THM Clavicula M3 User manual

Clavicula M³

Road

MTB

Instruction book

THM Clavicula M³_3_en, 2013-02

Don't forget that your THM component is a lightweight carbon design.

Be aware of this when carrying out assemly and maintenance work and when

handling the component. Proceed with utmost care!

4

Clavicula M³

Contents

INTRODUCTION

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fundamental safety precautions . . . . . . . . . . . . . 6

Assembly & maintenance . . . . . . . . . . . . . . . . . . 6

On the road . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Transport & storage . . . . . . . . . . . . . . . . . . . . . . 7

SPECIFICATIONS

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . 8

Bottom bracket . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tightening torques . . . . . . . . . . . . . . . . . . . . . . . 11

Application area . . . . . . . . . . . . . . . . . . . . . . . . . 11

ASSEMBLY

Installing the Clavicula . . . . . . . . . . . . . . . . . . . . 12

Preparing the frame . . . . . . . . . . . . . . . . . . . . . . 12

Spacers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the bottom bracket . . . . . . . . . . . . . . . 14

BSA/ITA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

BB30/PressFit 30/BBright™ PressFit . . . . . . . . . 15

Press-fit/EVO386 . . . . . . . . . . . . . . . . . . . . . . . 16

BBright™ Direct Fit . . . . . . . . . . . . . . . . . . . . . 16

Installing the spider . . . . . . . . . . . . . . . . . . . . . . 16

Assembling the chainwheels . . . . . . . . . . . . . . . 18

Installing the cranks . . . . . . . . . . . . . . . . . . . . . . 18

Adjusting the bottom bracket . . . . . . . . . . . . . . . 20

Assembling the pedals . . . . . . . . . . . . . . . . . . . . 21

Finishing touches . . . . . . . . . . . . . . . . . . . . . . . . 21

MAINTENANCE

Important maintenance information . . . . . . . . . . 22

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Before each trip . . . . . . . . . . . . . . . . . . . . . . . . . 24

Checking the bottom bracket clearance . . . . . . . 24

Regular maintenance . . . . . . . . . . . . . . . . . . . . . 25

Dismantling the bottom bracket . . . . . . . . . . . . . 26

LEGAL

Liability for defects . . . . . . . . . . . . . . . . . . . . . . . 28

Fair deal promise . . . . . . . . . . . . . . . . . . . . . . . . 28

Crash Replacement . . . . . . . . . . . . . . . . . . . . . . . 28

5

Clavicula M³

Introduction

Preface

This manual is an integral part of your THM component and it provides you with infor-

mation regarding the safe operation of your THM-Clavicula crank system.

Read this manual carefully prior to assembling your THM component. Always read and

observe all of the assembly and maintenance instructions in this manual, as well as those

provided in the manuals of other manufacturers whose products are used on your bicycle

(e.g. frame, chainwheels, pedals, etc.).

WARNING

Non-observance of the information contained in this manual could result in an accident

and death or serious injury.

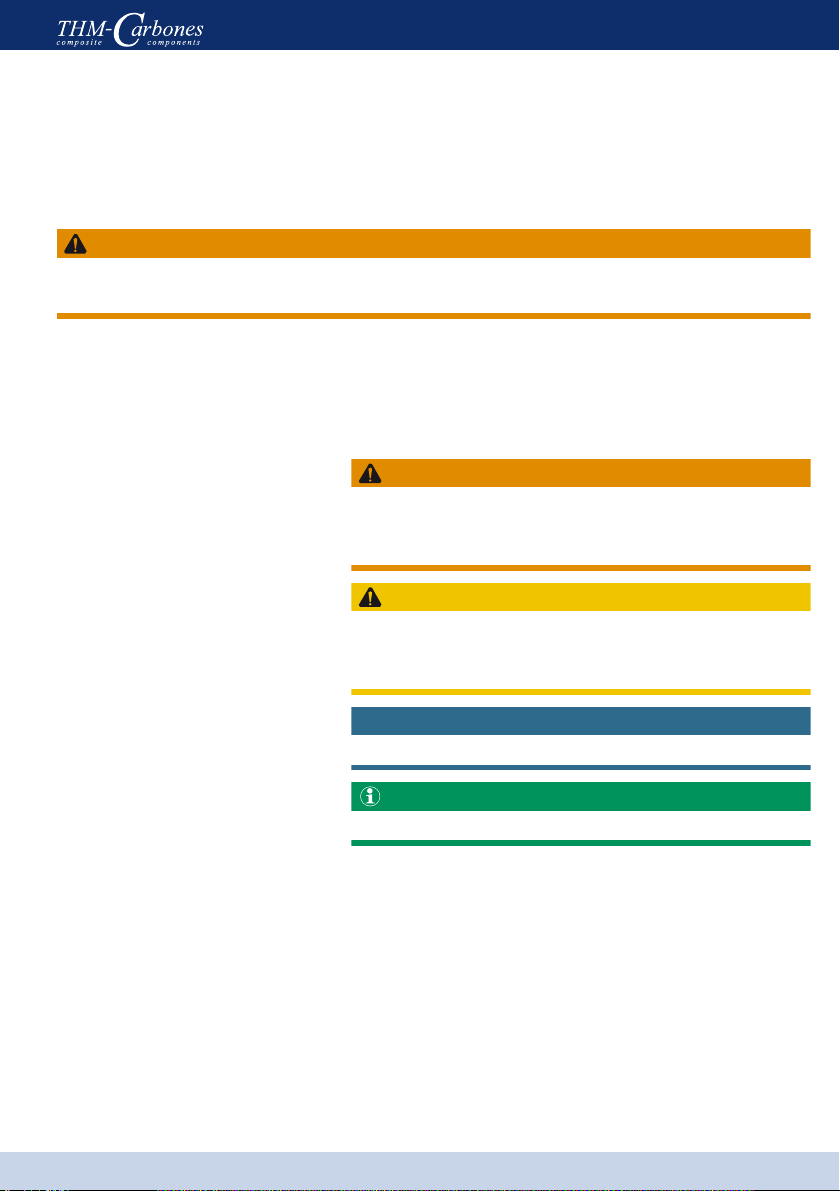

You will encounter the following symbols and references in this manual:

The index finger instructs you to perform a particu-

lar action.

The arrow indicates the consequence of your

action.

WARNING

This safety message indicates a hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION

This safety message indicates a hazardous situation

which, if not avoided, could result in minor or moder-

ate injury.

NOTICE

This message warns of a risk of material damage.

This refers to additional information or tips.

Retain this manual for other users of your THM components.

Make sure that all users read, understand and observe this manual.

If you ever sell or give away your THM components, this manual should be transferred

to the new owner.

We hope you get a lot of joy from your THM components!

Your THM-Carbones Team

6

Clavicula M³

Safety

Intended use

WARNING

Any use other than that intended can cause accidents resulting in death or serious injury.

