User guide

PRESSURE TRANSMITTER ST

NUOVA FIMA - Industrial instrumentation for Pressure and Temperature 3

The pressure transmitter turns the input pressure into an output electrical signal. The electrical signal changes

according to the input pressure level.

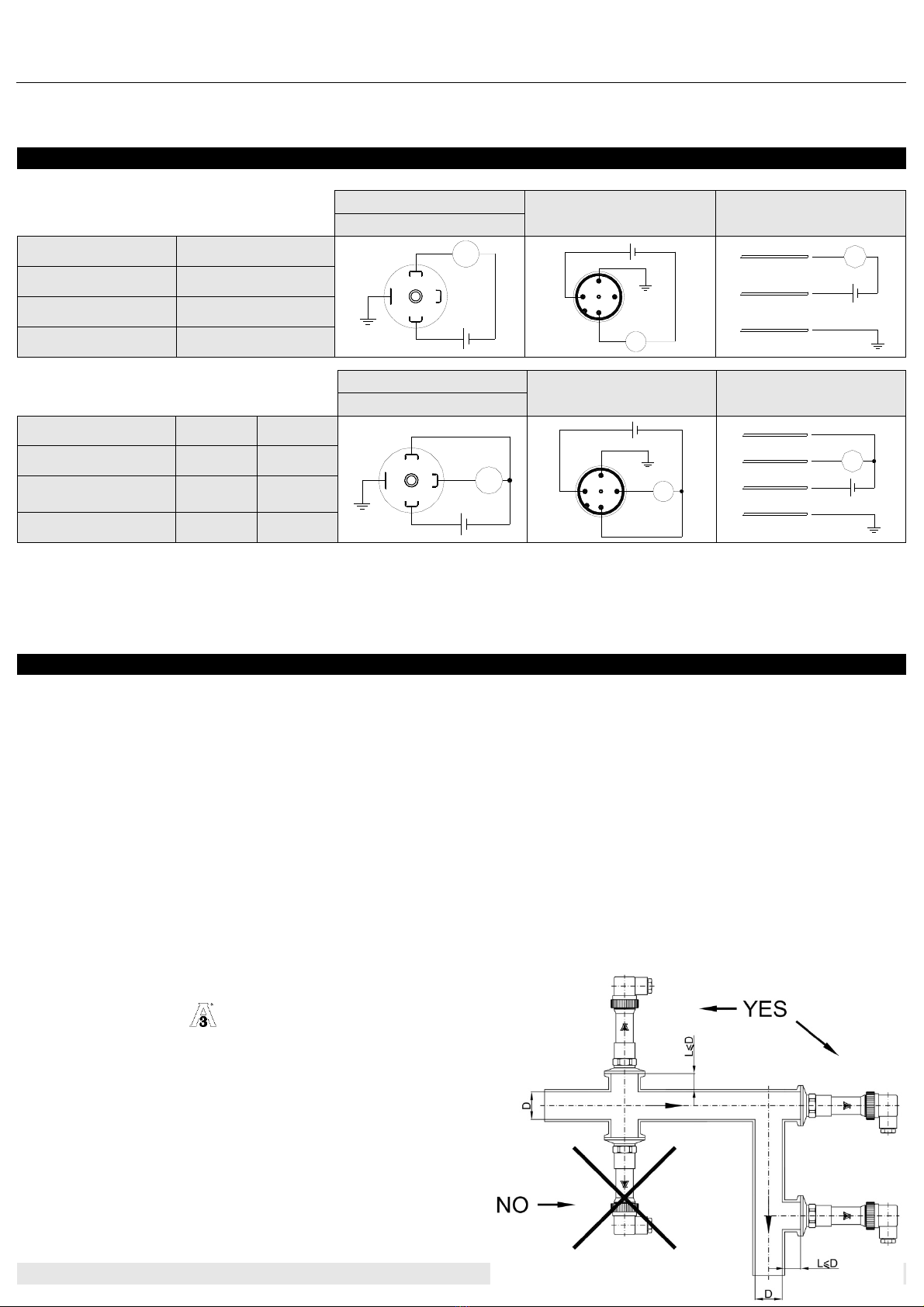

4. Electrical connections

EN 175301-803 Form A M12x1 Cable output

EN 175301-803 Form C

Output signal: 4...20 mA A

2

1

3

A out

+V in

123

4

A out A

+V in

Screen

A out

+V in

Brown

White A

N° of wires: 2

Charge (Ohm): RL – (Vin-10)/0,02

Input +Vin: 10…30

EN 175301-803 Form A M12x1 Cable output

EN 175301-803 Form C

Output signal: 0…5 Vdc 0…10 Vdc

+V in

1

-V in

2

3V

V out

+V in

2

4

13V

-V in

V out

+V in

Brown

Screen

White

Green

V out V

-V in

N° of wires: 3 3

Charge (Ohm): min.

5Koh

min.

10Koh

Input +Vin: 8…30 14…30

The transmitter metal case should always be connected to ground through the process connection thread in order to

protect it from disturbances due to electromagnetic fields or electrostatic charges.

If this procedure cannot be performed, the transmitter should be connected to the ground through the connector and

the cable screen.

