJURY AND PROPERTY LOSS,

OR DAMAGE FROM THE HAZARDS OF FIRE, EXPLOSION, BURN. ASPHYXIATION, CARBON

MONOXIDE POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW THE INSTRUCTIONS SHOULD

USE OR SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION SUCH AS AN INSTRUCTION

MANUAL, LABELS, ETCETERA, CONTACT THE MANUFACTURER.

CONSUMER: Retain this manual for future reference.

50-10-166 Printed in China Rev. 2013-03-26

RMC-FA60/L/L-01 (30,000/60,000 BTU/HR, FORCED - AIR)

LPFA125/L/L-01 (70,000/125,000 BTU/HR, FORCED - AIR)

THERMOHEAT

MODELS:

C US

GHP Group, Inc.

6440 W Howard St

Niles, IL 60714-3302

ANS Z83.7-2011 CSA 2.14-2011

Adequate ventilation must be provided.

Introduction & Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

• General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

• Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

• Unpacking Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Size & Capacity Of Propane Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

• Installation To The Propane Gas Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

• Relling The Propane Gas Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

• Leak Checking & Positioning Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

• Lighting & Shutdown Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

• Test Firing Heater & Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

• Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

• Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PROPANE CONSTRUCTION HEATER ILLUSTRATED / PARTS BREAKDOWN :

RMC-FA60 Series/LPFA125 Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

• Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

• Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TABLE OF CONTENTS

2

PROPANE CONSTRUCTION HEATER

WARNING: NOT FOR HOME OR RECREATIONAL VEHICLE USE.

WARNING

: FIRE, BURN, INHALATION, AND EXPLOSION HAZARD, KEEP SOLID

COMBUSTIBLES, SUCH AS BUILDING MATERIALS, PAPER OR CARDBOARD, A SAFE

DISTANCE AWAY FROM THE HEATER AS RECOMMENDED BY THE INSTRUCTIONS.

NEVER USE THE HEATER IN SPACES WHICH DO OR MAY CONTAIN VOLATILE OR

AIRBORNE COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE, SOLVENTS, PAINT

THINNERS, DUST PARTICLES OR UNKNOWN CHEMICALS.

CALIFORNIA PROPOSITION 65: Fuels used in gas or oil red appliances and the products of

combustion of such fuels, contain chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm. This product contains chemicals, including lead and lead

compounds, known to the State of California to cause cancer, birth defects or other reproductive

harm. Wash hands after handling.

WARNING

: Using this heater in a residential garage requires that the heater is positioned

so that it is protected against any possible damage by a moving vehicle, etc. It must be

positioned so that the base of the heater is no less than 18 in (450 mm) above the garage oor or

8 ft (2450 mm) in repair garages. The heater must be placed on a stable surface. Do not place it on

a chair, ladder, etc. Raising the heater will reduce BUT NOT eliminate the possibility of lighting the

vapor of any ammable liquids which may be improperly stored or accidentally spilled. If the smell of

gasoline is present, DO NOT operate this heater until the area has been properly ventilated.

WARNING: CONSTRUCTION HEATERS ARE NOT FOR USE IN

GARAGES IN CANADA.

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

The heater is designed and approved for use as a construction heater under ANS Z83.7 CSA 2.14. It is hard

to anticipate every use which may be made of this heater. CHECK WITH YOUR LOCAL FIRE SAFETY

AUTHORITY IF YOU HAVE QUESTIONS ABOUT APPLICATIONS.

DYNA-GLO PROPANE FORCED AIR CONSTRUCTION HEATERS

This is a direct-red forced air construction heater for either indoor construction or outdoor use. Its intended

use is primarily the temporary heating of buildings or structures under construction, alteration or repair. All the

products of combustion generated by the heater are forced through the heater and released into the area being

heated. This heater operates at approximately 98%+ combustion efciency but still produces a small amount

of carbon monoxide. Humans can tolerate small amounts of carbon monoxide for short periods. Carbon

monoxide can build up in a heated space and failure to provide adequate ventilation could result in poisoning

or death.

34

Other standards govern the use of fuel gases and heat producing products in specic applications.

Your local authority can advise you about these.

IMPORTANT: READ THIS USER’S MANUAL CAREFULLY AND COMPLETELY BEFORE TRYING

TO OPERATE OR SERVICE THIS HEATER. IMPROPER USE OF THIS HEATER CAN CAUSE

SERIOUS INJURY OR DEATH FROM FIRE, EXPLOSION AND CARBON MONOXIDE POISONING.

WARNING

: NOT FOR USE WITH DUCT WORK.

