Thonk MA VCA User manual

!

!

September 8th 2014 www.thonk.co.uk 1

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

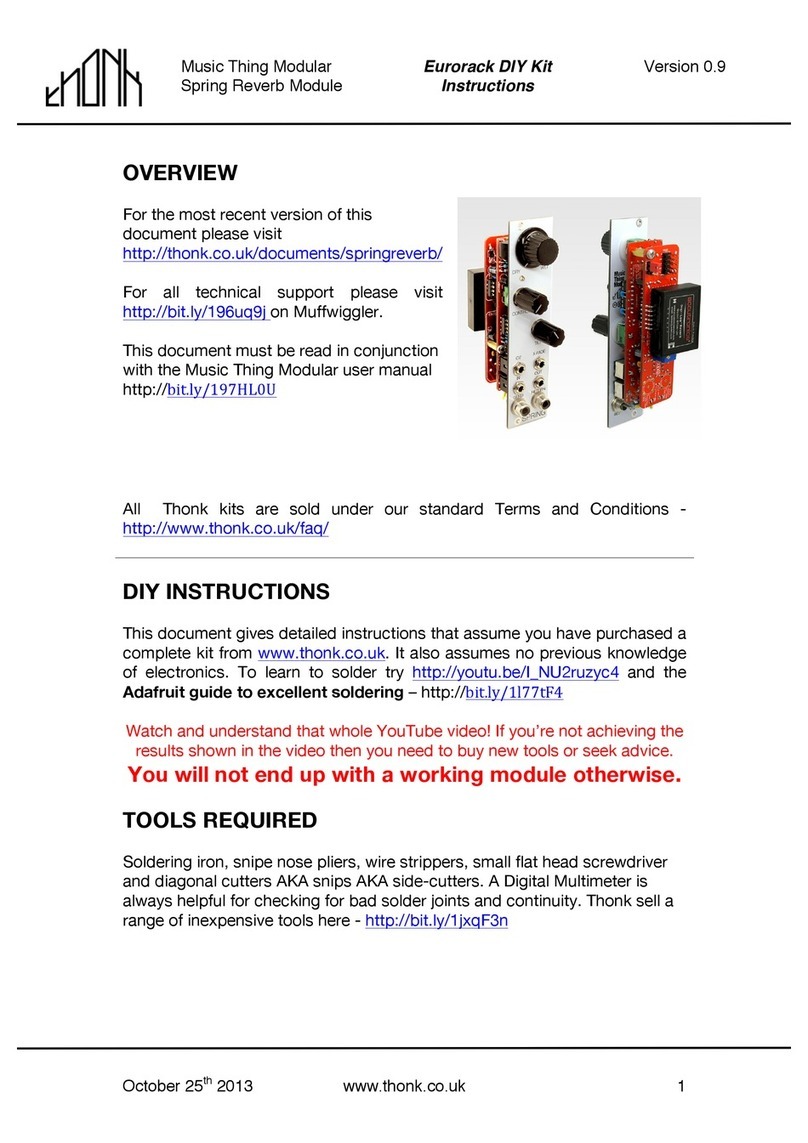

MA VCA OVERVIEW

For the most recent version of

this document please visit

http://thonk.co.uk/documents/MA/

For all technical support please

visit http://bit.ly/1tl78E0 on

Muffwiggler.

All Thonk kits are sold under our standard Terms and Conditions -

http://www.thonk.co.uk/faq/

DIY INSTRUCTIONS

This document gives detailed instructions that assume you have purchased a

complete kit from www.thonk.co.uk. It also assumes no previous knowledge

of electronics. To learn to solder try http://youtu.be/I_NU2ruzyc4 and the

Adafruit guide to excellent soldering – http://bit.ly/1l77tF4

Watch and understand that whole YouTube video! If you’re not achieving the

results shown in the video then you need to buy new tools or seek advice.

You will not end up with a working module otherwise.

TOOLS REQUIRED

Soldering iron, tweezers for SMD parts, snipe nose pliers, wire strippers,

small flat head screwdriver and diagonal cutters AKA snips AKA side-

cutters. A Digital Multimeter is always helpful for checking for bad solder

joints and continuity. Thonk sell a range of inexpensive tools here -

http://bit.ly/1jxqF3n

!

!

September 8th 2014 www.thonk.co.uk 2

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

SOLDER JOINTS

Your solder joints should look like those shown as ‘OK’ below, they should

have that neat conical shape on BOTH sides of the PCB. If they don’t look

the same on both sides then stop! Work out why from the soldering guides

linked and don’t continue until you are getting those results.

This isn’t about perfectionism, you are very likely to end up with a destroyed,

damaged or defective unit if you’re not hitting that standard.

This photo is from the Adafruit guide to excellent soldering - bit.ly/1l77tF4

and is reproduced under an Attribution-Sharealike creative commons license

- http://creativecommons.org/licenses/by-sa/3.0/

!

!

September 8th 2014 www.thonk.co.uk 3

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

VCA BUILD INSTRUCTIONS

1.

Start by emptying the whole of the VCA

bag into a bowl or container. This makes

it much easier to pick parts as you need

them and you’re a lot less likely to lose

anything.

2.

First you will solder the three 0.1uF SMT

capacitors.

When you remove the SMT parts from the

white plastic packaging I highly advise

doing so inside a bowl or smooth box with

some soft white tissue paper inside.

Carefully peel back the transparent plastic

with the parts angled down so they fall

into the receptacle. The tissue paper will

stop them bouncing and sliding. If the

receptacle is big enough to fit the PCB in

while you solder even better, then when

you move the part to the PCB for

soldering you remove the chance of losing

them.

Soldering the type of SMT parts included

with this kit is not hard if you have

tweezers. You have no tricky multi pin

SMT IC’s or anything of that nature to

deal with in this kit.

Good technique is important though. This

video is a great introduction to the

standard way of soldering SMT resistors

and caps by hand:

http://youtu.be/PU7wLcuqc-I

!

!

September 8th 2014 www.thonk.co.uk 4

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

3.

Using the same technique as previously,

solder the ‘1K tcr’ SMT tempco resistor

into place. The green face marked ‘33’

should face upwards if possible but it isn’t

vital. Like any resistor it can be soldered

in either orientation.

4.

Next solder the two 100R resistors into

place as shown.

