Thermokon DPA+ Dual User manual

DPA+ Dual | DPA+ LCD Dual RS485 Modbus

Differential Pressure Transmitter

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 fax: -400 www.thermokon.com· email@thermokon.com

DPA+_(LCD)_Dual_RS485_Modbus_Datasheet_en-us © 2023

Datasheet

Subject to technical alteration

Issue date: 20.02.2023 • A123

The following illustrations show the version with LCD

»APPLICATION

Differential pressure and volume flow transducer for monitoring differential pressure and volume flow of air and other non-flammable and non-

aggressive gases. LCD models with RGB background light have a transparent cover. Display configuration, k-values for flow calculation (default

1500) and threshold values for color changes can be parameterized via Thermokon USEapp. The option with input for a potential-free contact or

an NTC10k allow a variety of applications. The mounting base (included in delivery) allows mounting on a level surface or mounting on DIN rail

TS35 (35x7,5 mm) according to EN 60715.

»TYPES AVAILABLE

Differential pressure and volume flow transducer optional with display – RS485 Modbus

•DPAx+ Dual RS485 Modbus MultiRange <AZ>

•DPAx+ LCD Dual RS485 Modbus MultiRange <AZ>

Differential pressure and volume flow transducer optional with display and 2 digital inputs – RS485 Modbus

•DPAx+ Dual RS485 Modbus MultiRange <AZ> 2IN

•DPAx+ LCD Dual RS485 Modbus MultiRange <AZ> 2IN

x: 250 | 2500 | 7000

MultiRange: Measuring ranges adjustable at the transducer

<AZ>: automatic zero-point adjustment (optional)

»PRODUCT TESTING AND CERTIFICATION

Declaration of conformity

The declaration of conformity of the products are available on our website https://www.thermokon.de/ .

»NOTES ON DISPOSAL

As a component of a large-scale fixed installation, Thermokon products are intended to be used permanently as part of a building or a

structure at a pre-defined and dedicated location, hence the Waste Electrical and Electronic Act (WEEE) is not applicable. However,

most of the products may contain valuable materials that should be recycled and not disposed of as domestic waste. Please note the

relevant regulations for local disposal.

Page 2 / 7 Issue date: 20.02.2023

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 fax: -400 www.thermokon.com· email@thermokon.com

DPA+_(LCD)_Dual_RS485_Modbus_Datasheet_en-us © 2023

»SECURITY ADVICE – CAUTION

The installation and assembly of electrical equipment should only be performed by authorized personnel.

The product should only be used for the intended application. Unauthorised modifications are prohibited! The product must not

be

used in relation with any equipment that in case of a f

ailure may threaten, directly or indirectly, human health or life or result in

danger to human beings, animals or assets. Ensure all power is disconnected before installing. Do not connect to live/operati

ng

equipment.

Please comply with

•Local laws, health & safety regulations, technical standards and regulations

•Condition of the device at the time of installation, to ensure safe installation

•

This data sheet and installation manual

Before installation, commissioning and operation, make sure that the correct pressure gauge has been selected with regard to measuring range,

design and, based on the specific measuring conditions, the suitable medium in contact with the medium. Pressure gauges may only be installed

and serviced by trained specialist personnel authorized by the plant operator. Failure to observe the relevant regulations may result in serious

physical injury and/or damage to property.

»TECHNICAL DATA

Measuring values differential pressure, volume flow

Medium air or other non-flammable/non-aggressive gases

Output voltage 0..10 V or 0..5 V, min. load 10 kΩ

(live-zero configuration via Thermokon USEapp)

Network technology RS485 Modbus, RTU, half-duplex, baud rate 9.600, 19.200, 38.400 or 57600, parity: none (2 stopbits), even

or odd (1 stopbit), Fail-safe Biasing required

Power supply 15..35 V = or 19..29 V ~ SELV

Power consumption max. 2,3 W (24 V =) | max. 4,3 VA (24 V ~)

Measuring range velocity 0… 750.000 m³/h (default), optionally configured via Thermokon USEapp

