WWW.THERMOSTAHL.PL

- 8 -

MTX-400 and MTX-400 KTS burner technical documentation

Chimney

The exhaust gas ventilation system is an important component of the entire heating system. For safety reasons, and to

ensure proper operation of the burner and boiler, the chimney structure should be designed and built by persons properly

authorised to do this. The construction and mode of execution of the chimney need to be in line with the relevant local

provisions of construction laws in force.

Chimney line draught

In order to ensure proper operation of the burner, it is recommended that a chimney draught regulator be installed within

the exhaust gas ventilation line. This regulator should be adjusted so that the underpressure in the combustion chamber

during operation would not exceed the value of 0.1 mbar.

Exhaust gas temperature measurement

Exhaust gas temperature measurement should be done using a manual or electronic thermometer, or with the use of an

exhaust gas analyser unit. The measurement is taken through an opening, diameter 8, executed on the exhaust gas

ventilation duct, at a distance of double the duct diameter from the heating appliance.

The temperature sensor should be placed in the centre of the gas stream, where the temperature is highest. the

measured temperature value should be between 160 °C and 240 °C. Above this range, chimney losses begin to increase

and the device efficiency falls.

Basic adjustment procedures of the burner

The burner adjustment work should be done necessarily using results of analyses of the exhaust gases. Only in this way

may it be guaranteed that the best values of combustion are ensured, at the same time adhering to a maximum purity of

the exhaust gases, in order to protect the environment.

In order to execute the exhaust gas analysis correctly, it is necessary to have the following devices at hand:

precise chimney draught sensor

soot analysis pump

carbon dioxide analyser

exhaust gas thermometer.

All the measurement values should be recorded in the burner inspection form. The measurements need to be taken at the

operating temperature of the heating appliance. In case of water-based boilers, the water temperature in the boiler must

be at least 60 °C. A condition of achievement of proper measurement results is tightness of the boiler and the exhaust gas

ventilation line. The measurement opening, diameter 8, should be made downstream from the heating appliance on the

exhaust gas ventilation duct, at a distance of double the diameter of the duct, in which it is made