FA60Series LPFA125Series

30,000BTU/hr

60,000BTU/hr

70,000BTU/hr

125,000BTU/hr

Propane Propane

CylinderPressure CylinderPressure

5psig 5psig

11"W.C 11"W.C

1.4lbs/hr

2.8lbs/hr

3.3lbs/hr

5.8lbs/hr

120V,60Hz,1Ø 120V,60Hz,1Ø

Amperage Load 0.65amps 0.7amps

Fan

Unload

Load

3570rpm

3300rpm

3580rpm

3300rpm

ConInuousSpark ConInuousSpark

0.16"(4mm) 0.16"(4mm)

19.3"x8.3"x15.2"

(490x211x386)mm

25.59''x11.81''x16.64''

(650x300x410)mm

14.3lbs(6.48kg)

20.72lbs

(9.4kg)

Weight

ModelNo.

InputRaBng

TypeofGas

GasSupplyPressureto

RegulatorMaximum

Minimum(forpurpose

ofInputAdjustment)

ManifoldPressure

GasConsumpBon

ElectricalInput

IgniBon

SparkGap

Size(LxWxH)

SPECIFICATIONS

PROPANE CONSTRUCTION HEATER

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

Accidents are always tragic especially because so many of them could have been prevented with little care

and judgment. There are some basic good practices, we hope you will follow for safe use of your heater.

• Children should be carefully supervised, when they are in the area.

• Always maintain proper clearance from combustible materials. Minimum clearance from combustibles:

Side - 24” (61cm); Top - 36” (91cm); Front - 72” (1.8M). Floor - combustible. Not for use on nished oors.

• Heater must be placed on level and stable surface.

• Never place anything including clothes or other ammable items on the heater.

• The appliance area shall be kept clear and free from combustible materials, gasoline and other

ammable vapours and liquids.

• Do not modify or operate a heater which has been modied.

• Adequate clearance for accessibility and for combustion & ventilation air supply must be maintained

at all times when the heater is operating.

• Service and repair should be done by a qualied service person. The heater should be inspected

before each use and at least annually by a qualied person. More frequent cleaning may be required

as necessary. Do not service while hot or operating.

• Never connect heater to an unregulated gas supply.

• The heater is shipped from the factory for LP(Propane) gas. This heater is for use with propane gas only,

do not convert heater to any other gas. Installation must conform to local codes or, in the absence of local

codes, with the standard for the Storage and Handling of Liqueed Petroleum Gases ANSI/NFPA NFPA 58

and the Natural Gas and Propane Installation Code CSA B149.1

• The minimum and maximum inlet pressures to the regulator from the gas tank are 5 psi and bottle pressure,

respectively. Use only the regulator & hose assembly provided with the heater. Inspect the regulator/hose

assembly prior to each use of the heater. If there is excessive abrasion or wear, or hose is cut, replace with

regulator/hose assembly listed on the parts list prior to using this heater.

• Gas supply connections should be checked using a 50/50 solution of liquid dish soap and never use a ame

to check for gas leaks.

• The electrical connection & grounding must comply with National Electrical Code. ANSI/NFPA 70 or in

Canada CSA C22.1, Canadian Electrical Code, Part 1. Use only a properly grounded three

(3) prong receptacle.

• Do not restrict inlet or outlet by any means. The ow of combustion and ventilation air is not to be obstructed.

• This heater should not be directed toward any propane-gas container within 20 ft (6M). The heater must be

located at least 6 ft. (1.83 m) in the U.S.; or (ii) 10 ft. (3 m) in Canada, from any propane gas container.

• The propane cylinder supply system must be arranged to provide for vapour withdrawal from the

operating cylinder.

• This heater is not to be used with external thermostats, timers or other devices that control or alter electrical

supply to the heater.

34

PRODUCT FEATURES

• Portable & Stable • 100% Safety Shutoff System

• Wind Resistant & Rain Protected • Continuous Adjustable Input Ratings

• Continuous Spark Ignition

GENERAL SAFETY INSTRUCTION

IMPORTANT SAFETY INSTRUCTION

WARNING

: Motor and fan must be running before lighting, during operation and at shutdown,

in order to prevent a ame-out condition which could result in personal injury or property damage.

