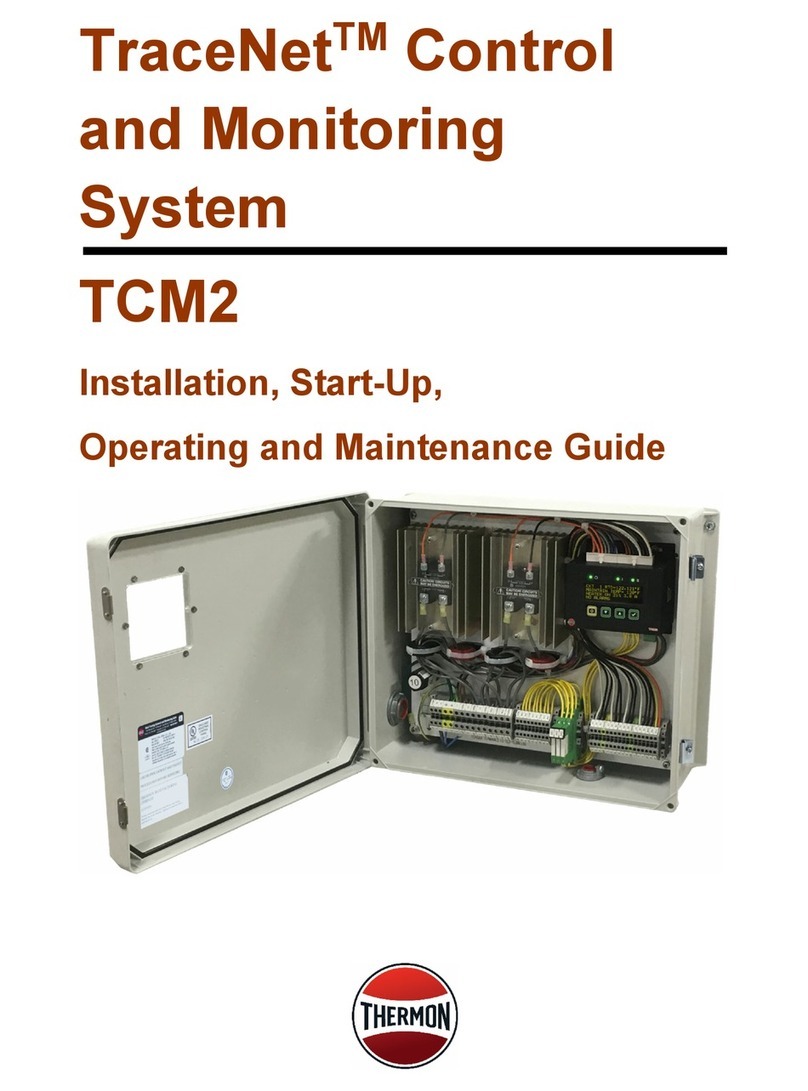

Thermon TraceNet TCM18 Installation manual

TraceNet™ TC

Series Control System

TCM18 Panel Installation, Start-Up,

and Maintenance Guide

Thermon Manufacturing Company

TraceNet™is a registered trademark of Thermon Manufacturing Company.

PN 50312

TCM18 Panel Installation and Start-Up Guide

©2013 Thermon Manufacturing Company. All Rights Reserved.

This guide, as well as the firmware described in it, is furnished under license and may only be used or

copied in accordance with the terms of such license. The information in this guide is furnished for infor-

mational use only, is subject to change without notice, and should not be construed as a commitment by

Thermon Manufacturing Company. Thermon Manufacturing Company assumes no responsibility or liabil-

ity for any errors or inaccuracies that may appear in this guide.

This documentation is considered proprietary and is protected by copyright. This document may not, in

whole or in part, be copied, photocopied, reproduced, translated, or reduced to any electronic medium or

machine-readable form without prior consent in writing from Thermon Manufacturing Company.

This information is subject to change without notice. It is recommended that a quick check of the current

revision status be done at www.Thermon.com prior to proceeding.

This guide is written and designed at Thermon Manufacturing Company, 100 Thermon Drive, San Marcos,

TX 78667-0609, USA.

Copyright ©2013 Thermon Manufacturing Company. All Rights Reserved.