Measuring range pressure

*selectable at the device

type 250

0..+1 | 0..+0.4 | 0..+0.2 | 0..+0.1 |

-0.1..+0.1 | -0.2..+0.2 | -0.4..+0.4

| -0.6..+0.6 inchWC

type 2500

0..+10 | 0..+8 | 0..+6 | 0..+4 | -0..+2

| 0..+1 | 0..+0.4 | -0.4..+0.4

inchWC

type 7000

0..+28 | 0..+20 | 0..+16 | 0..+12 |

0..+10 | 0..+8 | 0..+6 | 0..+4

inchWC

Accuracy pressure

*deviation from calibration

reference device (calibrator)

at range

<1 inchWC: typ. ±0.004 inchWC

at range

≤2 inchWC: ±0.02 inchWC,

>2 inchWC: ±0.04 inchWC

at range

≤8 inchWC: ±0.04 inchWC,

>8 inchWC: ±0.10 inchWC

Zero-point adjustment

(manual)

3 month at range:

≤2 inchWC: 6 month

>2 inchWC: 12 month

12 month

Zero-point adjustment

(automatic)

automatic zero-point adjustment (optional)

Max. working overpressure 160 inchWC

Sensor piezo measuring element

Inputs

(optional)

2IN

2x input for NTC10k or floating contact

Display

(optional)

LCD 1.14x1.38 in. with RGB backlight,

units, pressure: Pa, inchWC, volume flow: m3/h, cfm (configurable)

Enclosure

(type-dependent)

without LCD

enclosure USE-L, PC, pure white, with removable

cable entry

with LCD

enclosure USE-L, PC, pure white, cover PC,

transparent, with removable cable entry

Protection IP65 according to EN 60529

Cable entry M25, for wire max. Ø=7 mm, seal insert for fourfold cable entry

Connection electrical Mainboard

removable plug-in terminal, max. 14AWG

Plug-in card

removable plug-in terminal, max. 16AWG

Connection mechanical pressure connection male Ø=0.2 in / Ø=0.25 in., connection tube: PVC, soft

Ambient condition +14..+122 °F, max. 85% rH short term condensation

Mounting screw mounted onto flat surface, prepared for mounting on DIN rail TS35 (35x7,5 mm) according to

EN 60715

Issue date: 20.02.2023 Page 3 / 7

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 fax: -400 www.thermokon.com· email@thermokon.com

DPA+_(LCD)_Dual_RS485_Modbus_Datasheet_en-us © 2023

»MOUNTING ADVICES

Before installing the device, please check the leak tightness of the pressure lines. A prerequisite for the operation is a proper installation of all

electrical supply, control and sensing leads as well as the pressurized connection line.

•In order to connect the device, the process lines must be unpressurized

•Consider the suitability of the device for the medium to be measured

•Consider maximum pressures

1.

Mount the DPA+ mounting base in a

suitable location and attach the DPA+.

Note alignment

!

screwed

Rail mounting

2.

Prepare the duct for mounting and

mount the

duct connection piece.

Attention! Observe dimensions!

3.

Connect pressure tubes to the device.

Attention

! Oserve labeling!

4.

Connect pressure tubes to the duct

connection pieces

Below

atmospheric

pressure

-

+

+

-

-

+

Over-

pressure Filter Fan

Page 4 / 7 Issue date: 20.02.2023

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 fax: -400 www.thermokon.com· email@thermokon.com

DPA+_(LCD)_Dual_RS485_Modbus_Datasheet_en-us © 2023

»CONNECTION PLAN

RS485 cable is looped through, connect both cable shields using the enclosed 2-pol. connect terminal as shown.

DPA+ (LCD) Dual RS485 Modbus MultiRange

DPA+ (LCD) RS485 Modbus 2IN

A+

B-

A+

B-

RS485 cable is looped through, connect both cable

shields using the enclosed 2-pol. Connect terminal as

shown.

◄A+

►A+

◄B-

►B-

►differential pressure 2 | 0..10 V

►differential pressure 1 | 0..10 V

◄GND

◄15..35 V / 19..29 V

S1

S2

RS485 cable is looped through, connect both cable

shields using the enclosed 2-pol. Connect terminal as

shown.

A+

B-

A+

B-

◄A+

►A+

◄B-

►B-

►differential pressure 2 | 0..10 V

►differential pressure 1 | 0..10 V

◄GND

◄15..35 V / 19..29 V

◄IN2

►IN2

◄IN1

►IN1

S1

S2

Issue date: 20.02.2023 Page 5 / 7

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 fax: -400 www.thermokon.com· email@thermokon.com

DPA+_(LCD)_Dual_RS485_Modbus_Datasheet_en-us © 2023

»DIP SWITCHES, MAINBOARD (S1+S2)

Measuring range adjustment – Typ 250 | 2500 | 7000

default

Response time

Output voltage

Unit

default

default

default

»DIP SWITCHES, PLUG-IN CARD

The modbus address of the device is set in the range of 1 ... 31 (binary encoded) using a 5-pole DIP switch. With address 0 via DIP, an extended

address range (32..247) is available via USEapp.