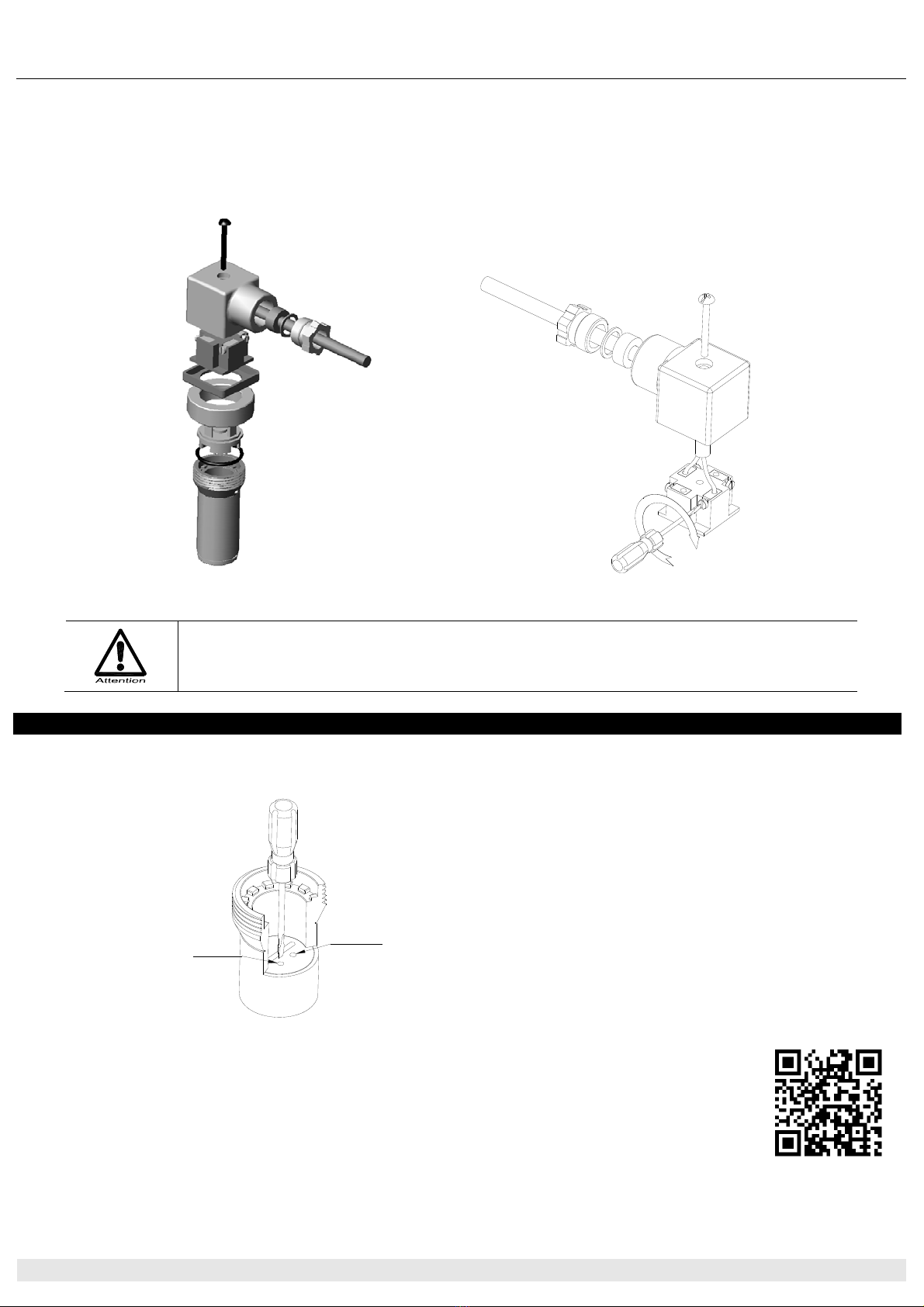

5. Installation

- Before installing an electric safety equipment into a plant or a system, the user should verify that the instrument is

suitable to the plant characteristics and that it is installed correctly. After installation procedure is finalized, the user

should verify that the instrument is not exposed to any source of heat that may exceed the established ambient limits.

Secure the instrument thread through a special key/wrench on the process connection hexagon without grasping the

case by the hands.

- Secure the instrument thread through a special key/wrench on the process connection hexagon (20…30Nm). The

correct torque depends on the type of process connection and the type of seal used (form and material). If the

connection thread is conical the instrument is tightened through a simple screwing on the plug. In order to improve the

thread tightness, the male thread should be wrapped with a PTFE layer.

- If the instrument is equipped with a fluid diaphragm seal the connection should be clamped on the diaphragm

otherwise the calibration could be compromised.

- The monitoring devices such as rings, clamps, nuts, flanges, seals and O-rings are not generally included in the

supply and are not included in this manual. Seals and O-rings must be chosen from the food industry approved

models.

Instruments showing symbol.

Instruments with a DIN11851 connection should be installed

using special seals such as those produced by Siersema

Komponenten System (S.K.S.) B. V. or seals type ASEPTO-

STAR k-flex produced by Kieselmann GmbH.

Instruments provided with a process connection complying

with the ISO 2853 (IDS/ISS) standards should be installed

using a “T-seal” seal type produced by Combifit

International B.V. In the opposite picture you can see how to

install it correctly in order to ensure a proper instrument

operation and cleanliness. Improper installation may produce