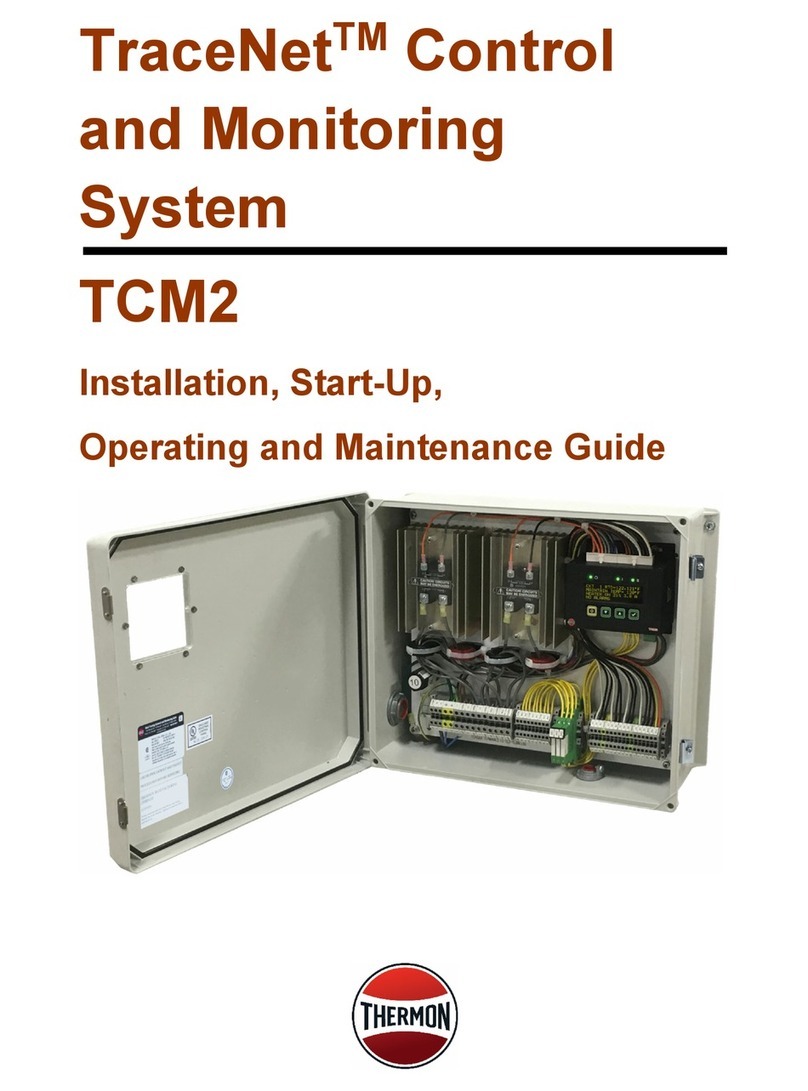

Thermon Tracenet Genesis Owner's manual

TRACENETTM GENESIS

CONTROL AND MONITORING SYSTEM

Installaon, Operaon & Maintenance Guide

2

TraceNet Genesis Installaon, Operaon & Maintenance Guide

This guide, as well as the soware and/or rmware described in it, is furnished under license and may only be used or

copied in accordance with the terms of such license. The informaon in this guide is furnished for informaonal use only,

is subject to change without noce, and should not be construed as a commitment by Thermon. Thermon assumes no

responsibility or liability for any errors or inaccuracies that may appear in this guide.

This informaon is subject to change without noce. It is recommended that a quick check of the current revision status

be done at www.thermon.com prior to proceeding.

PRODUCT WARRANTY INFORMATION

The seller warrants all equipment manufactured by it to be free from defects in workmanship or material under normal use and service. If any part

of the equipment proves to be defecve in workmanship or material and if such part is, within 12 months of the date of shipment from sellers

factory, and if the same is found by the seller to be defecve in workmanship or material, it will be replaced or repaired, free of charge, F.O.B. the

seller’s factory. The seller assumes no liability for the use or misuse by the buyer, his employees, or others. A defect within the meaning of this

warranty in any part of any piece of equipment shall not, when such part is capable of being renewed, repaired, or replaced, operate to condemn

such piece of equipment. This warranty is in lieu of all other warranes (including without liming the generality of the foregoing warranes of

merchantability and tness for a parcular purpose), guarantees, obligaons, or liabilies expressed or implied by the seller or its representaves

and by statue or rule of the law.

3

TraceNet Genesis Installaon, Operaon & Maintenance Guide

Table of Contents

Secon 1: Genesis Introducon And Overview ..........................................................................4

Secon 2: Panel Inspecon, Field Connecons And Internal Wiring.........................................4

2.1: Recommended Visual Inspecon Procedures ...............................................................4

2.2: Wiring and Connecons Survey .....................................................................................4

2.3: Control System Operaon Check ...................................................................................4

2.4: Heat Trace and Insulaon Installaon ............................................................................5

2.5: Power Distribuon Wiring and Breakers ........................................................................5

2.6: TraceNet Panel Wiring ....................................................................................................5

Secon 3: The Genesis System—Overview ................................................................................6

3.1: Genesis Modules Overview ............................................................................................6

3.1.1: The HMI Module ......................................................................................................6

3.1.2: The DCM ..................................................................................................................6

3.1.3: The DTM ...................................................................................................................6

3.1.4: The IOM ...................................................................................................................7

3.2: The Genesis HMI Screens ...............................................................................................8

3.3: Seng Addresses and Conguring Genesis DCM and DTM ........................................15

Secon 4: Genesis Control Opons and Examples ..................................................................16

4.1: Line Sensing Control .....................................................................................................16

4.2: Ambient Sensing Opons .............................................................................................16

4.3: Proporonal Control and Power Clamp .......................................................................17

Secon 5: Genesis Tesng and Start-Up ...................................................................................17

Secon 6: Operaon and Maintenance of the Genesis Control and Monitoring System .......17

6.1: Maintenance.................................................................................................................17

6.2: Maintenance Schedule Recommendaon ...................................................................17

Appendix A: Quick Start Guide For The Genesis Control And Monitoring System ..................18

Appendix B: Genesis Specicaons Guide With Component Limits And Specicaons .........20

Appendix C: Troubleshoong Tips For Reliable Electrical Heat Trace Performance ................28

Appendix D: Genesis Modbus Memory Reference ..................................................................34

Appendix E: Recommended Wiring For RS 485 Communicaons ...........................................35

NOTE: The TraceNet Command Communicaons Operang Instrucons are addressed in a separate document

covering TraceNet Genesis, as well as TN, TCM18, TC1818, TCM2, TC202, TC201, TC101, and ECM. TraceNet

Genesis requires TraceNet Command Version 2.3.0+ for operaon.

