Thunderbird T10 User manual

WEIGHING SYSTEMS

T10 Instruction Manual

Installation

Locate a weighing site that is well drained. For best weighing results, ensure the weigh

bars and weighing platform are on a level hard surface (i.e. concrete), and free from

contact of any obstruction. Do not use wooden platforms. Make sure the platform

doesn’t rock, pack with spacers if needed. If the installation has any flexing or twisting

in the platform, inaccurate weights may occur. The weight should be evenly distributed

over the top of the weigh bars.

When bolting the bars down, also eliminate any twisting of the platform. Avoid bolting

everything down tight. If in a fixed situation, it is best practice to bolt the rear bars to the

concrete, then bolt the platform or crush to the bars, then leave the front bars unbolted

with only guide pins into the concrete. Shim the bars and crate with washers or similar

pieces of metal so that no diagonal rocking motion occurs before tightening all of the

fixings. This will minimize any flexing that could occur.

When weighing animals, be sure that their weight is totally on the weighing surface, and

not leaning on fixed gates, rails, etc. If at all possible use a crush or weigh box, and

place the weigh bars so that the whole structure is weighed. This will eliminate

weighing errors if the animal does lean on any part of the structure

.

Care and Maintenance

WARNING! DO NOT WELD TO THE WEIGH BARS OR ANY STRUCTURE THAT

THEY ARE ATTACHED TO. The voltage and current from the welder can instantly

destroy the sensitive strain gauges used to measure the weight. Welding currents

create observable damage to the strain gauges, and will void your warranty. Remove

the weigh bars from the structure before attempting to weld.

Care of cables is important to avoid erratic readings or breakdown. Plugs should

be covered when not in use to avoid corrosion of contacts and to prevent moisture

penetrating the cables. Even a thin film of moisture around the pins in the plug may

cause erratic readings.

Do not allow the bars to remain wet or allow a build up of manure inside the bars

for long periods of time. This will shorten the life of the weigh bars, can cause

premature failure and may void your warranty. If the area does remain wet, remove the

weigh bars when not in use. The weigh bars are sealed, and can be hosed out with low

pressure water to keep clean.

Store the indicator in a dry area away from moisture when not in use. Although it

has a gasket seal to prevent water ingress, repeated cycling of warm and cool from day

to night in a damp area may cause a build up of moisture inside the indicator.

Do not transport weigh bars or load cells with a weight on them. If the vehicle

goes over a bump, the resulting ‘G’ forces increase the effective weight applied, which

may exceed the load cell capacity, causing damage to the load cells. Load cells that

have had excessive weight applied to them are not covered by warranty.

Power

The T10 is powered by 4 x AA batteries. These are inserted in a removable battery

pack and placed in the battery compartment at the rear of the indicator.

A battery level indicator is displayed while the scale is operating, which gives an

indication of the time remaining before the batteries go flat. The lowest segment will

start flashing when the battery level is low and the charger is not plugged in. Turn off

the indicator and replace the batteries when this occurs.

Good quality alkaline batteries will power the scale for up to 30 hours running time.

Rechargeable AA batteries may be used, but the battery level indicator will not be as

accurate.

The T10 will turn itself off after 30 minutes if no keys have been pressed or if the weight

has not changed.

