Thies CLIMA 7.1419.21 81 Series User manual

Silicon Irradiance Sensor

Instruction for Use

7.1419.21.x81

7.1419.20.x81

Dok. No. 022040/02/23

T H E W O R L D O F W E A T H E R D A T A

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 2 von 14

Safety Instructions

•Before operating with or at the device/product, read through the operating instructions.

This manual contains instructions which should be followed on mounting, start-up, and operation.

A non-observance might cause:

- failure of important functions

- endangerment of persons by electrical or mechanical effect

- damage to objects

•Mounting

, electrical connection and wiring of the device/product must be carried out only by a qualified

technician who is familiar with and observes the engineering regulations, provisions and standards ap-

plicable in each case.

•Repairs and maintenance may only be carried out by trained staff or Adolf Thies GmbH & Co. KG.

Only components and spare parts supplied and/or recommended by Adolf Thies GmbH & Co. KG

should be used for repairs.

•Electrical devices/products must be mounted and wired only in a voltage-free state.

•Adolf Thies GmbH & Co KG guarantees proper functioning of the device/products provided that no

modifications have been made to the mechanics, electronics or software, and that the following points

are observed:

•All information, warnings and instructions for use included in these operating instructions must be

taken into account and observed as this is essential to ensure trouble-free operation and a safe condi-

tion of the measuring system / device / product.

•The device / product is designed for a specific application as described in these operating instructions.

•The device / product should be operated with the accessories and consumables supplied and/or rec-

ommended by Adolf Thies GmbH & Co KG .

•Recommendation: As it is possible that each measuring system / device / product may, under certain

conditions, and in rare cases, may also output erroneous measuring values, it is recommended using

redundant systems with plausibility checks for security-relevant applications.

Environment

•As a longstanding manufacturer of sensors Adolf Thies GmbH & Co KG is committed

to the objectives of environmental protection and is therefore willing to take back all

supplied products governed by the provisions of "ElektroG" (German Electrical and

Electronic Equipment Act) and to perform environmentally compatible disposal and

recycling. We are prepared to take back all Thies products concerned free of charge if

returned to Thies by our customers carriage-paid.

•Make sure you retain packaging for storage or transport of products. Should packag-

ing however no longer be required, please arrange for recycling as the packaging ma-

terials are designed to be recycled.

Documentation

•© Copyright Adolf Thies GmbH & Co KG, Göttingen / Germany

•Although these operating instructions have been drawn up with due care, Adolf Thies GmbH & Co

KG can accept no liability whatsoever for any technical and Typeographical errors or omissions in this

document that might remain.

•We can accept no liability whatsoever for any losses arising from the information contained in this doc-

ument.

•Subject to modification in terms of content.

•The device / product should not be passed on without the/these operating instructions.

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 3 von 14

Table of contents

1Models............................................................................................................................ 4

2Application...................................................................................................................... 4

3Setup and Mode of Operation......................................................................................... 4

3.1 Mechanical design.....................................................................................................5

3.2 Optional temperature measurement ..........................................................................5

4Recommendation Side Selection / Standard Installation................................................. 5

5Installation....................................................................................................................... 5

5.1 Mechanical Mounting.................................................................................................5

5.2 Electrical Connection.................................................................................................6

5.2.1 Cable ................................................................................................................. 6

5.2.2 Connection recommendation for the cable shield............................................... 6

5.2.3 Plug and Cable Mounting................................................................................... 6

5.3 Connection Diagram..................................................................................................7

6Maintenance................................................................................................................... 7

7Interface.......................................................................................................................... 7

7.1 Supported Settings....................................................................................................8

7.2 Modbus Specification ................................................................................................8

8Technical Data...............................................................................................................12

9Dimensional Drawing.....................................................................................................12

10 EC-Declaration of Conformity .....................................................................................13

11 More Information / Documents as download...............................................................14

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 4 von 14

1 Models

Scope of supply:

1 x Silicon Irradiance Sensor

1 x Instruction for Use

1 x Cable socket (mating connector) is included in the scope of delivery, if no cable is sold.

The instructions for use are available for download under the following link:

https://www.thiesclima.com/db/dnl/7.1419.2x.xxx_Silicon_Irradiance_Sensor_en.pdf

2 Application

Silicon irradiance sensors (Si sensor) show a but rugged and reliable solution for the meas-

urement of solar irradiance, especially for the monitoring of Photovoltaic (PV) systems. Based

on the construction of the sensor element corresponding to a PV module they are ideal as

reference for the monitoring of PV systems. Especially the spectral response comparable to

PV modules as well as the similar inclination error (incident angle modifier) allow an exact

analysis of PV energy yields using Si sensor data.

3 Setup and Mode of Operation

A silicon solar cell can be used as an irradiance sensor, because the short-circuit current is

proportional to the irradiance. Our sensors are built out of a monocrystalline Si solar cell con-

nected to a shunt. Due to the low resistance of the shunt the cell operates next to short-circuit.

To minimize influences of temperature to the measuring signal all of our sensors

have an active temperature compensation via a temperature sensor laminated to the back

surface of the solar cell.

All sensors are calibrated in artificial sunlight against a reference cell calibrated

at the Physikalisch-Technische Bundesanstalt (PTB, National Metrology Institute of

Germany).