4

Secon 1: Genesis Introducon and

Overview

The following serves as a general guide and overview on

the installaon, startup, operaon, and maintenance of a

TraceNet Genesis heat tracing control panel. This guide is

to be sent in conjuncon with the project specic panel

drawings and any other installaon instrucons/guides

and standards provided. In the unlikely event that a conict

or uncertainty arises, contact the Thermon engineering

support personnel assigned to this project to clarify.

NOTE: All personnel should be properly trained and

qualied to safely install, service, operate, and program

this TraceNet heat tracing control panel as well as to install,

operate, and maintain all associated heat tracing.

Secon 2: Panel Inspecon, Field

Connecons and Internal Wiring

A typical Genesis Panel may include electrical distribuon

(oponal main breaker with branch breakers for each

electrical heang circuit, either within the Genesis panel

or in an adjacent electrical distribuon enclosure. (Refer to

the project specic drawings for each panel.)

Wide variees of TraceNet Genesis panel conguraons

are possible and can be located in site locaons having

electrically classied areas and/or ordinary locaons. The

actual panel markings provided with the panel will detail

the approvals for the specic locaon of the panel.

2.1: Recommended Visual Inspecon Procedures

• Inspect door and/or solid state heat sink gaskets for

water intrusion as indicated by mineral deposits and

rust. Where feasible replace any gaskets which appear

to be faulty.

• Survey panel exterior and interior for dust, lint, moisture,

or foreign residue. Remove any such residue with a lint

free cloth material. Heavy residues may be addressed

with wood scrapers and a cleaning agent. Do not soak

parts with cleaning agent but only use dampened cloths

in removing heavy residues. Excessive applicaon of

cleaning agents can damage components.

• Check for panel corrosion and scratches. Remove

corrosion and prepare any damaged areas with

sandpaper. Repaint with the approved primer and

touch up paint.

• Check door hinges, latches, and other moving parts

for proper operaon. Use machine oil to lubricate the

moving parts and restore proper operaon where

necessary.

• Check for mechanical damage to any windows as well

as check the window seals. Repair or replace damaged

materials. In all cases where equipment damage is

observed, a root cause analysis should be iniated

to determine any future correcve acon needed to

prevent a recurrence.

2.2: Wiring and Connecons Survey

• The wiring and connecons survey recommended is as

follows:

• If the servicing of removable electrical connectors is

to be conducted, then make certain the area is free of

explosive atmospheres.

• If equipment is available, an infrared scan of the interior

of the panel cabinet and associated wiring (during

operaon) is recommended.

• Any unusually high temperatures at connecons

are usually evidence of poor connecons. Tighten

connecons, repair with new terminaons, and/or

replace any components which have been exposed to

long term overheang. All terminal block connecons

should be ghtened using a torque indicang screw

driver to the levels indicated in Table 1 and project

installaon drawings.

• Check for corrosion at electrical connecons and

terminaons. Where corrosion of electrical terminals

is observed, this may be addional evidence of loose

connecons and excessive heat. A part replacement

may be necessary.

• Inspect wiring for abrasion wear, mechanical damage,

and thermal overexposure. Repair or replace any

damaged or defecve wiring. In all cases where

equipment damage is observed, a root cause analysis

should be iniated to determine any future correcve

acon needed to prevent a recurrence.

2.3: Control System Operaon Check

The Genesis controller screen is an ideal resource in

facilitang operaon checks of the control system. To begin

this program, energize the panel and the appropriate heat

trace circuits for a minimum of 24 hours or unl all circuits

are cycling within their appropriate control band. A typical

list of operaonal maintenance checks are available for a

successful installaon of a TraceNet Genesis heat tracing

control and monitoring panel, a number of equally crical

parts of the system must be installed properly. Areas

requiring close aenon are:

• The heat trace and insulaon

• The RTD temperature sensor installaon

• The distribuon of the eld RTD and power wiring

• The installaon and roung of wiring inside the TraceNet

panel.

Note: The heat tracing system installaon shall be in

accordance with the electrical area classicaon requirements

as well as shall conform to the latest requirements as detailed

in applicable heat tracing standards, the local Electrical Code

and plant standard pracces. Where conicts arise, contact the

project engineer for resoluon.

5

2.4: Heat Trace and Insulaon Installaon

All heat trace circuits and insulaon shall be installed in accordance with project installaon details provided. In addion,

refer to the Electric Heat Tracing Maintenance and Troubleshoong Guide (Thermon Form No. 20745) for general

procedures and installaon ps. RTD Installaon and Wiring RTD control sensors should generally be installed on the

process lines (see gure below) or in ambient (where ambient sensing is applied) in a locaon that is most representave

of the enre heat trace circuit. In general, it is recommended that the sensors not be located at heat sinks such as pipe

supports, pumps, and valves as the control system response needs to be based on the majority of the process line.

2.5: Power Distribuon Wiring and Breakers

All eld power wiring materials used shall be suitable for the intended service and shall be rated for insulaon service

temperatures up to and not exceeding 221°F (105°C) unless otherwise higher values are noted in project specicaons.

Circuit breakers (if not already supplied in the TraceNet panel) should be selected based on the heat trace type being

used, the service voltage, and the circuit current draw characteriscs. It is especially important when using self-regulang

heat trace to make sure that the circuit breaker response curve type is coordinated with the startup characterisc of

the heat trace cable in a cold start condion. All distribuon wiring connecons should be ghtened using a torque

indicang screw driver to the levels indicated below.

Recommended Torque Values (Typical)*

Solid State Relays on Heat Sink (where used): 12.5–13.5 in. lbs. (1.41–1.53 Nm)

Distribuon Equipment: 13.2–15.9 in. lbs. (1.49–1.8 Nm)

* Required torque values may vary depending on individual panel designs and size of terminals. Refer to project documentaon for

addional informaon.