PROPANE CONSTRUCTION HEATER

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

PROPANE CONSTRUCTION HEATER

56

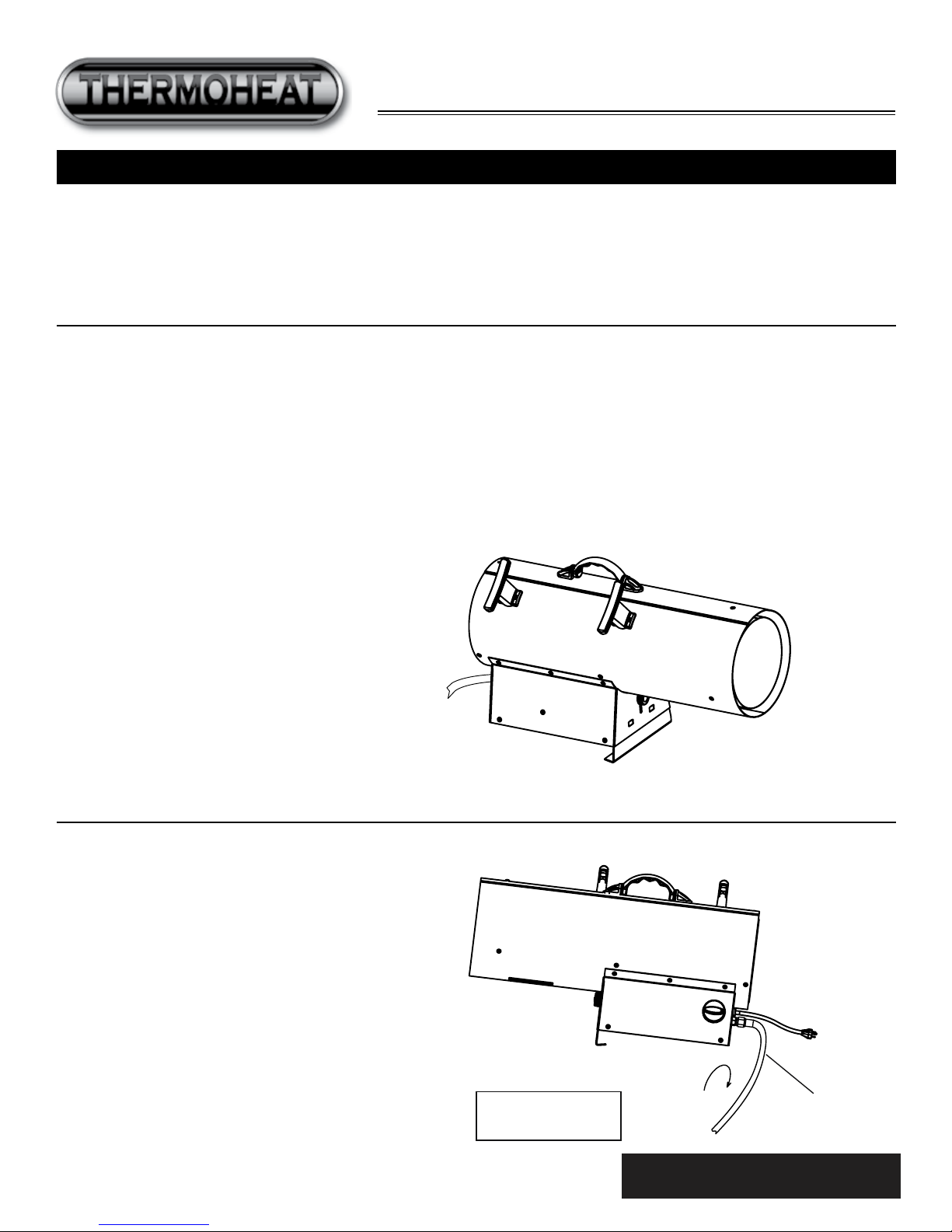

UNPACKING HEATER

1. Remove heater from carton.

2. Remove all protective packing applied to heater for shipment.

3. Retain cartons and packaging material until unit is operated and found in good condition.

4. Check heater for any shipping damage. If heater shows any external or internal

damage, promptly inform dealer/distributor where you purchased heater.

Assembly Components and Instructions:

1. Assembling the Cord Wrap Attachments:

(LPFA125 Series Only)

Parts Required:

4 Screws (ST3.5x10),

and 2 Cord Wrap Attachments

Place the cord wrap attachment

as shown, then use Phillips

screwdriver to tighten the

screws and secure the

cord wrap attachments.

2. Regulator and Hose Connection:

(All Models)

See gure on right.

Connect the hose tightly to

the heater using a wrench.

Please also refer to

page 8 in the manual.