Operation

On-Off Tare

Up

Weigh Kg/lbs

Settings Mode

OK

Back Down

Load cell 1 Load cell 2

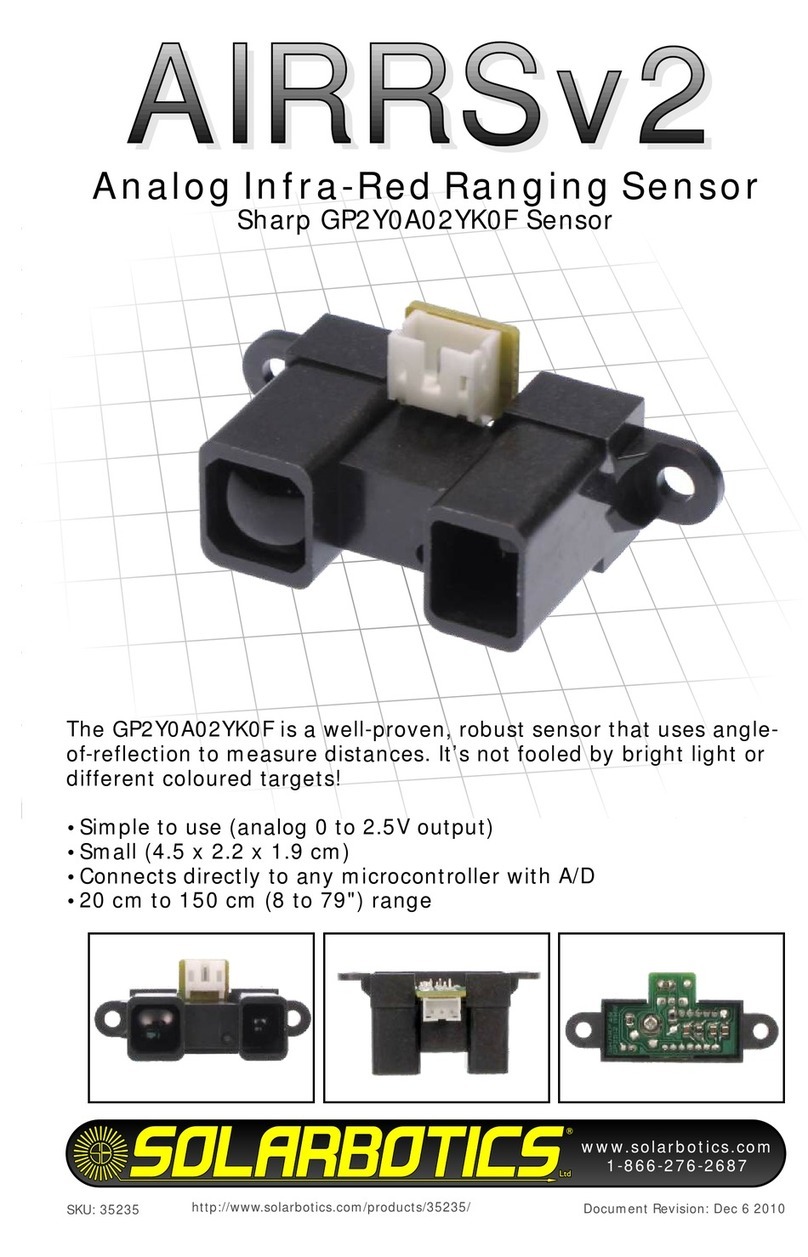

The T10 has a water resistant 10 button keypad for a user interface. An extra large

40mm digit display provides the user with the ability to view the weight at a distance.

The display also has other indications that are used at various times. All mode settings

and changes are memorized at the time of change, so that the indicator will return to the

previous set up when it is turned on.

The T10 contains highly stable and sensitive circuitry, which is designed to improve

accuracy.

Following is a description of each button and what it does:

Off/On

This button does what it says. There is no power drained from the batteries when the

scale is turned off.

When powering up, the indicator will display all relative segments for a short time, then

the firmware version number, and then a tare is performed automatically after a short

delay. If there was a weight on the load bars when the indicator was turned off, this

weight is displayed if it hasn’t changed, otherwise zero weight is displayed. The scale is

then ready for weighing. This means that no buttons need to be touched if the scale is

used for weighing the same thing each time.

Tare

When pressed during normal weighing, the scale will display 4 dashes (----) and cancel

any weight that exists on the weigh bars. After a few seconds the display will show zero

weight, regardless of any weight (such as a weigh box) that may be present. The tare

button also has other purposes that will be described during other various functions.

Mode

Mode selects the weighing mode. The current mode is displayed during normal

operation. There are 3 available weigh modes, each with a different purpose. They are:

Livestock – (Cow icon) This mode is designed to weigh moving weights, such as

animals. The indicator switches to a damping system that filters out sudden changes in

weight, and averages many weight samples over a couple of seconds. Two weights are

displayed at first at one second intervals, then there is a delay until the weight becomes

stable, at which point the actual weight is displayed. The displayed weight will change if

the indicator determines that the weight isn’t quite right.