2.6: TraceNet Panel Wiring

TraceNet panels are congured and pre-wired into an integrated heat trace control and monitoring system. Clean

terminal strips are provided to facilitate the eld wiring into the panels. Refer to the project specic panel drawings

when installing the eld wiring within the panel. All terminal block connecons should be ghtened using a torque

indicang screw driver to the levels indicated, including terminal block connecons to/on TraceNet Genesis modules.

All heat trace circuits should be properly terminated and meggered prior to energizing the heat trace power distribuon

and control panels. In addion, all pipes should be insulated and weather sealed to achieve the expected heat-up and

temperature maintenance performance of the system.

Heang Cable

(Typical)

Pipe Wall

Temperature Sensor

(Typical)

45° 45°

45° 45°

45°

90°

45°

45°

90°

Single Trace Installaon Triple Trace InstallaonDual Trace Installaon

RTD Sensor Locaon On Piping

6

Secon 3: The Genesis System—Overview

The TraceNet Genesis system modules include a Human Machine Interface, or HMI; at least

one (1) Distributed Control Module, or DCM; at least one (1) Distributed Temperature

Module, or DTM; and at least one (1) Input-Output Module, or IOM.

3.1: Genesis Modules Overview

3.1.1 The HMI Module

The HMI (Human Machine Interface) serves as the central monitoring and interrogaon

point for a TraceNet Genesis control & monitoring system. It allows the operator to

access operang control parameters and operang condions throughout the heat

tracing system network. The HMI communicates directly with other Genesis modules

through CAN bus and with a DCS or host PC for TraceNet Command through Ethernet.

HMI

3.1.2: The DCM

The DCM (Distributed Control Module) provides control output to solid state and/or

mechanical relays as well as heater current and earth leakage current measurement for up

to six (6) EHT heaters/circuits. LEDs indicate output status for each circuit.

Every panel will have one (1) DCM for each six (6) individually controlled

relays as idened by its six (6) sub-addresses to represent six (6) specic

individual heaters. (Mulple heaters can be connected in parallel to

a common control relay, but the Genesis HMI will not be able to

disnguish individual circuit segments from a common control

relay.)

3.1.3: The DTM

The DTM (Distributed Temperature Module) is a DIN rail mountable six RTD sensor input module and provides

input for up to six (6) RTD sensors. Any RTD sensor may be mapped to any heater circuit on the CAN Bus network. A single

RTD sensor can provide temperature informaon for an enre Genesis panel (i.e. ambient sensing). Because individual

EHT circuits can have mulple sensors (up to twenty (20) RTD sensors per heater), the

total number of DTM cards per panel can vary by system. Refer to the project specic

drawings for each panel.

Every panel will have at least one (1) DTM which can receive inputs from up to six (6)

individually idened RTD temperature sensors. The DTM has six (6) sub-addresses to

disnguish each of up to six (6) individual sensors.

• For an Ambient Sensing Control Panel, a single RTD sensor can provide input for the

enre panel. In this case, there is a single DTM for that panel.

• For Line-Sensing Control, at least one (1) RTD sensor per control relay is provided, and

the number of DTM's will match the number of DCM's.

• "RTD Mapping” is required to monitor mulple RTD temperature sensors for a common

heater. Up to twenty (20) RTD sensors can be assigned to a heated line or surface, in which

case there could be more DTM's than DCM's.

DCM With Solid State Relays

Mounted On Heat Sink

DCM

DTM

7

IOM Interface

Two (2) 7-segment LED displays

Driven by two (2) latched shi registers

Reverse surface mounted through board cutout

Push-buon to change address and terminate CAN

IOM System Fault Alarm

Normally ON, OFF on fault (open-collector)

The recommended IOM (Input Output Module) code range is 81-99.

3.1.4: The IOM

The IOM (Input-Output Module) is a DIN rail mountable input/output module with one

(1) dedicated system fault alarm output. (Outputs to signal a variety of condions such as

circuit trips, low temperature alarms, ground/earth leakage alarms, and high temperature

alarms.

Every panel will have at least one (1) IOM which can receive inputs and outputs determined

by the requirements and design of the system. There will be at least one (1) IOM for a

Genesis panel to provide common alarm output. The IOM can be congured to perform

many dierent funcons, and mulple IOM's can be arranged on a Genesis panel.

IOM Inputs

The inputs on the IOM are labeled 5 and 6. They are designed to sense 24 Vdc supplied by

the IOM through an open or closed relay contact. This allows input from various types of

signals from 0 Vdc to 24 Vac. As long as the coil side of the relay used is appropriate for the

signal and the contact side of the relay has a 24 Vdc rang or beer, any relay could be used.

The standard alarm relays are Phoenix Contact relays #PLC-RSC-24DC/2 l/EX -2909524.

To use an IOM input, wire the appropriate relay as pictured in the diagram.

IOM Outputs

The outputs on the IOM are labelled 1-4 plus 7. Output 7, (SYS), is a non-congurable output for system fault alarm.

To use an IOM output, wire the appropriate relay as pictured in the diagram. Each output is designed to drive an

interposing relay ≤ 24 Vdc with < 100 mA for local or remote alarms. (For specic rangs, consider a Phoenix PLC-RSC-

24DC/2 l/EX, or equal.)

Default I/O Conguraon

IOM

Sub-address I/O Default LED State Alarm LED

State Funcon

1 Output ON OFF Common Alarm

2Output ON OFF Circuit Trips

3Output ON OFF HIgh Temperature

Alarm

4Output ON OFF Low Temperature

Alarm/RTD Fault

5Input -- -- Load Shed

6 Input -- -- Force On

7Output ON OFF System Fault Alarm

IOM

Two-digit

code for IOM

module

IOM

Sub-address

8

3.2.1: Circuit Overview

Provides a quick status of

all circuits at a glance while

highlighng one circuit a

me with more detail. Each

dot around the perimeter of

the selector dial represents

one circuit. Circuit 1 is at the

top of the dial and circuit

numbers ascend clock-wise

around the dial.

• Red dots represent

circuits in acve alarm.

• Yellow dots represent

circuits with

acknowledged alarm.

• Green dots represent

enabled circuits with no

alarms present.

• Grey dots represent

disabled circuits.