Tighten, clockwise,

use a wrench

Hose Assembly

Assembly Time:

5 Minutes

Contents:

All Models: Unit, Manual, Hose and Regulator

Assembly

LPFA125 Series Includes:

2 Cord Wrap Attachments, 4 Screws (ST3.5x10)

Tools required for assembly:

All Models: Adjustable Wrench

LPFA125 Series: Phillips Head

Screw Driver

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

PROPANE CONSTRUCTION HEATER

56

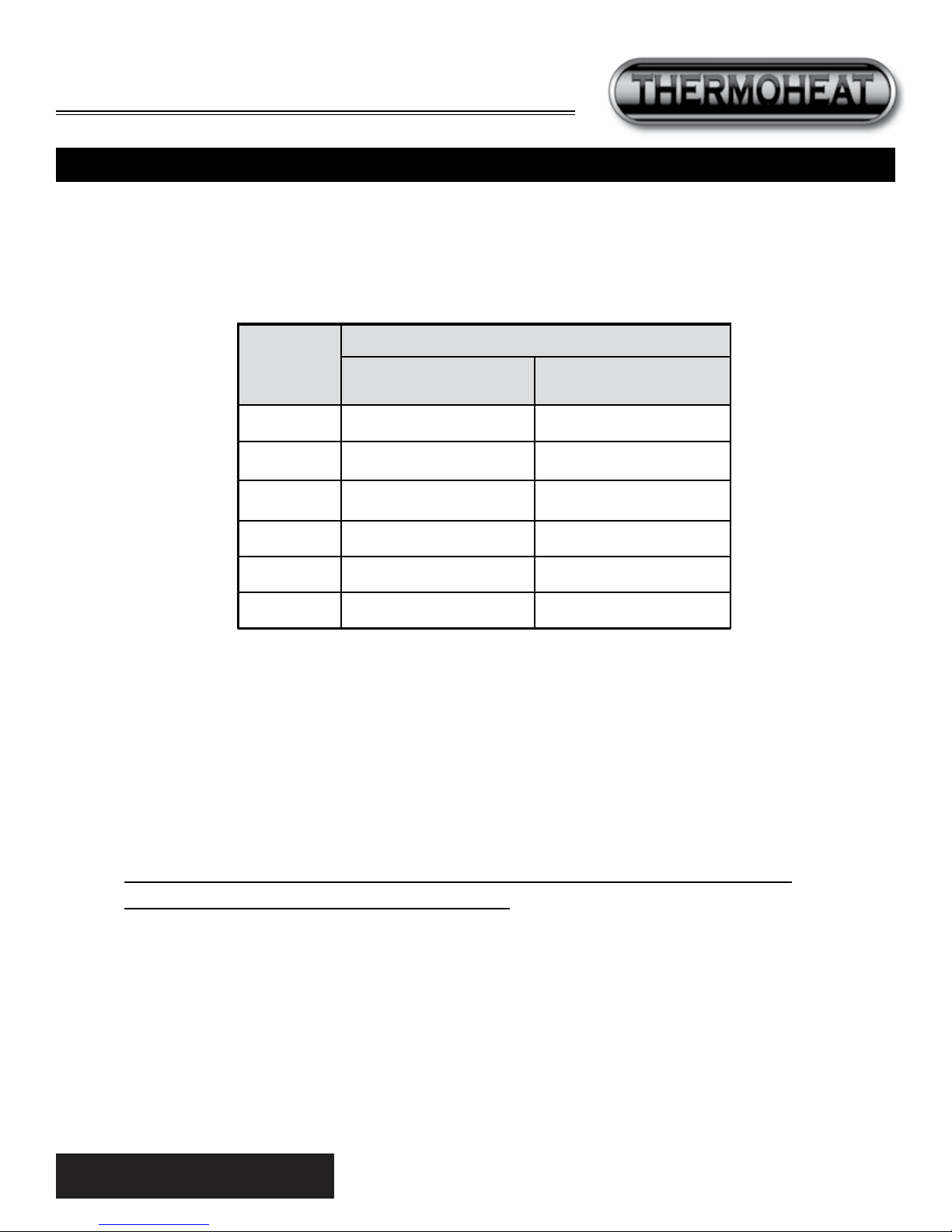

INFORMATION ON SIZE * CAPACITY OF PROPANE GAS CYLINDERS:

The chart below shows the number and size of propane tanks needed to run this heater.

*Less gas is vaporized at lower temperatures.

You may need two or more 100 pound tanks or one larger tank in colder weather.

(See the parts list for your model of heater to get the specied regulator assembly.)

The propane (LP) gas tank must also be equipped with the following:

• A collar to protect the Propane gas valve.

• A shutoff valve terminating a Propane gas cylinder valve outlet as specied in the

American National Standards for Compressed Gas Cylinder Valve Outlets and Inlet

Connections.

• A safety relief valve having direct communications with the vapor space of the tank.

• An arrangement of vapor withdrawal.