* factory default settings

Termination 120 Ω

Modbus adress

Not active*

active

ON=20(1)*

ON=21(2)

ON=22(4)

ON=23(8)

ON=24(16)

Baud

Sample adress: 26

9600*

19200

Parity

38400

57600

none*

(2-stopbits)

even

(1-stopbit)

odd

(1-stopbit)

none

(1-stopbit)

»CONFIGURATION

The Thermokon bluetooth dongle with micro-USB (Item No.: 668262) is required for communication

between USEapp and USE-M / USE L products. Commercial bluetooth dongles are not compatible.

Application-specific reconfiguration of the

devices can be carried out using the Thermokon USEapp. The

configuration is carried out in the voltage-supplied state.

The configuration-app and the app description can be found in the Google Play Store or in the Apple

App Store.

»APPLICATION NOTICE

The Bluetooth dongle snaps into the socket easily. When removing, please fix the plug-

in card (option PCB) so that it is not

unintentionally pulled out.

ON

1 32 4

5

S1 – Dip-switch 1 (pressure sensor 1)

S2

– Dip-switch 2 (pressure sensor 2)

Page 6 / 7 Issue date: 20.02.2023

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 fax: -400 www.thermokon.com· email@thermokon.com

DPA+_(LCD)_Dual_RS485_Modbus_Datasheet_en-us © 2023

»MODBUS KONFIGURATION

Modbus addresses:

USE-RS485 Modbus Interface

A detailed description of the Modbus addresses can be found under the following link: → Download

Register 400 = 1 (Unit SI) Register 400 = 2 (Unit Imperial)

Adress Access

Description Resolution / Unit Resolution / Unit

8 R / s16

Differential pressure 1

SI 1.0 Pa Imperial 0.001 inWC

9 R / u16

Volumetric flow 1 (16 Bit) (if register address

404 is set to the value 2, the value scales the

unit m³/s)

SI 100.0 m³/h

m³/s Imperial 10.0 cfm

10

R / s16

Differential pressure 2

SI

1.0

Pa

Imperial

0.001

inWC

11 R / u16

Volumetric flow 2 (16 Bit) (if register address

404 is set to the value 2, the value scales the

unit m³/s)

SI 100.0 m³/h

m³/s Imperial 10.0 cfm

50

Low

R / u32

Volumetric flow 1 (32 Bit) (if register address

404 is set to the value 2, the value scales the

unit m³/s)

This register is available since firmware V1.6

(see register 505)

SI 1.0 m³/h

m³/s Imperial 1.0 Cfm

51

High

52

Low

R / u32

Volumetric flow 2 (32 Bit) (if register address

404 is set to the value 2, the value scales the

unit m³/s)

This register is available since firmware V1.6

(see register 505)

SI 1.0 m³/h

m³/s Imperial 1.0 Cfm

53

High

Optional (IN1 | IN2)

NTC10k temperature sensors or floating contacts can be connected to the inputs (IN1 & IN2)

Adress Access

Description Values

92

R / s16

Input 1 – Binary signal

0

Contact open

93

R / s16

Input 2 – Binary signal

1

Contact closed

Register 400 = 1 (Unit SI)

Register 400 = 2 (Unit Imperial)

Adress Access Description Resolution / Unit Resolution / Unit

90 R / s16

Input 1 - Temperature NTC10k

(beta value configurable, register address 490,

default: 3864)

SI 0.1 °C Imperial 0.1 °F

91 R / s16

Input 2 - Temperature NTC10k

(beta value configurable, register address 491,

default: 3864)

SI 0.1 °C Imperial 0.1 °F

»FLOW CALCULATION: (DEFAULT PARAMETERS)

=2

with k=1500, fan manufacturer Rosenberg, Comefri, Nicotra Gebhardt, default measuring range 0..750.000 m³/h. Further

calculation formulas, fan manufacturers and k-values can be selected via the USEapp.

Rosenberg ∙Comefri ∙Gebhardt ∙Nicotra Ziehl-Abegg ∙EBM-Papst Fläkt Woods

»AUTOMATIC ZERO-POINT ADJUSTMENT - (OPTIONAL)

Transmitters equipped with the auto-zero adjustment are maintenance free.