THM-Clavicula crank systems have been exclusively designed

- for installation on standard racing cycles, time trial and mountain bikes.

- for the permitted area of application – see Application area, page 11.

Fundamental safety precautions

The following warnings for the THM-Clavicula component apply to all Clavicula models

(Clavicula Road, Clavicula MTB etc.), unless otherwise specified.

For the time being we limit the service life of your THM-Clavicula crank system to

100,000 km or 10 years. It is imperative you contact us before continuing to use your

THM-Clavicula crank system after one of these limits has expired!

Always remember that riding a bicycle involves potential danger for the rider and other

road users, as well as for the bicycle and its components. Even if protective equipment

and safety devices are used, accidents resulting in death or serious injury can still occur.

You should also rely on your common sense and avoid any unreasonable behaviour!

Assembly & maintenance

WARNING

Risk of accident caused by assembly and maintenance work which has not been con-

ducted in a professional manner.

-Do not overestimate your technical ability. All assembly and maintenance work should

be performed by a specialist workshop for bicycles. This is the only way to ensure that

work is conducted in a professional manner.

-Always observe all of the specified tightening torques for the screw connections.

-Only use suitable, undamaged, high-quality tools.

-Only ever use original THM components which are available from your specialist dealer

or directly from THM.

-Never make any modifications to your THM components.

-Check your crank system (incl. cranks, bottom bracket, chainwheels) to make sure it is

undamaged and functioning properly before every ride. Send us your THM-Clavicula

component before further use if damage is visible (cracks, fractures, deformations, etc.)

or if you are in any doubt about its functionality.

-Check your THM components before each journey to ensure the surfaces are completely

undamaged. Send us your THM components for inspection before further use if damage

is visible (deep scratches in the paintwork which extend into the carbon structure, large

abrasions, etc.), if you are in any doubt about their functionality or if the Clavicula let-

tering is abraded at one or more points (wear indicator).

-Always ensure your bicycle is maintained in a flawless condition. Care and maintenance

will prolong the service life of your bicycle and its components and also improve your

personal safety.

7

Clavicula M³

Safety

On the road

WARNING

Danger of accidents due to improper behaviour or improper equipment during riding.

-Always ride with foresight, attention and a readiness to brake.

-Adjust your speed to the prevailing conditions (traffic, weather, visibility, etc.).

-Do not use your THM components at ambient temperatures below -10°C (14°F).

-Do not exceed the maximum overall weight for which your THM components have

been approved – see Size, page 10.

-Do not perform jumps with your bicycle as this generates an enormous amount of force.

-Always comply with the traffic regulations that are in force in the country where you are

using your bicycle.

-When riding your bicycle you should always wear a high quality cycling helmet (e.g.

ANSI certified) that is in excellent condition. Your clothing should be close-fitting but

not restrictive.

-Only ride your bicycle if you are in good physical condition and your bicycle and all of

its components are in perfect working order.

-If you are involved in a heavy fall you should not continue riding your bicycle. If such

a case occurs, send us your THM components for inspection, even if no external damage

is visible! In your own interest you should treat all components on your bicycle which

are produced by other manufacturers in the same way.

When riding your mountain bike, also comply with the directives of the International

Mountain Bike Association (IMBA):

-Only use permitted routes.

-Avoid leaving tracks.

-Always keep your bicycle under control.

-Ride in a manner that is suitable for the terrain.

-Do not startle any animals.

-Always ride in an anticipatory manner.

-Be prepared for any eventuality.

For more information please visit www.imba.com .

Transport & storage

WARNING

Risk of accident caused by damaged bicycle components.

-Always transport your bicycle in an appropriate and careful manner.

-Do not store your THM components at an ambient temperature below -15°C (5°F) or

above 55°C (131°F).

Risk of accident.

-Do not allow children to play with your bicycle.

8

Clavicula M³

Specifications

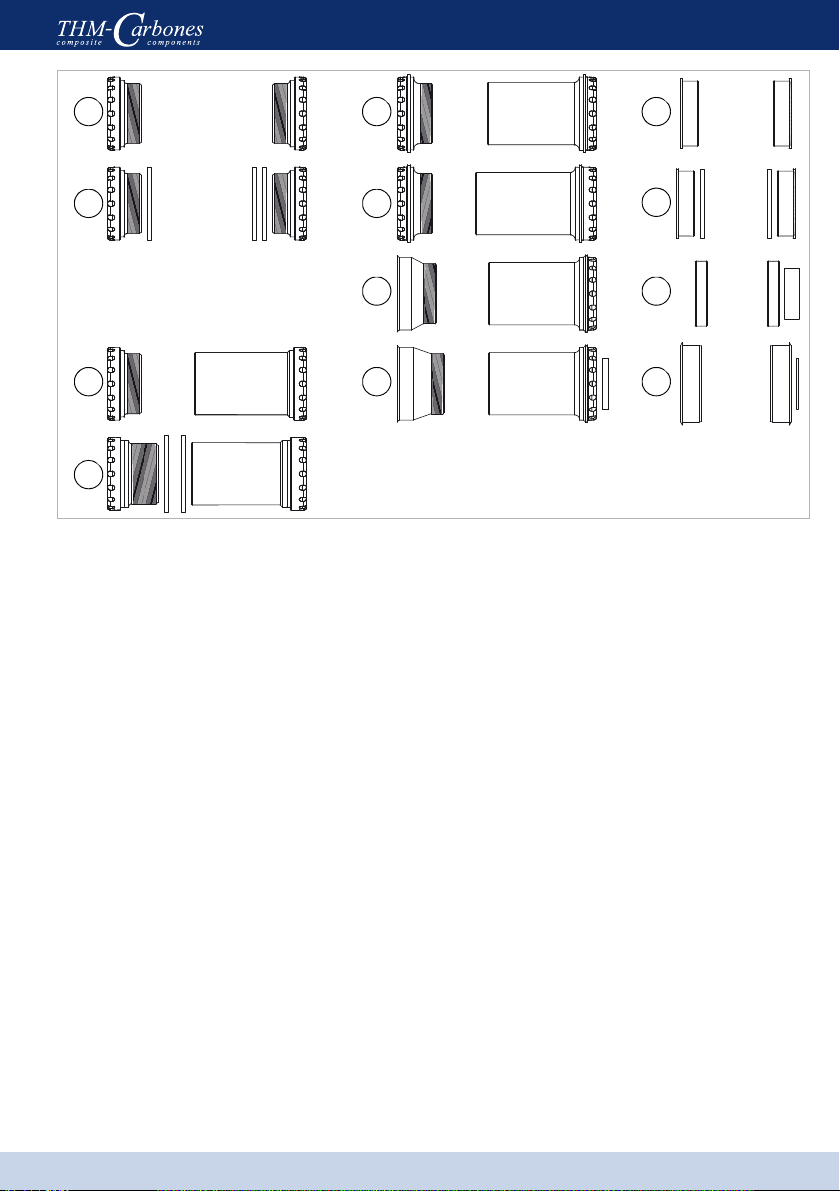

Scope of delivery

(1) Adjusting screw

(2) Crank, left

(3) Spacer ring, 1× 2.5mm (Road)

(4) Spacer ring, 1× 9.7mm (MTB)

(9) Lockring for spider (MTB)

(10)Hollow screw for spider (Road),

5× M8×0.75 × 10mm

(11)Spider* (optional)

(12)Axle crank

Instruction book

Not included in delivery:

(5) Bottom bracket (optional)

–seeBottom bracket, page 9

(6) Bearing cup, left (marked by groove)

(7) Spacer, 2.5mm

(8) Bearing cup, right

(13)THM adjusting tool

(14)THM bottom bracket tool (optional)

(15)THM lockring tool (MTB)

These items must be ordered separately if necessary.