To move between circuits,

touch the circuit dot, drag

the black selector around

the dial or use the arrows

on either side of the circuit

number. The center of the dial displays the highlighted circuit’s live temperature, maintain temperature, circuit

name, and on-o duty cycle. Touch anywhere inside the dial to enter that circuit’s dashboard.

A slightly dierent view for circuits set for ambient control emphasizes electrical current (amps) measurement versus

present temperature.

Note: Temperature shown for line sensing

control method.

Note: Operang current shown for

ambient sensing control method.

3.2 The Genesis HMI Screens

The following secon details conguraon of the TraceNet Genesis HMI module.

9

3.2.2: Main Menu

To access the Main Menu, touch the ‘hamburger’ icon in the upper le

corner of any screen. Use the Menu to navigate between Overview, Circuit

List, Global Sengs and the System screen as well as to switch between

night and day color proles and to Import and Export conguraons,

isometrics, etc.

3.2.3: Admin Login

The user will be prompted to log in as an administrator when aempng

to change any seng or set-point or Admin Login may be selected from

the Menu. Admin mode is indicated by the red nt and red boarder on and

around all screens. The system will remain in Admin Mode for 5 minutes

aer a valid password entry, even if acvely programming circuits.

Note: The inial "Admin Login" value is "abc123" (it is not case-sensive).

The "Admin Login" should be assigned to the responsible Project Manager

or Administrator with the authority over process unit(s) where this panel

is installed. This informaon should be secured but accessible in the

event of an emergency.

10

Seng Descripon Acceptable Lower

Limit Upper Limit Units

Number of

Acve Circuits

Total number of circuits to display in

Overview Number 1 72 None

System Date

and Time Current Time and Date

Gregorian

Calendar; 24 hr

me; me zone

oset from GMT

Language Displayed system language

English (US),

English (UK),

Arabic, Chinese,

Spanish, French,

Japanese,

Korean, Russian

Self Test

Interval (Hrs)

Time in hours between automacally run

self tests Number 0168 Hours

Max Current

with Heater

O

Maximum current reading allowed when

a heater is o before a circuit fault alarm

is triggered

Number 0.5 5 A

Ground Fault

Samples

Before Trip

Number of ground current samples

read above trip set point before trip is

triggered. (does not aect me to trip

because the samples are microseconds

apart) This is to improve noise immunity.

Number 06

Start Up Delay

Time in minutes before heaters turn on

for the rst me aer system power

up. This allows users to stagger start up

across many panels to reduce load step

on plant power.

Number 0 30 Minutes

High Current

Alarm Delay

Time in minutes to delay current alarms

aer high readings. This is to prevent

nuisance alarms on startup current.

Number 0 7 Minutes

Temperature

Delay Alarm

Time in minutes to delay temperature

alarms. This is useful for avoiding

nuisance alarms due to steam-out.

Number 0 30 Minutes

Ground Fault

Loop Test

Runs self contained test to conrm

integrity of the ground current

measurement system.

Touch to Start

Self-Test

Runs self contained test including the

ground fault loop test and addionally

turns measures heater current with

heater on and o to verify relay operaon

and current measurements.

Touch to Start

Mechanical

Relay Duty

Cycle Time

Duty cycle period for relays in

proporonal control mode. 20 Minutes Minutes

DTM

Temperature

Units

Switch temperature units between

Fahrenheit and Celsius

Fahrenheit,

Celsius

Sengs Poll

Period in

Minutes

Time in minutes between requests

from HMI to modules for all system

informaon

Number 5 20 Minutes

Selected

Network

Switch between Onboard Ethernet

(default) or USB (for use with USB-

Ethernet adapter - diagnoscs)

Onboard/USB

IP Address Internet Protocol Address (see network

administrator for IP Address assignments) IPv4 Address 0.0.0.0 255.255.255.255

Subnet Mask

Binary mask which denes the

subnetwork to which a device belongs

(see network administrator for Subnet

Mask assignments)

0.0.0.0 255.255.255.255

Gateway IP

First networking device connected to on

the network (see network administrator

for Gateway IP assignments)

IPv4 Address 0.0.0.0 255.255.255.255

Admin

Password

Password used to protect the system

from unintended or unauthorized

changes

Alpha-numeric

50 character

limit

Number of

Ambient RTDs

Sets the number of ambient RTD sensors

used by the system Number 06

Mapped

Ambient RTD#

Address and Subaddress of the assigned

RTD; the number of "Mapped Ambient

RTD#" elds corresponds to the "Number

of Ambient RTDs" value, i.e. if "Number of

Ambient RTDs" is set to 3, there will be 3

"Mapped Ambient RTD#" elds to provide

an address for each RTD

DTM: number

1-99; RTD:

Number 1-6

3.2.4: Global Sengs

Global Sengs can be reached from

the Menu. These sengs such as

Temperature Units and Start-up Delay

apply to the system as a whole.

11

Set-point Descripon Available Opons Lower Limit Lower Bound Upper Bound Upper

Limit Units

Circuit Informaon

Circuit Number Number of the circuit within the panel Read-Only 1 72 None

Circuit Tag Alpha-numeric Idener Read-only in Dashboard, User-

dened in Sengs 50 Characters

Circuit Status Percent On (Duty-Cycle); Enable Buon Disabled, Enabled, Enabled

Forced-On, Enabled Forced-O 100 %

Temperature

High High Alarm/

High Temp Trip1

High High Alarm: If Temperature Trip is disabled.

High Trip: If Temperature Trip is enabled User-Dened -200 (-328) High Temperature

Alarm Set Point Upper Limit 650

(1200) °C (°F)

High Temp Alarm2

High Temperature Alarm acvates at and

above this set point User-Dened -200 (-328) Max + 1 High High Alarm/

High Trip Set point

650

(1200) °C (°F)

Max Above Max heater duty cycle is 0%, i.e.

