PAGE 4 Reznor, FSE, Installation Manual, EN 2020-02, D301160 Iss H

General

This manual is an integral part of the

heater, therefore it should always be

carefully kept and it should always be

provided together with the heater, if it is

transferred to another owner or user. If

this manual is damaged or lost, a new one

should be requested from the installer or

from the manufacturer. After unpacking

the product, please check the contents to

ensure all components are present. If not,

please contact your supplier.

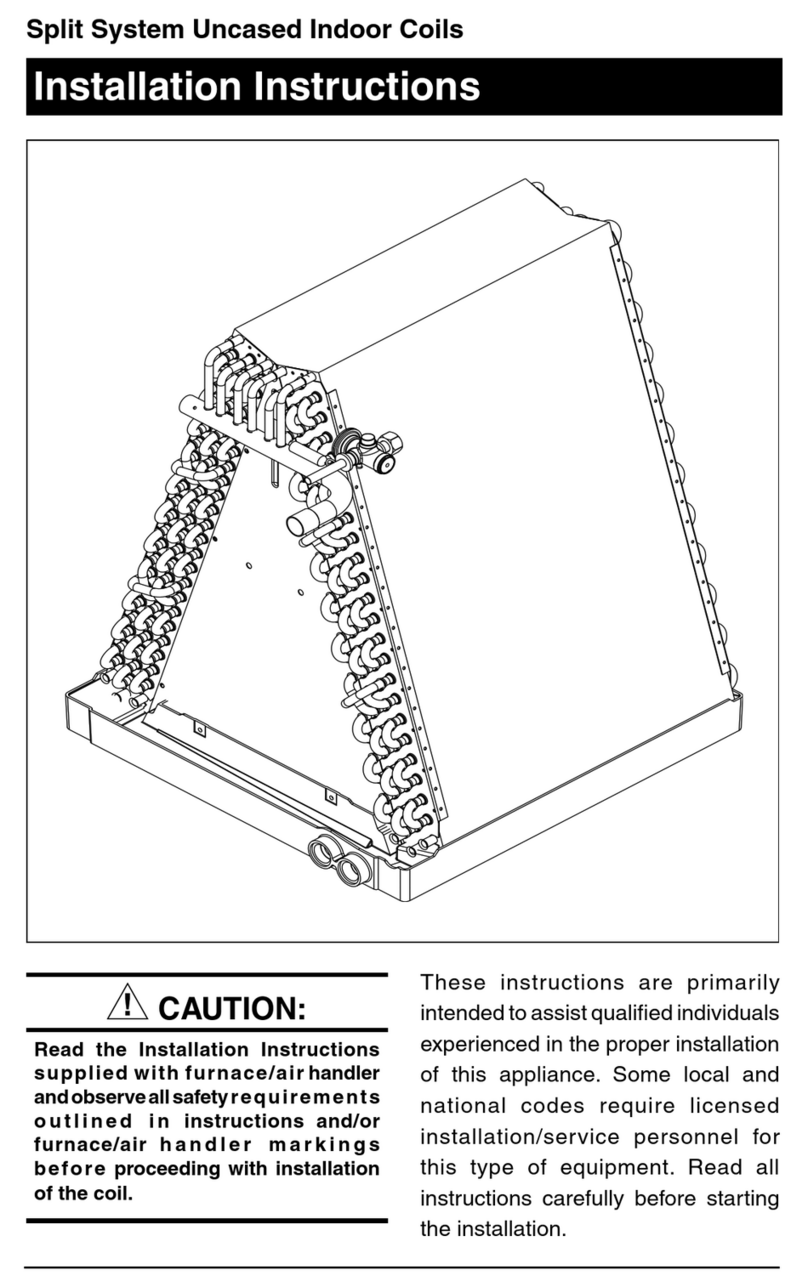

The installation must be carried out by

suitably qualified personnel who, at the end

of the work, will commission the appliance

and issue to the owner a copy of the

commissioning report, which also confirms

that the installation has been carried out in

accordance with regulations & standards

applicable to the country of use and

in accordance with the manufacturers

instructions.

This appliance has been manufactured

specifically for room heating and must be

used for this purpose. Contractual liability

of the manufacturer in respect of damages

caused to people, animal or premises by

incorrect installation, settings, maintenance

or by improper use of the heater is

excluded.

During the initial start-up, there may be

the formation of odours and fumes due

to the evaporation of the oil added to

protect the heat exchanger during storage;

this is normal and will disappear after a

short period. It is recommended to ensure

suitably ventilation for room.

WARNING

If the appliance is to remain

unused for long periods, it is

recommended that the following

operations are carried out:

• Turn the appliances’ electrical supply off

via the local isolator.

• Close the main fuel supply valve

If there is a long period of time between

operation, it is recommended that you

contact your installer to carry out the new

start-up.

The heater shall be fitted with approved

accessories only. The manufacturer is

not liable for damages arising from the

improper use of the heater or from the use

of non-original materials or accessories.

References to Laws, Regulations, Directives

and Technical Rules mentioned in this

manual are provided only for information

purposes and are in force when the manual

is printed.

The introduction of new provisions

or amendments to current laws does

not represent an obligation of the

manufacturer towards third parties. Repairs

or maintenance are to be performed by

trained personnel only.

Do not modify or tamper with the

appliance, the manufacturer will not

be held responsible for any third party

modifications to the heater.

The services that are to be connected (fuel

pipes, power supply, etc.) must be suitably

secured and must not be hazardous with

the risk of tripping.

The manufacturer is responsible for the

product compliance with Laws, Directives

or Construction Rules in force when the

product is marketed. The knowledge and

observance of the laws and standards

regarding plant design, installation,

operation and maintenance are the sole

responsibility of the designer, installer and

user. The manufacturer shall not be held

responsible for failure to comply with

the instructions of this manual, for the

GENERAL