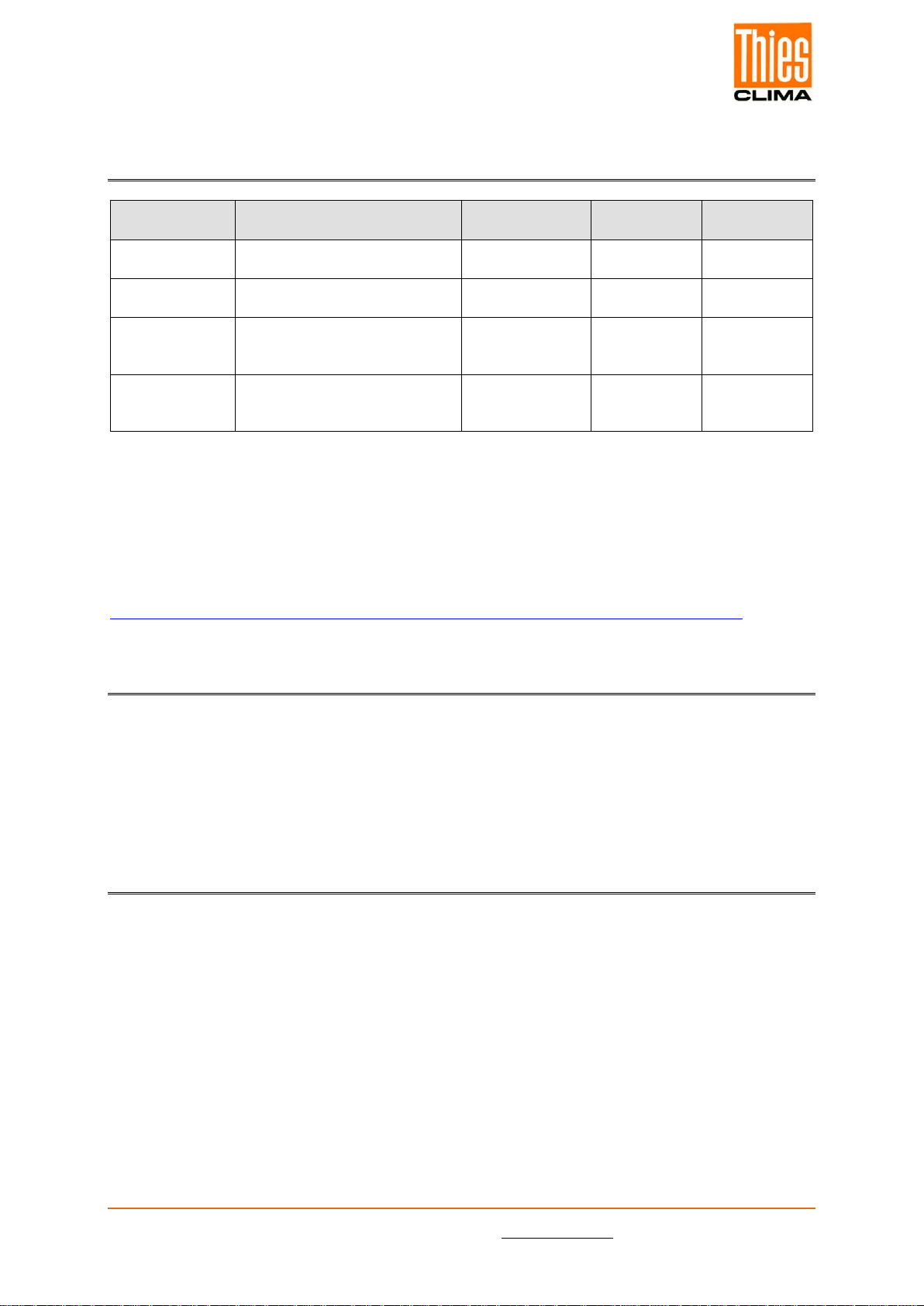

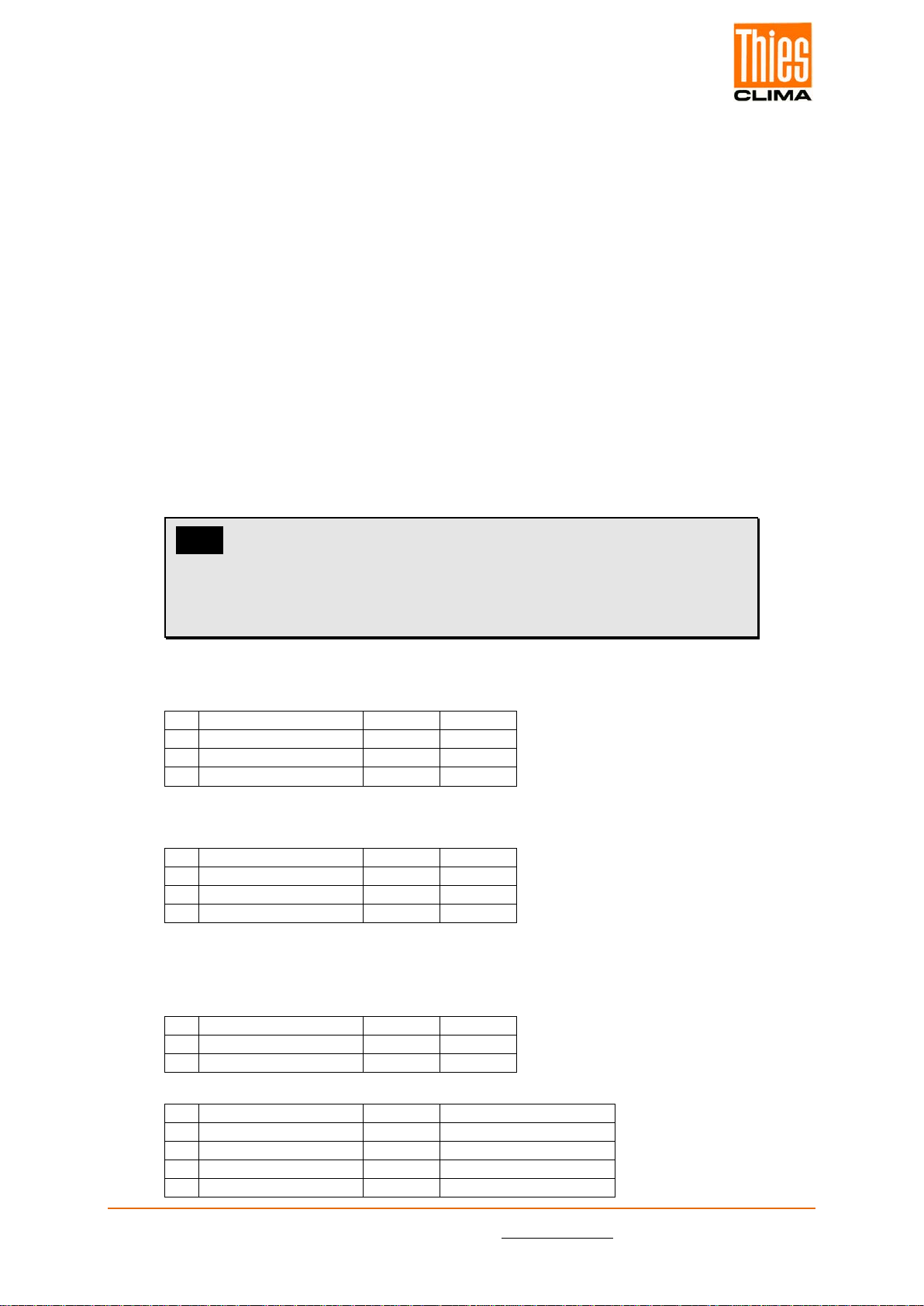

Article No.

Description

Interface /

Data output

Supply

Connection

type

7.1419.20.081

Solar irradiance incl. cell tem-

perature sensor

RS 485 /

Modbus RTU

10 … 28V DC

3m calbe

7.1419.20.781

Solar irradiance incl. cell tem-

perature sensor

RS 485 /

Modbus RTU

10 … 28V DC

Plug

7.1419.21.081

Solar irradiance incl. cell tem-

perature and

module temperature sensor

RS 485 /

Modbus RTU

10 … 28V DC

3m cable

7.1419.21.781

Solar irradiance incl. cell tem-

perature and

module temperature sensor

RS 485 /

Modbus RTU

10 … 28V DC

Plug

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 5 von 14

3.1 Mechanical design

The solar cell is embedded in Ethylen-Vinyl-Acetat (EVA) between glass and Tedlar. The lam-