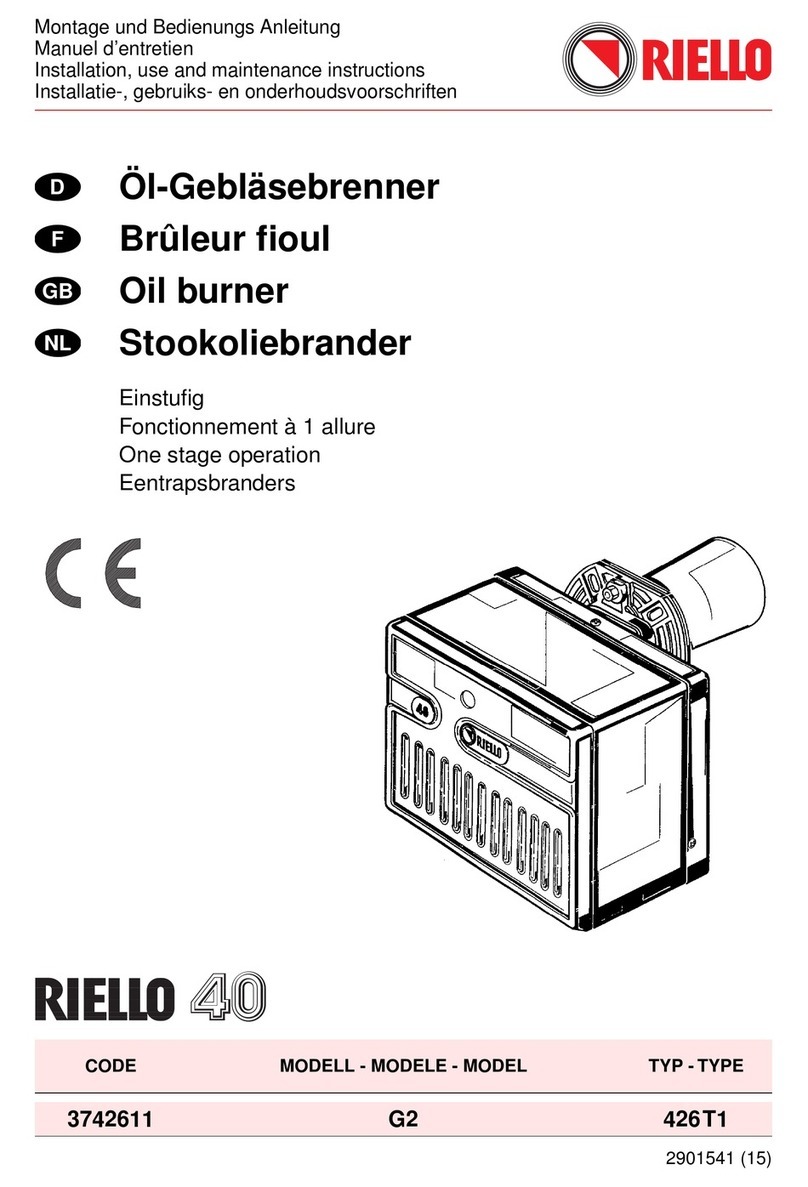

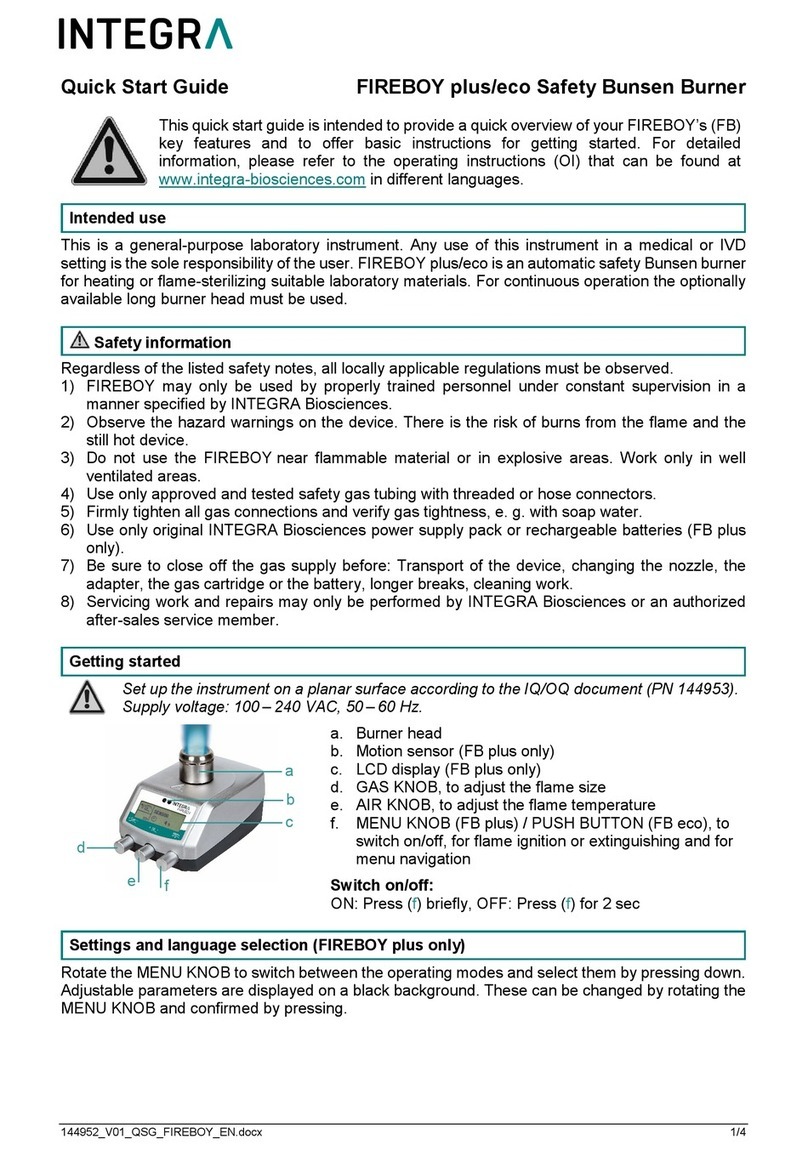

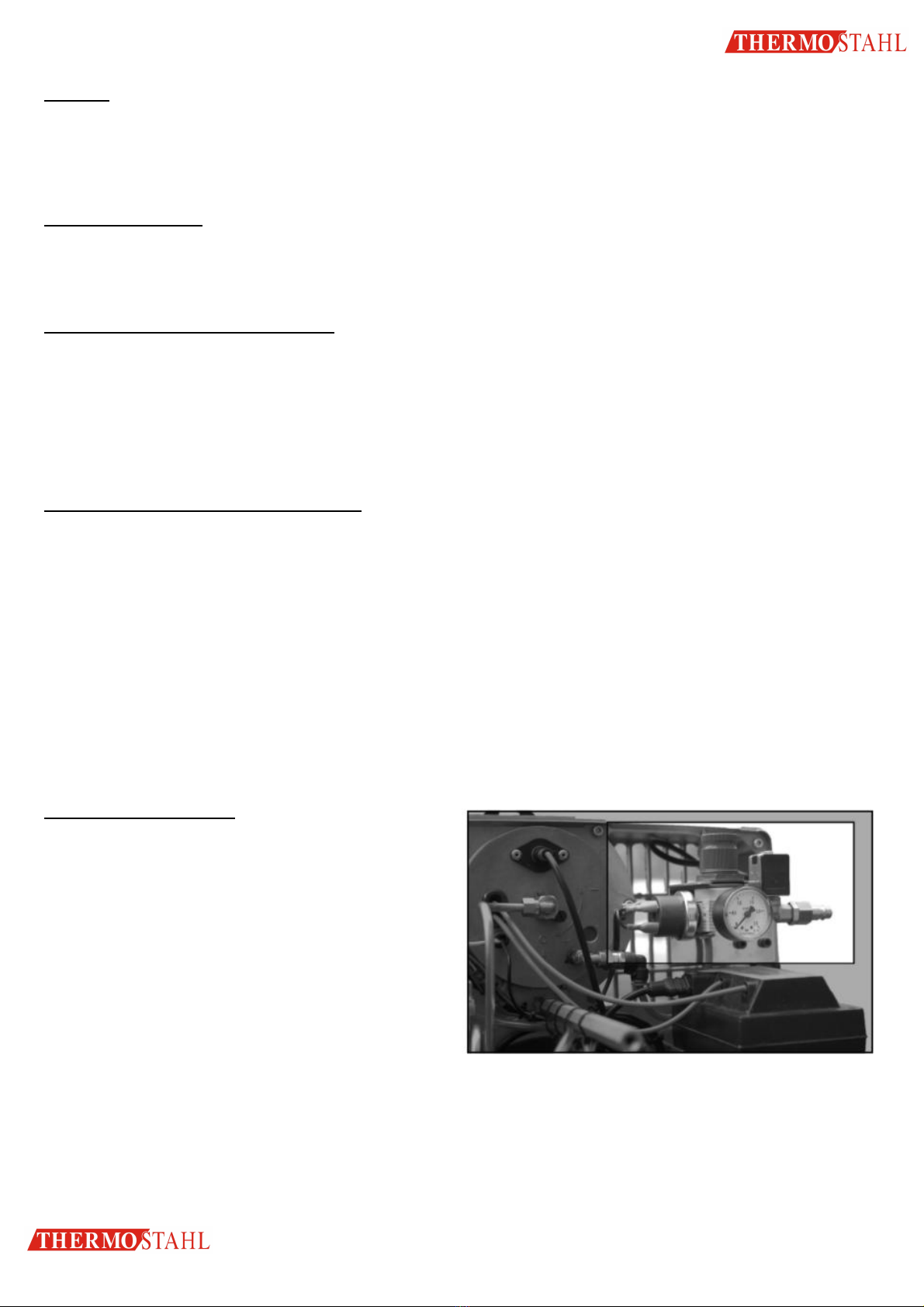

Spray air pressure setting

The spray air pressure should be set on the reducer, fig. 9,

following the start-up phase. The correct air pressure value

is 1.2 bar. This value is appropriate for the full burner power

capacity range.

Fig. 9