Livestock Locking – (Cow with a lock icon) Locking mode works the same as normal

livestock mode, except that once a weight is displayed, any change in weight won’t be

shown until the change exceeds +/-5% of that displayed.

General – (Trolley icon) This mode is for weighing static weights and produce. The

displayed weight is updated every second, and doesn’t have any weight damping or

zero tracking. It is suitable for weighing products that are slowly added to, such as

weighing grain being augured into a bin.

Weigh

The weigh button has different functions depending on the mode setting.

In livestock locking mode, pressing the weigh button will cause a new weight reading to

be taken and displayed, regardless of a change in weight.

In livestock and general modes, pressing the weigh button will cause the weight to be

held on the display, even after the weight has been removed. The large lock icon will

be displayed. This held weight will disappear automatically and a new weight will be

displayed when another weight is applied onto the scale. Pressing the weigh button

again when the weight has been removed will cause the display to return to zero.

Kg/lb

The indicator is capable of displaying weights in either pounds or kilograms. Alternate

presses of this button swaps between units. The unit the weight is shown on the display.

Settings

Pressing the settings key once will cause the system capacity to be displayed. Pressing

it again will cause the scale to return to normal weighing. The calibration mode may be

entered by pressing the settings key once, and then pressing the down arrow key.

OK, Back, Up and Down

These keys are mainly used during calibration. Refer to the calibration procedure.

Calibration

The T10 has the capability of being calibrated in the field. The electronics in this

weighing system is very stable, and this calibration procedure should rarely need to be

done. However, if the weights are critical, it is advisable that the scale be calibrated

every year or two. If the load cells have been slightly overstressed, or specific errors

have been displayed as described later, it is also advisable to re-calibrate the system

before returning the scale for repair. It may be that recalibration will solve the problem.

Re-calibration may not fix the problem if the weigh bars or load cells have been grossly

overstressed.

To perform the calibration, a known fixed weight must be at hand. Also, if the indicator

is not connected to standard Thunderbird load cells, the capacity of the total system and

the number of load cells in the system must be known. The capacity should be printed

on the label attached to the weigh bar or load cell. The test weight must be a minimum

of 5% of the capacity of the system, and small enough to be able to balance easily on 1

weigh bar or load cell. The maximum test weight is the total capacity of the system

divided by the number of weigh bars or load cells. For example, a 2 tonne system with

2 load cells would have a maximum test weight of 1 tonne. Similarly, a 500kg system

with 2 bars has a maximum test weight of 250kg.

Each weigh bar or load cell is calibrated independently, and they must be removed from

any structure that they’re supporting before calibration starts.

The calibration procedure may be aborted at any time up until ‘donE’ is displayed by

turn the indicator off. The back key may be used to repeat a procedure at any time.

When inputting a value, the up and down arrows may be pressed briefly to increase or

decrease a value, or held down. When held down, the value will increase by 1 unit at a

time until a tens digit changes, and then the value will change by 10 units at a time.

Releasing the key will re-start the procedure.

The procedure is as follows:

1. Press the settings key once, and then press the down arrow key. ‘CAL-‘ will be

displayed. Press OK to continue, or the settings, down arrow or weigh key to

exit. Press the back key to show the system capacity again.

2. If non-standard Thunderbird load cells or older Thunderbird load cells are used,

the system capacity needs to be entered. Otherwise go to step 4. Use the up

and down arrow keys to input the system capacity and then press OK.

3. If non-standard Thunderbird load cells or older Thunderbird load cells are used,

the number of load cells needs to be entered. Otherwise this step is skipped.

Use the up and down arrow keys to select the number of load cells and then

press OK.

4. If there are 2 load cells in the system ‘bAr1’ will be displayed and ‘zero weight’

will flash, otherwise go to step 5. Press tare, weigh or OK to continue.

5. ‘rdY?’ will be displayed and ‘zero weight’ will be flashing. Remove any weight

from load cell 1 (the load cell plugged into the left hand socket) and then press

tare, weigh or OK. If there is only one load cell, pressing back will exit the

calibration procedure.

6. ‘Zero weight’ will cease flashing, and ‘----‘ will be displayed for 4 seconds while

samples are obtained and averaged from load cell 1 with no load.