Heater is o User-Dened 1 1 High Alarm set point -

Maintain set point - 1

650

(1200) °C (°F)

Temperature Real-me Temperature measurement Read-only Measurement -200 (-328) 650

(1200) °C (°F)

Maintain Set point at and below which heater duty

cycle is 100% User-Dened -200 (-328) Low Alarm set

point + 1 Max - 1 650

(1200) °C (°F)

Low Alarm3

Low Temperature Alarm acvates at and

below this set point User-Dened -200 (-328) Lower Limit Maintain

Temperature - 1

650

(1200) °C (°F)

Notes:

1. HIGH TEMP TRIP (HIGH HIGH TEMP) If HIGH TEMPERATURE TRIP is ON (OFF), this message will be displayed if the measured temperature rises above a value equal to the HIGH TEMPERATURE TRIP (HIGH) set-point.

2. HIGH TEMP ALARM The measured temperature has risen above a value equal to the HIGH TEMPERATURE ALARM set-point but has not yet risen above a value equal to the HIGH TEMPERATURE TRIP/HIGH set-point.

3. LOW TEMP ALARM The measured temperature has fallen below a value equal to the LOW TEMPERATURE ALARM set-point.

Heater Current

High High Alarm/

High Current Trip4

High High Alarm: If Current Trip is disabled.

High Trip: If Current Trip is enabled User-Dened 0High Alarm Upper Limit 100 A

High Current

Alarm5

High Current Alarm acvates at and above

this set point User-Dened 0Low Alarm + 1 High High Alarm/

High Trip 100 A

Low Current

Alarm6

Low Current Alarm acvates at and below

this set point User-Dened 0High Alarm set

point - 1 100 A

Notes:

4. HIGH CURRENT TRIP (HIGH HIGH AMPS) If HIGH CURRENT TRIP is ON (OFF), this message will be displayed if the measured heater current is higher than the HIGH CURRENT TRIP (HIGH) set-point.

5. HIGH CURRENT ALARM The measured heater current rise is higher than the HIGH CURRENT ALARM set-point but not above the HIGH CURRENT TRIP/HIGH.

6. LOW CURRENT ALARM The measured heater current has fallen lower than the LOW CURRENT ALARM set-point.

Ground Current

High High Alarm/

High Leakage Trip7

High High Alarm: If Ground Trip is disabled.

High Trip: If Ground Trip is enabled User-Dened 20 High Alarm Upper Limit 255 mA

High Leakage

Alarm8

High Ground Fault Current Alarm acvates

at and above this set point User-Dened 20 Lower Limit High High Alarm/

High Trip 255 mA

Notes:

7. HIGH LEAKAGE TRIP (HIGH HIGH GROUND) If GROUND CURRENT TRIP is ON (OFF), this message will be displayed if the measured ground/earth leakage current rises above the GROUND CURRENT TRIP (HIGH) set-

point.

8. HIGH LEAKAGE ALARM The measured ground/earth leakage current has risen above the GROUND CURRENT ALARM set-point but not above the GROUND CURRENT TRIP/ALARM2 set-point.

3.2.5: Dashboard/Circuit Details

The dashboard provides a comprehensive single circuit view. It includes the circuit

number, tag, pipeline number, or other status as well as real-me temperature,

heater current, ground leakage current and related alarm set points. This screen

can be reached by tapping a circuit in the Overview or the Circuit List. The limits

below dene the lowest and highest possible values. (The bounds dene the

constraints for valid values, e.g. maintain temperature should not be set below

the low temperature alarm.)

Circuit Alarms

In the event that the measured condions of the heat trace circuit fall outside

the user-dened parameters, the Genesis will nofy the user. When an alarm

condion rst occurs, the common alarm digital output will annunciate and a

message will appear on the Circuit Screen to inform the user of the type of alarm

present. Pressing will acknowledge the alarm and deacvate the digital output.

Alarms will automacally clear when the alarm condion is no longer present.

Circuit Trips

In the event that the measured condions of the heat trace circuit go beyond the

TRIP sengs of the circuit, the circuit will trip, i.e. turn o. When a circuit trips,

the circuit will be deacvated and a corresponding message will be displayed.

(A TRIP event is dierent from an ALARM event in that the heat trace circuit is

deacvated and will remain deacvated unl the circuit is manually reset by the

user.)

12

Seng Descripon Available Opons Lower

Limit Upper Limit Units

Circuit Name User dened Alpha-numeric

Idener unique to circuit

Alpha-numeric, Upper/

Lower Case, hyphen,

dot

150 Characters

Process Tag User dened alpha-numeric

Idener For

Grouping

Circuits

Together By

Associated

Process

Alpha-numeric, Upper/Lower

Case, hyphen, dot 1 Characters

Acve Alarm

Hexadecimal code for acve

alarms and a buon to

display and acknowledge

acve alarms

Acknowledge individual

alarms or acknowledge

all alarms

0x0000 0xFFFF

Alarm

Acknowledge

Hexadecimal code for acve

alarms and a buon to

display and acknowledge

acve alarms

Acknowledge individual

alarms or acknowledge

all alarms

0x0000 0xFFFF

High Trip

Sengs

Enable or disable buons for

Temperature, Current and

Ground Current trips

Enable/Disable

Control Type Chose control method for

circuit

On/O,

On/O with So-Start,

Proporonal,

Ambient Proporonal

Control

RTD Fault9

Chose the forced duty cycle

in the event of an RTD Fault Number 0100 %

Power Clamp10

Maximum duty cycle allowed

on circuit Number 0100 %

Times The

Heater Has

Cycled

Cycle count for mechanical

relay controlled by circuit Number; read-only 02,147,483,648 Since

Commissioning

Heater Relay

Type

Displays mechanical or solid-

state relays Mechanical/SSR Fixed at panel

shop

Heater Voltage11

Voltage provided to trace

heater from relay(s) Number 0Fixed at panel

shop Volts

Heater

Amp Hour

Accumulaon

Running total of Amp Hours

accumulated since last reset

of value

Number 02,147,483,648

Heater

Wa Hour

Accumulaon

Running total of Was

accumulated since last reset

of value

Number 02,147,483,648 Was

Time Heater

Will Come Back

On

Applies to APCM; me le

unl the heater switches

on again

Number 0 32 Minutes

Ground Current

Reading At Trip

Ground fault current reading

that caused most recent trip Number 20 255 mA

Heater Current

Reading At High

Current Trip

Heater current reading that

caused most recent trip Number 1 100 A

DCM Address

Address (displayed on each

board) unique to each board

that allows communicaon

between modules

Fixed number between

01-20 1Fixed at panel

shop

Notes:

9. RTD FAULT ALARM An RTD reading is out of range when the resistance exceeds 313 Ω or is less than 48 Ω. In either case, the RTD has

been damaged or has been disconnected in service. NOTE: The Genesis will connue to control if a second undamaged RTD is available.

