MTS25-Z8 and MTS50-Z8 DC Motorized Translation Stages

Contents

Chapter 1 Overview ...............................................................................................................1

1.1 Introduction..................................................................................................1

Chapter 2 Safety.....................................................................................................................2

2.1 Safety Information.......................................................................................2

2.2 General Warnings........................................................................................2

Chapter 3 Installation............................................................................................................3

3.1 Environmental Conditions ........................................................................3

3.2 Mounting........................................................................................................4

3.2.1 Invalidation of Warranty..................................................................................4

3.2.2 General.............................................................................................................4

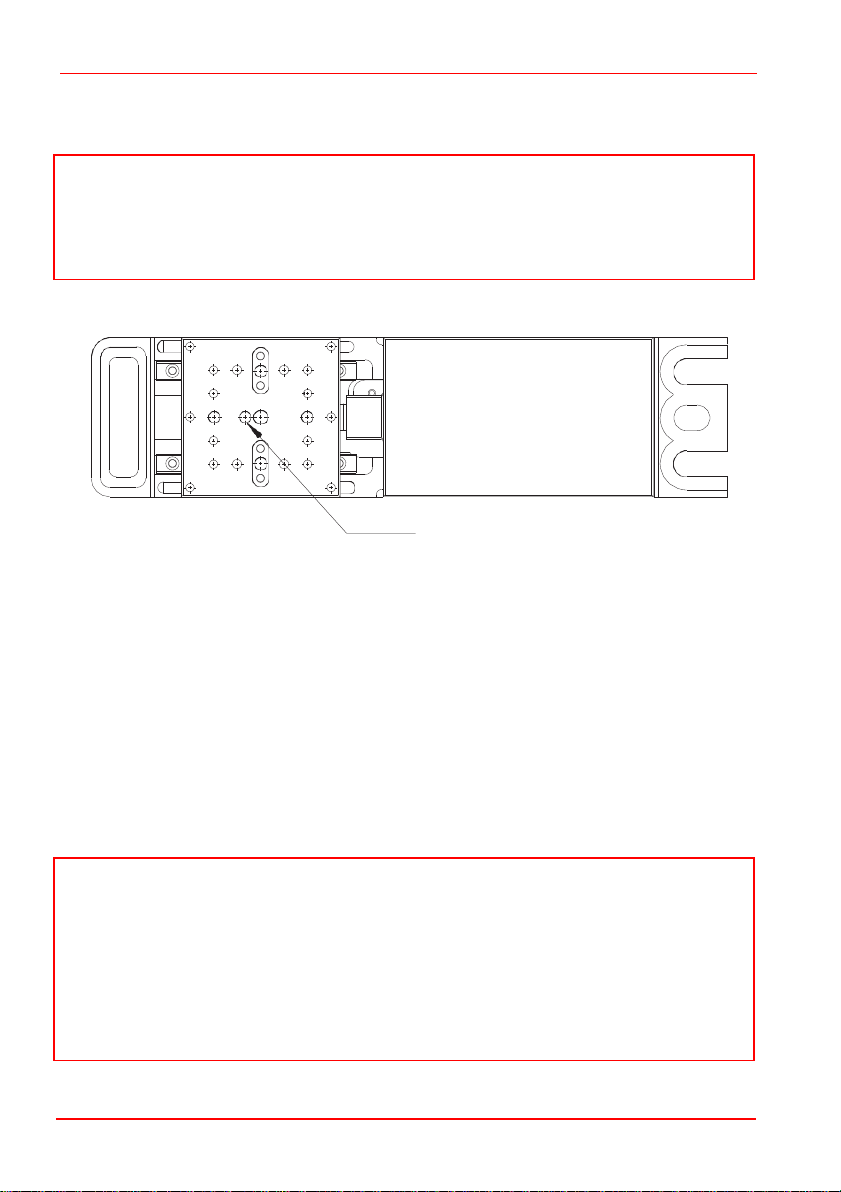

3.2.3 Connecting The Motor Driver.........................................................................5

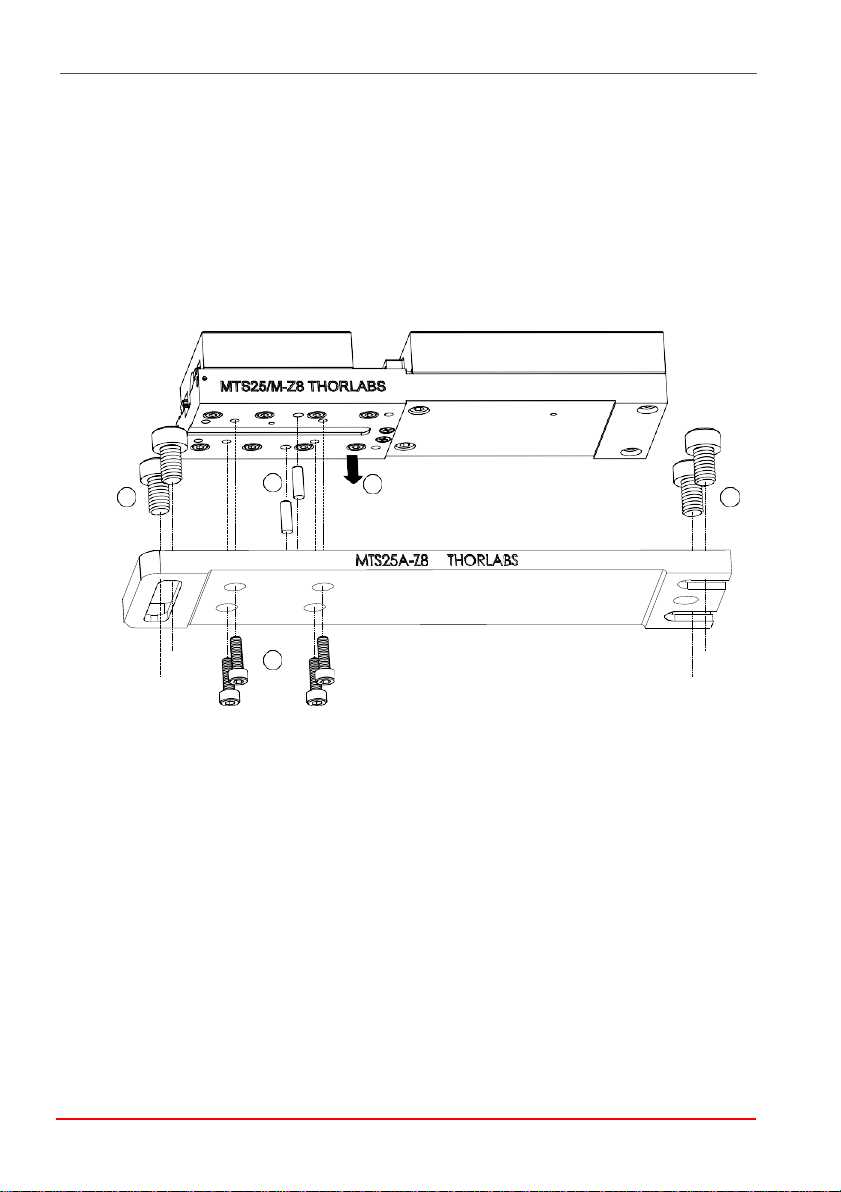

3.2.4 Fitting and Removing the Base Plate............................................................6