NOTE! In some of the kits the 100R

resistors are provided as two separate

bags with 1 piece in each.

NOTE! You should have nice shiny solder

cones on BOTH sides of the board. If you

have not then re-evaluate your soldering

technique and equipment and revisit the

YouTube video linked on page 1 and the

‘good joints’ image on page 2.

5.

Next solder the single 330R resistor into

place as shown.

NOTE! Keep a couple of resistor legs

spare as you will need one later!

!

!

September 8th 2014 www.thonk.co.uk 5

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

6.

Next solder the four 1K resistors into

place as shown.

7.

Next solder the single 4.12K resistor into

place as shown.

8.

Next solder the single 10K resistor into

place as shown.

9.

Next solder the two 20K resistors into

place as shown.

10.

Next solder the seven 100K resistors into

place as shown.

!

!

September 8th 2014 www.thonk.co.uk 6

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

11.

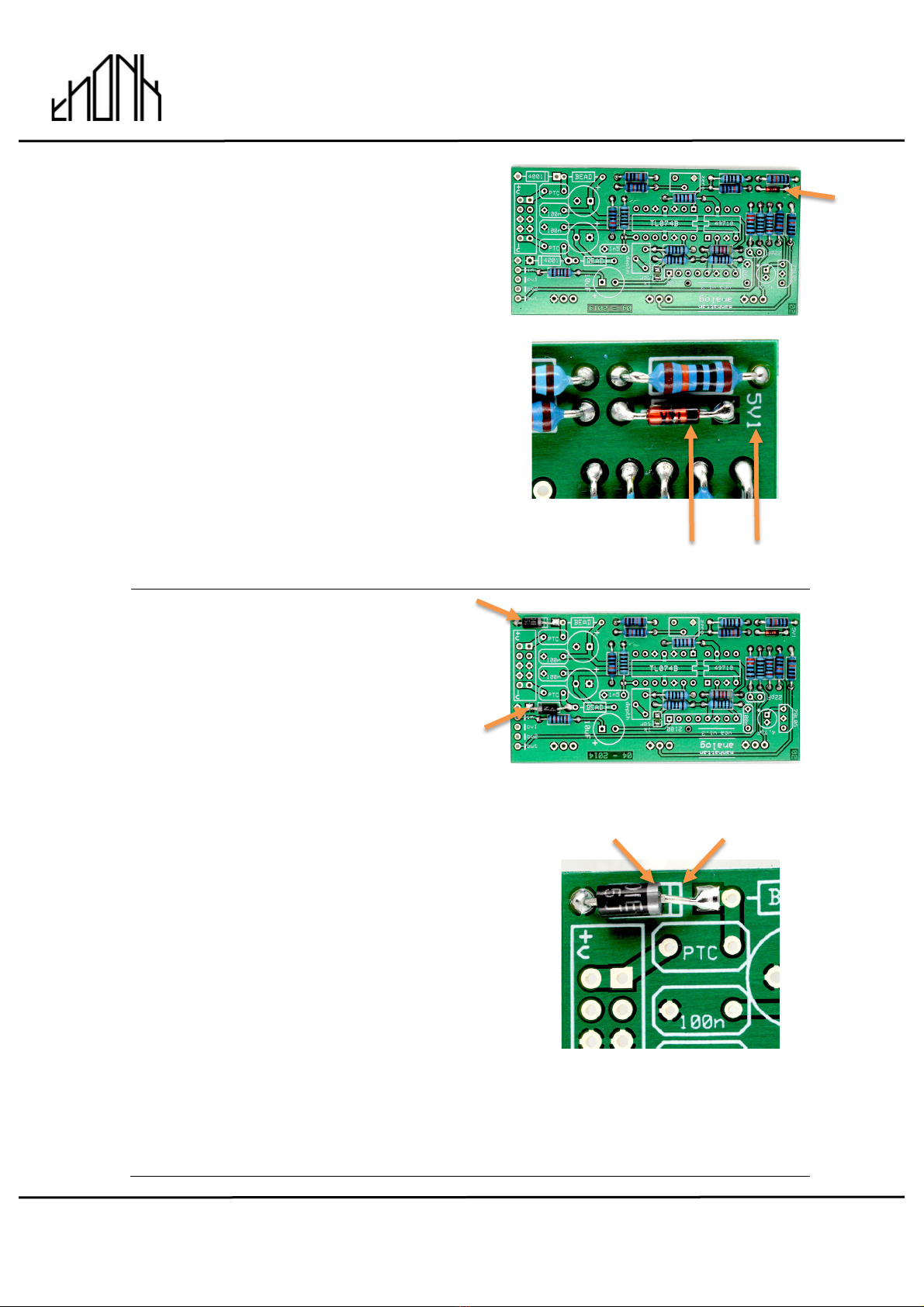

Next open the bag containing the 5

diodes, select the orange 5.1V Zener

Diode and solder it into place as shown.

NOTE! Orientation is vital. The Black ring

on the diode should be closest to the 5V1

text.

NOTE! Diodes can be damaged with a

long exposure to the heat of the iron.

Solder neatly and quickly, you should

achieve the nice shiny solder cones

mentioned previously on both sides of the

board without needing to apply heat for

longer than 3 seconds per joint.