Otherwise, the default heater status is “De-energized”.

10. “Power Clamp” for Genesis Systems are available when the units are used with solid-state relays, and is enabled when a circuit is set

for “on/o with so start”. This feature literally provides “so start” using a reduced on/o duty me cycle of 1 second iniang at the

percentage selected.

• Example 1: Power Clamp of 20% is selected this results in an inial duty cycle of 0.2s “full on” and 0.8s o)

• Example 2: “on/o with so start” is selected with 100% Power Clamp. The result is that the circuit will operate in a normal on/o

method.

11. The heat/voltage value is not measured by the Genesis system. This value is xed before panel shipment to match design and distribuon

voltage as constructed.

3.2.6: Circuit Sengs

Sengs on a per circuit basis (disnct

from set points) can be found here.

This includes things like trip enabling

assignments with number and

address of RTDs.

13

3.2.7: Circuit History

Plots up to six months of temperature and current data with accompanying

set point changes.

3.2.8: Circuit ISO

Use mul-touch pinch and zoom gestures to view the ISO (isometric

drawing) for the circuit.

3.2.9: Circuit Notes

Useful notes can be stored here for any purpose such as for operators

across shis or for maintenance (requires log-in).

14

3.2.11: Circuit Alarm List

The Circuit Alarm List can be reached from the Menu. Here, live panes for

each circuit in alarm, appear in a list organized with tabs for all alarms, by

alarm type or by process. To acknowledge an alarm, tap Ack on the le of

the circuit pane. A box will appear displaying each alarm for that circuit.

Any individual alarm or all alarms for that circuit can be acknowledged.

3.2.12: Import/Export

The Import/Export feature is used to load isometrics and to import and

export system conguraon les to easily and quickly set up an enre

panel. (Import/Export is via USB port on the back of the HMI.)

3.2.13: System

Provides a means of updang system soware and rmware. Shows the

current installed version. Use the Mount USB Drive buon to show a list

of all Genesis modules, including address and rmware versions. Requires

Admin Login for access.

15

3.3: Seng Addresses and Conguring Genesis DCM and DTM

The Genesis DCM (Distributed Control Module), DTM (Distributed Temperature Module), and IOM (Input Output

Module) each have a two-digit address code. The two (2) digit code used to idenfy each module through the CAN bus

to the HMI (Human Machine Interface). The HMI does not have a two (2)-digit code.

There are ninety-nine (99) addresses available for Genesis modules: 01 through 99. (Note that “00” is not a valid code).

No two modules within a panel can share the same code. Each of the Genesis Modules is addressed separately below.

3.3.1: Conguring the DCM

The DCM (Distributed Control Module) codes are typically set at the factory so that

each individual control relay is correlated to a specic electrical circuit breaker in the

panel as designed and built. If a heang circuit is to be moved to an alternate breaker

and control relay, it’s best to have the heater reassigned to the desired breaker relay

and idened at the HMI (see secon 3.2.6: Circuit Sengs).

The recommended DCM code range is 01-20.

3.3.2: Conguring the DTM

The recommended DTM (Distributed Temperature Module) code range is 21-80. For an

Ambient Sensing RTD, the DTM is typically coded 21.

3.3.3: The IOM is not congurable.

Two-digit

code for DTM

module

Sub-address of

specic sensor for

"RTD mapping"

Two-digit

code for DCM

module

3.3.4: Genesis Modules Address Sengs

The addresses of all DCM, DTM and/or IOM's are generally set at the panel shop to match the panel design so that each

circuit breaker is aligned with the proper DCM and control relay. Properly trained Genesis technicians can manually

recongure Genesis modules by pressing and holding the buon unl the address ashes. Pushing the buon again

before the ve seconds have passed will restore the previous seng. The new address will ash for ve seconds aer

which the new address will be set.

16

Secon 4: Genesis Control Opons and

Examples

The TraceNet system allows a variety of control opons for

heat trace operaon.

• Line sensing (RTD Sensor on pipe-wall)

• APC (Ambient Proporonal Control)

• Ambient Sensing (On-O Control)

The most energy ecient control mode is to use one (or

more) line sensing RTD’s for each heat trace circuit. When

using this control mode, the TraceNet Genesis panel will

have the RTD(s) connected to the DTM module in the

panel.

4.1: Line Sensing Control

When the RTD is directly sensing pipe-wall surface for

control, the key parameters are “Maintain Temperature” at

which the heat trace is energized or turned on. The “Max”

temp seng is where the heat trace will be de-energized,

or turned o. The dierence between these control sengs

denes the “dead band” (aka “control dierenal”)

From the line sensing RTD(s) the temperature of the

process line is read by the Genesis and is/are also able

to alarm for the user’s low and high temperature alarm

sengs. (A “high-high” temperature seng with circuit

“trip” opon is also determined from the RTD(s) placed

directly on the process line.)

Line sensing is the most energy ecient method of control

as the heat trace is only energized when the temperature

of the line is at the “Maintain” seng (or lower) and the

heat trace is de-energized when the it reaches the “Max”

seng, (aka “Maintain” plus “Dead Band”.)

4.2: Ambient Sensing Opons

Any ambient sensing control mode is less energy ecient

than line-sensing control, but generally allows fewer

heang circuits of longer lengths. This is because there is

no concern about process ow paths for heang circuit

layout, which will inuence RTD placement, the number

of sensors, and the number of heang circuits required.

For the TraceNet Genesis system, and its predecessor

the TCM18, “Proporonal Control” refers to a “me

proporoning” funcon for saving energy or more

accurately controlling maintain temperatures. So, if a given

situaon calls for 50% power, then the controller cycles on

and o 50% of the me to achieve this energy delivery.

There is a “Power Clamp” feature for these controllers that

is available when the controller is used with solid-state

relays, and is enabled when a circuit is set for “on/o with

so start”. This feature literally provides “so start” using

a reduced on/o duty me cycle of 1 second iniang at

the percentage selected.

There are two opons for Ambient Sensing with the

TraceNet Genesis System: Ambient Proporonal Control

and Ambient "On-O" Control.

