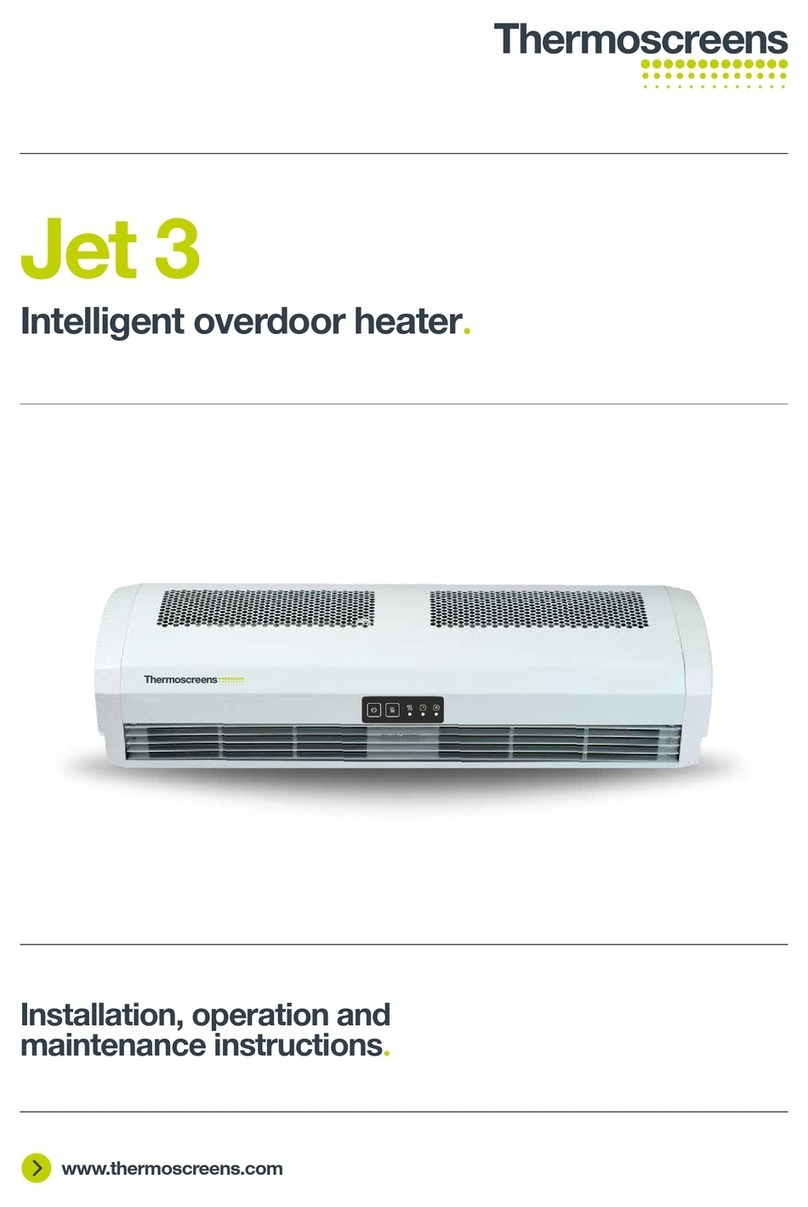

JET 3 2.25/1.125 kW

JET 6 4.91/2.455 kW

L N E

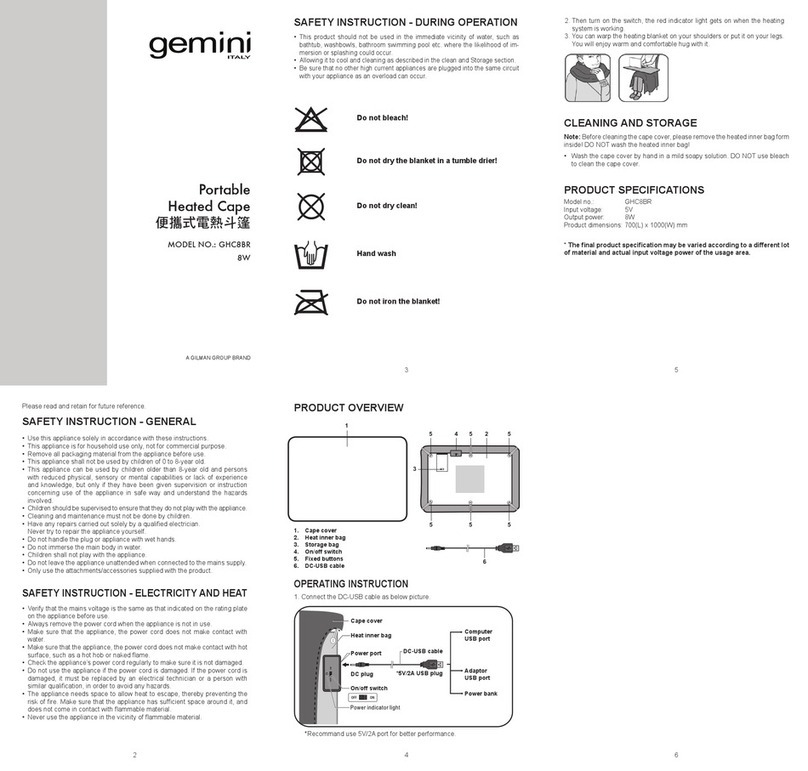

Ensure that the supply cables, circuit breakers and other electrical

installation equipment are correctly sized for the

DTAC being installed, see Table 1. For each DTAC a single phase local

isolator with a contact separation on both poles of at least 3mm must be

fitted to the supply wiring (the isolator must be fitted within an

accessible position). The DTAC should be connected to a 208V 2-pole

AC 60Hz electrical supply and must be earthed. Remove the two outer

M4 x 12mm pan head Philips screws atop the DTAC and release the

power connector plate. Fit cable gland to power connector plate. Insert

electrical supply cable via cable gland (see Figure 5) and tighten gland

around cable.

Figure 5: Electrical Connection

Connect each of the cables as follows:

Live brown cable to terminal marked L or L1

Neutral blue cable to terminal marked N or L2

Earth green/yellow cable to terminal marked PE

Position the electrical supply cables as they come out of the terminal

block as shown in Figure 5. Ensure only sufficient cable is pulled

through to enable connection to terminal block and to avoid excess

cable coming into contact with any moving parts. Carefully insert all

cables through the rectangular hole in the top of the DTAC and refit the

power connector plate. Ensure mains supply cable is correctly and

sufficiently strained by the plastic cable gland.

service. Before leaving site it is important that the sliding window DTAC

installation and these instructions are “Handed-Over” to the end user or

their representative and the operation of it is fully explained and that

they understand how it operates.

THERMAL SAFETY CUT

-

OUTS

If the DTAC exceeds normal operating temperature the thermal safety

cut-outs will operate and isolate electrical supply to the heating

elements. Thermoscreens recommend only competent qualified

persons service the DTAC.

To reset the thermal safety cut-outs disconnect electrical supply to the

DTAC, determine and resolve the cause of the fault. Allow DTAC

sufficient time to cool before restoring supply. If the fault persists

arrange for a competent technician to attend site and investigate. In

order to avoid a hazard due to inadvertent resetting of the thermal cut-