BLACK RING TEXT

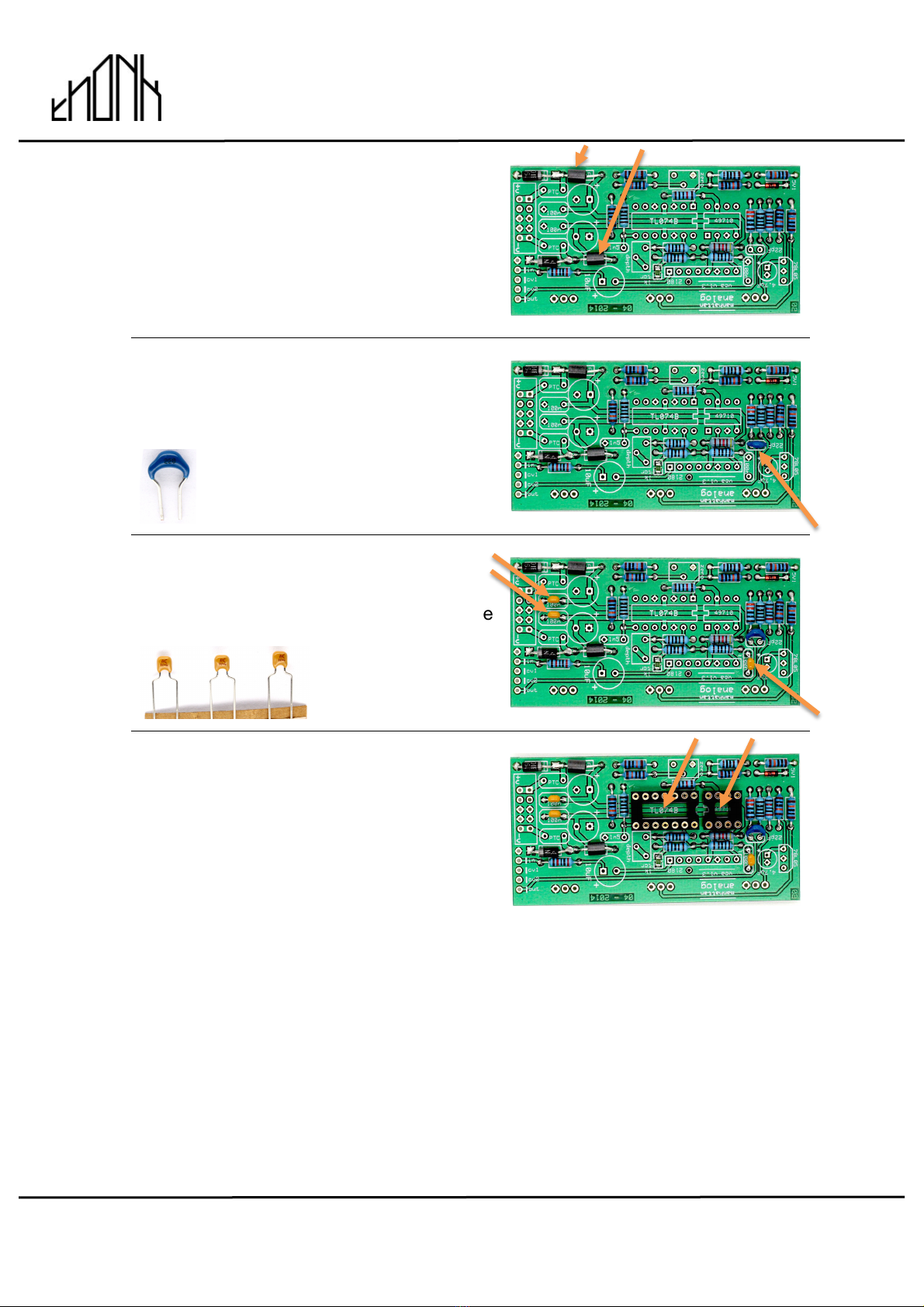

12.

Next take the two black and silver diodes

marked 1N4001 and solder into the

positions shown.

Do not mistake the two dark grey ferrite

beads for the 1N4001. You are soldering

the parts with writing on in this step.

NOTE! Orientation is vital. The silver ring

on the diode should match the boxed end

on the silkscreen.

NOTE! Diodes can be damaged with a

long exposure to the heat of the iron.

SILVER RING BOXED END

!

!

September 8th 2014 www.thonk.co.uk 7

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

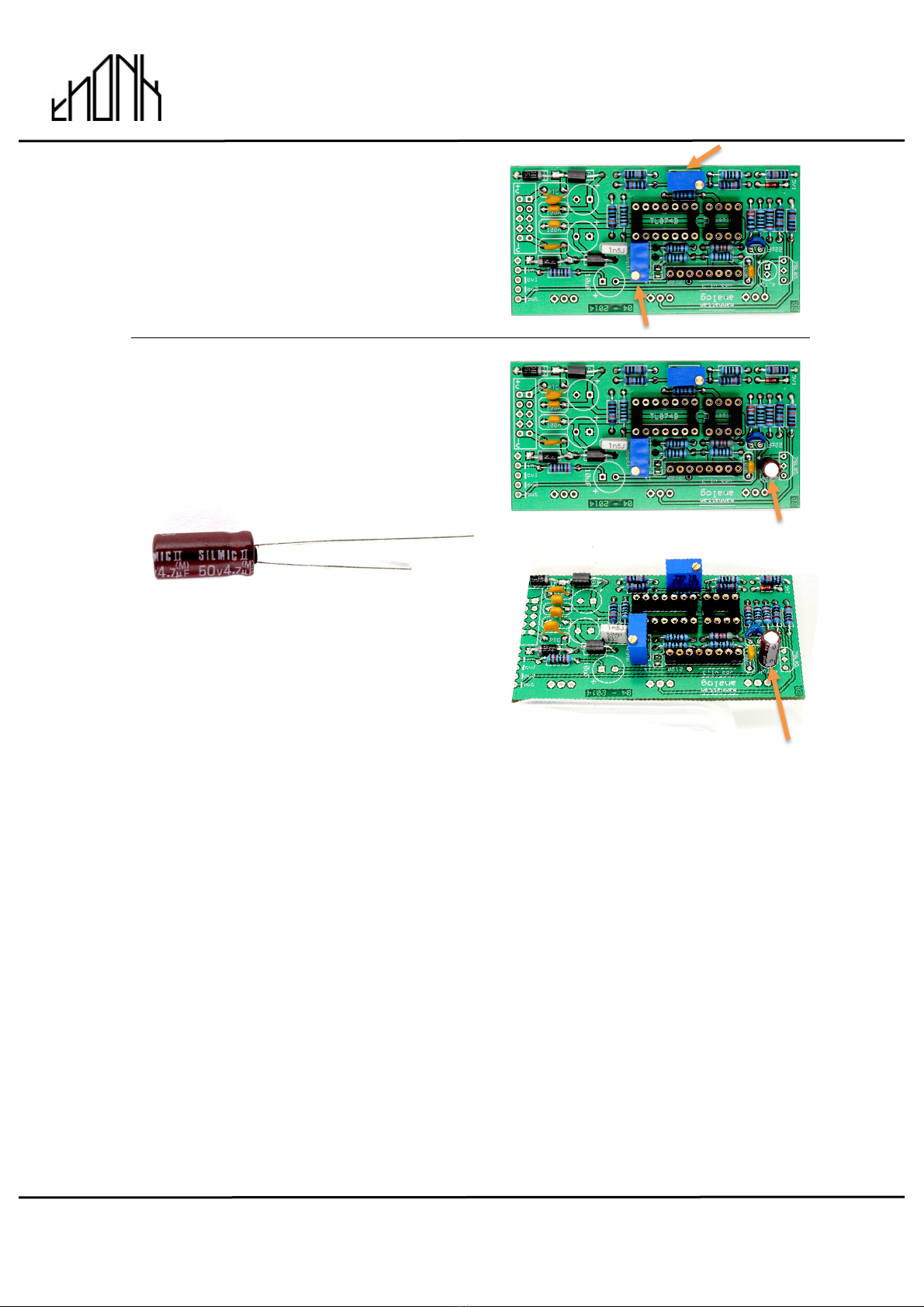

13.