inated cell is integrated into a case of powder-coated aluminium. Therefore the sensor con-

struction is comparable to that of a standard PV module. The electrical connection is realized

by a 3m cable or a water proof (IP67) connector.

3.2 Optional temperature measurement

Additionally to the irradiance measurement our silicon sensors are able to measure the tem-

perature of the solar cell using a temperature sensor laminated to the back of the cell. This

solar cell temperature can approximately be used as module temperature.

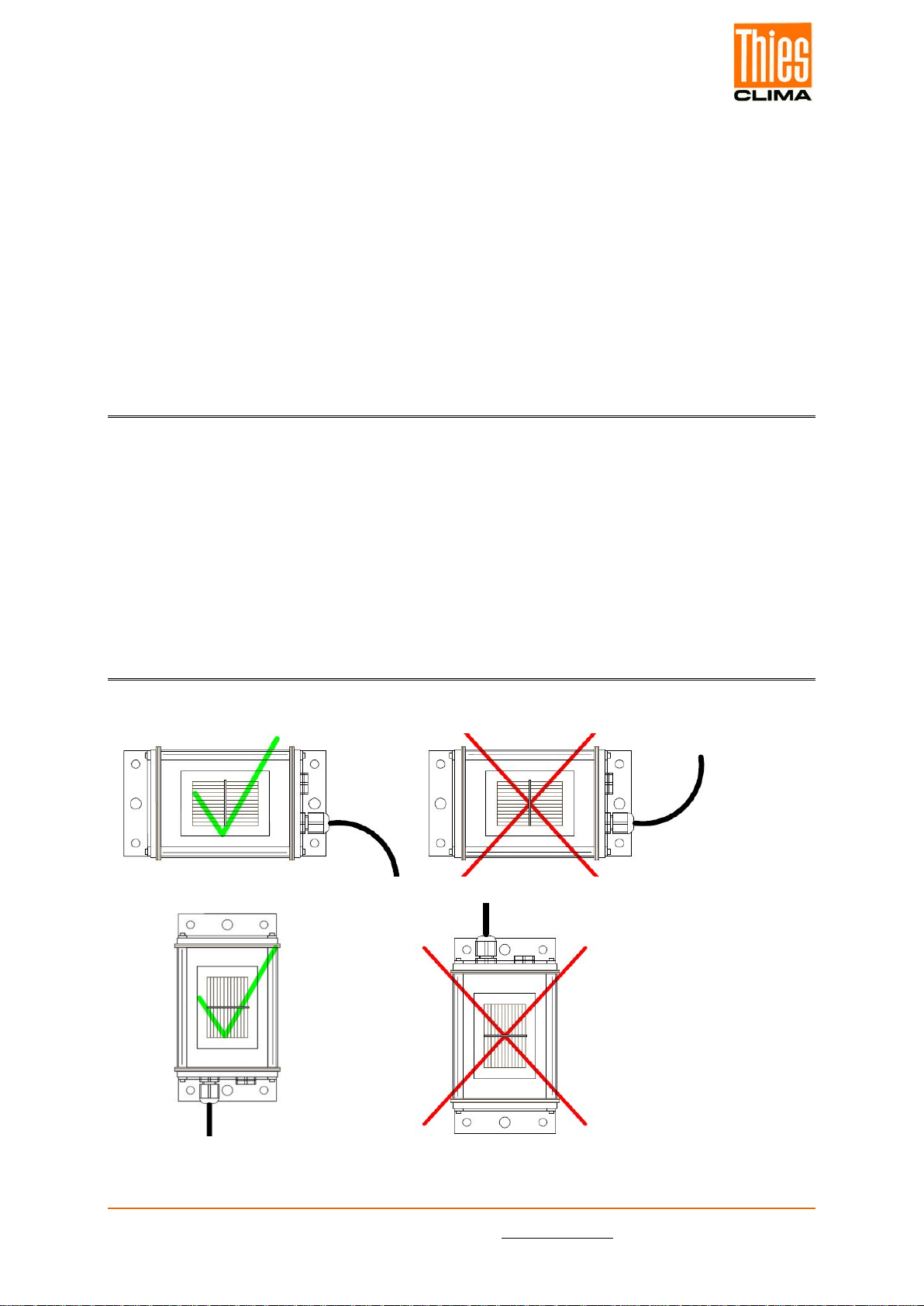

4 Recommendation Side Selection / Standard Installation

Si sensors that are used for monitoring PV installations must be installed with the same align-