7. ‘Test weight’ will start flashing after the samples have been taken, and the default

test weight will be displayed. Use the up and down arrow keys to enter the

known weight on hand that will be used for calibration. Press OK once the

correct weight is displayed.

8. ‘rdY?’ will be displayed with ‘test weight’ still flashing. Place the weight on load

cell 1 so that it is balanced evenly in the middle. Press weigh or OK to continue

or the back key to go back to the last procedure.

9. ‘Test weight’ will cease flashing and ‘----‘ will be displayed for 4 seconds while

samples are taken from load cell 1 with the weight applied.

10.If there was only 1 load cell in the system go to step 16. Otherwise ‘bAr2’ will be

displayed and ‘zero weight’ will be flashing. Press tare, weigh or OK to

continue, or the back key to go back to the previous procedure.

11.‘rdY?’ will be displayed and ‘zero weight’ will be flashing. Remove any weight

from load cell 2 (the load cell plugged into the right hand socket) and then press

tare, weigh or OK. Press back to go back to the previous procedure.

12.‘Zero weight’ will cease flashing, and ‘----‘ will be displayed for 4 seconds while

samples are obtained and averaged from load cell 2 with no load.

13.‘Test weight’ will start flashing after the samples have been taken, and the test

weight used for bar 1 will be displayed. Use the up and down arrow keys to

adjust the weight if necessary. Press OK once the correct weight is displayed.

14.‘rdY?’ will be displayed with ‘test weight’ still flashing. Place the weight on load

cell 2 so that it is balanced evenly in the middle. Press weigh or OK to continue

or the back key to go back to the last procedure.

15.‘Test weight’ will cease flashing and ‘----‘ will be displayed for 4 seconds while

samples are taken from load cell 2 with the weight applied.

16.‘donE’ will be displayed. This is the final step. If OK is pressed at this point the

new settings will be committed to memory and a tare will be performed. Remove

the test weight before pressing OK.

The new settings will be remembered until another calibration procedure is performed.

Increments

The T10 displays in varying weight increments, depending on a number of factors.

These factors include the capacity of the system, the weighing mode, and the amount of

weight applied. The guide below shows the increments used.

If system capacity is 200kg (440lb) or less;

General - 0.1kg (0.2lb)

Livestock - 0-50kg (0-110lb), 0.2kg (0.4lb)

50-200kg (110-440lb), 0.5kg (1lb)

For 201kg (441lb) to 2000kg (4400lb) load cell systems;

General - 0-50kg (0-110lb), 0.1kg (0.2lb)

50-500kg (110-1100lb), 0.2kg (0.4lb)

500-1000kg (1100-2200lb), 0.5kg (1lb)

>1000kg (2200lb), 1kg (2lb)

Livestock - 0-100kg (0-220lb), 0.5kg

100-500kg (220-1100lb), 1kg (2lb)

>500kg (1100lb), 2kg (5lb)

For systems over 2000kg (4400lb);

General - 0-50kg (0-110lb), 0.2kg (0.5lb)

50-500kg (110-1100lb), 0.5kg (1lb)

>500kg (1100lb), 2kg (5lb)

Livestock - 0-100kg (0-220lb), 1kg (2lb)

100-1000kg (220-2200lb), 2kg (5lb)

>1000kg (2200lb), 5kg (10lb)

Error Messages

The T10 has a very comprehensive self monitoring system that detects any problems

that may occur. Should such a problem be detected, an error message will be

displayed on the screen, for example ‘Er36’. Most error messages displayed concern

problems with the signal coming from the weigh bars or load cells. The signals from the

sensitive strain gauges are extremely small. A load bar that has its rated capacity

weight applied outputs less than 0.007 volts of signal.

Each load cell is sampled independently many times per second, which allows the T10

to continuously monitor any problems that could occur. One of these problems is an

overload condition. Any bar that is overloaded will be displayed, even if the overload

only lasts for a fraction of a second. This feature enables the user to minimize possible

damage and ensure a more reliable weight, as well as extending the useful life of the

scale.

If an error message is displayed, turn the indicator off, and closely inspect the cables

connecting the weigh bars or load cells. If there is a cut in the outer sheath, or a

squashed section of cable, it may have to be replaced.