Next solder the two Ferrite Beads into

position as shown.

14.

Next solder the single blue 22pF capacitor

into place as shown.

15.

Next solder the three 100n caps into place

as shown.

16.

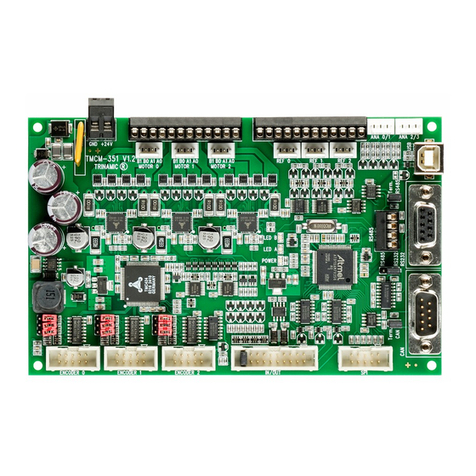

Next solder the 14 pin and 8 pin IC DIL

sockets into place as shown. Make sure

the notches in the sockets match the

silkscreen, on this board they face each

other.

!

!

September 8th 2014 www.thonk.co.uk 8

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

17.

Next you’re going to cut the 16 pin DIL

socket in the positions shown to create a

single line 8 pin socket as shown.

18.

Next solder your newly created 8 pin

single line socket into place. The other

half of the socket can be kept for future

projects.

19.

Solder the single 1n5 capacitor into place

as shown.

20.

Solder the two orange fuses into position

as shown.

CUT HERE

!

!

September 8th 2014 www.thonk.co.uk 9

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

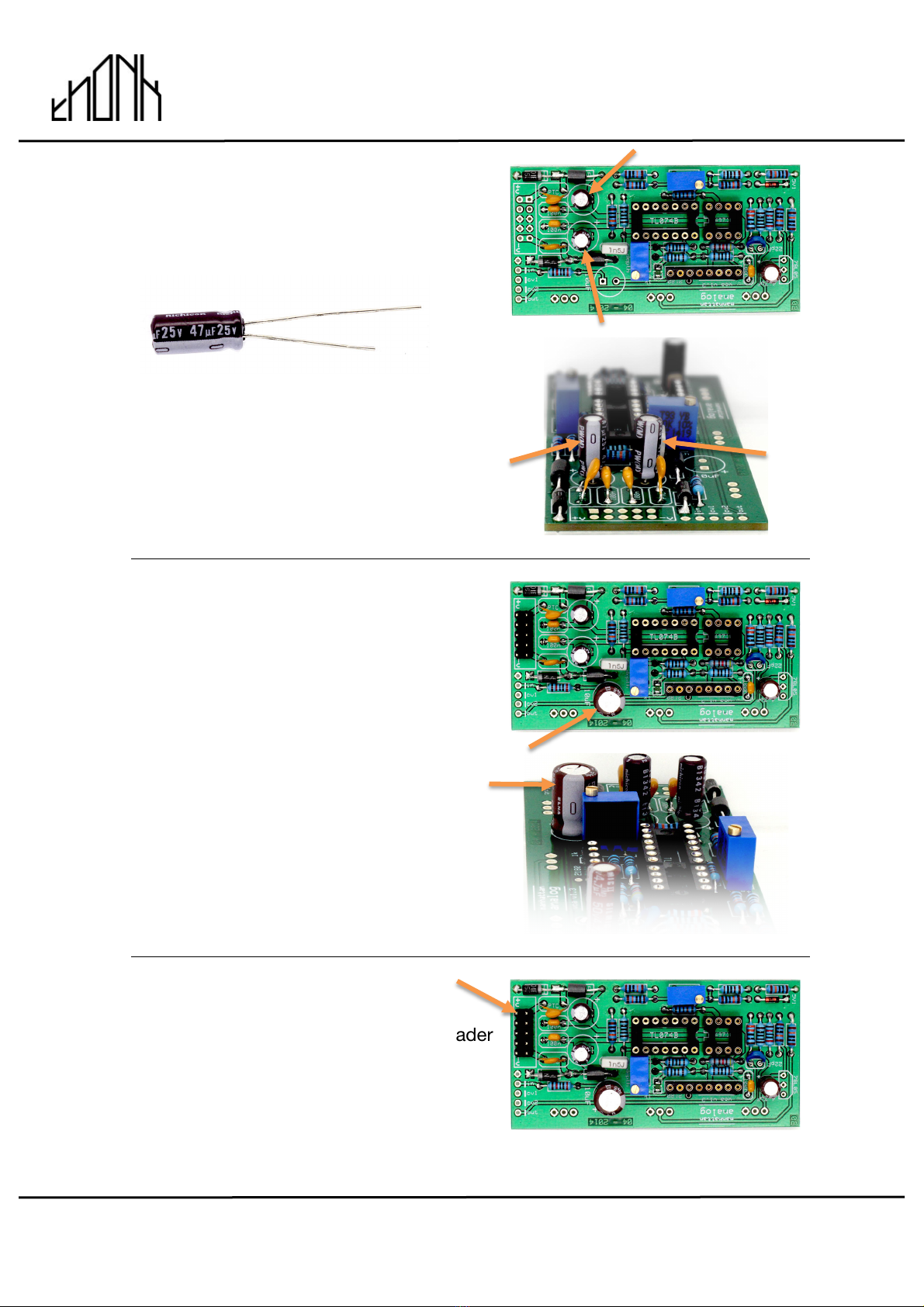

21.

