Thunderstone Thunder 6000XR User manual

Thunder 6000XR Troubleshooting Guide –9/1/17

1

Thunder 6000XR Tarp System Troubleshooting Guide

Below you will find troubleshooting steps for common tarp system issues. Solution after above steps are taken.

Remote will not program to keypad.

1. Remove power for 15 seconds then reconnect.

2. Turn on the tarp system by pressing the (Open) & (Close) buttons on the keypad for 3-5 seconds until the LED

and buttons illuminate.

3. Re-enter the programming mode per the remote programming instructions.

Replace RF keypad. Re-enter programming mode to verify.

Tarp system will not power on.

1. Make sure that the 2-pole power cord is plugged into the trailer and has the proper polarity and voltage to the

tarp system.

2. Check that the tarp system circuit breaker near the tractor battery is reset, if applicable.

3. Turn on the tarp system by pressing the (Open) & (Close) buttons on the keypad for 3-5 seconds until the LED

and buttons illuminate.

4. Test the remote functions of the tarp system by pressing the (Open) & (Close) buttons on the remote 3-5

seconds to verify keypad button failure.

5. Check for grease, dirt, and corroded connections at the battery terminals, circuit breaker and also at the trailer

power receptacle plug and outlet.

6. Check for voltage on the back side of the 2-pole trailer receptacle. Also check for corrosion and looseness.

7. Check for proper connection of the communication cable between the inner control box and the RF keypad.

8. Unplug the power receptacle, wait 10 seconds, re-plug truck power and verify operation.

Replace RF keypad. Test functions before re-installation to verify.

Replace Communication Cable. Test functions before re-installation to verify.

Replace inner control box. Test functions before re-installation to verify.

Tarp system powers on but does not function when pressing either (Open) or

(Close), no flash codes are present.

1. Check for low voltage & looseconnections.

2. Test the remote functions of the tarp system to verify keypad buttonfailure.

3. Check for loose & corroded connections at the motor terminals and inspect the wires from the motor to the inner

control box located in the nose of the trailer.

4. Unplug the power receptacle, wait 10 seconds, re-plug truck power and verify operation.

Replace RF keypad. Test functions before re-installation to verify.

Replace inner control box. Test functions before re-installation to verify.

Tarp system does not function and a red/orange flashing light is present on the RF

keypad, indicating an error code. See error code explanations below:

a) Three flashes indicates an Overheat Protection issue. This typically occurs if the system has been started and

stopped rapidly in a short period of time. Also, it can indicate increased drag in the tarp system causing

increased amperage. Re-check the tarp system after a cool down period.

Thunder 6000XR Troubleshooting Guide –9/1/17

2

b) Four flashes indicates an Over Voltage Protection issue. Using a voltmeter, check the tractor batteries &

alternator for voltage exceeding 15.5 volts.

c) Five flashes indicates an Under Voltage Protection issue. Using a voltmeter, check the system for low

voltage. Also check all connection points for looseness and corrosion including battery terminals, circuit

breaker, power cord, and receptacle plug. Connect an alternate power source toverify.

d) Six flashes indicates Ground Fault Protection. This can be caused by moisture intrusion to the inner control

box, motor terminals shorted to the motor case, and also wire insulation damage. To determine which

failure has occurred please follow the steps below:

(1) If 6 code is intermittent when running the tarp, ground the motor arm to the trailer ladder assembly with

a jumper wire or a conductive equivalent. This will ensure proper grounding during testing.

(2) Remove the motor leads from the motor terminals. Touch the ends together completing the circuitand

observe if the flashing stops or continues. DO NOT OPERATE THE TARP SYSTEM DURING THIS TEST

If flashing stops, there is a short inside the motor case. Replace the defective tarp

motor. Test functions before completing installation to verify.

(3) If 6 flashes continue after the wires are touched together, inspect the wiring from the inner control

box to the motor for any frays, pinched areas, or insulation being worn through. Fix or replace any

areas that show insulation wear or damage.