*without chainwheels and chainwheel bolts

23

6

5

8

12110 11

4

7

9

13

14 15

9

Clavicula M³

Specifications

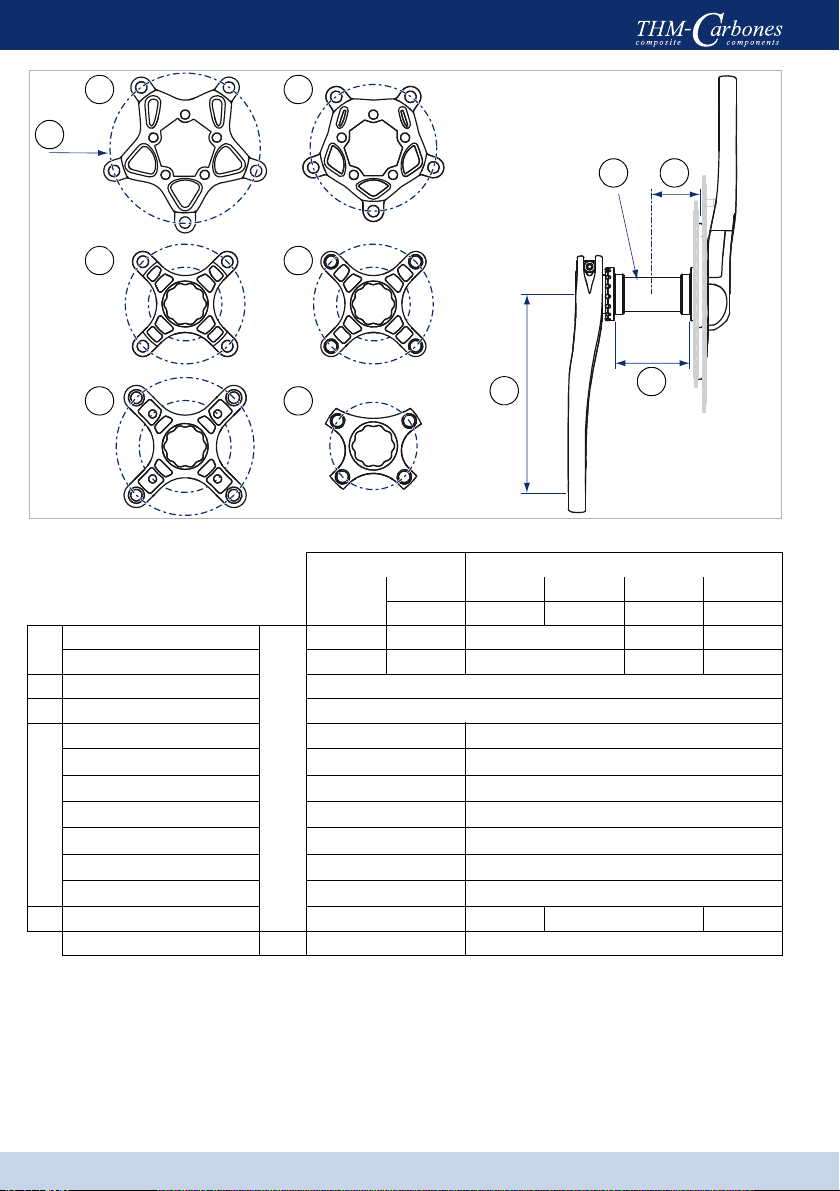

Bottom bracket

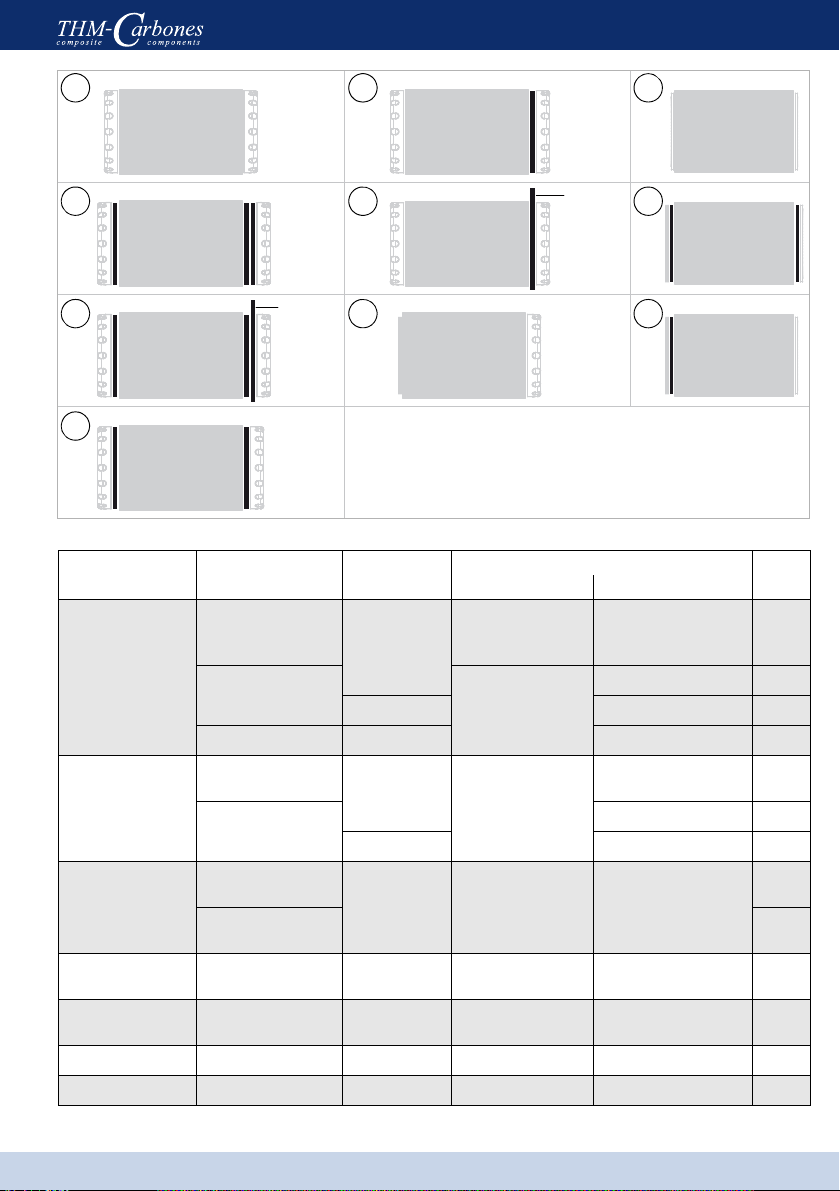

(a) Road (BSA/ITA): Bearing cup left/right

(b) MTB (BSA): Bearing cup left/right,

3× spacer ring (2.5mm)