If there doesn’t appear to be any visible damage after inspecting the installation, contact

your supplier or distributor, quoting the error number that appeared. They may be able

to help with a cure.

The possible error messages are as follows:

Error Explanation Possible Cause/Remedy

Err Load cells not plugged in properly Connect load cells

Er01 Load cell 1 at minimum signal Broken cable, new cable

Er02 Load cell 1 at maximum signal Broken cable, new cable

Er03 Load cell 2 at minimum signal Broken cable, new cable

Er04 Load cell 2 at maximum signal Broken cable, new cable

Er09 A/D converter not communicating Servicing required

Er13 No EEROM Servicing required

Er15 3.3V low Shorted cable or failure

Er28 No A/D samples Servicing required

Er32 A/D converter timeout Servicing required

Er36 Test weight < zero weight Incorrect wiring, L/C inverted

Er38 No load cell in socket 1 Connect load cell 1

Er39 No load cell in socket 2 Connect load cell 2

Er40 Shorted identifier in socket 1 Wiring error, incorrect load cell

Er41 Shorted identifier in socket 2 Wiring error, incorrect load cell

Er42 Not enough span in load cell 1 Faulty load cell

Er43 Not enough span in load cell 2 Faulty load cell

Er44 Can’t turn off Servicing required

Er45 Circuitry mismatch Servicing required

Troubleshooting

Problem Cause Remedy

Won’t turn on Batteries are flat Fit new batteries

A battery has been Fit batteries correctly

put in backwards

Short in load cell cables Disconnect cables and try.

If still won’t turn on, servicing

is required.

Faulty indicator Return scale for service

Won’t tare Moving weight The weight must be still and stable

before the indicator is able to obtain

a tare reading, make sure any weight

on the load cells does not move.

Poor installation The load bars must be installed on a

solid base such as concrete. Sitting the

load cells on the ground is not

satisfactory. Refer to the installation

guide.

Flexible platform Any platform that may be used on top of

load bars must be rigid, and the load

must be spread over the entire bar.

Timber paneling is not acceptable.

Moisture in plug Moisture is the most common cause of

erratic weights in any scale. If there is

moisture in the plug, undo the plug and

thoroughly wipe out and dry all parts of

the plug before reassembling.

Erratic weight Moisture in plug Moisture is the most common cause of

erratic weights in any scale. If there is

Moisture in the plug, undo the plug, and

thoroughly wipe out and dry all parts of

the plug before reassembling.

Poor installation The load bars must be installed on a

such as concrete. Sitting them on the

ground is not satisfactory. Refer to the

installation section.

‘OL’ displayed There is too much This error will self clear when the weight

on the load cells applied is removed.

Er15 is displayed There is most likely a If the cable is damaged it must be

short in the weigh bar replaced. If the problem is in a weigh

or its cable bar, return the complete scale for

service.

‘1 OL’ displayed There is too much weight This error will self clear when the weight

on the bar indicated. removed. This display could flash up for

a fraction of a second if there is a

momentary overload due to a heavy

weight being put down.

Options

The T10 can be supplied with various load cell options. These are:

Easymove 500kg bars- 2 bars, 580mm in length designed for portability.

Easymove 2000kg bars- 2 bars 580mm in length also designed for portability.

Extender 3000kg bars- 2 bars 1000mm in length.

The 3000kg bars are designed to fit under cattle crushes or large weigh bins for

maximum stability.

Specifications

Indicator:

Battery Voltage - 6Vdc (4 x AA batteries)

Supply Current:

Indicator only - 10mA

System with 1 weigh bar- 39mA

System with 2 weigh bars- 68mA

Load Cell Excitation Voltage - 3.3Vdc

Load cell input sensitivity - 1.2-3.2mV/V

Maximum offset voltage:- +/- 20mV

Accuracy - Greater than 99%*

IP Rating - IP56

Weigh Bars:

Gauge resistance - 120 Ohms

Offset Error - Within +/- 10mV

Sensitivity - 1.35 – 2.1mV/V

Overload Capacity - 150% of rated capacity

*Provided installation is done correctly.

E&OE. This information was correct at the time of compilation. Changes may be made to improve the product.