(4) Disconnect the large Delphi connector for the motor wires in the nose of the trailer. Insert a paperclip,

or conductive equivalent, across the contacts in the connector on the side coming from the inner

control box. Verify if flashing stops. DO NOT OPERATE THE TARP SYSTEM DURING THIS TEST

If flashing stops, there is a ground fault occurring in the wiring to the motor.

Inspect for damage. Replace cable if necessary.

(5) If the 6 flashes continue, disassemble the inner control box located in the nose of the trailer and inspect

for water intrusion. Green corrosion around the amp control relay terminals is a positive sign of relay

failure due to moisture.

If moisture is present, replace the inner control box. Test functions before re-

installation to verify.

e) Seven flashes indicates there is not enough amperage or voltage to run the motor OR the drive motor windings

are shorted. REQUIRES REMOVING POWER TO RESET.

(1) Connect an alternate power source to verify a low amperage/voltage problem.

(2) Make sure the charging system on the truck or power supply is running and working properly.

Replace motor. Test functions to verify.

f) Eight flashes indicates com failure from the inner control box. Check com cable between RF keypad and inner

control box for damage.

Replace Communication Cable. Test functions before re-installation to verify.

Tarp system does not make a full cycle or closes/opens intermittently.

1. Two flashes indicates an overcurrent protection issue which is normal if the tarp fully opened or closed. If not, check

for obstructions in the operation of the tarp such as snow or ice buildup. This also could indicate increased drag in

the tarp motor or other motor problems causing premature tarp stoppage.

2. Remove the motor terminals and connect to a battery source using jumper cables to determine if the motor labors or

stops with direct current indicating a motor gear mesh issue causing excessdrag.

Replace the tarp motor. Test functions to verify.