(c) BB30 Road: Bearing cup left/right

(d) BB30 MTB: Bearing cup left/right,

2× spacer ring (2.5mm)

(e) PressFit 30 Road: Bearing cup left/right

(f) PressFit 30 MTB: Bearing cup left/right

(g) BBright™ PressFit Road:Bearing cup left/right

(h) BBright™ PressFit MTB:Bearing cup left/right,

1× spacer ring, right (4.0mm)

(i) Press-fit Road: Bearing cup left/right

(k) Press-fit MTB: Bearing cup left/right,

2× spacers (2.0mm)

(l) BBright™ Direct Fit Road: 2× bearings,

1× spacer ring, right (9.0mm)

(m) EVO386 Road (FSA®): Bearing cup left/right,

1× spacer ring, right (1.0mm)

a

g

i

l

e

b

d

fk

m

c h

10

Clavicula M³

Specifications

Size

*Technical specifications, dimensions and weights are to be understood with the corresponding tolerances

and can differ slightly from your THM components.

** BSA (1.37"×24 tpi) / ITA (36×24 tpi)

*** Total weight = rider + bicycle + luggage

A

D

B

EC

12

3

56

4

A

CE

BD

Road MTB

Compact 3–104/64 2–104/64 2–120/80 XX1–76

*(1)(2)(3)(4)(5)(6)

(A) Ø bolt circle

mm

130 110 104/64 120/80 76

Teeth, min. 39 34 32/21 37/25 26

(B) Crank length 170.0/172.5/175.0

(C) Ø axle 30

(D)

BSA (ITA)** 68.0 (70.0) ±0.5 68.0/73.0 ±0.5

BB30 68.0±0.5 (Ø 42.0) 68.0/73.0±0.5 (Ø 42.0)

PressFit 30 (SRAM®)68.0±0.5 (Ø 46.0) 73.0±0.5 (Ø 46.0)

BBright™ PressFit 79.0±0.5 (Ø 46.0) 84.0±0.5 (Ø 46.0)

Press-fit (Shimano®)86.5±0.5 (Ø 41.0) 89.5/92.0±0.5 (Ø 41.0)

BBright™ Direct Fit 79.0±0.2 (Ø 42.0) –

EVO386 (FSA®)86.5±0.5 (Ø 46.0) –

(E) Chain line (ITA) 43.5 (44.5) 50.0 49.5 47.0

Total weight, max.*** kg(lb) 110 (243) 120 (265)

11

Clavicula M³

Specifications

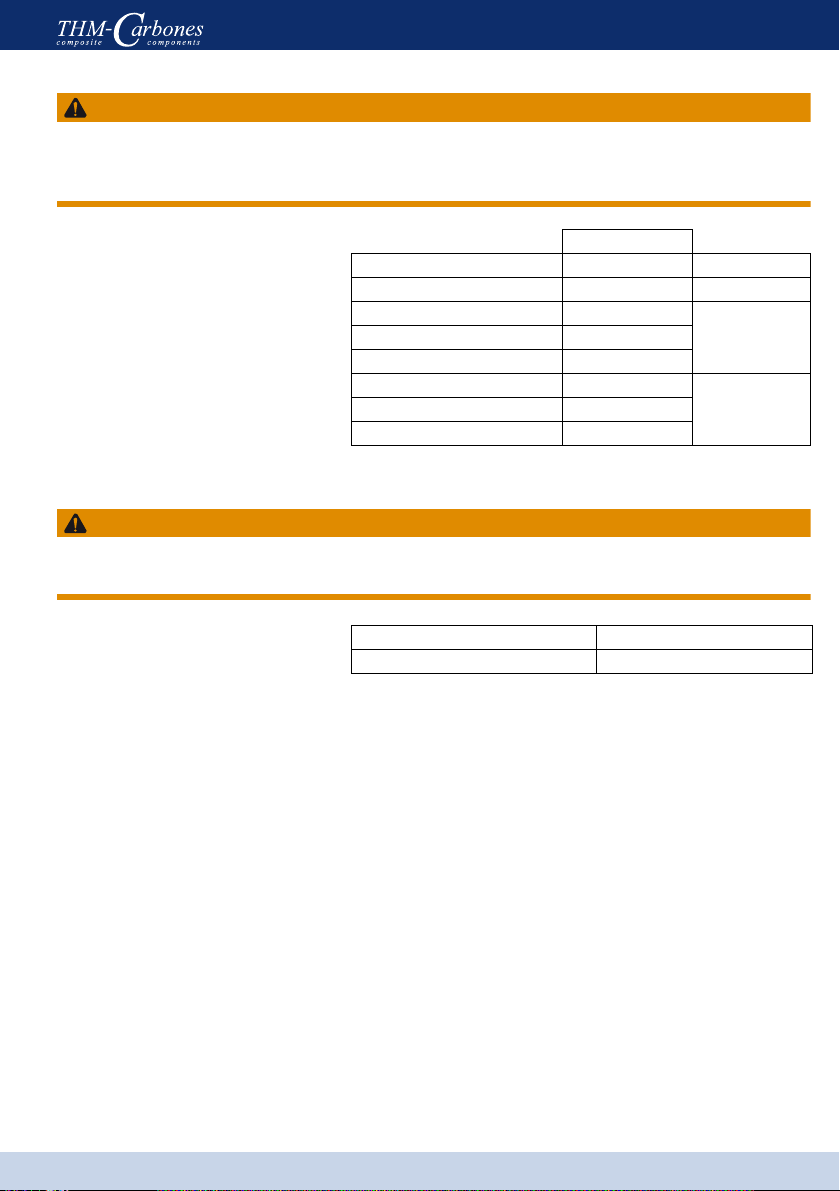

Tightening torques

WARNING

Risk of accident caused by a malfunctioning crank system due to loose screw connections.

-Check the required tightening torque of all screw connections after the first 100 km - re-

tighten the connections if necessary. Repeat this check every 2500km!