4.2.1: APC (Ambient Proporonal Control)

With APC the heat trace will be set to operate at 100%

power (connuously on) at the minimum ambient

temperature, and reduce power as the ambient

temperature rises to the maintain temperature. When the

ambient temperature reaches the maintain temperature,

the heat trace produces no heat for that circuit. This

“Proporonal Control” is achieved by cycling the power

to the heat trace “on” and “o” so the me “on” is

proporonal to the dierence between the “Maintain”

and ambient temperatures. (Note: The minimum power

level is 8%, so that the electrical current and earth leakage

current levels can be accurately measured.)

Example of Ambient Proporonal Control (APC):

Maintain +40°F (+5°C) (i.e. to keep water from freezing) in a

minimum ambient condion of -40°F (-40°C) with APC control

method, follow this procedure:

The “Maintain” Temperature is set at +40°F (+5°C), at which

the heat trace would be de-energized, or “O”.

The “Minimum Ambient” temperature (at or below which

power is on 100%) would be programmed to be a value of

-40°F (-40°C).

(Note that the dierence between the Maintain and the

Minimum Ambient temperature denes the “Dead Band”,

across which the me “on” and “o” is established do deliver

the heat proporonally. The reduced power delivery results

in overall energy consumpon when compared to Ambient

“On-O” Control.)

APC control method can be successfully used for maintaining

elevated temperatures as well. This can reduce the number of

heang circuits by allowing longer heang circuits, but is not

as energy ecient as line sensing RTD temperature control.

The APC control method has tradionally been used only

with Solid State control relays because of rapid cycling of the

control relays during operaon. Now, by expanding the cycle

me between “on” and “o”, mechanical relays can be used.

“On/o with so start” is selected with 100% Power Clamp.

The result is that the circuit will operate in a normal on/o

method.

4.2.2: Ambient “On-O” Control

In this case the heat trace is fully “on” when the ambient

temperature falls below the “Maintain” temperature and

is fully “o” when the ambient temperature rises above

the “Maintain” plus the minimum control dead band.

Example of "On-O" Ambient Sensing Control:

As a third control mode opon, the TraceNet Genesis panel

may be congured for Ambient “On-O” Control. In this case,

one or two RTD’s may be used to sense ambient temperature,

typically in a shaded area subject to wind and rain in an area

convenient to the panel locaon.

In this case, the heat trace operates at 100% power whenever

the ambient temperature drops below the “Maintain”

temperature. To winterize water lines this is typically +40 to

50°F (+5 to 10°C). If the ambient rises above this value, plus

the minimum control dead band of +3° (°F or °C)) the heat

trace will turn o.

17

This is a less energy ecient approach to heat trace control,

but is consistent with what is rounely provided with ambient

sensing mechanical thermostats controlling a contactor

between a distribuon panel’s main circuit breaker and the

branch breaker panel board.

4.3: Proporonal Control and Power Clamp

If “on/o with so start” is selected with any Power Clamp

percentage other than 100% the circuit will operate as

follows:

• Below the Low Temperature alarm (LTA) setpoint, the

heater will be “full on” 100% of the me.

• When the temperature reaches/exceeds the LTA, the

so start feature will energize the heater “full on” for

the Power Clamp (me) percentage selected (n% of 1

second) and over 90 seconds will ramp up to “full on”

for 100% of the me.

* Regardless of what Power Clamp (me) percentage

is selected, it will take a maximum of 90 seconds for

the heater to be “full on” for 100% of the me.

* The heater will be turned o once the Maximum

Temperature (Maintain Temperature plus Control

Band, or MT+CB) is reached, even if that temperature

is reached in less than 90 seconds.

* Once the heater is at MT+CB (Maximum

Temperature), it will connue to cycle based on

the so start sengs. In other words, once MT+CB

is reached the heater is de-energized unl the

temperature drops to the Maintain Temperature

(MT), then the heater will be energized “full

on” starng at the selected Power Clamp (me)

percentage (n%) and will go through the 90 second

ramp up to “full on” for 100% of the me, or unl

the MT+CB is again reached.

Secon 5: Genesis Tesng and Start-Up

All heat trace circuits should be properly terminated and

megger tested prior to energizing the TraceNet Genesis

control panels. In addion, all pipes should be insulated

with weather barrier to achieve the required temperatures

to be maintained.

Troubleshoong Tips

When starng up a newly installed heat trace and control

system, it is common to encounter numerous circuit

alarms and possibly circuit “trip” events. Data entry errors,

unancipated temperature condions and/or dead band

sengs that are too narrow, and other possible installaon

errors can be expected.

A table of Troubleshoong Tips is provided in Appendix C

to assist during start-up.

Secon 6: Operaon and Maintenance of

the Genesis Control and Monitoring System

6.1: Maintenance

Prevenve maintenance consists of inspecon,

tesng, checking connecons, and general cleaning of

equipment at scheduled intervals. The maintenance

recommendaons that follow are intended to support

and in some cases “add to” those procedures detailed in

the facility’s Planned Maintenance System (PMS). In case

of conicts, contact the project engineer for resoluon.

When carrying out the scheduled maintenance program,

the following safety precauons should be observed.

Safety Precauons the heat tracing can be powered by the

project specied nominal voltages ranging from 100 to 600

Vac. It is important that only authorized trained personnel

conduct these maintenance and service acvies. Before

conducng any maintenance or service procedure, exercise

required lockout and tag out procedures at the appropriate

circuit breakers. Addionally, do addional tesng within

the control panel to ensure that the specic heat tracing

and control circuit of interest is fully de-energized and the

equipment is grounded. If it becomes necessary to service

or test live equipment, the following instrucons must be

followed:

• Use one hand when servicing the equipment. Accidental

death or severe injury may occur especially if a current

path is created through the body from one hand to the

other.

• First, de-energize the equipment. To de-energize any

capacitors connected into the circuits, temporarily

ground the terminals where work is to be done.

• Connect the mul-meter/instrument to the terminals of

interest using a range higher than the expected. Make

sure that you are not grounded whenever a need arises

to adjust equipment or test circuit operaon. Verify that

all test equipment used is properly maintained and safe

for the intended use.

• Without touching the mul-meter/instrument energize

the equipment and read the values indicated on the

mul-meter/instrument.