WARRANTY

THUNDERBIRD

Agricultural Scales

Thunderbird warrant all scale indicators and load cells against defective

workmanship and faulty materials for 2 years from the date of purchase.

We undertake, at our option, to replace or repair free of charge each

product, or part thereof, on condition that it is returned to our factory

freight prepaid, and found on examination to be suffering from material or

constructional defect. We cannot be held responsible for any repair other

than those carried out by us or our authorized agent.

A photocopy of your proof of purchase and a request for warranty

must also be returned with the item.

This warranty is void if the product is subject to improper use or handling,

incorrect power input voltage, load cells found to have electrical damage

caused by welding, damage through contact with chemicals, flooding, fire,

explosion, excessive heat, lightning strikes, insect damage, moisture

damage or damage to external wiring. Any warranty on load cells will

become void if they are found to have been subject to excessive

weight, or failure caused by corrosion due to excessive buildup

of manure and moisture.

Thunderbird Ag Pty Ltd

ABN 75 145 262 246

11 Industrial Avenue PO Box 391

Mudgee NSW 2850 Mudgee NSW 2850

Phone: 02 63723600

Fax: 02 63722597 Email: sales@thunderbird.net.au

For your records:

Model No.: ...............................................................................................................

Serial No.: ...............................................................................................................

Date of Purchase: ...................................................................................................

Place of Purchase: ..................................................................................................

Receipt No.: ............................................................................................................