The propane (LP) gas pressure regulator and hose assembly supplied with

this heater must be used without alteration.

The hose assembly shall be visually inspected prior to each use of the heater. If it is evident

that there is excessive abrasion or wear, or the hose is cut, it must be replaced prior to the

heater being put into operation. The replacement hose assembly shall be that specied

by the manufacturer.

Number of Tanks

Temperature

(°F) At tank 50,000-60,000 BTU/h 100,000 -

125,000 BTU/h

1 - 20lb 2 - 100lb

1 - 20lb 2 - 100lb

1 - 20lb 2 - 100lb

1 - 20lb 3 - 100lb

2 - 20lb Use Larger Tank

1 - 100lb Use Larger Tank

Above 32°F

32°F

20°F

10°F

-10°F

-20°F

Assembly Time:

5 Minutes

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

INSTALLATION TO THE PROPANE GAS TANK

IMPORTANT: You must use a propane/LP gas supply cylinder that is compatible with the connection device

provided with the hose and regulator.

REFILLING THE PROPANE GAS TANK

ALL NEW CYLINDERS MUST BE PURGED BEFORE THE FIRST FILLING.

• Turn heater gas valve knob and gas tank valve to OFF position.

• Propane tank valve equipped with the old style tting has LEFT HANDED THREADS. Turn POL tting

CLOCKWISE to loosen. Protect POL tting when disconnected from tank.

• Have tank lled by your local Propane gas supplier.

• Fasten full Propane tank and connect POL tting to tank valve by turning COUNTERCLOCKWISE.

• With heater gas valve knob still in the OFF position, turn ON tank valve and check for leaks

with soap solution.

WARNING

: Purging and lling of LP gas tanks must be performed by personnel who

has been thoroughly trained in accepted LP gas industry procedures. Failure to follow

these instructions may result in explosion, re, severe personal injury, or death.

1. Provide propane/LP supply system. Ensure that the valve on the cylinder is fully closed by turning the knob

fully clockwise ( ). Ensure that the cylinder is fully upright for vapor withdrawl. (see size/capacity, page 6).

2. Connect hose to heater inlet. Tighten rmly using a wrench. You must use the regulator supplied with heater.

3. Connect fuel gas tting hose/regulator assembly to propane LP tank(s) (see gure 1). Turn fuel tting

counterclockwise into threads on tank. Tighten rmly using a wrench. Some models have a hand wheel

that can be used to tighten the tting. This hand wheel can be slid off of the nut so that a wrench can also be

used to tighten the tting. IMPORTANT: Position regulator so that hose leaving the regulator is in a

horizontal position.

4. Open propane/LP supply valve on propane/LP tank(s) slowly. NOTE: If not opened slowly, excess ow

device in regulator may stop gas ow. If this happens, close propane/LP supply valve, wait one minute

(or until you hear a click) and open again slowly.

5. Check all connections for leaks. Apply a 50/50 solution of liquid dish soap and water to gas joints.

Bubbles forming show a leak that must be corrected.

6. Close propane / LP supply valve before attempting to repair connection.

Propane/LP

Supply Valve

Propane/LP

Tank

Regulator

Fuel Gas

Fitting

Connector Inlet

Hose to Regulator

Hose Fitting

FIGURE 1

FIGURE 2

Hose to

Heater

PROPANE CONSTRUCTION HEATER

78

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

ALL NEW CYLINDERS MUST BE PURGED BEFORE THE FIRST FILLING.

• Turn heater gas valve knob and gas tank valve to OFF position.

• Propane tank valve equipped with the old style tting has LEFT HANDED THREADS. Turn POL tting

CLOCKWISE to loosen. Protect POL tting when disconnected from tank.

• Have tank lled by your local Propane gas supplier.

• Fasten full Propane tank and connect POL tting to tank valve by turning COUNTERCLOCKWISE.

• With heater gas valve knob still in the OFF position, turn ON tank valve and check for leaks

with soap solution.

PROPANE CONSTRUCTION HEATER

78

PROPANE SAFETY

Propane is safe to use when properly handled. Careless handling of the Propane gas tank could

result in re and/or an explosion. Therefore:

• Always keep tank/cylinder securely fastened in an upright position.

• Avoid tipping tank on its side when connected to a regulator since this may cause damage to

diaphragm in regulator.

• Handle valves with care.

• Never connect an unregulated Propane tank to construction heater.

• Do not subject Propane tank to excessive heat.

• Tightly close the gas shutoff valve on the Propane tank after each use.

• The POL tting must be protected when disconnected from the propane tank.