• Remove the test leads aer de-energizing the circuit of

interest.

6.2: Maintenance Schedule Recommendaon

The service schedule is somewhat dependent on the

“in service” hours. As a general rule, however, it is

recommended that the heat tracing control and monitoring

panel be serviced on a twelve month basis to start. The

schedule may be adjusted depending on the operang

history of the panel and as the historical maintenance

records dictate.

18

Appendix A: Quick Start Guide For The Genesis Control And Monitoring System

The TraceNet Genesis HMI serves

as the central user interface.

• View Status For 72 Circuits

On Dashboard

• Allows Up To 20 RTD’s Per

Circuit

• Communicaons to Host

Computer via Ethernet

Communicaons

• Reduced Wiring And

Connecons

• Each RTD is Addressable

• Control Panel - IP66 IP Rang

The TraceNet Genesis has a

simple "glove touch" interface

that allows the operator to

adjust and monitor heat tracing

circuits. The following steps show

navigaon of the controller's

basic funcons.

TraceNet

TM

Genesis

CONTROL AND MONITORING SYSTEM

OVERVIEW "HAMBURGER" MENU

The Overview screen displays

informaon on any circuit.

• Select Admin Login.

• To edit circuit values,

log in by touching the

"Hamburger" menu.

OVERVIEW

• Rotate the teardrop

cursor or use the

arrows to select a

circuit.

• Touch inside the circuit

dial to show the Circuit

Dashboard.

CIRCUIT DASHBOARD

• Touch any value on circuit

details to edit a setpoint.

NUMBER PAD

• Select check to accept new

setpoint.

• Edit Maintain Temp,

Alarms, and Control

Band using the number

pad.

QUICK START GUIDE

19

CIRCUIT ISO NOTESSETTINGS

Select Sengs to adjust

variables specic to a

circuit.

Select History to view up

to 6 months of data for the

circuit.

Select ISO to view the

isometric drawing for the

circuit.

Select Notes to add

comments to a circuit.

HISTORY

Select an icon at the boom

of any Circuit Screen::

GLOBAL SETTINGS

Select any value on global

sengs to make adjustments

to circuit level or updates to

global sengs.

• Select Global Sengs to

adjust how the Genesis

displays system-wide

variables such as language,

temperature, system me.

• Select Import/Export

to import or export ISO

drawings and circuit-level

details.

"HAMBURGER" MENU

• Select the "Hamburger"

menu to make global

adjustments.

Corporate Headquarters: 7171 Southwest Parkway • Building 300, Suite 200 • Ausn, TX 78735 • Phone: 512-690-0600

For the Thermon oce nearest you visit us at . . . www.thermon.com

© Thermon, Inc. • Printed in U.S.A. • Informaon subject to change.Form TEP0217-0219

20

Appendix B: Genesis Specicaons Guide With Component Limits And Specicaons

TRACENETTM GENESIS

CONTROL AND MONITORING SYSTEM

SPECIFICATION GUIDE

Table of contents

Other Thermon Control System manuals

Popular Control System manuals by other brands

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SC-SL4-AE installation manual

Western Innovator

Western Innovator FHM2 SERIES Installation and operating instructions

TIS

TIS RLY-8CH-16A installation manual

Lutron Electronics

Lutron Electronics RadioRA 2 Commisioning Checklist

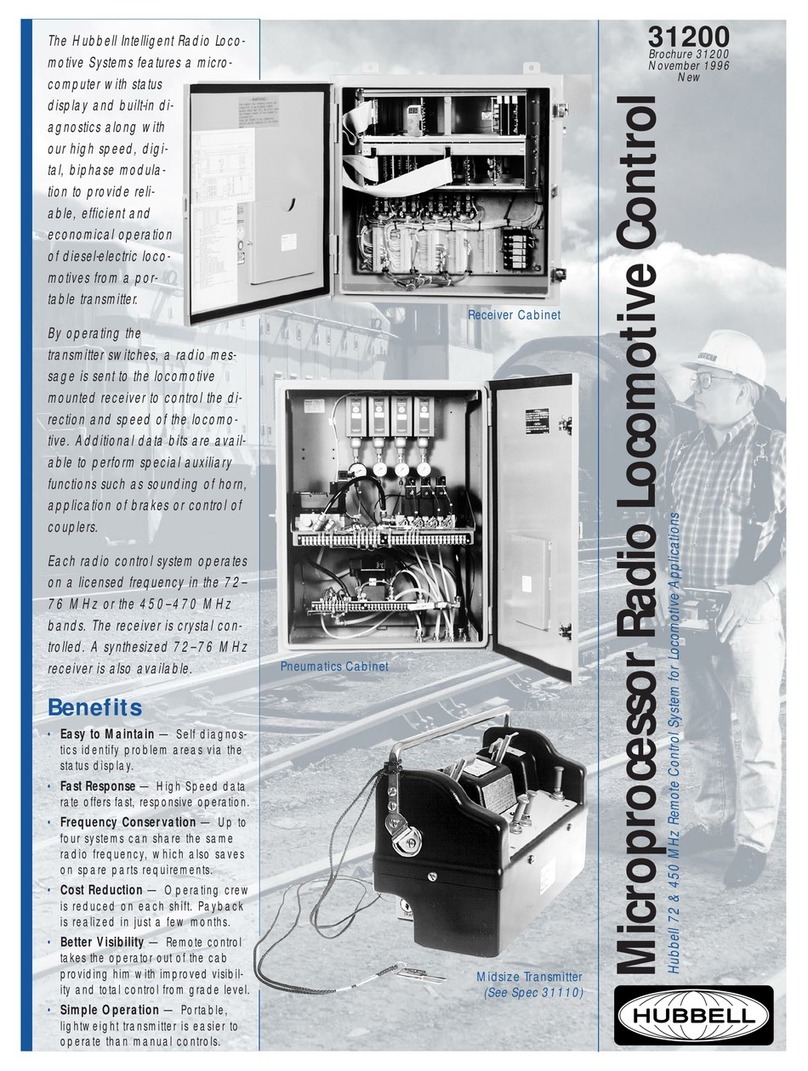

Hubbell

Hubbell Microprocessor Radio Locomotive Control... Brochure & specs

Carson

Carson Reflex Wheel Pro instruction manual