The auto-zero adjustment electronically adjusts the transmitter to zero every 10 minutes. The function eliminates all output signal drift

due to thermal, electronic or mechanical effects. The auto-zero adjustment takes approx. 4 seconds after which the device returns to

its normal measuring mode. During the 4 second correction period, the output and display values will freeze to the latest measured

value.

=2

==

1

Issue date: 20.02.2023 Page 7 / 7

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 fax: -400 www.thermokon.com· email@thermokon.com

DPA+_(LCD)_Dual_RS485_Modbus_Datasheet_en-us © 2023

»MANUAL ZERO-POINT ADJUSTMENT (FOR DEVICES WITHOUT AUTO-ZERO FUNCTION)

In normal operation zero point adjustment should be executed depending on the device and

the measuring range.

Attention! For executing zero point adjustment the power supply must be connected

one hour before.

•Release both connection tubes from the pressure terminals + and -

•Press the button until the LED lights permanently

•Wait until the LED flashes again and reinstall the connection tubes to the pressure ports

(note + and -)

»DIMENSIONS (IN.)

»ACCESSORIES (INCLUDED IN DELIVERY)

Mounting base enclosure USE-L Item No. 668361

2x 2 m PVC connection tube Item No. 484268

2x KKS40 kit Item No. 430135

• 2 plastic duct flanges • 4 mounting screws 4x20

Mounting kit universal Item No. 698511

• Cover screw + screw cover• 2 Rawlplugs • 2 Screws (countersunk head) • 2 Screws (rounded head)

»ACCESSORIES (OPTIONAL)

