Contents

What is Chipper Check II (CCII)?......................................................4

Chipper Check (CC) vs. Chipper Check II (CCII) .............................4

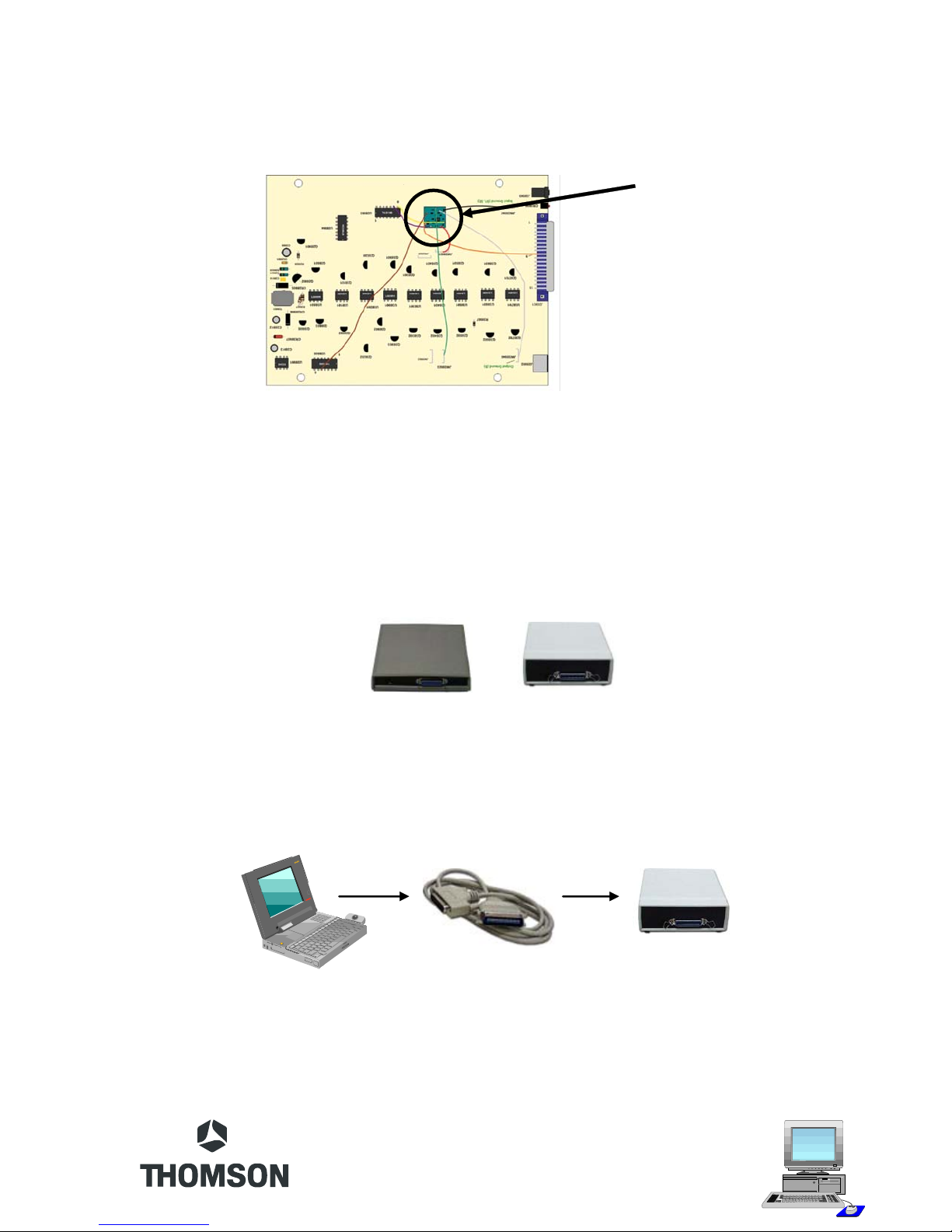

Chipper Check II Interface ................................................................5

Connecting the Interface Box to the PC............................................7