3.2.5 Building an XY Configuration.........................................................................7

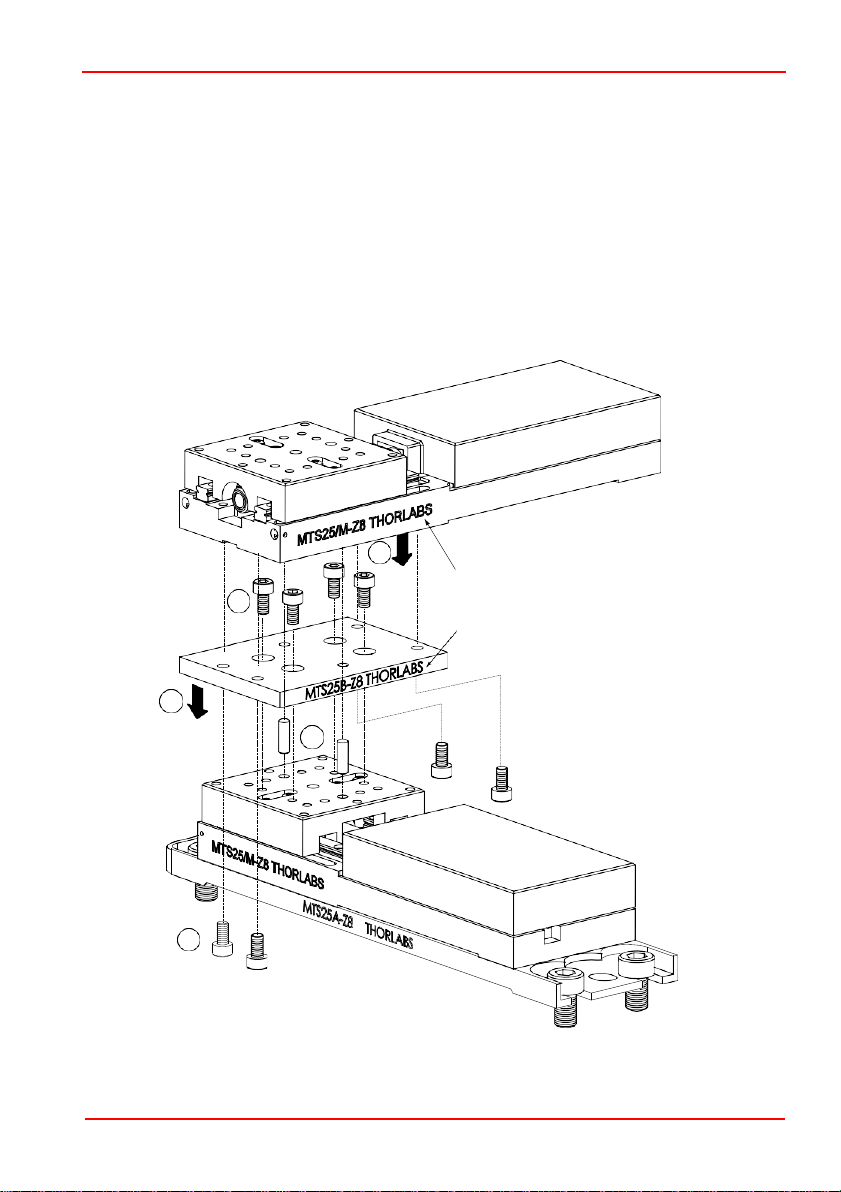

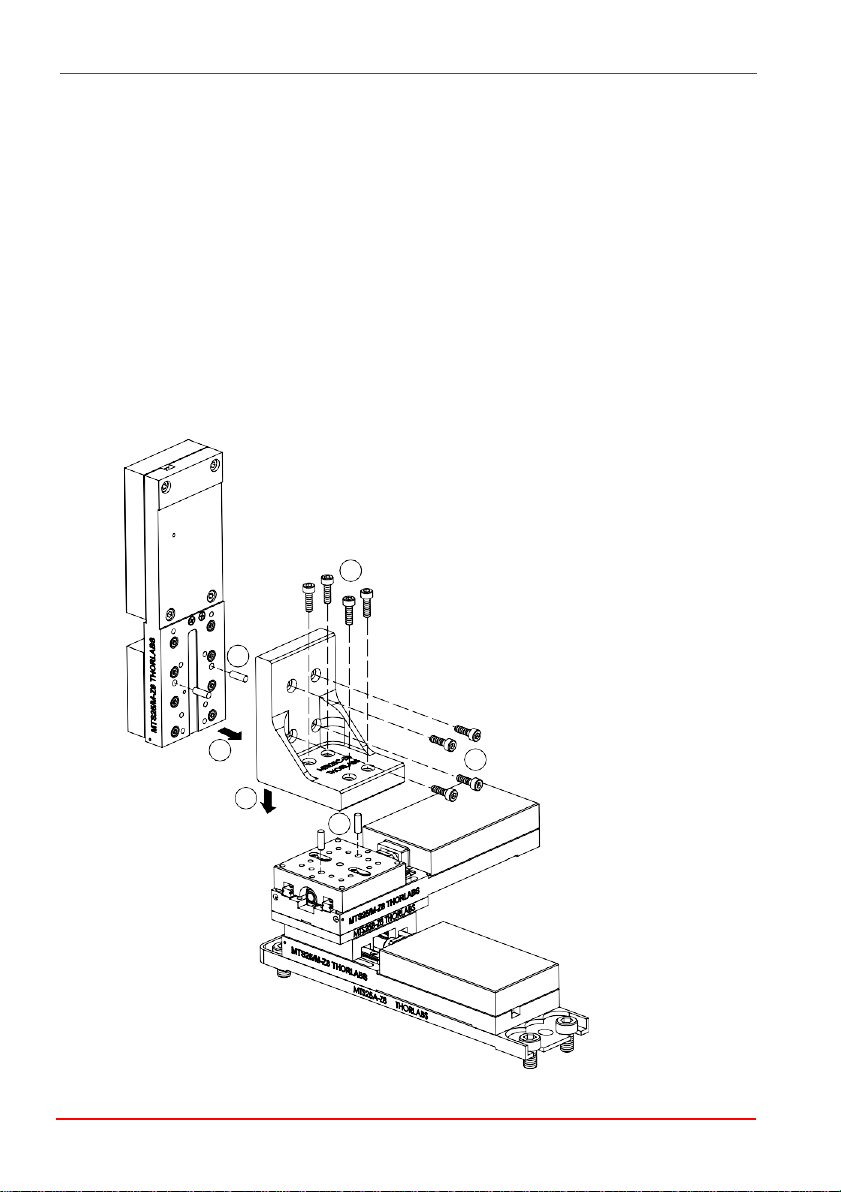

3.2.6 Building an XYZ Configuration.......................................................................8

3.3 Transportation..............................................................................................9

3.4 Dimensions................................................................................................ 10

3.4.1 MTS Dimensions ...........................................................................................10

Chapter 4 Operation........................................................................................................... 11