Solder the two blue trimmers into position

as shown.

22.

Solder the single 4.7uF ‘SILMIC II’

electrolytic capacitor into position as

shown.

NOTE! DO NOT MISTAKENLY SOLDER ONE

OF THE TWO 47uF NICHICON ELECTRO

CAPS HERE!

NOTE! Orientation is vital. The longer lead

on the part should be positioned in the

square pad marked with the plus/positive

symbol.

+!

!

!

September 8th 2014 www.thonk.co.uk 10

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

23.

Solder the two 47uF Nichicon electrolytic

capacitors into position as shown.

NOTE! Orientation is vital. The longer lead

on the part should be positioned in the

square pad marked with the plus/positive

symbol.

24.

Solder the larger remaining electrolytic

capacitor into position as shown.

NOTE! Orientation is vital. The longer lead

on the part should be positioned in the

square pad marked with the plus/positive

symbol.

25.

Solder the ten pin Eurorack power header

into position as shown.

+!

!

!

September 8th 2014 www.thonk.co.uk 11

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

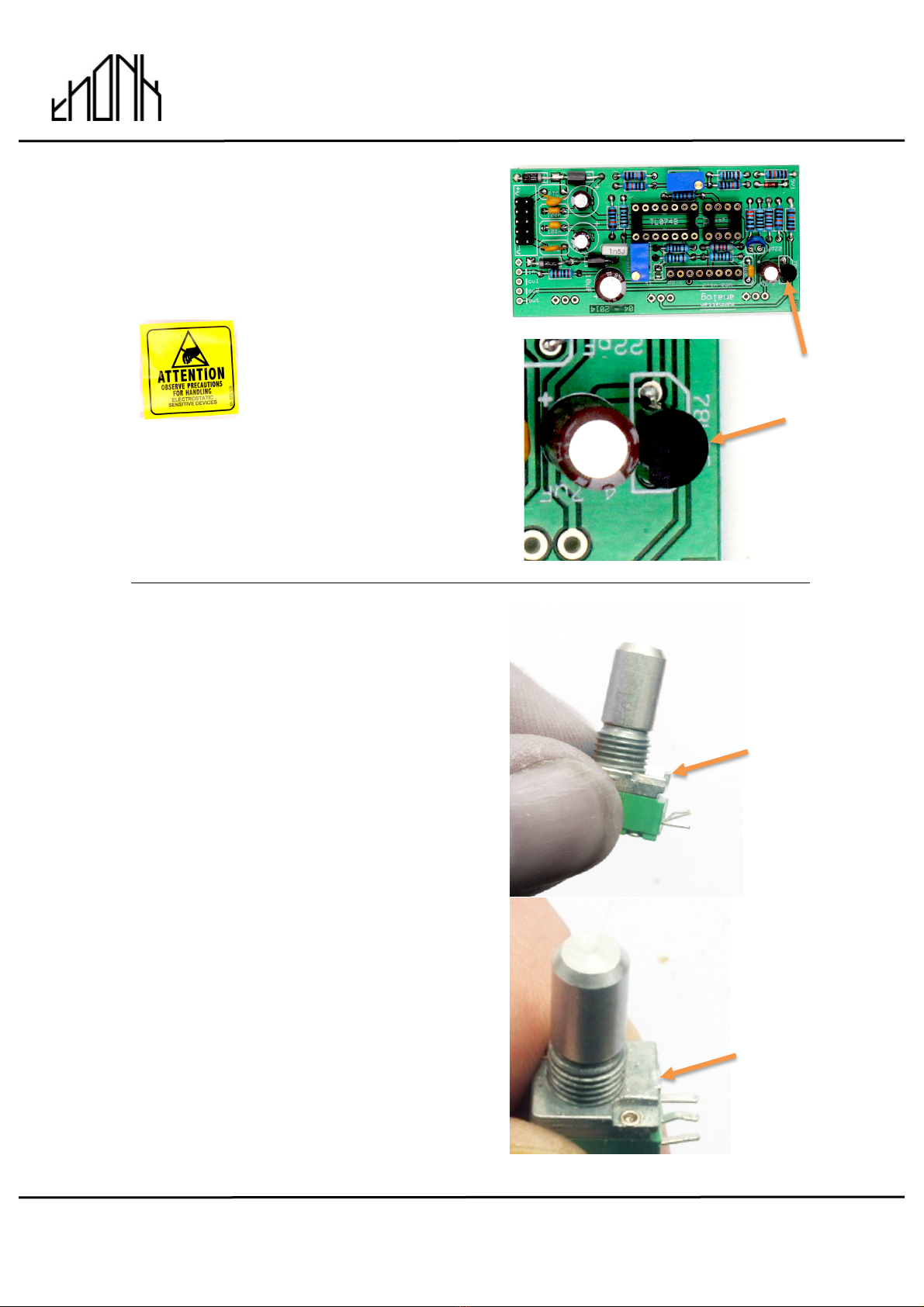

26.

Open the yellow ESD packet and solder

the 78L05 into position. The rounded side

of the component faces out towards the

edge of the board.

27.

Remove the nut and washer from each

pot and cut or break off the small anti-

rotation lug on each one.

!

!

September 8th 2014 www.thonk.co.uk 12

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

28.

Next position the pots as shown but DO

NOT SOLDER yet. Hand-tighten the nuts

and washers onto the pots to secure the

panel into place.

Make sure all three pots are flat and

touching the PCB then solder all 9 joints.

You may just want to tag one terminal on

each pot with solder first so that the pots

are all definitely flush with the PCB. Then

finish the other 2 joints on each pot.

Remove the panel again and put the

washers and nuts somewhere safe.

B100K B100K C50K

CV2 CV1 OFFSET

29.

Next take the coloured ribbon wire

provided, break it down to a 5 stranded

piece, fan out one end, strip the insulation

and tin the conductors.

30.

Solder into place as shown so there is one

wire going into each of the 5 pads as

shown.

31.

You can now split the wires apart.

!

!