PRODUCT WARRANTY INFORMATION

The seller warrants all equipment manufactured by it to be free from defects in workmanship or material

under normal use and service. If any part of the equipment proves to be defective in workmanship or

material and if such part is, within 12 months of the date of shipment from sellers factory, and if the same

is found by the seller to be defective in workmanship or material, it will be replaced or repaired, free of

charge, F.O.B. the seller’s factory. The seller assumes no liability for the use or misuse by the buyer, his

employees, or others. A defect within the meaning of this warranty in any part of any piece of equipment

shall not, when such part is capable of being renewed, repaired, or replaced, operate to condemn such

piece of equipment. This warranty is in lieu of all other warranties (including without limiting the generality

of the foregoing warranties of merchantability and fitness for a particular purpose), guarantees, obligations,

or liabilities expressed or implied by the seller or its representatives and by statue or rule of the law.

PN 50312_0414

Contents

Chapter 1: Introduction

.............................................................................................. 1

Chapter 2: Panel Specifications

.............................................................................................. 3

Chapter 3: Module Connections

.............................................................................................. 5

Chapter 4: Field and Panel Wiring

.............................................................................................. 9

Chapter 5: The User Interface

.............................................................................................. 13

Chapter 6: Heat Trace Control

.............................................................................................. 21

Chapter 7: System Start-Up

.............................................................................................. 23

Chapter 8: Maintenance

.............................................................................................. 24

Chapter 9: Notes

.............................................................................................. 29

Chapter 10: More Information

.............................................................................................. 30

Appendix A:

.............................................................................................. 31

Appendix B:

.............................................................................................. 43

Appendix C:

.............................................................................................. 44

PN 50312_0414

1Introduction

The following serves as a general guide and overview on the installation and startup of

a TraceNet TC Series heat tracing control panel. This guide shall be used in conjunc-

tion with the project specific control system drawings and any other standard installation

instructions/guides provided. In the unlikely event that a conflict or uncertainty arises,

contact the Thermon engineering support personnel assigned to this project to clarify.

All installation personnel should be properly trained and qualified to safely install, service,

and program this TraceNet heat tracing control panel as well as to operate the associated

heat tracing system.

THE PANEL LOCATION

A wide variety of TraceNet TC Series panel configurations are possible. The TraceNet

modules are designed to operate in ambients ranging from -40◦F (-40◦C) to 140◦F (60◦C)

and higher. The TraceNet panels can be located in site locations having electrical clas-

sifications ranging from ordinary to hazardous. The actual panel markings provided with

the panel will detail the design intended specific location requirements.

INITIAL INSPECTION AND HANDLING

Upon receiving the TraceNet TC Series panel, it is important to confirm that the contents

of the shipping containers agree with the shipping documents and with the purchase or-

der. Also, it is important to check the shipped container exterior and packing materials

for any possible freight damage. Where damage is observed, take photos and notify the

carrier as well as your nearest Thermon engineering support center before proceeding

further.

After carefully removing the panel from its shipping container, move the panel to its se-

lected location utilizing the pallet base and the securement strapping provided using a

lift truck/fork lift. Where lifting eyes are provided on the panel, they should be used when

handling.

Where the panel has external heat sinks to dissipate the heat generated by solid state

1PN 50312_0414

relay switching, it is recommended that a minimum of 6” (150 mm) of space be allowed

between sinks and walls or other panels to minimize heat buildup at the heat sinks.

Where heat sinks are present on adjacent panels, allow 12” (300 mm) spacing between

heat sinks for sufficient natural air movement.

Adequate door clearance for service work entry and conduit panel entries should be

anticipated when establishing the exact panel location. When the panel is located out-

doors, a concrete base pad of sufficient height to avoid potential standing water should

be constructed.

Once the panel has been properly located, refer to the project specific installation details

for the recommended floor mounting as well as wall mounting details.

Once bolted in place, the panel is ready for final configuration, wiring, and site required

assembly. Note that the TCM18 control and monitoring module is normally shipped in a

separate container to minimize any undue impact stress during shipment. It should be

removed from its shipping container again being attentive to any shipping damage that

may have occurred during its transit. The TCM18 mounting details are likewise provided

in the project specific drawing details.

Note: For installation requirements specific to purged panels, please see Appendix B.

2PN 50312_0414

2Specifications

The general TraceNet TC Series panel specifications are as given below.