Bluetooth dongle USE for USEapp Item No. 668262

Converter RS485 Modbus-USB incl. driver CD Item No. 668293

USB RS485 Modbus RTU Logger Item No. 809917

RS485 Biasing Adapter Item No. 811378

T-hose connector for pressure hoses Ø=0.16 in. (10 pcs) Item No. 668323

Adapter 90° angle for pressure hoses Ø=0.16 in. Item No. 668330

Metal duct connectors 1.6 in. Item No. 265138

This manual suits for next models

1

Table of contents

Popular Transmitter manuals by other brands

Labom

Labom PASCAL CS21 0 Series operating instructions

Altinex

Altinex Intera Video+Audio to Twisted Pair (UTP) Transmitter... user guide

R.V.R. Elettronica

R.V.R. Elettronica TEX3500LCD user manual

Mobility Sound

Mobility Sound PTT-220-VZ user guide

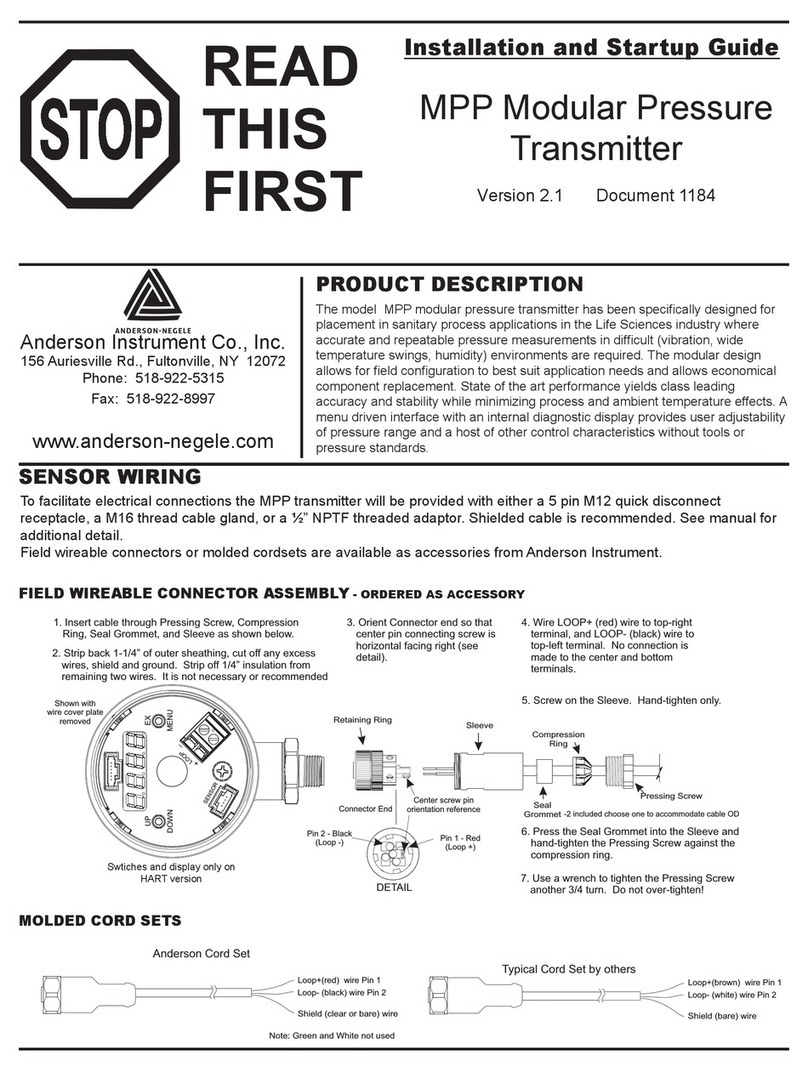

ANDERSON-NEGELE

ANDERSON-NEGELE MPP Installation and startup guide

Shure

Shure AD2 user guide

KROHNE

KROHNE OPTIWAVE X500 Supplementary instructions

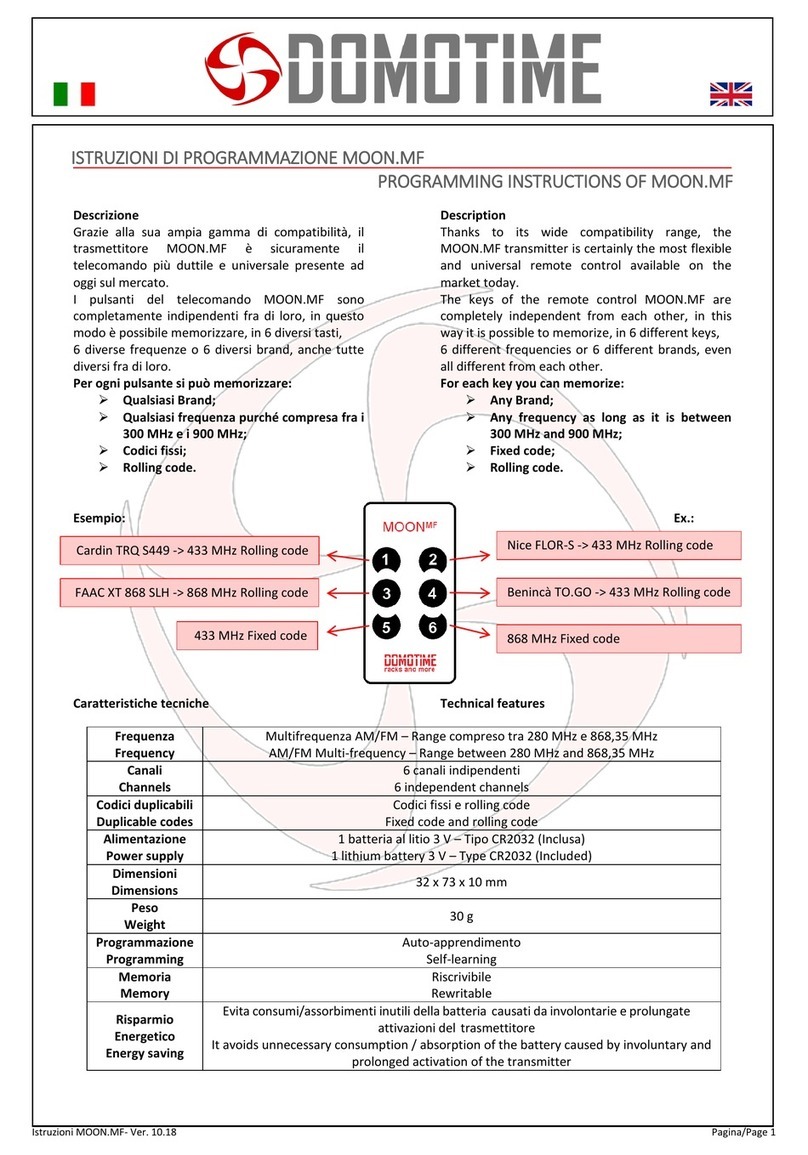

Domotime

Domotime MOON.MF Programming instructions

Technical Materiel Corporation

Technical Materiel Corporation GPT-10K Technical manual

CEBEK

CEBEK TL-6 quick start guide

Intelix

Intelix AvoCat AVO-V3HD-F installation manual

Labom

Labom PASCAL CS operating instructions