Application area

WARNING

Risk of accident caused by a malfunctioning crank system due to overload.

-Only ever use your Clavicula component within its permitted area of application.

X1 Racing cycle and light cross-country terrain

X2 Touring, road

X3 medium/heavy terrain

X4 Free ride, heavy terrain

X5 Downhill, extreme terrain

N·m(lbf·in) max.

Bearing cups 40 (354) greased

Adjusting screw 6 (53) dry

Crank clamping bolt 8 (71)

with thread lockHollow screw for spider 6 (53)

Lockring spider 30 (266)

Chainwheel bolts, aluminium 6 (53)

greasedChainwheel bolts, steel 12 (106)

Pedal threads 20 (177)

Clavicula M³ Road X1–X2

Clavicula M³ MTB X1–X3

12

Clavicula M³

Assembly

Installing the Clavicula

WARNING

If not properly performed, assembly and maintenance work can cause accidents resulting

in serious or fatal injury.

-Do not overestimate your technical ability. All assembly and maintenance work should

be performed by a specialist workshop for bicycles. This is the only way to ensure that

work is conducted in a professional manner.

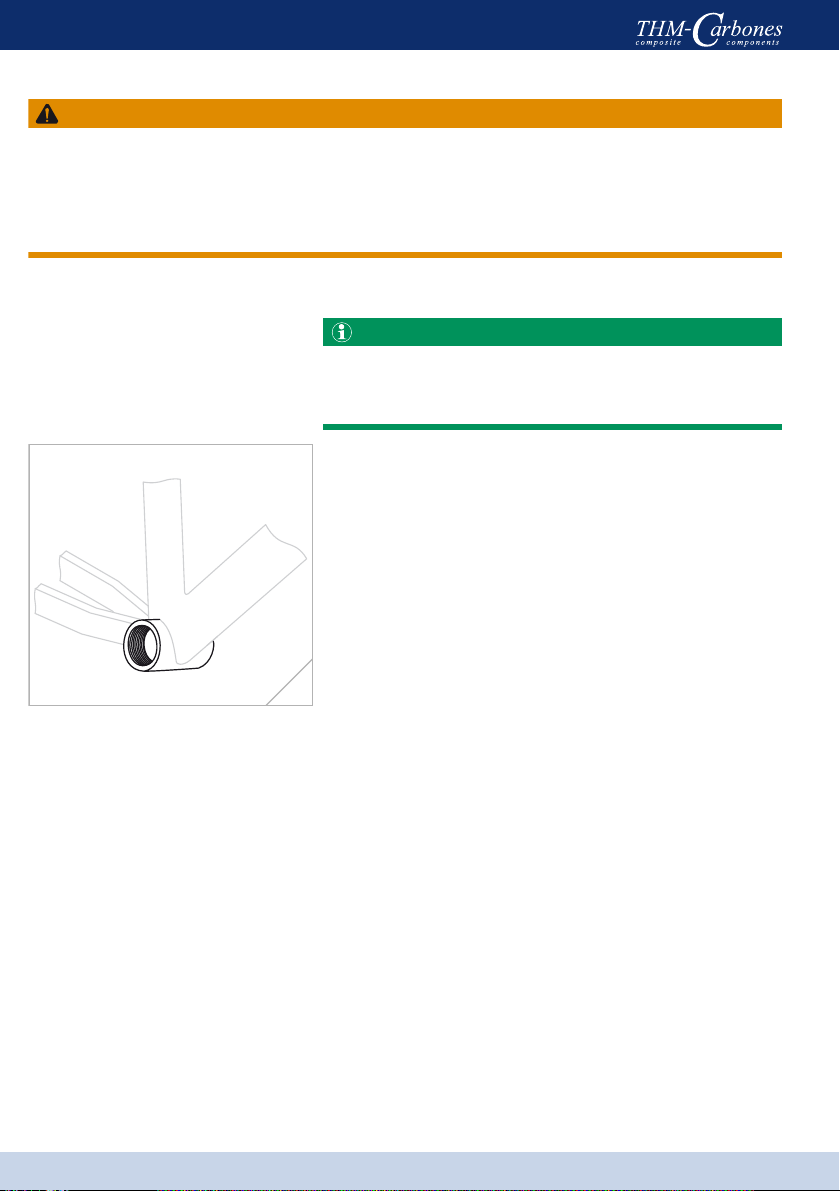

Preparing the frame

It is imperative you read and observe the safety and

assembly information provided by the manufacturer

of your frame.

Secure your bicycle in an appropriate assembly

stand.

If necessary remove the crankset and the old bottom

bracket.

If necessary, use cleaning solvent or other similar

agents to clean the bottom bracket housing of your

frame.

Make sure that the edges of the bottom bracket

housing are plane, parallel, milled to the correct

dimensions and free of burrs – see Size, page 10.

If necessary, rework the bottom bracket housing

using an appropriate milling tool (Cyclus, ParkTool

or other similar tool).

Make sure that the threads of the bottom bracket

housing are clean, free from paint residues and

adequately tapped into the housing. If necessary,

rework the threads with an appropriate cutting tool

(Cyclus, ParkTool or other similar tool).

(fig. 1)

1

13

Clavicula M³

Assembly

Spacers

E-TYPE,

Chain-

guide, …

E-TYPE,

Chain-

guide, …

A

B

C

D

E

F

G

H

I

K

Bottom bracket

housing Bottom bracket Front derail-

leur type

Spacers Fig.

Anticlockwise Clockwise

68.0mm (70.0mm)

Road BSA (ITA);

BB30 Road; PressFit

30 Road Clip-on/

braze-on

0 0 (A)

MTB BSA 1× 2.5mm

2× 2.5mm (B)

E-TYPE 1× 2.5mm + E-TYPE (C)

BB30 MTB Clamp 1× 2.5mm (D)

73.0 mm

BB30 MTB; PressFit

30 MTB Clamp 0

0(A)

MTB BSA 1× 2.5mm (E)

E-TYPE 0 + E-TYPE (F)

79.0 mm

BBright™ PressFit

Road Clip-on/

braze-on 0 0

(G)

BBright™ Direct Fit

Road –

84.0 mm BBright™ PressFit

MTB Clamp 00

(G)

86.5 mm Press-fit

Road;Evo386 Road

Clip-on/

braze-on 0 0 (H)

89.5 mm Press-fit MTB sym. Clamp 1× 2.0mm 1× 2.0mm (I)

92.0 mm Press-fit MTB asym. Clamp 1× 2.0mm 0(K)

14

Clavicula M³

Assembly

Installing the bottom bracket

Do not use the Clavicula Road in combination with an E-TYPE front derailleur!

The THM socket wrench(1)(fig. 3), which can be used as a torque wrench, can be ob-

tained from us or from your specialised dealer.