Interior panel operating ambient range -40◦F to 140◦F (-40◦C to 60◦C)

Exterior panel operating ambient range -40◦F to 131◦F (-40◦C to 55◦C)

Ambient storage range -40◦F to 158◦F (-40◦C to 70◦C)

Relative humidity range 0 to 90% Non Condensing

Nominal instrument control voltage 100 to 240 Vac, 50/60 Hz

Temperature sensor types 100 Ohm 3 Wire Platinum RTD

Control temperature range -200◦F to 1112◦F (-129◦C to 600◦C)

Maximum power consumption of TCM18 module 70 Watts

Current ratings in hazardous (classified) locations based on TraceNet TC Series panels

for up to 72 circuits are as follows1:

Maximum Panel Exterior

Ambient (◦C)

For: 1 - 36 Circuits For: 37 - 72 Circuits

Maximum Allowable Average Amps per Relay

(Calculated for each side of enclosure)2

40 22.2 18.0

45 21.0 16.8

50 19.7 15.6

55 18.3 14.3

3PN 50312_0414

Current ratings in nonhazardous (ordinary) location based on TraceNet TC Series panels

for up to 72 circuits are as follows1:

Maximum Panel Exterior

Ambient (◦C)

For: 1 - 36 Circuits For: 37 - 72 Circuits

Maximum Allowable Average Amps per Relay

(Calculated for each side of enclosure)2

20 27.0 22.7

25 25.8 21.6

30 24.7 20.4

35 23.5 19.2

40 22.2 18.0

45 21.0 16.8

50 19.7 15.6

55 18.3 14.3

Note 1: Contact the manufacturer for the maximum allowable amps per relay for custom enclosure sizes.

Note 2: Based on factory panel wiring rated for 105◦C.

TCM18 LCD heated display 1-3/4” ( 44 mm) x 4.875” (124 mm)

TCM18 touchpad tactile feel, stainless steel dome keys

TCM18 communication 2 RS485 ports

TCM18 operating temperature range -40◦F (-40◦C) to 140◦F (60◦C)

TCM18 alarm relay outputs -U Option Three, sealed dry contacts rated @

0.4 Amp, 24 Vdc

-A Option Three, sealed dry contacts rated 100-

240 Vac @ 0.5A

Entries into panels must meet IP54 and/or NEMA-4 ingress protection levels to maintain

the environmental rating of the panel.

4PN 50312_0414

3Module Connections

Due to its flexible architecture, a variety of TraceNet TC Series panel configurations are

available. The specific project drawings should be followed when installing the power

supply and field distribution wiring into the TraceNet panel as well as when installing the

data highway interface wiring. As an overview and to provide a more general under-

standing of the inner workings of this panel, the following general connection diagrams

are provided.

The TCM18 Connections

The TCM18 is the TraceNet interface to the outside world. It monitors the condition of

the heat tracing circuits as well as the heat traced piping temperatures and allows inter-

rogation of heat trace status, alerts the operator to alarm and trip events, and allows the

changing of the operating parameters and system configuration.

The connections for the TCM18 are described in Figure 1 which follows.

Figure 1: Wiring and Connection Details on the TCM18

5PN 50312_0414

The RTB6 Module Connections

The RTB6 module allows the connection of six 3-wire 100 Ohm platinum RTD inputs to

the TraceNet control system. The RTB6 circuit board is a passive device which commu-

nicates the discrete temperature inputs into a 26 pin bundled ribbon cable which then

interconnects to a TCM18 module.

The connections within a TraceNet panel for the RTB6 are shown in the illustration which

follows.

Figure 2: RTB6 Wiring and Connections

6PN 50312_0414

The PM6 Connections

The PM6 serves as the heat trace power solid state switching module for a TraceNet

TCM18 controller. It includes the heater and ground current measurement transformers,

solid state heat trace control relays, and the heat dissipating heat sink. This module in-

cludes a ground leakage functional test circuit. In addition, alarm and trip output capabil-

ity to indicating lights on the panel front door are also provided.The module connections

for the PM6 are as detailed in the following illustration.

Figure 3: PM6 Wiring and Connections

7PN 50312_0414

The RM6 Connections

The RM6 is a DIN rail mounted six circuit relay interface module for linking to individual

solid state or mechanical relays via ribbon cable from the TCM18 controller. The RM6

includes individual terminal strips which allow the interconnection of individually mounted

heater and ground current sensing transformers. This module is primarily used where

custom current transformers, solid state relays with integral heat sinks, or individual pilot

and mechanical relays are to be used. The module connections for the RM6 are as de-

tailed in the following illustration.

Figure 4: RM6 Wiring and Connections

When receiving a new TraceNet TC Series control panel shipment, it is recommended

that all module connections within the panel be re-torqued to the recommended tightness

levels as provided in the project panel drawing and in Table 1 Chapter 4. Occasionally,

it is possible that handling and shipment can loosen some wiring terminations or

components cables.

Servicing allowed for removable electrical connectors only when the area is known to be

free of explosive atmospheres.