4.1 General....................................................................................................... 11

Chapter 5 Specifications................................................................................................... 13

5.1 Stage Specifications................................................................................ 13

5.2 Motor Specifications.................................................................................14

Chapter 6 Motor Pin Out Details & Associated Parts................................................. 15

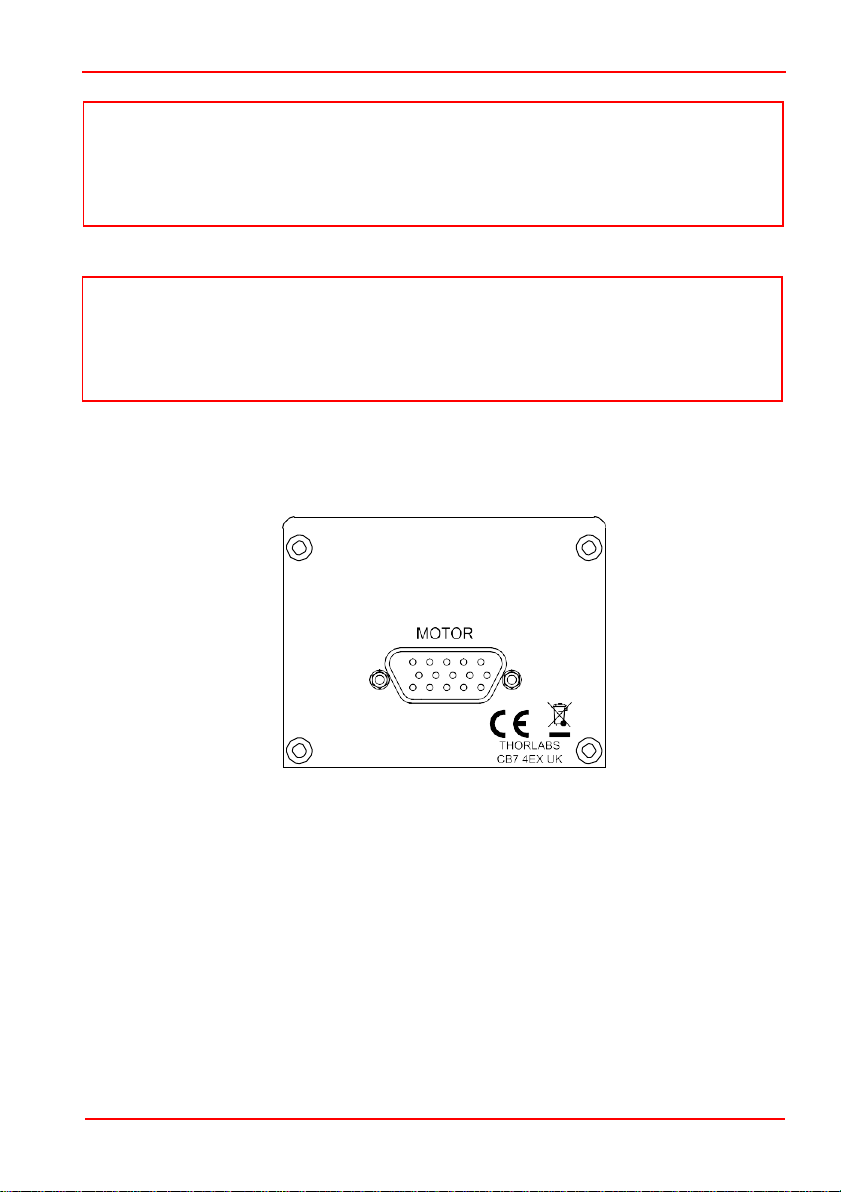

6.1 Motor Connector Pin Out........................................................................ 15

6.2 Associated Products............................................................................... 15

Chapter 7 Regulatory ......................................................................................................... 16

7.1 Declarations Of Conformity....................................................................16

7.1.1 For Customers in Europe .............................................................................16

7.1.2 For Customers In The USA..........................................................................16

7.2 CE Certificates........................................................................................... 17

Chapter 8 Thorlabs Worldwide Contacts ...................................................................... 18

19593-D02