Table of contents

Other Thunderbird Accessories manuals

Popular Accessories manuals by other brands

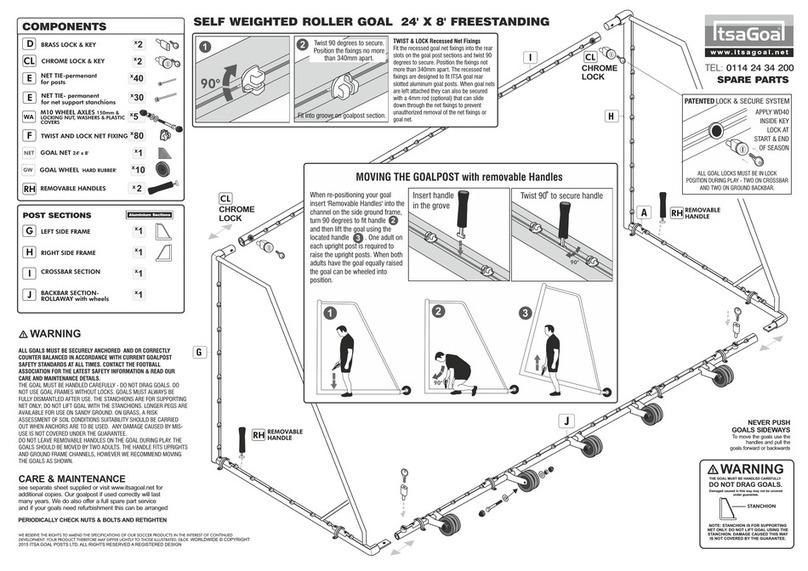

IstaGoal

IstaGoal SELF WEIGHTED ROLLER GOAL quick start guide

Lifetime

Lifetime 90179 owner's manual

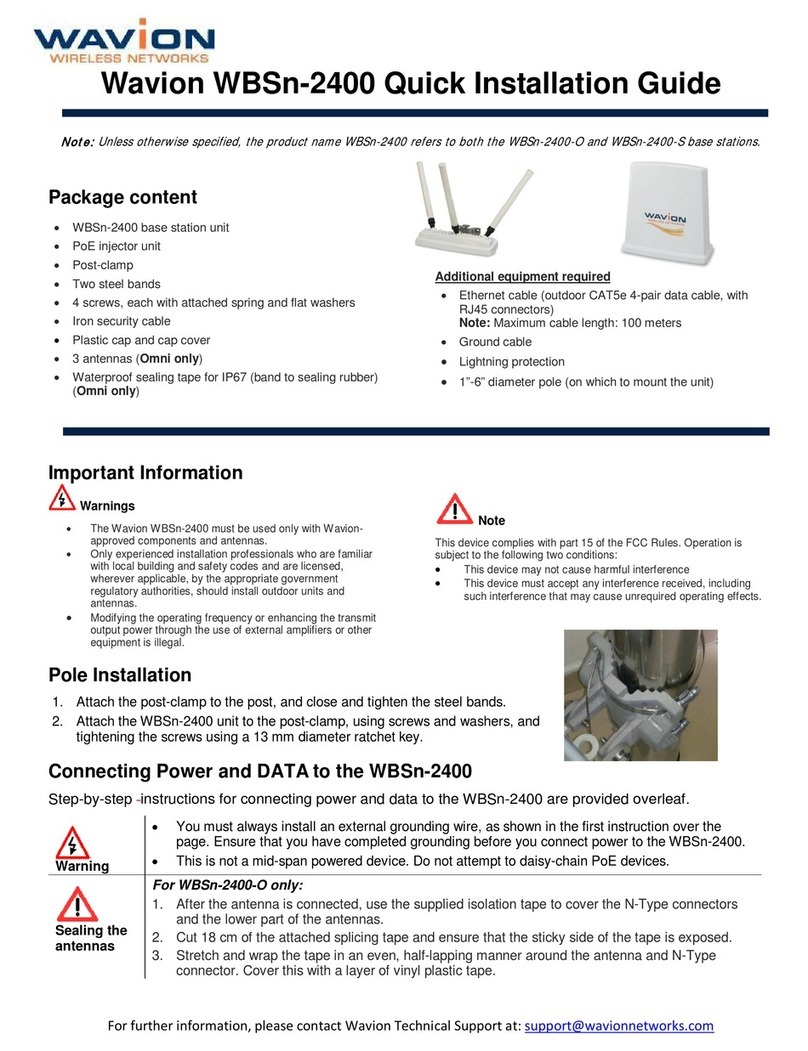

Wavion