September 8th 2014 www.thonk.co.uk 13

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

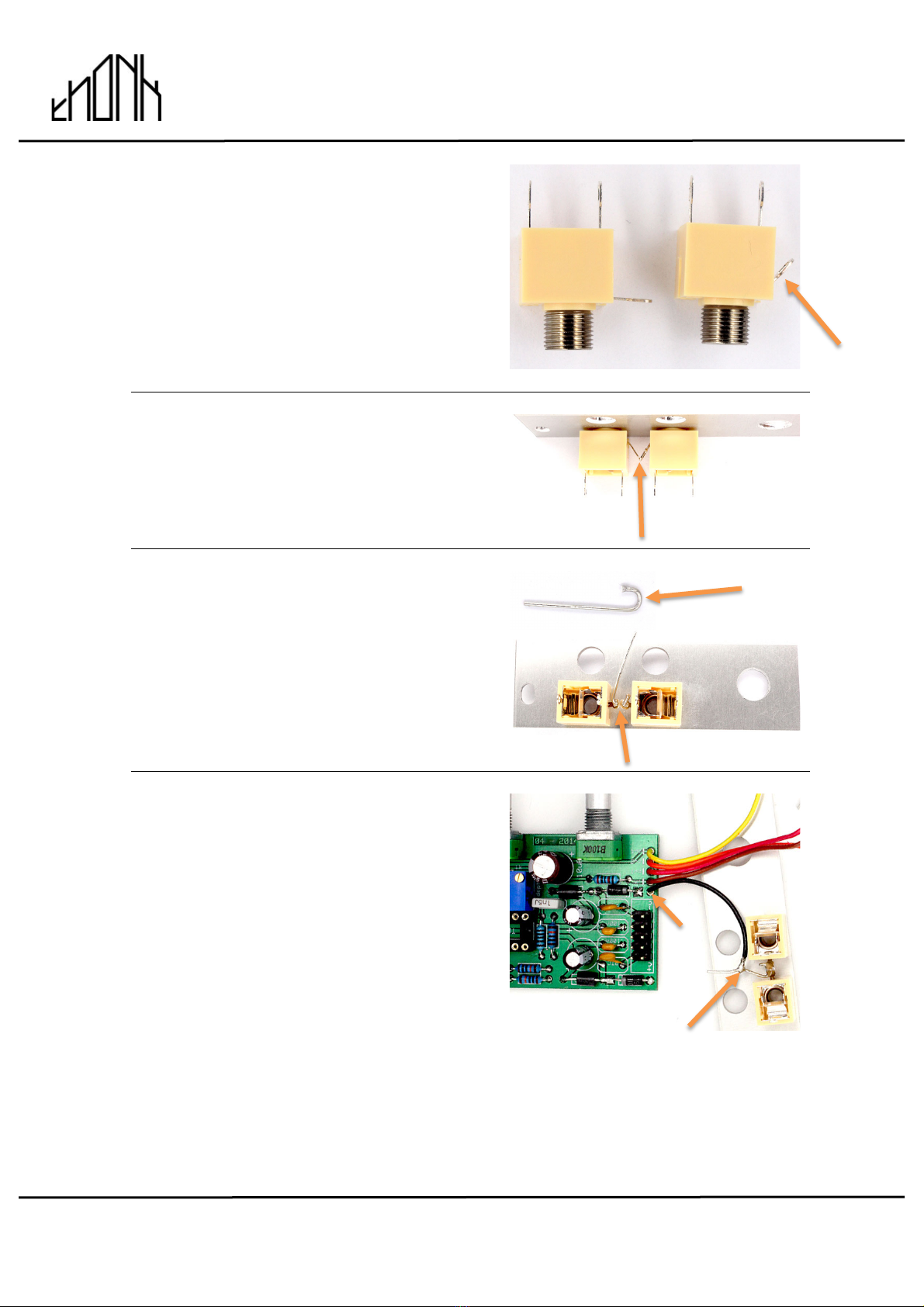

30.

Take the four cream coloured jacks and

bend the ground pins up as shown.

31.

Tighten the jacks into place on the CV1

and IN positions so the ground pins are

touching as shown.

32.

Take one of the resistor leads you saved

earlier, use pliers to bend into a ‘crook’

shape and thread through the two

touching jack ground pins. Solder so there

is a solid conection between the jacks and

the lead.

33.

Now solder the wire going from the

ground pad on the PCB (my wire here is

black yours may be a different colour!) to

the centre of the jack lead.

The Ground pad is the one closest to the

power socket.

!

!