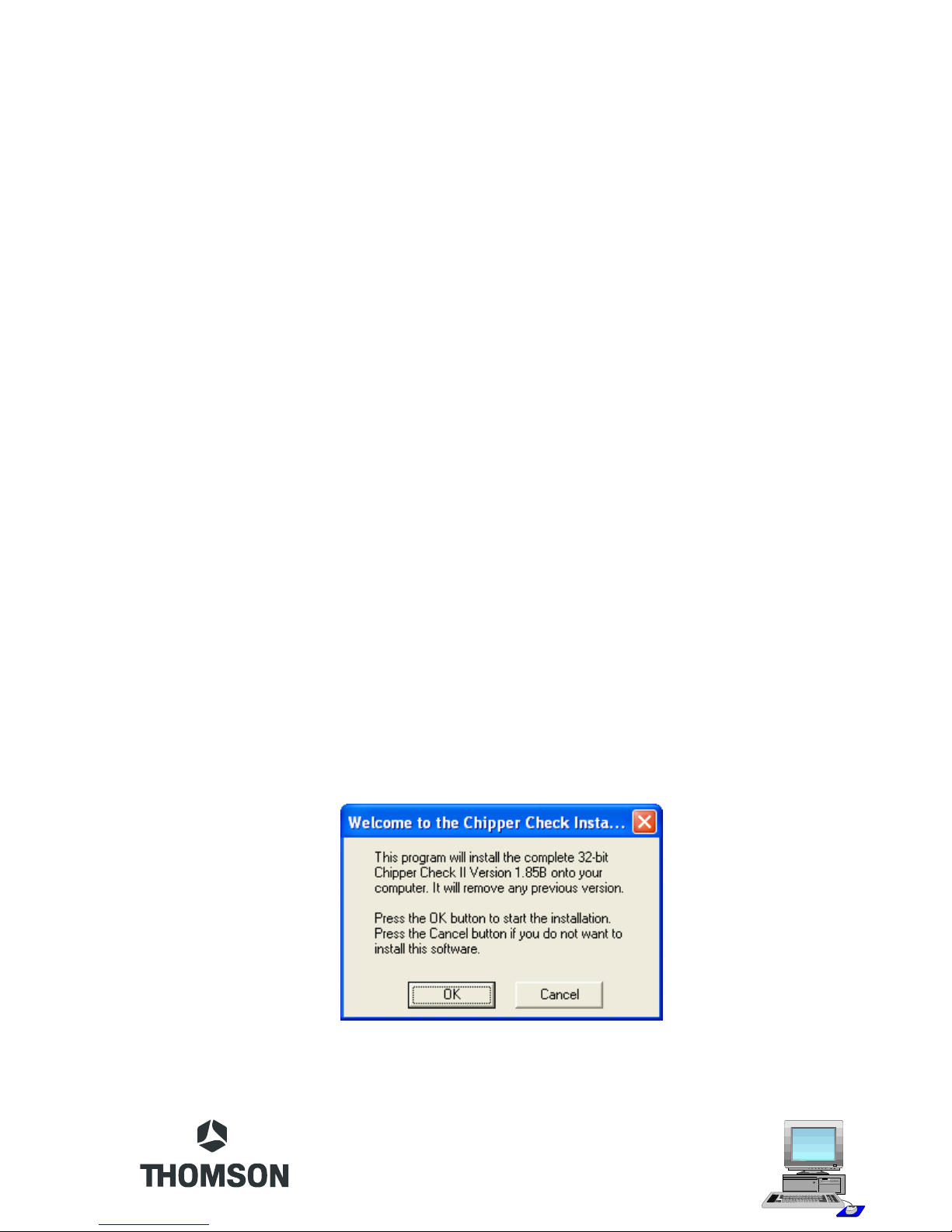

CCII Install Software..........................................................................7

CCII Software Start-UP....................................................................10

Entering the Service Mode ..............................................................13

CTC175, 176, 177, 186 & 187 Setup Procedure...........................14

CTC178, 179, 188 & 189 Setup Procedures .................................16

Procedure: ..................................................................................16

Dead Set .....................................................................................18

CTC195, 197 & 203 Setup Procedures..........................................19

Procedure: ..................................................................................19

Dead Set .....................................................................................20

Setup MM101, MM102, CTC210, CTC211, and LCOS Chassis....20

Procedure: ..................................................................................21

PTV Convergence Setup............................................................21

Dead Set .....................................................................................21

Setup DTV306, DTV307 Chassis ...................................................22

Service Mode (Manually).............................................................22

TECI1 Switch Position ................................................................23

ATC221 and ITC222 Setup Procedure...........................................23

Procedure: ..................................................................................24

Dead Set .....................................................................................24

DLP, ATC311, 321, 322, and 323 Setup.........................................25

Establishing a connection: ..........................................................25

Dead Set .....................................................................................28

Interface Box Diagnostic Tests........................................................29

Frequently Asked Questions ...........................................................34

Contact Phone Numbers .................................................................36