Wavion WBSn-2400-O Quick installation guide

Dometic

Dometic CABANA 747 1 002 Series Installation & operating instructions

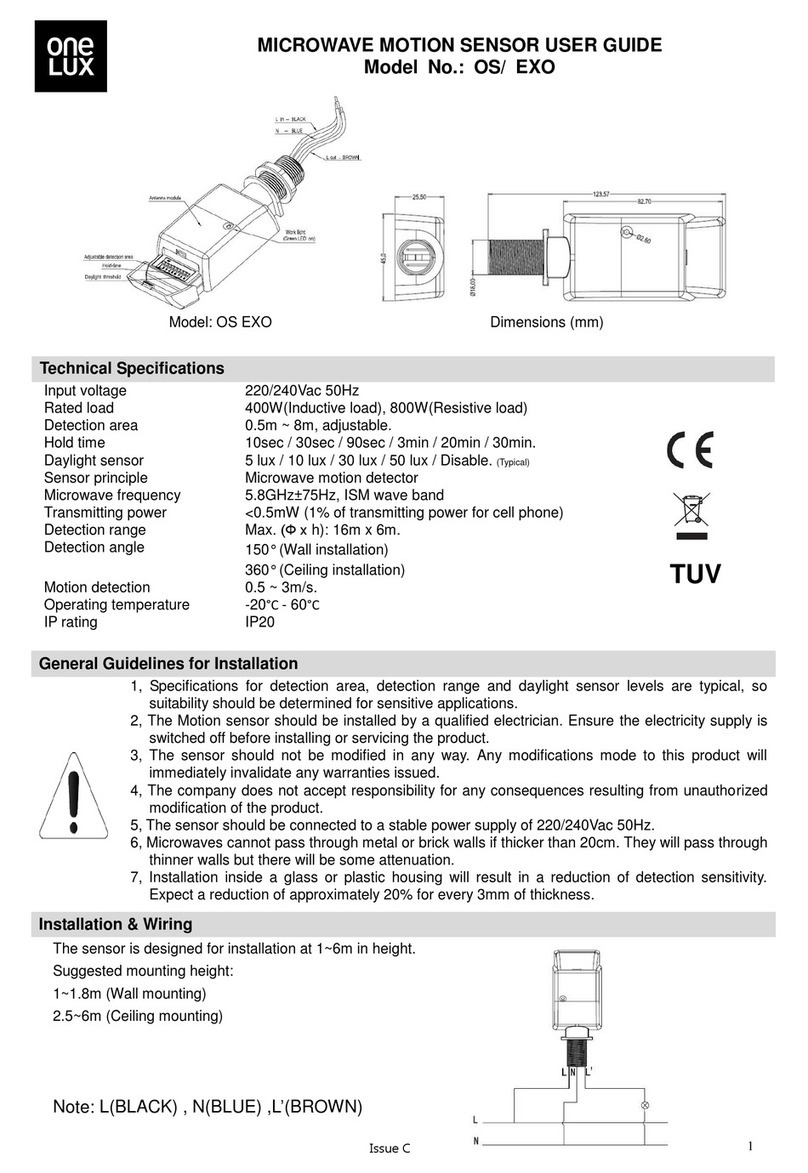

One Lux

One Lux ONE-SENSE EXO user guide

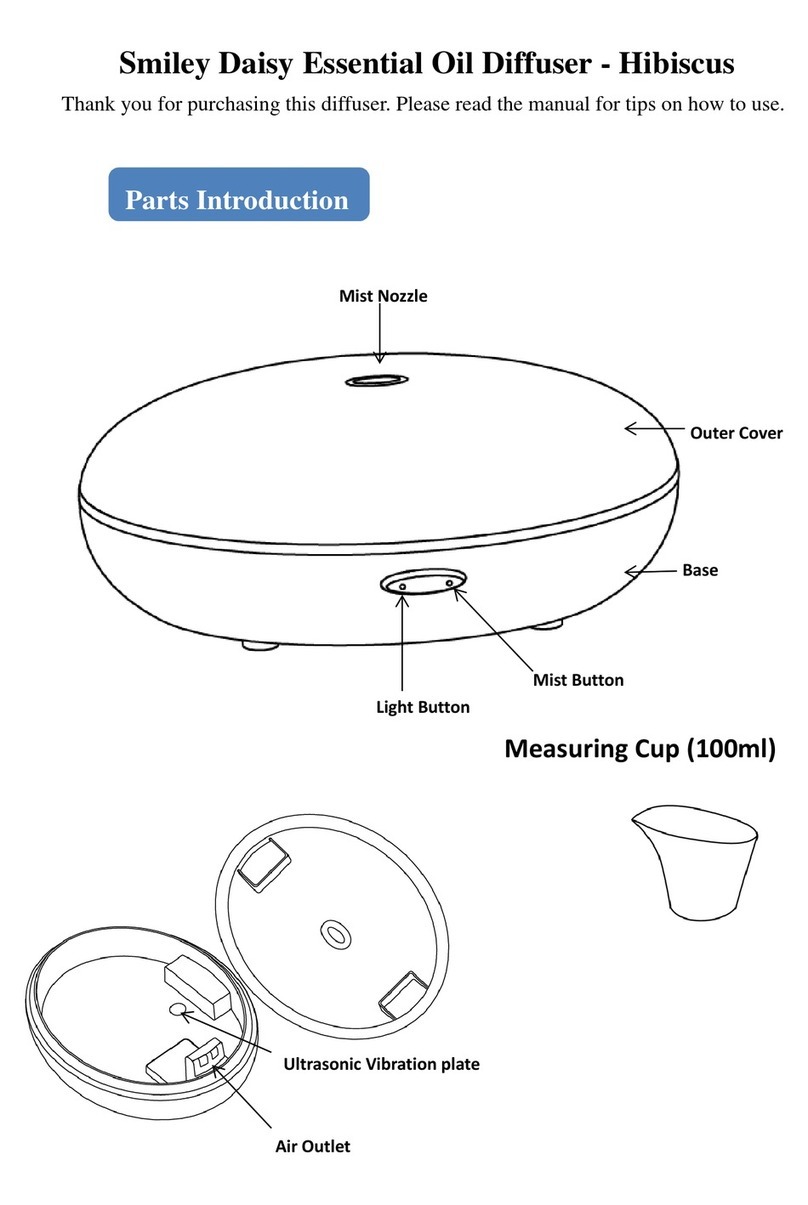

Smiley Daisy

Smiley Daisy Hibiscus user manual