September 8th 2014 www.thonk.co.uk 14

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

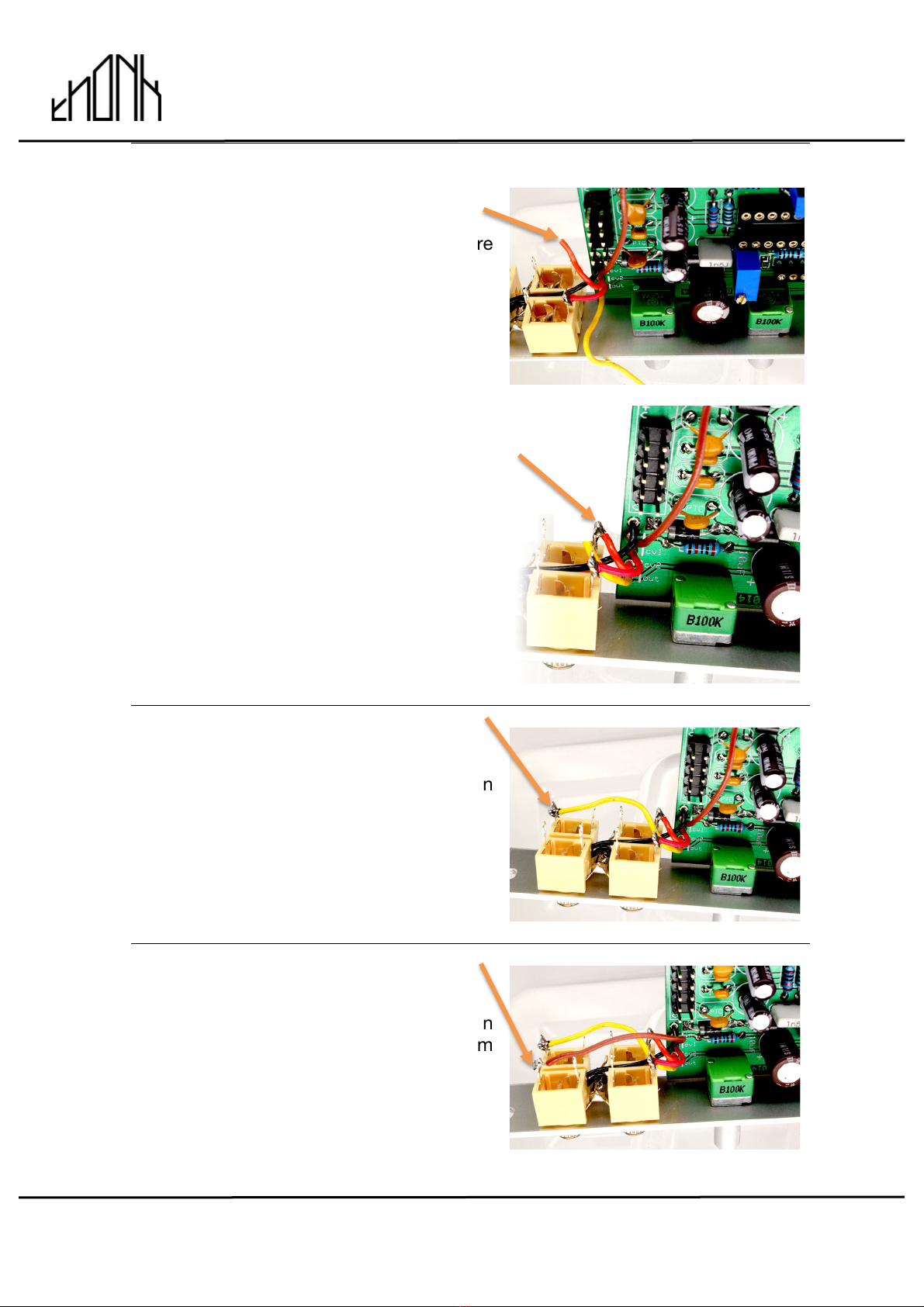

34.

Next you need to fix the other two jacks to

the panel and solder both ground pins

together to the lead. It’s easiest to thread

the ground pins onto the hanging lead

BEFORE pushing the jack barrel through

the hole in the panel.

Now there is a connection between:

1. The ground pins on all 4 jacks

2. The bridging resistor lead

3. The wire to the ground pad on the

PCB

35.

Push the ground wire down between the

four jacks so it is out of the way and

secure.

Cut the CV1 wire down (in my diagram it’s

red, yours may be a different colour) so

that it’s extending about 1cm further than

the closet vertical pin on the CV1 jack.

Check the panel legend for reference!

36.

Strip then solder the CV1 wire (red in my

photo) to the nearest pin on the CV1 jack

!

!

September 8th 2014 www.thonk.co.uk 15

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

37.

Now repeat the process with the wire

leading to the CV2 pad on the PCB (in my

photo it is orange).

Trim the CV2 wire so it protrudes 1cm

from the nearest vertical pin on the CV2

jack and solder.

38.

Now solder the wire from the OUT pad on

the PCB to the vertical pin furthest from

the PCB on the OUT jack.

In my photo this wire is yellow.

39.

Finally solder the wire from the IN pad on

the PCB to the vertical pin furthest from

the PCB on the IN jack.

In my photo this wire is brown.

!

!

September 8th 2014 www.thonk.co.uk 16

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

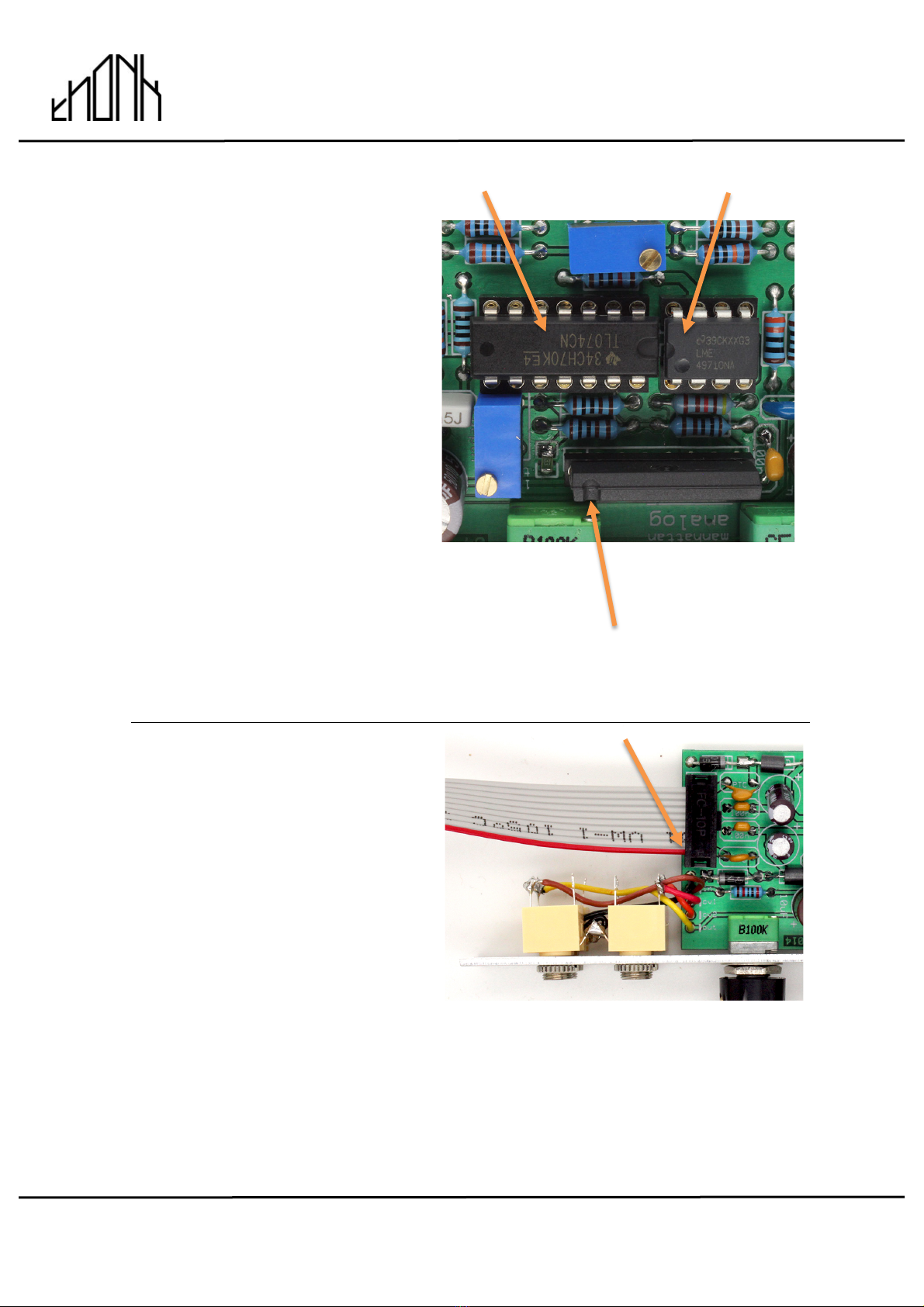

40.