Table of contents

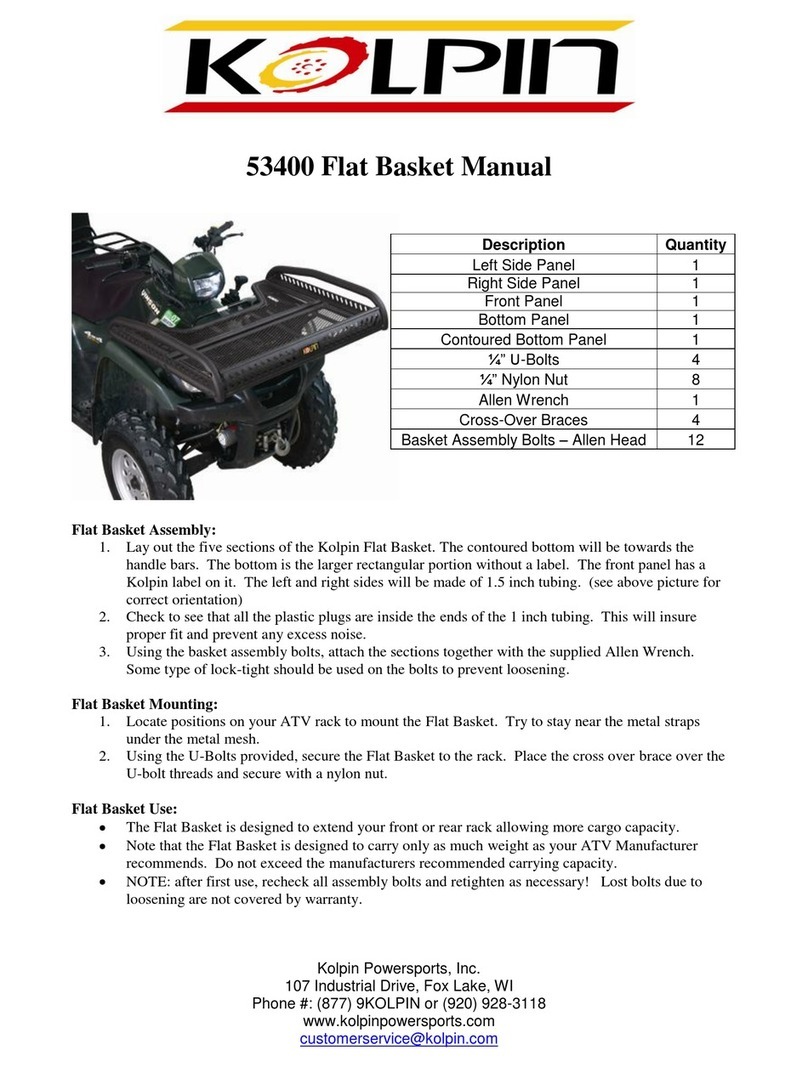

Other Thunderstone Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Response

Response AR-3135 user manual

Fortin Electronic Systems

Fortin Electronic Systems EVO-CAN SUGGESTED WIRING CONFIGURATION

Cruz

Cruz Alu-Rack L 13-120 Assembly instructions

Techtom

Techtom AL-100 instruction manual

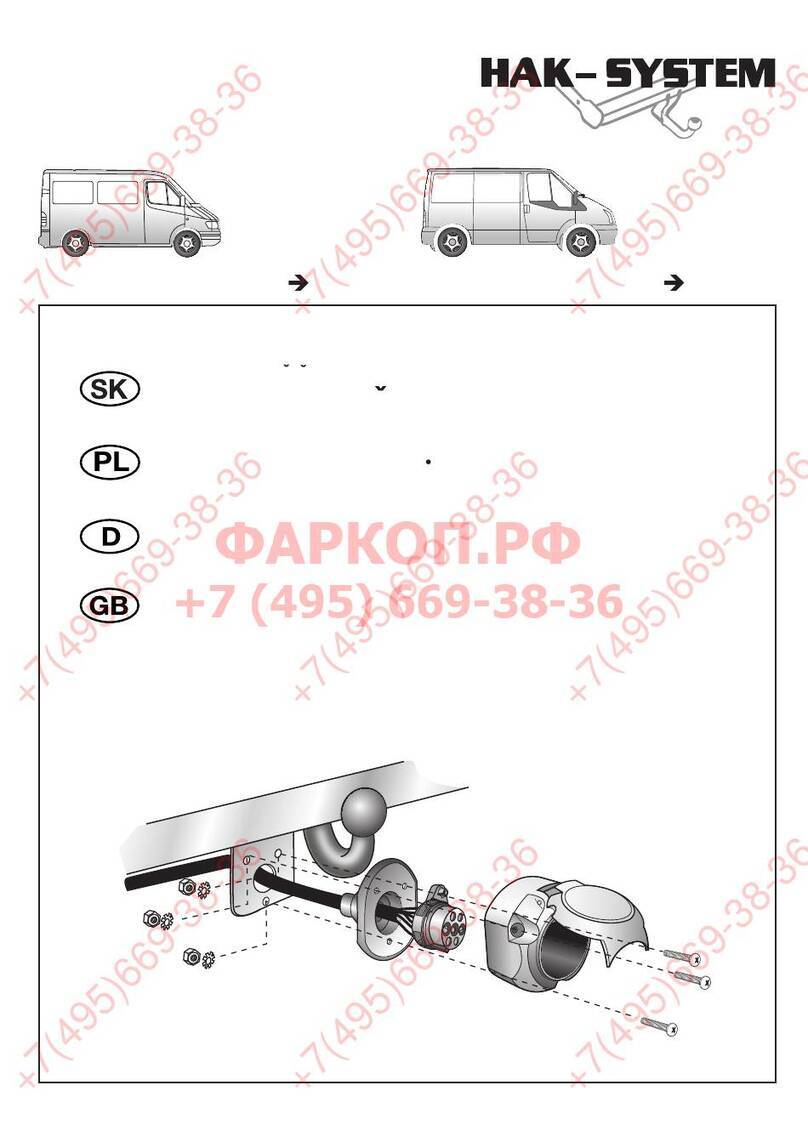

Hak-System

Hak-System 16060521PL Fitting instructions

Fortin

Fortin TB-TOYOTA installation guide