Measure the width of the bottom bracket housing of

your bicycle frame.

Identify the type of front derailleur used on your

bicycle.

Use the table to determine the correct number of

spacers for both sides of the bottom bracket –

see Spacers, page 13.

Make sure that the securing bolt of the derailleur

cable guide does not protrude into the bottom

bracket housing by more than 1mm.

Apply grease to the threads and contact surfaces of

the bearing cups.

BSA/ITA

Fit the correct number of spacers to the right-hand

bearing cup (R).

Screw the right-hand bearing cup (R) – initially by

hand – into the right-hand side of the bottom bracket

housing using an anti-clockwise (BSA) or clockwise

(ITA) motion.

Fit the correct number of spacers to the left-hand

bearing cup (L) (marked by groove).

Screw the left-hand bearing cup (L) – initially by

hand – into the left-hand side of the bottom bracket

housing using a clockwise motion (BSA & ITA).

(fig. 2)

Tighten both bearing cups using a tightening torque

of 40N·m (354lbf·in).

This torque corresponds to a manual force of

approx. 20kg (44lb) at the end of the THM bottom

bracket tool. (fig. 3)

L R

2

20 kg

(44 lb)

40 N·m (354 lbf·in)

1

3

15

Clavicula M³

Assembly

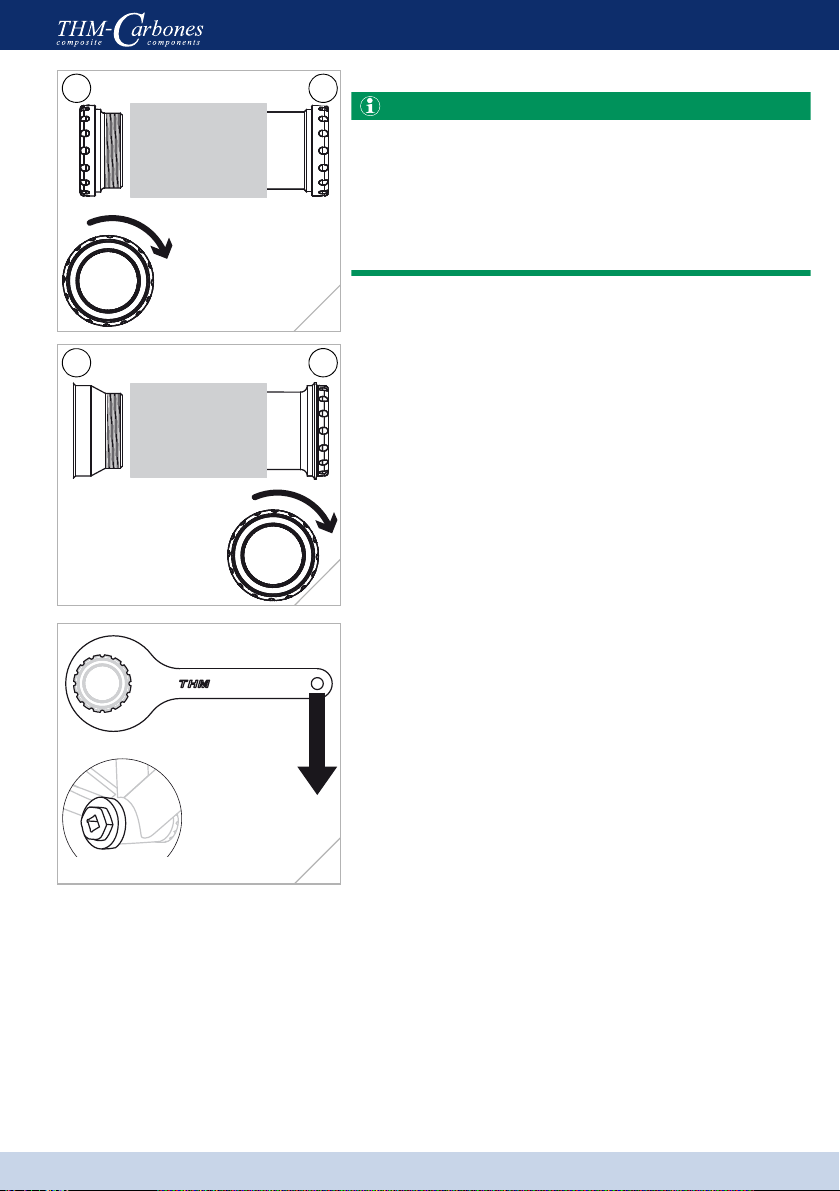

BB30/PressFit 30/BBright™ PressFit

When dealing with BB30, PressFit 30 and BBright™

PressFit bottom brackets, the bearing cup with internal

thread (2) or (4) is always located to the right, while

the bearing cup with external thread (3) or (5) is

always located to the left.

–seeBottom bracket, page 9.

Fit the correct number of spacers to the bearing

cup (2).

Insert the bearing cup (2) or (4) by hand as far as

possible into the right-hand side of the bottom

bracket housing.

Fit the correct number of spacers to the bearing

cup (3).

Screw the bearing cup (3) or (5) by hand as far as

possible into the right-hand bearing cup using a

clockwise rotation.

Make sure that both bearing cups are located cen-

trally in front of the bottom bracket housing.

(fig. 4, 5)

Tighten the bearing cup (3) or (4) using a tightening

torque of 40N·m (354lbf·in).

This torque corresponds to a manual force of

approx. 20kg (44lb) at the end of the THM bottom

bracket tool.

(fig. 6)

3 2

4

5 4

5

20 kg

(44 lb)