Take the remaining three ICs from

the black foam in the ESD packet

and position as shown. Make sure

the notches in the TL074 and

LME49710 are facing inwards as

shown and matching with the

notches on the IC sockets.

Note that on the single row header

you cut down to size, there is a

box marked on the PCB, at the

point closest to the blue trimmer.

Align the notch on the

THAT2180B chip.

The pins on the THAT2180B are

quite long so take care to not

bend them when pushing into the

socket. A little effort is required at

first but once it starts moving it

will slip in easily.

TL074 LME49710

THE NOTCH IN THE EXPENSIVE CHIP!

Incorrect orientation will destroy the ICs

41.

Finally connect the power cable

as shown, so the red stripe is at

the point on the board marked –V,

closest to the frontpanel.

Next we’ll connect the power,

switch on and user a Multimeter to

trim the module.

!

!

September 8th 2014 www.thonk.co.uk 17

Manhattan Analog

VCA Module

Eurorack DIY Kit

Instructions

Version 1.0

42.

Here are the Manhattan Analog instructions for trimming the module.

1. Probe the pad on the PCB marked 'TP' ("Test

Point")

2. Set offset to max CW (full volume) *or* insert

a +5.00V CV source into one of the inputs

3. Use the trimpot labelled 'zero' to set the

voltage @ 'TP' to 0V

4. Set offset to max CCW (off)

5. Use the other trimpot to set voltage @ 'TP' to

305.00mV, give or take ~3mV (~1%).

It should then open fully to unity gain with a +5V CV signal. The zener

diode limits the offset + incoming CV sum to ~5.14V, so if you mash it

up to the diode's break point you'll get a little bit of positive gain

with it trimmed to unity at +5.00V.

If you like distortion I encourage you to tweak the trimpots to taste

as you can really overdrive it by setting the zero-point (step 3) to a

positive value. (*this is from memory so forgive me if I got something

backwards...) The THAT chip sounds really meaty when you overdrive the

shit out of it. It's not a bad distortion module if patched/set up that

way. cool

Alternative CV response is possible - you can set it up to accept 8V or

10V signals by changing the zener diode to an appropriate value and

trimming as above. I did a few @ 8V as prototypes when I ran out of

5.1V zeners.

Table of contents

Other Thonk Control Unit manuals

Popular Control Unit manuals by other brands

VISTEON

VISTEON AUXILIARY IDLE operating instructions

Befaco

Befaco Trolley Bus V1 Assembly guide

Trenz Electronic

Trenz Electronic TE0726 manual

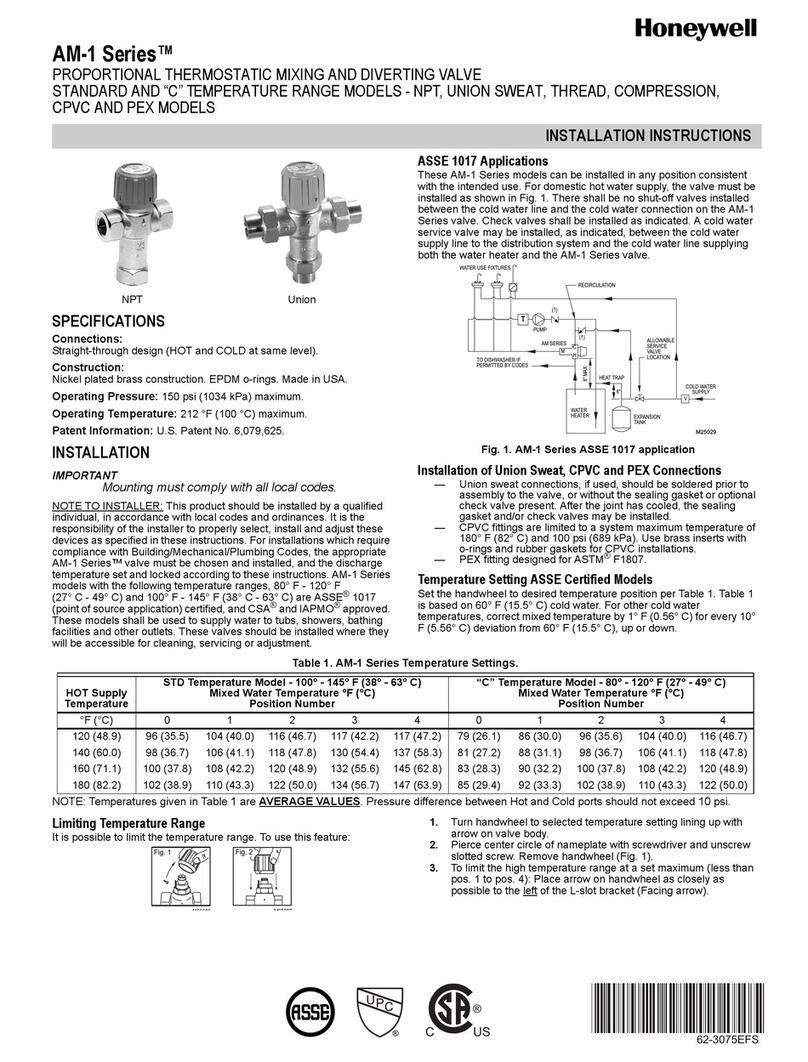

Honeywell

Honeywell AM-1 Series installation instructions

GEM

GEM 601 Installation, operating and maintenance instructions

hager

hager ZZ45WAN2PP Mounting instructions