RENEWABLE HEATING & COOLING TECHNOLOGY

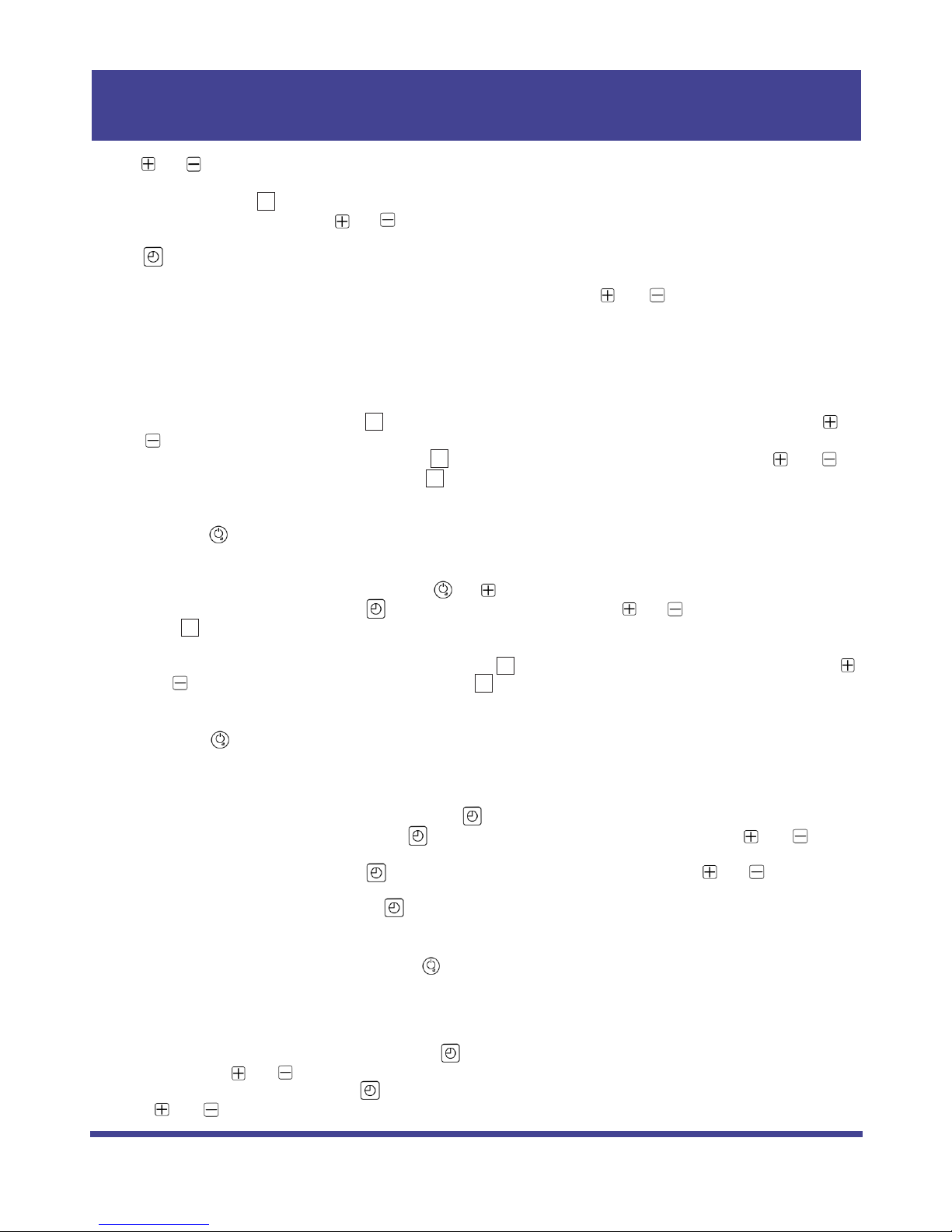

and adjust button

>Turn pages up and down to check,modify parameters.

>Combining with to query and change parameters.

>Under unit ON status,press and to set temperature in current mode.

Timer button

Press this button for 10 seconds to set clock.

Press this button to enter into Timer ON/OFF setting mode,combing with and buttons to set 2 groups

of Timer ON/OFF.

M

LCD operation

Parameter query and settings

>User parameter query and settings(available when unit ON or OFF).

>On main interface screen, press for 3 seconds to enter into user parameter query interface, press and

buttons to check each parameter.

>On user parameter query interface, press to enter into parameter setting interface, press and

buttons to modify parameter value, press again to go back to parameter query status.

>Under user parameter query or setting interface, if there is no any press on buttons within 30 seconds, user

parameter query or setting interface will automatically exit and return back to main operation interface.

Can press to go back to main operation interface.

Factory parameter query and settings(available when unit ON or OFF).

>On main operation interface screen,press and for 3 seconds to enter into factory parameter password

interface,on this interface, press to switch password digit and press and buttons to modify value,

press to confirm password input. If password is correct, will enter into factory parameter query interface

(factory parameter query password:0814, manufacturer setting password:8563).

>On factory parameter query interface screen, press to enter into parameter setting interface, press

and buttons to modify parameter value, press to go back to factory parameter query interface.

>Under factory parameter query or setting interface, if there is no any press on buttons within 30 seconds,

user parameter query or setting interface will automatically exit and return back to main operation interface.

Can press to go back to main operation interface.

M

M

M

M

M

M

Clock settings

>Under main operation interface screen, press for 5 seconds to enter into clock setting interface.

On clock setting interface screen,press on time,the “hour” digit is flashing,then press and buttons

to modify value for “hour”.

>After setting “hour” digit,press again,the “minute” digit is flashing,then press and buttons to

modify value for “minute”.

>After setting “minute” digit, press again to confirm clock settings and go back to main operation interface.

Under clock setting interface, if there is no any press on buttons within 30 seconds,will automatically confirm

current clock settings and go back to main operation interface.

>Under clock setting interface, can press to confirm clock settings and go back to main operation interface.

Timer settings

>On main operation interface screen, press to enter into Timer setting interface.

>Then press and to set Timers, there're 4 groups of Timers.

>When Time 1 is flashing, press to enter into Timer 1 ON “hour” digit setting which will flash, then press

and buttons to set value for “hour” digit.

Page 10