ment and inclination as the PV generator. The mounting location should be free of shading as

far as possible. To facilitate maintenance and cleaning of the Si sensor, the Si sensor should

be mounted in an easily accessible place.

The mounting location at a PV generator must be selected such that snow cannot jeopardise

the Si sensor as it slides off. For this reason do not mount along the drip edge on the PV

generator.

5 Installation

5.1 Mechanical Mounting

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 6 von 14

5.2 Electrical Connection

The sensors are designed for safety extra-low voltage (SELV) operation. The maximum power

of the voltage supply is 50 VA.

Reversing the polarity or mixing up the connections on the Si sensor may cause irreversible

damage to the sensor. The cable shield is to be connected to PE during installation.

5.2.1 Cable

Core count / Cross-section / Type

Cable 4 x 0,25mm² LIYCY - BLACK, UV-resistant

5.2.2 Connection recommendation for the cable shield

The connecting cable should always be laid separated from, e.g. main DC cables or AC cables.

The connecting cable is to be laid so it is fixed. The minimum bending radius of 15 x cable

diameter (ø approx. 5mm) is to be observed. The voltage drop at the cable has to be consid-

ered when calculating the maximum cable length.

The pressure equalisation element must not be damaged. The cable gland is not allowed to

be undone or tightened by the user. The housing for the Si sensors is not allowed to be opened,

because as a consequence, the housing will no longer be sealed after it is closed. If the hous-

ing is nevertheless opened, no liability for the sealing can be accepted.

The surge protection concept must be adapted to the specific local situation. This means, for

instance, that the measuring cables must be equipped with a separate surge arrester at the

entry to a building. The sensor must be integrated into the lightning protection concept.

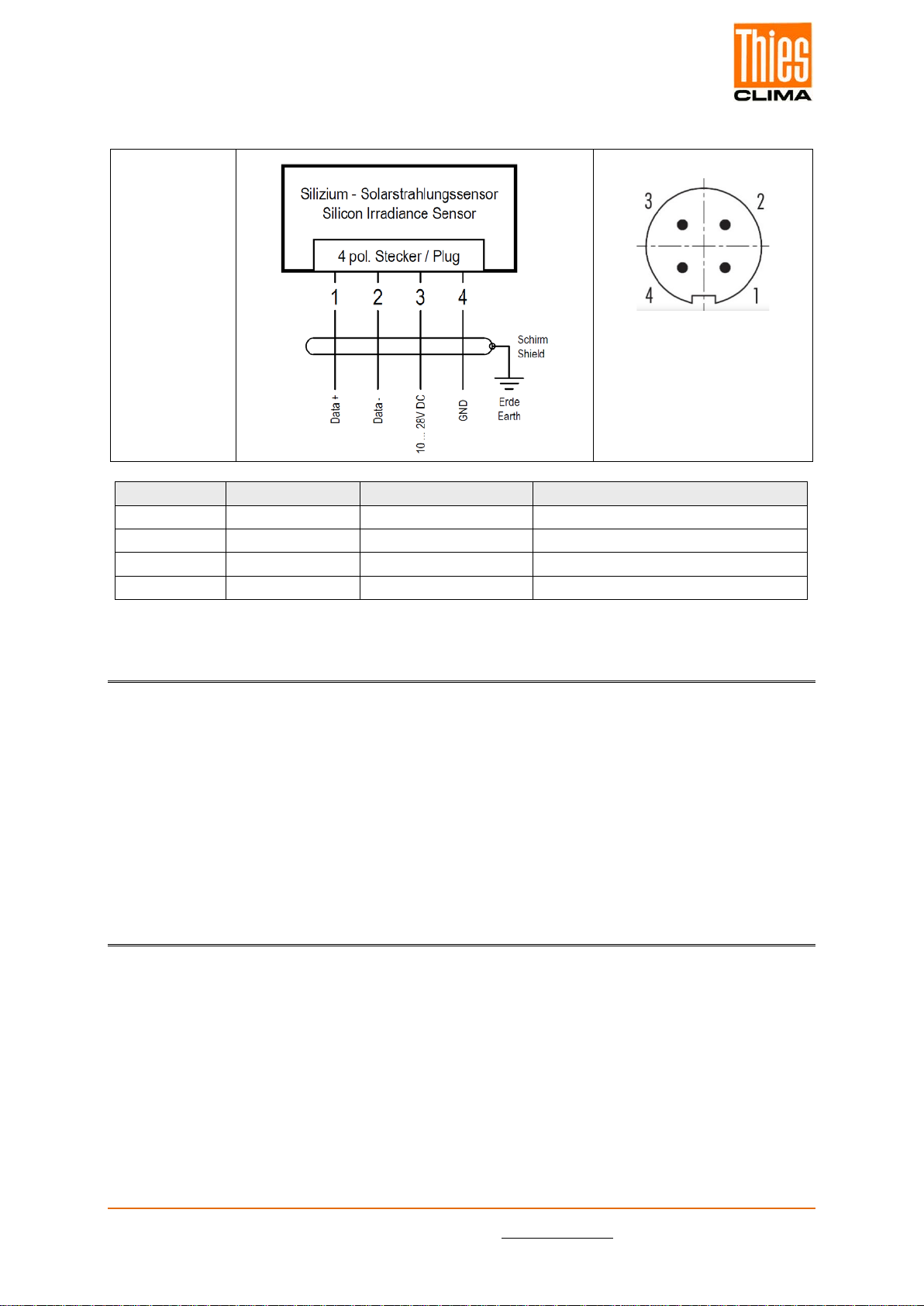

5.2.3 Plug and Cable Mounting

Coupling socket, Type: Binder, Serie 712 – 4 pol

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 7 von 14

5.3 Connection Diagram

Order no.