out, this appliance must not be supplied through an external switching

device, such as a timer, or connected to a circuit that is regularly

switched on and off by the utility.

SERVICE

&

MAINTENANCE

Always disconnect and isolate the main electrical supply before

installing, maintaining or repairing this equipment. All

maintenance/repairs should only be carried out by a competent

electrician or Thermoscreens appointed technician. To ensure the

DTAC operates efficiently, the air inlet and outlet grilles, fan impellers,

housings and motors must be kept free of dust and debris. Regularly

vacuum and clean any build-up of dirt and debris within the DTAC

(please note that the motor is permanently lubricated and require no

additional lubrication). Once the DTAC has been cleaned check all

electrical connections within the unit ensuring terminals are tight and

that crimped connections have not become loose. If the outer casing

requires cleaning this should be carefully done using a warm soft cloth.

Do not use solvents or abrasive materials. Reconnect the electrical

supply and fully function test the DTAC to ensure correct operation.

WARRANTY

If any problems are encountered, please contact your installer or

supplier. All units are covered by a one year warranty. Subject to

availability we undertake to repair or exchange this product.

Care has been taken in compiling these instructions to ensure they are

correct, although Thermoscreens disclaims all liability for damage

resulting from any inaccuracies and/or deficiencies in this

documentation. Thermoscreens retain the right to change the

specifications stated in these instructions.

Conforms to: CAN CSA-C22.2 no.46-13 & UL 2021(Ed.3): 2013

Figure 6: Jet 6 Wiring Diagram

O

PERATION

Control of the DTAC is achieved by using the three integral switches

mounted adjacent to the discharge grille.

Switch Action

I Fan on

I + Middle Fan + half heat

I + Middle + End Fan + full heat

The DTAC panels are coated in an easy to peel protective film. Please

ensure all the protective film is removed before the DTAC is put into

2

Thermoscreens Canada 11 King St. Unit #3

Barrie, Ontario Canada L4N 6B5

Toll Free: 877 445 3739 Tel: 705 797 0007 Fax: 705 797 0013

e-mail: salescanada@thermoscreens.com www.thermoscreens.com