8PN 50312_0414

4Field and Panel Wiring

For a successful installation of a TraceNet TC Series heat tracing control and monitoring

panel, a number of equally critical parts of the system must be installed properly. Areas

requiring close attention are the heat trace and insulation, the RTD temperature sensor

installation, the distribution of the field RTD and power wiring, and the installation and

routing of wiring inside the TraceNet panel.

The heat tracing system installation shall be in accordance with the electrical area clas-

sification requirements as well as shall conform to the latest requirements as detailed in

applicable heat tracing standards, the local Electrical Code and plant standard practices.

Where conflicts arise, contact the project engineer for resolution.

Heat Trace and Insulation Installation

All heat trace circuits and insulation shall be installed in accordance with project instal-

lation details provided. In addition, refer to the Electric Heat Tracing Maintenance and

Troubleshooting Guide (Thermon Form No. 20745) for general procedures and installa-

tion tips.

RTD Installation and Wiring

RTD control sensors should generally be installed on the process lines or in ambi-

ent(where ambient sensing is applied) in a location that is most representative of the

entire heat trace circuit. In general, it is recommended that the sensors not be located

at heat sinks such as pipe supports, pumps, and valves as the control system response

needs to be based on the majority of the process line. The RTD control sensor location

on the process piping should follow the guidelines detailed below.

9PN 50312_0414

Figure 5: RTD Sensor Location

Where limiter RTD sensors are installed on the process piping it should follow the guide-

lines above. In cases where the limiter is to be installed on the heater itself, it is important

to recognize that an offset should be anticipated in the limiter trip value to allow for sen-

sor reading error and overshoot.

As a general rule, field RTD wiring and power wiring should not be routed in the same

conduit or proximity in a tray as the temperature signals can become distorted and result

in improper readings.

Power Distribution Wiring and Breakers

All field power wiring materials used shall be suitable for the intended service and shall

be rated for insulation service temperatures up to and exceeding 221◦F (105◦C) unless

otherwise higher values are noted in project specifications. Power supply wiring from

the power transformers to the power distribution panel and distribution wiring to the heat

trace circuits shall be rated for the heat trace use voltage or higher and sized sufficiently

large in wire size to minimize voltage drop. Circuit breakers if not already supplied in

the TraceNet panel should be selected based on the heat trace cable type being used,

the service voltage, and the circuit current draw characteristics. It is especially important

when using self regulating cable to make sure that the circuit breaker response curve

type is coordinated with the startup characteristic of the heat trace cable in a cold start

condition. All distribution wiring connections should be tightened using a torque indicat-

ing screw driver to the levels indicated in Table 1.

10 PN 50312_0414

Location of Terminals Torque Values (Typical)*

RTB6 5.3 to 7.0 in. lbs. (0.60 to 0.79 N-m)

PM6 12.5 to 13.5 in. lbs. (1.41 to 1.53 N-m)

Distribution Equipment 13.2 to 15.9 in. lbs. (1.49 to 1.80 N-m)

*Required torque values may vary depending on individual panel designs and size of

terminals. Refer to project documentation for additional information.

Table 1: Recommended Torque Values

TraceNet Panel Wiring

TraceNet TC Series panels are configured and prewired into an integrated heat trace

control and monitoring system. Clean terminal strips are provided to facilitate the field

wiring into the panels. Refer to the project specific panel drawings when installing the

field wiring within the panel. Field wiring is conventionally shown by dashed lines. All

field power wiring materials used shall be suitable for the intended service and shall

be rated for insulation service temperatures up to and exceeding 221◦F (105◦C) unless

otherwise higher values are noted in project specifications. All TraceNet components

terminal block connections should be tightened using a torque indicating screw driver to

the levels indicated in Table 1.

Serial Communication Wiring

TraceNet TC Series panels may be linked together for communications with a RS485

communication cable at distances up to 4000 feet (300 m.) or more. In addition, a ter-

mination module should be used at each end of the RS485 network. The recommended

communication cables for use in the RS485 network are as given in Table 2 which fol-

lows.

11 PN 50312_0414

Cables for RS485 Communication

CableType Recommended

120 Ohm, -20 to +60 C 22AWG FHDPE

insulation PVC outer jacket

Belden 3107A or equal

120 Ohm, -30 to +80 C 24AWG PE insula-

tion PVC outer jacket

Belden 9842 or equal

120 Ohm, -70 to +200 C 24AWG Teflon

FFEP insulation Teflon FEP outer jacket

Belden 89842 or equal

Note all these products are designated as 120 ohm impedance for balanced line com-

munication uses.