• Never store a Propane gas tank inside a building or in the vicinity of any gas burning appliance.

THE DISCONNECTED TANK MUST NEVER BE STORED IN A BUILDING, GARAGE

OR ANY OTHER ENCLOSED AREA.

LEAK CHECKING

Check all gas connections with a soap solution to be sure they are tight and leak proof.

• The installation of your heater must meet all local codes and/or gas utility requirements or, in the

absence of local codes, with the Storage and Handling of Liqueed Petroleum Gases, ANSI/ NFPA

58 and the Natural and Propane Installation Code, CSA B149.1.

• The minimum clearances to combustible construction: Side - 24” (61cm); Top - 36” (91cm);

Front - 72” (1.8M); Floor - combustible, must be maintained at all times.

• The hose assembly should be visually inspected prior to each use of the heater. If it is evident that

there is excessive abrasion or wear, or the hose is cut, it must be replaced prior to the heater being

put into operation.

• The replacement hose assembly shall be that specied by the manufacturer (Refer to parts list).

LIGHTING INSTRUCTIONS

WARNING

: Motor and fan must be running before lighting, during operation and shutdown,

in order to prevent a ame-out condition which could result in personal injury or property damage.

NOTE: This heater uses a continuous spark ignition system. This unit will continue to make a clicking/

ticking sound at all times before ignition, after ignition and during operation, regardless of valve knob

positioning.

1. Connect power cord to a properly grounded three (3) prong 120V, 60Hz, single phase receptacle.

2. Turn gas valve knob clockwise to OFF position.

3. Wait ve (5) minutes to clear any gas. Then smell for gas, if you don’t smell gas, go to next step.

4. Turn gas supply ON by turning Propane tank valve counterclockwise .

5. Push in and turn gas control knob counterclockwise to “LOW/IGN”. This will light the burner. If

needed, keep pressing control knob until the burner lights and keep depressing and turning from

OFF to LOW/IGN.

6. Keep the valve knob depressed for at least 30 seconds after lighting the burner. After 30 seconds

release valve knob.

7. If burner does not stay lit, repeat the lighting procedure.

8. When burner is lit, turn gas valve knob counterclockwise to desired setting.

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

PROPANE CONSTRUCTION HEATER

SHUTDOWN INSTRUCTIONS

TEST FIRING HEATER

Test re your construction heater, following the lighting instructions applicable to the gas control sys-

tem employed. Leak test all gas connections with soap solution. Soap bubbles indicate gas leakage.

DO NOT use a match or ame to test for gas leaks.

STORAGE

Never store a Propane gas tank inside a building or in the vicinity of any gas or oil burning appliance.

When the Propane tank is not disconnected from the construction heater, the gas tank and heater

must be stored outdoors in a well ventilated area, out of the reach of children. If for any reason the

heater is to be stored indoors, the tank must be disconnected and stored outdoors in a well ventilated

area out of reach of children, in accordance with the standard for the the Storage and Handling of

Liqueed Petroleum Gases, ANSI / NFPA 58 and CSA B149.1, Natural Gas and Propane Installation

Code. The plastic tank valve plug supplied with your tank must be tightly installed when the tank is

disconnected from the heater.

MAINTENANCE INSTRUCTIONS

1. Turn unit off, allow heater to fully cool and disconnect propane hose before performing any Mainte-

nance

functions. Unplug the unit from the 120V receptacle.

2. Keep unit clean and keep the inside of the torpedo housing debris free.

3. Have unit checked by a qualied technician at least once a year, preferably prior to the heating

season.

WARNING

: Motor and fan must be running before lighting, during operation and at shutdown,

in order to prevent a ame-out condition which could result in personal injury or property damage.

Turn gas valve knob clockwise to OFF position.

Turn gas supply OFF by turning Propane tank valve fully clockwise to close.

Disconnect the power cord once the heater has cooled to ambient temperature.

REPLACEMENT PARTS

Warning: Use only original replacement

parts. This Heater must use design-specic

parts. Do not substitute or use generic parts.

Improper replacement parts could cause

serious or fatal injuries.

This will also protect your warranty coverage

for parts replaced under warranty.

Parts warranty and non-warranty: Contact au-

thorized dealers of this product. If they can not

supply original replacement part(s), either con-

tact your nearest Parts Central or GHP Group

Inc., Technical Service Department at 1-877-

447-4768.

When calling GHP Group Inc., have ready:

• your name

• your address

• how heater was malfunctioning

• serial number of heater

• model number of heater

• replacement part number

910

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

PROPANE CONSTRUCTION HEATER PROPANE CONSTRUCTION HEATER

Always be sure to follow proper maintenance procedures, by cleaning the heater once per

month during regular usage, and check spark gap at least once per season.