40 N·m (354 lbf·in)

6

16

Clavicula M³

Assembly

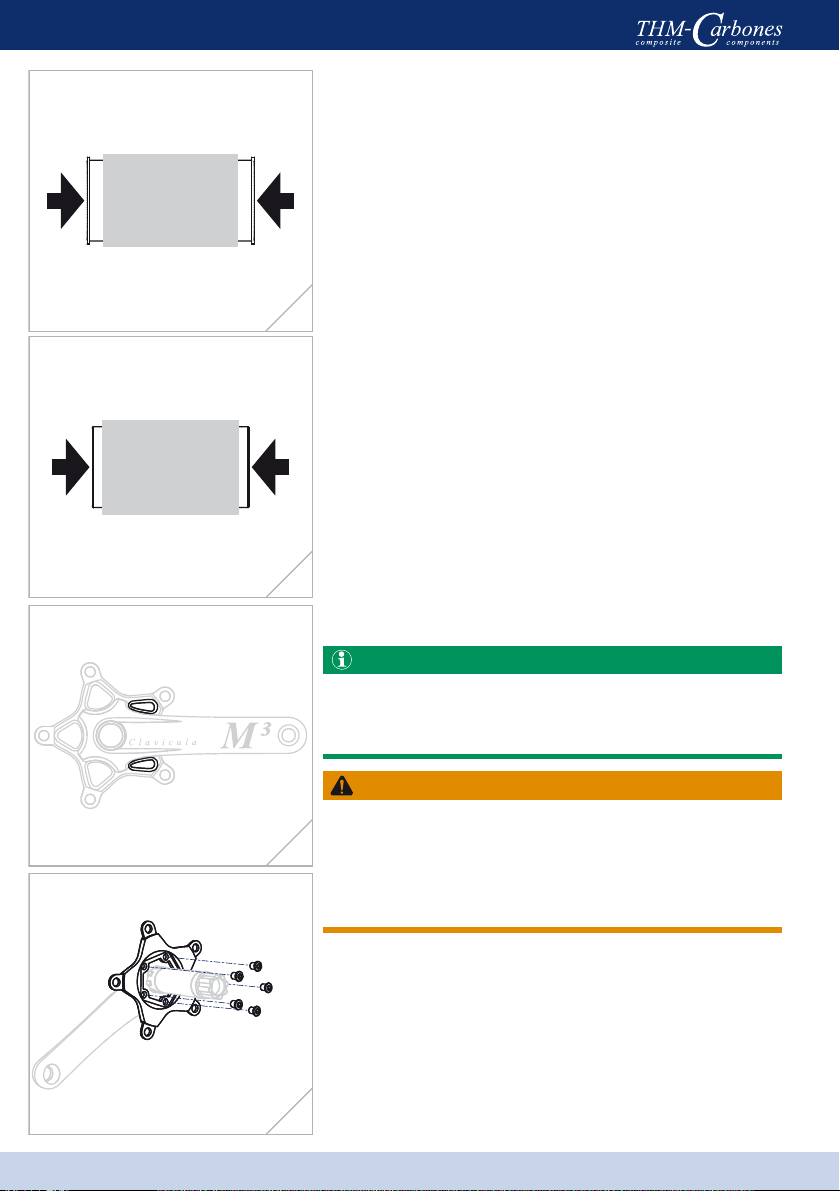

Press-fit/EVO386

Fit the correct number of spacers to the bearing

cups – see Spacers, page 13.

Press both bearing cups simultaneously into the

bottom bracket housing as far as possible by using a

suitable pressing tool (e.g. Park Tool®).

(fig. 7)

BBright™ Direct Fit

Press both bearings simultaneously into the bottom

bracket housing as far as the housing stop by using

a suitable pressing tool (e.g. Park Tool®).

(fig. 8)

Installing the spider

Road

The spider is positioned correctly when the two small

contoured sections on the outer side are located next

to the arm of the axle crank. (fig. 9)

WARNING

Risk of accident caused by a malfunctioning spider

due to the use of hollow screws that are too long or too

short.

-Only ever use original THM hollow screws when

attaching the spider.

Make sure that the hollow screw threads are provid-

ed with fresh, medium-strength thread lock.

Always tighten the hollow screws in a crosswise

manner using a tightening torque of 6N·m

(53lbf·in).(fig. 10)

7

8

9

10

17

Clavicula M³

Assembly

MTB

The spider is positioned correctly when the mounts for

the chainwheel bolts are located symmetrically to the

arm of the axle crank.

When using the XX1 spider both of the mounts of the

chainwheel bolts must point in the direction of the

pedal eye. (fig. 11)

WARNING

Risk of accident caused by a malfunctioning spider

due to an unsuitable lockring.

-Only ever use the original THM lockring when

attaching the spider.

Make sure the thread of the lockring is provided

with fresh, medium-strength thread lock.

Use the THM lockring tool to tighten the lockring

with a tightening torque of 30N·m (266lbf·in).

(fig. 12)

SRM PowerMeter

If you have an SRM PowerMeter that you would like

to use, please contact SRM directly to inquire whether

it is compatible with your Clavicula M³.

Always observe the installation instructions provided

by SRM. Tighten the mounting screws (Road) or

lockring (MTB) of the SRM PowerMeter by using the

specified tightening torque; when doing this make

sure you do not exceed a tightening torque of max.

6N·m (53lbf·in) (screws, Road (fig. 13)) or max.

30N·m (266lbf·in) (lockring, MTB (fig. 14)) under any

circumstances.

XX1

11

12

13

14

18

Clavicula M³

Assembly

Assembling the chainwheels

NOTICE

Danger of damage to the chainwheel mount or axle crank.

-The number of chainwheel teeth must never be below the minimum number required –

see Size, page 10.

-Always mount 2 chainwheels on the outer chainwheel mount for the corresponding spi-

ders (Road, Road Compact, MTB 3-104/64) (fig. 15).

-Always observe the tightening torques specified by the manufacturer of the chain ring

bolts; however, do not exceed a max. tightening torque of 12N·m (106lbf·in) under any

circumstances.