7.1419.20.081

7.1419.20.781

7.1419.21.081

7.1419.21.781

PIN

Wire color

Name

Function

1

White

Data+

RS485 Data +

2

Brown

Data-

RS485 Data -

3

Green

VCC

Power supply +10 ... 28V DC

4

Yellow

GND

Ground

6 Maintenance

Scope of the regularly check (at least every 2 years): Cleaning of solar cell, external damage,

mechanical fastening, cable laying and any damage to the cable.

In the report IEA-PVPS T13-03: 2014 "Analytical Monitoring of Grid-connected Photovoltaic

Systems" an interval of 1 to 2 weeks is recommended.

Should damage be found that degrades the function or safety, the sensor is to be replaced.

A recalibration is recommended at least every 3 years.

7 Interface

The interface consists of an RS485 connection with the following settings:

•9600 Baud (the Baud rate can be set).

•8 Data bits.

•No parity.

•1 Stop bit.

•Data in binary format (command interpreter: MODBUS RTU).

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 8 von 14

7.1 Supported Settings

Baud Rate: 1200, 2400, 9600, 19200, 38400, 57600)

Parity: None, Even, Odd

Stop Bit: 1, 2 (only at no parity)

Factory Default: 9600 Baud, 8N1, address: 1

The sensor offers the function code 0x46 of the Modbus protocol for setting the bus protocol

parameters. Should you need any further information, please do not hesitate to contact us..

7.2 Modbus Specification

References:

- Modbus over Serial Line Specification and Implementation Guide V1.02

- Modbus Application Protocol Specifiation V1.1b

Transfer mode:

- Modbus RTU.

Die Sensoren starten den Modbus-Betrieb 4 Sekunden nach dem Einschalten.

Supported short codes:

- 0x03: Read holding register

- 0x04: Read input register

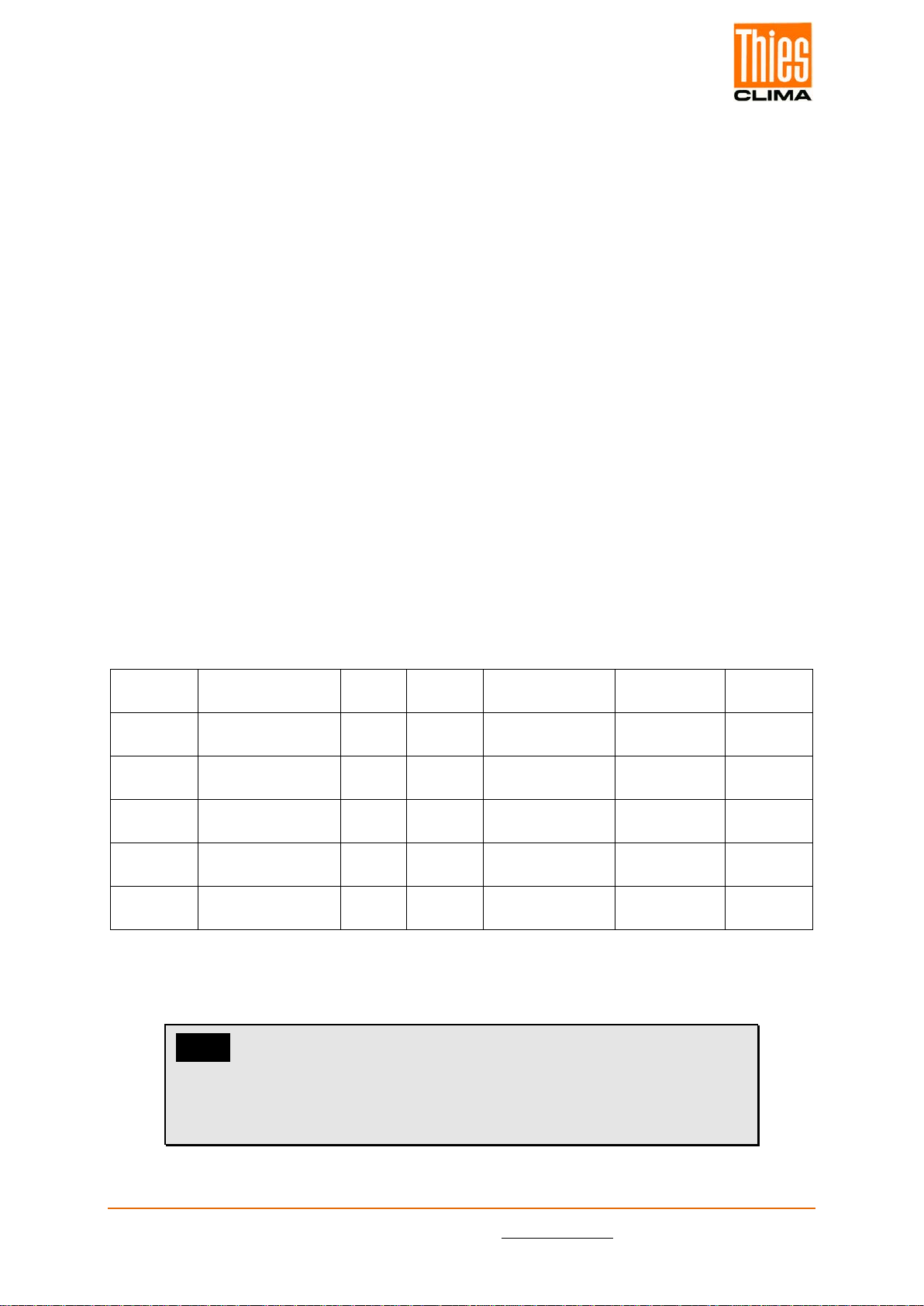

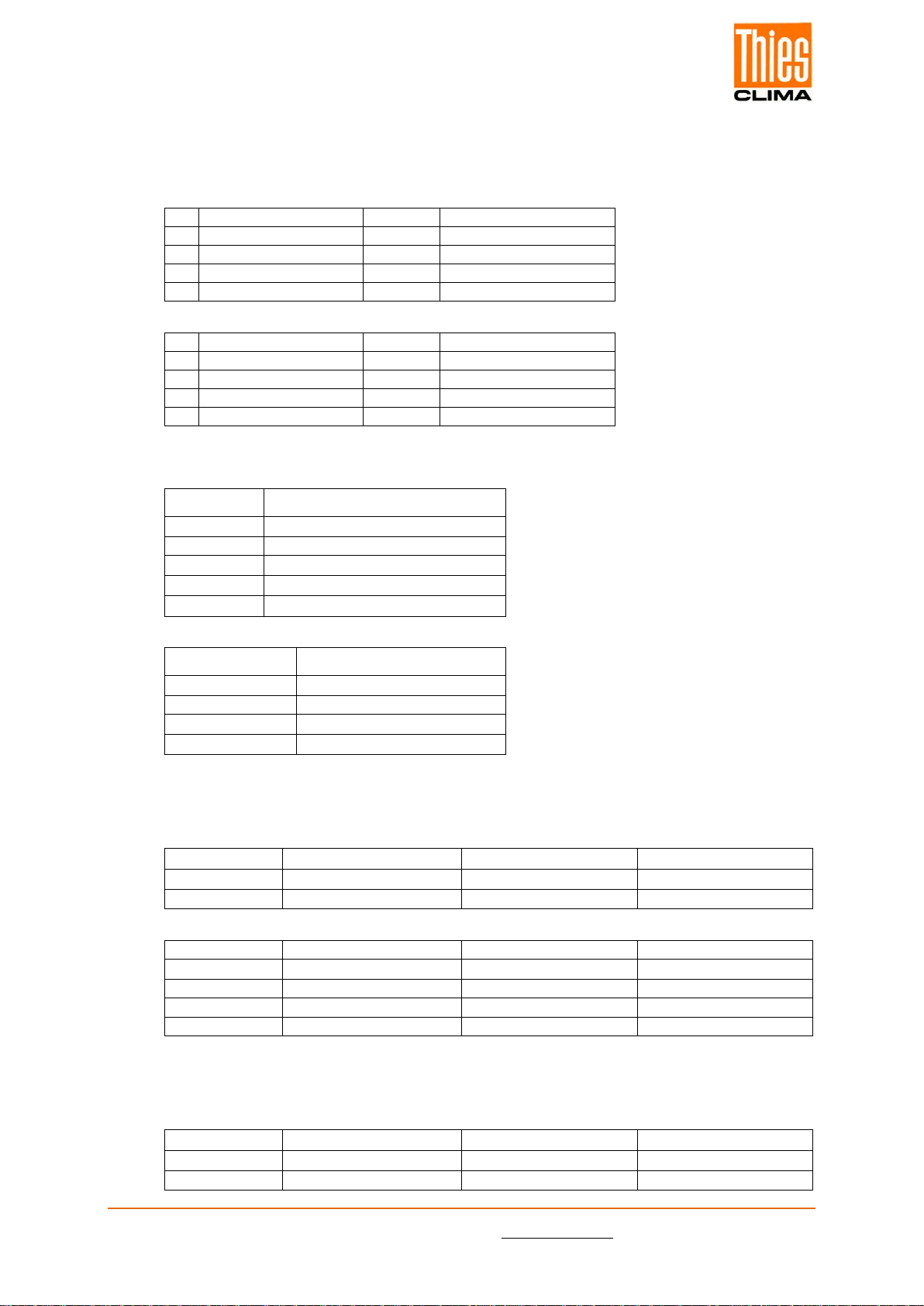

Register

Value

Gain

Offset

Phys. Range

Data Range

Data

Type

0000

Cell Temperature

in W/m²

0,1

0

0…1500W/m² 1

0…1500 1

UINT16

0003

Wind Speed in

m/s

0,1

0

0…80m/s

0…800

UINT16

00072Cell Temperature

in °C 0,1 0 -40…+90 °C -400…+900 INT16

00082External Temper-

ature no. 1 in °C 0,1 0 -40…+90 °C -400…+900 INT16

0009

3

External Temper-

ature no. 2 in °C

0,1

0

-40…+90 °C

-400…+900

INT16

1) Up to Firmware Version 1.52 is range 0…1400 W/m²

2)Only available from Firmware Version 1.53

3)Only available from Firmware Version 2.01

Note:

The Register 0003, 0008 and 0009 are optional for some sensor

types. If your sensor does not support this register, it will return

the value 0 for this register

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 9 von 14

0x08: Diagnostics

Sub function 0x00: Return Query Data

Sub function 0x01: Restart Communications Option

Sub function 0x04: Force Listen Only Mode

Sub function 0x0A: Clear Counters

Sub function 0x0B: Return Bus Message Count

Sub function 0x0C: Return Bus Communication Error Count - Sub function 0x0D: Re-

turn Slave Exception Error Count

Sub function 0x0E: Return Slave Message Count

Sub function 0x0F: Return Slave No Response Count

Sub function 0x10: Return Slave NAK Count

Sub function 0x11: Return Slave Busy Count

Sub function 0x12: Return Bus Character Overrun Count

0x46: Communication Parameter

Info:

These settings will take effect after restart of the sensor by

power on reset or restart communication command (function

0x08, Sub function 01).