TROUBLESHOOTING:

PROBLEM POSSIBLECAUSE CORRECTIVEACTION

TROUBLESHOOTING

910

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

11 12

WIRING DIAGRAMS

*

*100K,125K & 150K Models only

*100K,125K & 150KSólo modelos

*100K,125K & 150K Les modèles Seulement

*

*

PROPANE CONSTRUCTION HEATER

*LPFA125 Series Models Only

*LPFA 125 Series Sólo Modelos

*LPFA125 Séries Les modéles Seulement

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

11 12

PROPANE CONSTRUCTION HEATER

REPLACEMENT PARTS LIST

MODELS: RMC-FA60 Series/LPFA125 Series

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

FA40THROUGHFA150STEELBASEUNITS

QTY FA60SERIES LPFA125SERIES

1 INNERSHELLASS'Y 1 2304818 2304929

2 NOZZLE 1 2325121 5030077*

3 FLAMEHOLDERCAP 1 2325120 2325122

4 THERMALSWITCHBRKT. 1 2304826 2315515

5 THERMALSWITCH 1 2201599 2201373

6 NOZZLENUT 1 2304578 2304945

7 SPARKPLUGASSY 1 2206033 2206034

8 THERMOCOUPLEASSY(1130/1474425L) 1 2304885 2304885

9 GASTUBINGASS'Y 1 2304830 2325138

10 OUTERSHELLORANGE 1 2305403 2325360

11 CORDWRAP 2N/A 2101423

12 HANDLEASSYBLACK 1 2101447 2101447

12.1 SCREWHANDLEFRONT 1 2001355 2001355

12.2 SCREWHANDLEFRONT 1 2001077 2001077

12.3 NUTHANDLEREAR 1 2000384 2000384

13 MOTORSUPPORT 1 2304823 2304823

13.1 BOLTMOTORMOUNTING 2 2001332 2001332

13.2 SLEEVE 1 2304949 2304949

14 MOTORASS'Y 1 2304547 2304548

14.1 MOTORFAN 1 2304821 2304936

15 GUARDFANBLACK 1 2304828 2304939

16 MOTORBRKT 1 2304937 2304938

17 VALVEGAS 1 5051233 5051235

18 PRESSURESWITCH 1 N/A 2305976

19 VALVEBRKT 1 2304624 2304624

20 BASEASSYBLACK 1 2304923 2304924

21 POWERCORDASS'Y 1 2101670 2101673

22 GASCONNECTORINLET 1 2304831 2304831

23 CAPACITOR 1 2201372 2301390

24 BASELOWERBLACK 1 2304925 2304926

25 KNOBGASVALVEBLACK 1 2101451 2101451

26 HEIGHTCONTROLLERBLACK 1 2304927 2304928

27 HEIGHTCONTROLSCREWBLACK 1 2304510 2304510

28 LEADWIREASSY 1 2201371 2201371

29 SPARKMODULE 1 2201391 2201391

30 PCBASSEMBLY 1 2201369 2201369

31 REG&HOSEASSY10FT(3M) 1 5002614 5055549

REG&HOSEASSY10FT(3M)w/HANDWHEEL 1 5055533 5055551

REG&HOSEASSY15FT(4.6M) 1 5055298 5055550

REG&HOSEASSY15FT(4.6M)w/HANDWHEEL 1 5055415 5055552

USETHISCHARTWITHTHEEXPLODEDVIEWOFTHEFA125AONPAGE200FTHEMANUALCHRISTYSENTMEYESTERDAY.

ITEM

No.

DESCRIPTION

PARTNUMBER

*Notshowninexplodedview.

13 14

REPLACEMENT PARTS LIST

PROPANE CONSTRUCTION HEATER

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

LIMITED WARRANTY:

This limited warranty is extended to the original retail purchaser of this Forced Air/Convection/Radiant Heater and warrants against any

defect in materials and workmanship for a period of one (1) year from the date of retail sale. GHP Group, Inc., at it’s option, will either

provide replacement parts or replace or repair the unit, when properly returned to the retailer where purchased or one of our service centers

as directed by GHP Group, Inc., within one (1) year of retail purchase. (Shipping costs, labour costs, etc. are the responsibility of the purchaser.)

DUTIES OF THE OWNER:

This heating appliance must be operated in accordance with the written instructions furnished with this heater. This warranty shall not excuse

the owner from properly maintaining this heater in accordance with the written instructions furnished with this heater. A bill of sale, canceled

check or payment record must be kept to verify purchase date and establish warranty period. Original carton should be kept in case of warranty

return of unit.