Table 2: Recommended RS485 Cable Type

12 PN 50312_0414

5The User Interface

The TCM18 functions as the user interface for a TraceNet TC Series control panel net-

work of heat tracing control modules. The TCM18 allows the operator to access oper-

ating control parameters and operating conditions throughout the heat tracing system

network.

There are four display message lines on the TCM18 display. All interfacing to the TCM18

and the heat tracing circuit information is via the dedicated tactile feel membrane touch-

pad and the companion four line LCD display as shown in Figure 6

Figure 6: TCM18 Control and Monitoring Module Front Panel

On power up, the TCM18 will display the following start-up screen message:

THERMON TCM18

COPYRIGHT 2013

Figure 7: TCM18 Start-Up Screen

After this start-up message, the TCM18 will immediately proceed to operation in its SCAN

13 PN 50312_0414

MODE.

The TCM18 will operate in a heat tracing circuit SCAN MODE during normal operation.

That is, the LCD display will automatically scroll through each enabled heat tracing cir-

cuit number, indicating the actual measured temperature and the control set point for

maintain temperature on the first two display screen lines. The third display screen line

will indicate the heater status (ON % or OFF) and the heat tracing circuit heater current

value. The fourth display screen line will indicate any alarm(s) present on the circuit

displayed. Where multiple alarm events occur on a circuit, the TCM18 will display only

one alarm message at a time until all have been cleared. A typical SCAN MODE screen

when the heat tracing circuit is operating normally is as shown below in Figure 8:

CKT 7 TEMP= 61◦C

MAINTAIN TEMP= 60◦C

HEATER ON 80% 12.0A

Figure 8: Typical TCM18 information when in SCAN MODE

Note that the fourth message line on the display screen will be empty as long as there are

no alarm or trip conditions present on a given circuit. During SCAN MODE, the TCM18

will sequence through all enabled heat tracing circuits beginning with the first circuit and

then loop back to the first circuit after displaying the last circuit and repeat the scanning

process.

To access information on a specific heat tracing circuit, press the appropriate yellow or

red key. Pressing these keys will directly access the information and functions associ-

ated with that key. As a typical example, press the MAINTAIN TEMP key as shown in

Figure 9.

14 PN 50312_0414

Figure 9: TCM18 Touch Pad

This will result in the display screen response as illustrated below in Figure 10.

CIRCUIT = 7

MAINTAIN TEMPERATURE

MAINT= 49◦C

Figure 10: TCM18 LCD Response

The TCM18 has an electronic password security provision. To access the programming

mode, enter the 4 digit numerical security code. If no code has been entered, press the

PROG key followed by the ALARM ACK key and subsequently followed by the PROG

key. Next, successively select a numerical code using the UP and DOWN arrow keys

along with the ENTER key. An entry of 0000 will deactivate the security code feature.

Note that once a security code has been entered, the user has unlimited access as long

as activity is present. A period of inactivity of 30 minutes or more will result in program-

ming access being denied. At this point, re-entry of the security code will be required. If

the security code is forgotten at some future date, enter a value of 1954 (during the first 5

15 PN 50312_0414

minutes after power is applied to the TCM18) as the security code, then a new code may

be entered by pressing the ALARM ACK key and subsequently followed by the PROG

key.

To program circuit control settings or control parameters, multiple keys in sequence will

need to be pressed. For example, to change the settings associated with the MAINTAIN

TEMP key, first press the green PROG key.

Figure 11: TCM18 PROG Key

The Display now reads as shown below:

PROGRAM MODE ENABLED

SELECT FUNCTION KEY

Figure 12: Program Mode Enabled

Press the MAINTAIN TEMP key.

16 PN 50312_0414

Figure 13: MAINTAIN TEMP Key

The Display now reads as shown below with the flashing cursor zrepresenting the active

data entry field:

PROGRAM CIRCUIT = 7z

MAINTAIN TEMPERATURE

MAINT= 49◦C

Figure 14: Programming Maintain Temperature

Pressing the green UP or DOWN Arrow programming keys followed by the green EN-

TER key allows the selection of the heat tracing circuit to program.

17 PN 50312_0414

Table of contents

Other Thermon Control System manuals

Popular Control System manuals by other brands

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SC-SL4-AE installation manual

Western Innovator

Western Innovator FHM2 SERIES Installation and operating instructions

TIS

TIS RLY-8CH-16A installation manual

Lutron Electronics

Lutron Electronics RadioRA 2 Commisioning Checklist

Hubbell

Hubbell Microprocessor Radio Locomotive Control... Brochure & specs

Carson

Carson Reflex Wheel Pro instruction manual