Sub function 04: Write Module Address

Request:

00

Address

1 Byte

1 to 247

01

Function Code

1 Byte

0X46

02

Sub Function Code

1 Byte

0x04

03

New Address

1 Byte

1 to 247

Response:

00

Address

1 Byte

1 to 247

01

Function Code

1 Byte

0X46

02

Sub Function Code

1 Byte

0x04

03

New Address

1 Byte

1 to 247

- Sub function 05: Read Communication Parameter

Request:

00

Address

1 Byte

1 to 247

01

Function Code

1 Byte

0X46

02

Sub Function Code

1 Byte

0x05

Response:

00

Address

1 Byte

1 to 247

01

Function Code

1 Byte

0X46

02

Sub Function Code

1 Byte

0x05

03

Baud rate

1 Byte

0 to 4, see table below

04

Parity / Stop Bit

1 Byte

0 to 3, see table below

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 10 von 14

- Sub function 06: Write Communication Parameter

Request:

00

Address

1 Byte

1 to 247

01

Function Code

1 Byte

0X46

02

Sub Function Code

1 Byte

0x05

03

Baud rate

1 Byte

0 to 4, see table below

04

Parity / Stop Bit

1 Byte

0 to 3, see table below

Response:

00

Address

1 Byte

1 to 247

01

Function Code

1 Byte

0X46

02

Sub Function Code

1 Byte

0x05

03

Baud rate

1 Byte

0 to 4, see table below

04

Parity / Stop Bit

1 Byte

0 to 3, see table below

Communication Parameter Setting Sub Function 05 and 06

Baud Rate

Value

1200

0

2400

1

9600

2

19200

3

38400

4

Parity / Stop Bit

Value

8N1 (10 Bit)

0

8N2 (11 Bit)

1

8E1 (11 Bit)

2

8O1 (11 Bit)

3

Sub function 07: Hardware and Firmware Version

Request:

00

Address

1 Byte

1 to 247

01

Function Code

1 Byte

0x46

02

Sub Function Code

1 Byte

0x07

Response:

00

Address

1 Byte

1 to 247

01

Function Code

1 Byte

0x46

02

Sub Function Code

1 Byte

0x07

03

Hardware Version

2 Byte

0 to 65535

04

Firmware Version

2 Byte

0 to 65535

Sub function 08: Read Serial Number (from Firmware Version 1.54)

Request:

00

Address

1 Byte

1 to 247

01

Function Code

1 Byte

0x46

02

Sub Function Code

1 Byte

0x08

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 11 von 14

Response:

00

Address

1 Byte

1 to 247

01

Function Code

1 Byte

0x46

02

Sub Function Code

1 Byte

0x08

031

Serial Number

30 Byte

Char

1) In firmware versions 1.54 and 1.55, the length of the serial number is fixed at 20 bytes. If

the serial number is shorter than 20 characters, the output is padded with "blank" (0x20).

The response for the "Read serial number" function consists of 30 characters and is structured

as follows:

- Any "-" characters printed on the sensor label will be omitted.

- For serial numbers less than 30 characters, the output is padded with null bytes "\0" (0x00).

Example:

Serial number printed on the sensor label:

485-12003-17-20311234

Output of Read Serial Number Function:

485120031720311234\0\0\0\0\0\0\0\0\0\0\0\0

Output of Read Serial Number Function in hex:

3438 3531 3230 3033 3137 3230 3331 3132 3334 0000 0000 0000 0000 0000 0000

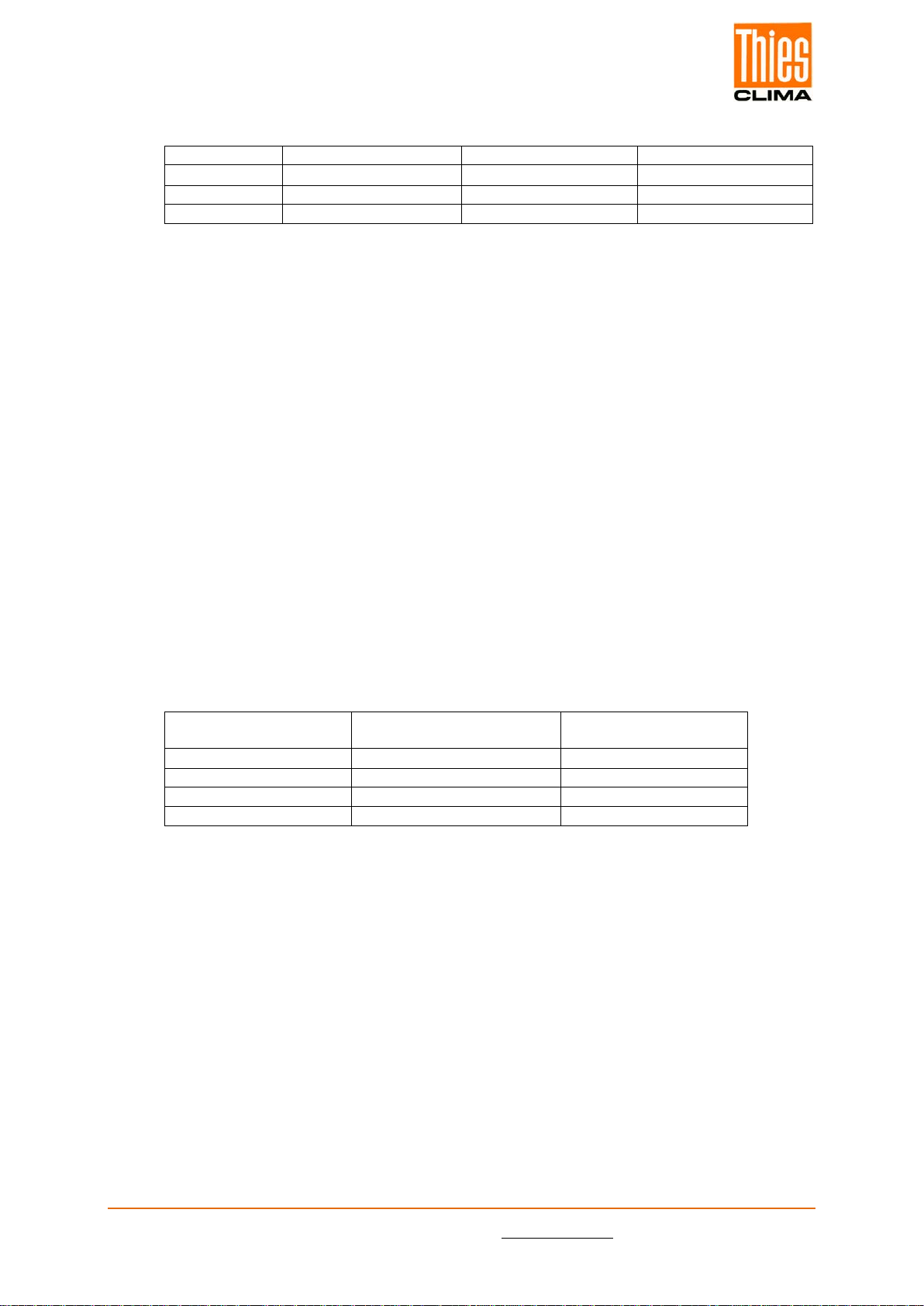

Identification of the sensor type based on the serial number:

Serial number beginning

with

Sensor Type

Active Register

485-1

Si-RS485TC-T-MB

0000, 0007

485-2

Si-RS485TC-2T-MB

0000, 0007, 0008

485-3

Si-RS485TC-2T-v-MB

0000, 0003, 0007, 0008

485-4

Si-RS485TC-T-Tm-MB

0000, 0007, 0008

Code exceptions:

- 01: Illegal Function

- 02: Illegal Data Access

- 03: Illegal Data Value

- 04: Slave Device Failure

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 12 von 14

8 Technical Data

Characteristic

Description

Solar cell

Monocrystalline silicon; 50mm x 33mm

Measuring range irradiance

0 … 1500W/m²

Measurement uncertainty

1

irradi-

ance

±1W/m² ± 2,0 % v. MW

Range 100 to 1,500W/m², perpendicular incidence of light,

Spectrum AM1.5

Measuring range temperature

-40 … +90 °C

Measurement uncertainty

1

tem-

perature

1,0K in range -35 … 80°C

Ambient conditions

-35 ... +80 °C

0 ... 100% rel. Humidity, including condensation

Operating voltage

24VDC (10 ... 28VDC)

Power consumption

Typ. 25mA @ 24VDC

Connection type

4-pin connector for shielded cable

(see connection diagram)

Sensor cable

Cable 4 x 0,25mm² LIYCY, Black, UV- resistant

Max. cable length

1.000m

Galvanic isolation

Up to 1.000V between supply and RS485

Dimensions

Acc. dimensional drawing.

Weight

ca. 350 up to 470g

Type of protection

IP 65

Material

Housing

Powder-coated aluminum

1) according GUM (Guide to the Expression of Uncertainty in Measurement), k = 2

9 Dimensional Drawing

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 13 von 14

10 EC-Declaration of Conformity

Manufacturer: Adolf Thies GmbH & Co. KG

Hauptstraße 76

37083 Göttingen, Germany

http://www.thiesclima.com

Product: Solar irradiance incl. cell tem-perature sensor

Doc. Nr. 2018-44970_CE

Article Overview:

7.1419.20.081 7.1419.20.781 7.1419.21.081 7.1419.21.781

2014/30/EU 26.02.2014

2017/2102/EU 15.11.2017

2012/19/EU 13.08.2012

The indicated products comply with the regulations of the directives. This is proved by the compliance with the following standards:

Göttingen, 13.02.2023

General Manager - Dr. Christoph Peper

Development Manager - ppa. Jörg Petereit

This declaration of conformity is issued under the sole responsibility of the manufacturer.

DIRECTIVE2014/30/EU OFTHEEUROPEANPARLIAMENT AND OFTHECOUNCIL of 26 February 2014 on the harmonisation of the laws of

the Member States relating to electromagnetic compatibility.

This declaration certificates the compliance with the mentioned directives, however does not include any warranty of characteristics.

Please pay attention to the security advises of the provided instructions for use.

The indicated products correspond to the essentialrequirement of the following European Directives and Regulations:

DIRECTIVE 2012/19/EU OF THEEUROPEAN PARLIAMENT AND OFTHECOUNCIL of 4 July 2012 on waste electrical and electronic

equipment (WEEE).

DIRECTIVE (EU) 2017/2102 of the European Parliament and of the Council of November 15, 2017 amending Directive 2011/65 / EU on

the restriction of the use of certain hazardous substances in electrical and electronic equipment.

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 022040/02/23

Tel. +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com Seite 14 von 14

11 More Information / Documents as download

These document are available for download under the following links.

Instruction for use

https://www.thiesclima.com/db/dnl/7.1419.2x.xxx_Silicon_Irradiance_Sensor_en.pdf

Please contact us for your system requirements.

We advise you gladly.

ADOLF THIES GMBH & CO. KG

Meteorology and environmental metrology

Hauptstraße 76 · 37083 Göttingen · Germany

Phone +49 551 79001-0 · Fax +49 551 79001-65

www.thiesclima.com

This manual suits for next models

5

Table of contents

Other Thies CLIMA Accessories manuals