WHAT IS NOT COVERED:

1. Damage resulting from use of improper fuel.

2. Damage caused by misuse or use contrary to the owners manual and safety guidelines.

3. Damage caused by a lack of normal maintenance.

4. Fuses

5. Use of non-standard parts or accessories.

6. Damage caused in transit. Freight charges on warranty parts or heaters to and from the factory shall be the responsibility of the owner.

This warranty does not imply or assume any responsibility for consequential damages that may result from the use, misuse, or the lack of

routine maintenance of this heating appliance. A cleaning fee and the cost of parts may be charged for appliance failures resulting from lack of

maintenance. This warranty does not cover claims which do not involve defective workmanship or materials. FAILURE TO PERFORM

GENERAL MAINTENANCE (INCLUDING CLEANING) WILL VOID THIS WARRANTY.

THIS LIMITED WARRANTY IS GIVEN TO THE PURCHASER IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE. THE

REMEDY PROVIDED IN THIS WARRANTY IS EXCLUSIVE AND IS GRANTED IN LIEU OF ALL OTHER REMEDIES. IN NO EVENT WILL

GHP GROUP, INC. BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. Some states do not

allow the exclusion or limitation of incidental or consequential damages so the above limitation or exclusion may not apply to you.

CLAIMS HANDLED AS FOLLOWS:

1. Contact your retailer and explain the problem.

2. If the retailer is unable to resolve the problem, contact our Customer Service Dept. detailing the heater model, the problem, and proof

of date of purchase.

3. A representative will contact you. DO NOT RETURN THE HEATER TO GHP GROUP,INC. unless instructed by our Representative.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

TO REGISTER THE WARRANTY ON YOUR HEATER, PLEASE FILL OUT THIS CARD COMPLETELY

AND MAIL WITHIN 14 DAYS FROM DATE OF PURCHASE OR REGISTER ON-LINE AT www.ghpgroupinc.com

NAME: ______________________________________ PHONE: ( ) __________________ EMAIL: ____________________________

ADDRESS: _________________________________ CITY: ______________________________ STATE: __________ ZIP: ____________

MODEL: ____________________ SERIAL #: _______________________________________ DATE PURCHASED: __________________

DEALER PURCHASED FROM: ____________________________________________ TYPE OF STORE: __________________________

CITY & STATE WHERE PURCHASED: ______________________________________________ PRICE PAID: _______________________

Please Take a Minute To Give Us Your Answers To The Following Questions.

All Responses Are Used Solely For Market Research And Are Held In Strict Confidence.

Who primarily decided this purchase? Male Female 18-24 25-39 40-59 60 and over

Purpose of Purchase? _______________________________________________________________________________________________

Do you own any other portable heaters? Yes No If yes, type____________________________brand_____________________

How do you intend to use your new heater? Construction Site Farm Warehouse/Commercial Garage/Outbuilding Other

How did you become aware of this heater? In-Store Display Newspaper Ad Magazine Ad Friend/Relative

TV Commercial Store Salesperson Other ___________________________

What made you select this heater? Style Size/Portability Price Package Brand Other ___________________

Do you: own rent Would you recommend this heater to a friend? Yes No

Please give us your comments:________________________________________________________________________________________

THANK YOU FOR COMPLETING THIS FORM!

Information will be held confidential.

WARRANTY

13 14

WARRANTY REGISTRATION

IMPORTANT: We urge you to fill out your warranty registration card within fourteen (14)

days of date of purchase. You can also register your warranty on the internet at

www.ghpgroupinc.com. Complete the entire serial number. Retain this portion of the card

for your records.

SAVE THIS CARD!

Place

Postage

Stamp

Here

GHP Group, Inc.

8280 Austin Avenue

Morton Grove, IL 60053-3207

GHP Group, Inc.

8280 Austin Ave.

Morton Grove, IL 60053-3207

Tel: (877) 447-4768

www.ghpgroupinc.com

8280 Austin Avenue

Mo rton Gr ove, IL.

6 0 053-3207

Tel: ( 847 ) 324 - 5900

Fax: ( 847 ) 324 - 5901

Toll Free (877) GHP Group

( 8 7 7 ) 44 7 - 4 7 6 8

www.ghpgroupinc.com

GHP

GHP Group, Inc.

6440 W Howard St

Niles, IL 60714-3302

Tel: (877) 447-4768

www.ghpgroupinc.com

GHP Group, Inc.

6440 W Howard St

Niles, IL 60714-3302

This manual suits for next models

3

Table of contents

Other Thermoheat Heater manuals