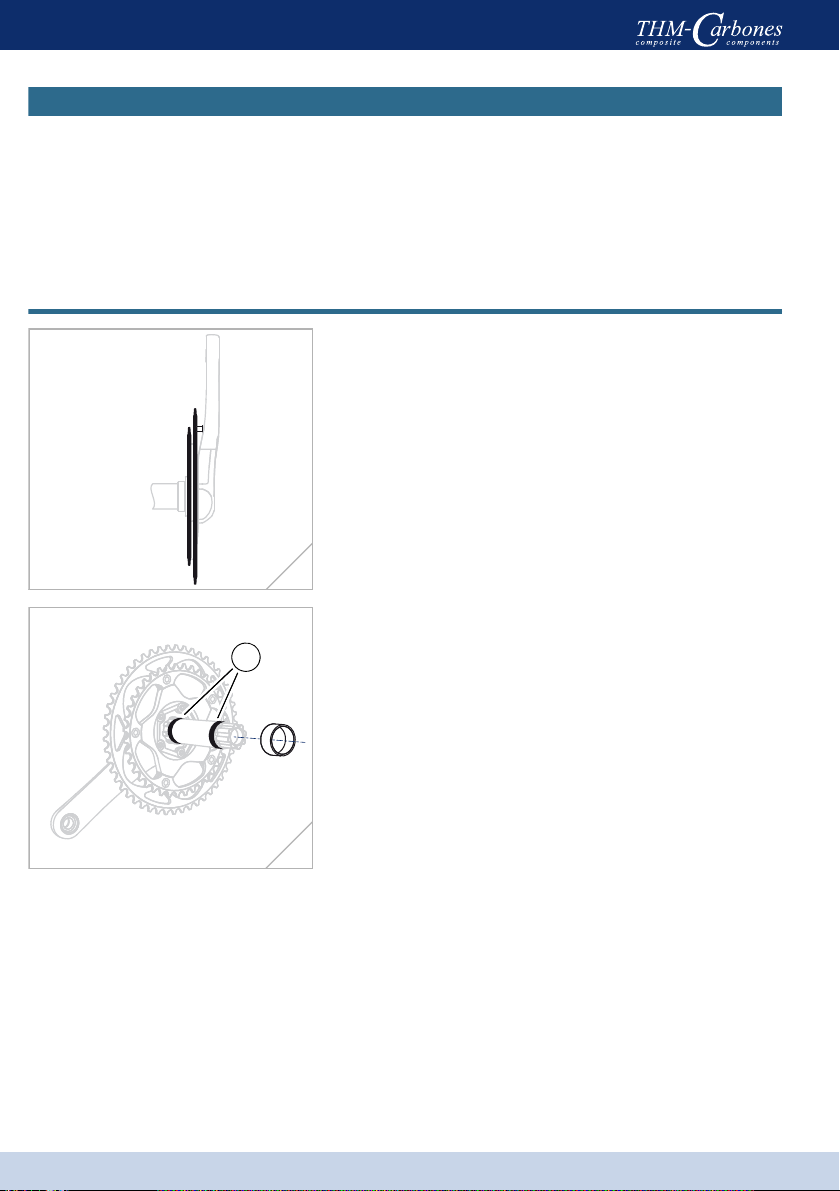

Installing the cranks

Insert the corresponding spacer ring onto the axle -

only when using the following bottom brackets:

BBright™ Direct Fit Road: 9.0mm.

BBright™ PressFit MTB: 4.0mm.

EVO386 Road: 1.0mm.

Lightly grease the bearing seat(1) of the axle.

(fig. 16)

15

1

16

19

Clavicula M³

Assembly

Insert the axle crank through the bottom bracket up

to its stop. (fig. 17)

Thoroughly degrease the axle and crank multi-tooth

segment.

Insert the spacer ring onto the axle.

Road: 2.5mm

MTB: 9.7mm

(fig. 18)

Fit the left-hand crank to the multi-tooth segment of

the axle.

Make sure the left and right-hand crank are seated

correctly!

Press the cranks together by hand up to the limit

stop.

Both cranks abut against the inner rings of the

bearings. (fig. 19)

Check the clearance between the cranks and the

chainstays of the frame.

Minimum crank to chainstay clearance: 3mm

17

Road MTB

18

19

20

Clavicula M³

Assembly

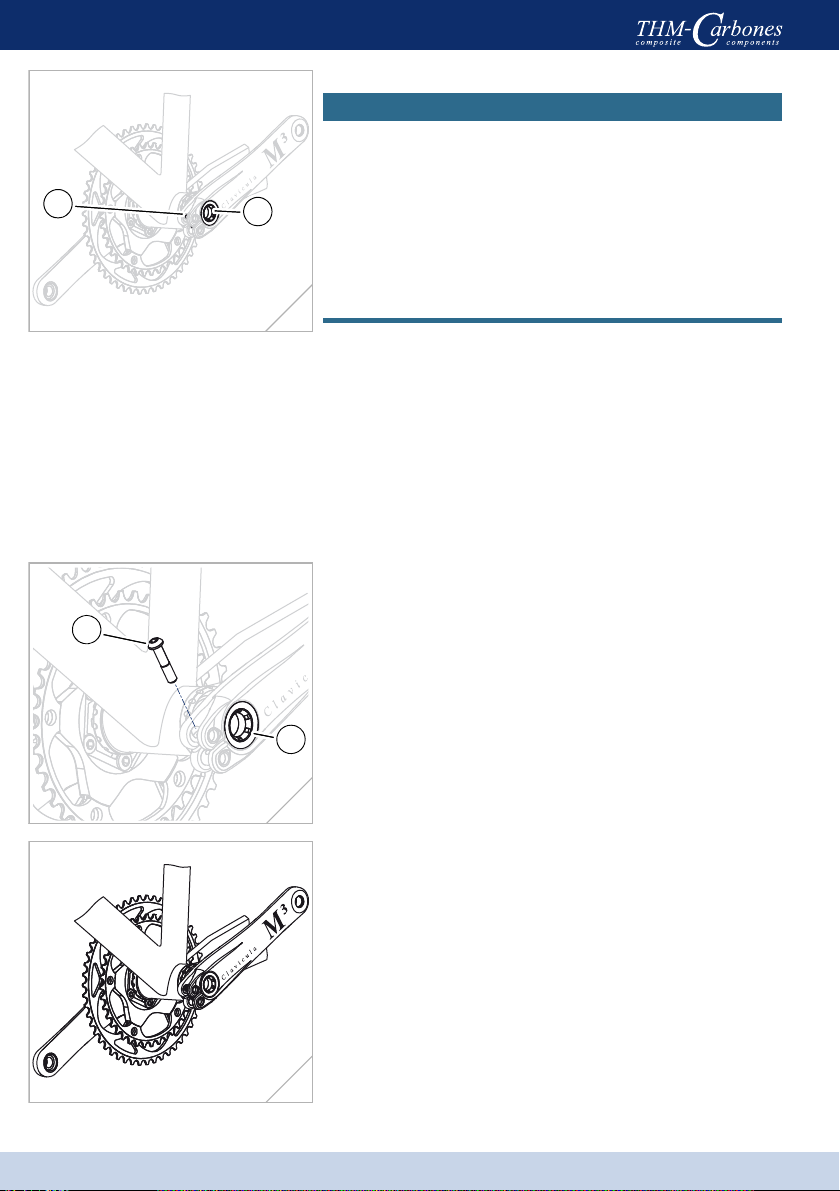

Adjusting the bottom bracket

NOTICE

Accelerated bearing wear if the bottom bracket is set

too rigidly due to excessive pre-tensioning of the ad-

justing screw.

-Only adjust the bottom bracket if the clamping

screw(1) has been loosened!

As a rule, the required tightening torque of the adjust-

ing screw(2) for a correctly adjusted bottom bracket

is approximately 0.3–1N·m (3–9lbf·in).

Screw the adjusting screw into the axis – when

doing this use the THM adjusting tool, the end of

the THM bottom bracket tool or, if necessary,

a suitable coin (such as a 1 Euro piece).

Tighten the adjusting screw carefully and slowly

until the bottom bracket does not exhibit any play,

but can still be turned easily by hand.

Adjustment of the bottom bracket is now complete.

(fig. 20)

Remove the clamping screw(1).

Apply a medium-strength thread lock (Loctite or

other similar substance) to the thread of the clamp-

ing screw.

Replace the clamping screw.

Tighten the clamping screw using a tightening

torque of 8N·m (71lbf·in).

Tighten the adjusting screw(2) using a tightening

torque of 6N·m (53lbf·in) to prevent it from becom-

ing lost during travel. (fig. 21)

Installation of your Clavicula component is now

complete.

(fig. 22)

12

20

1

2

21

22

Table of contents

Other THM Bicycle Accessories manuals